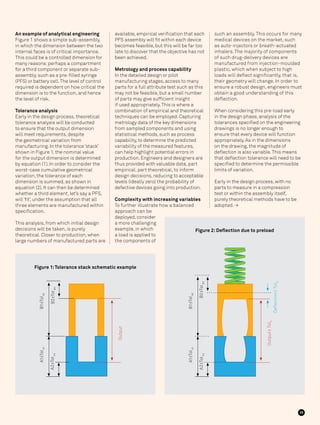

Analytical engineering uses both theoretical and empirical methods to inform product design decisions. Theoretical methods include mathematical modeling and simulation, while empirical methods involve physical testing and measurement. Early in design, theoretical tolerance analysis is used, while later empirical metrology data from prototypes is combined with simulation to validate models. For complex issues like component deflection under load, a hybrid approach using initial modeling followed by targeted physical testing and model validation is most effective. Combining methods alleviates limitations of any single approach and ensures high quality data at all stages of design.