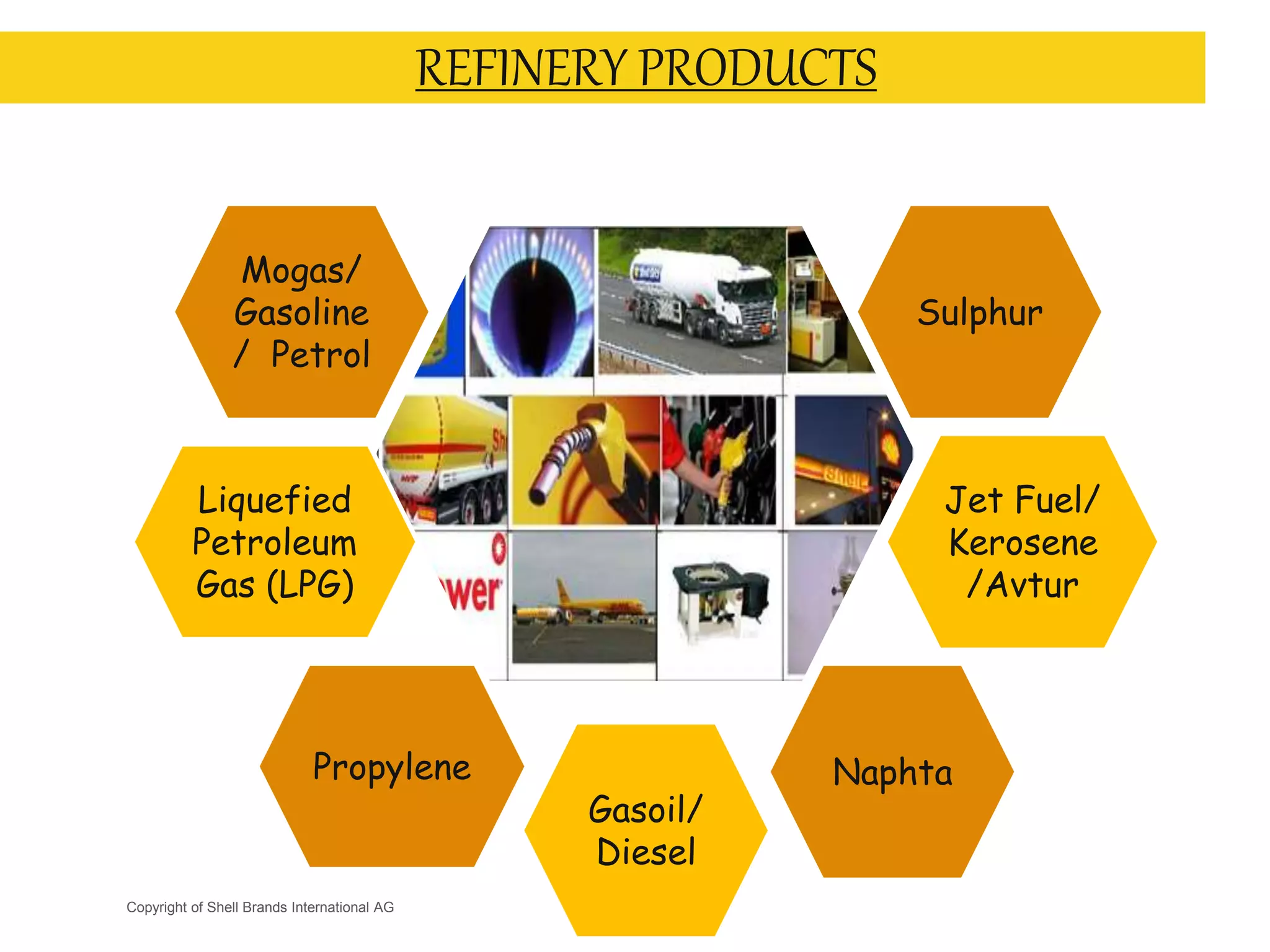

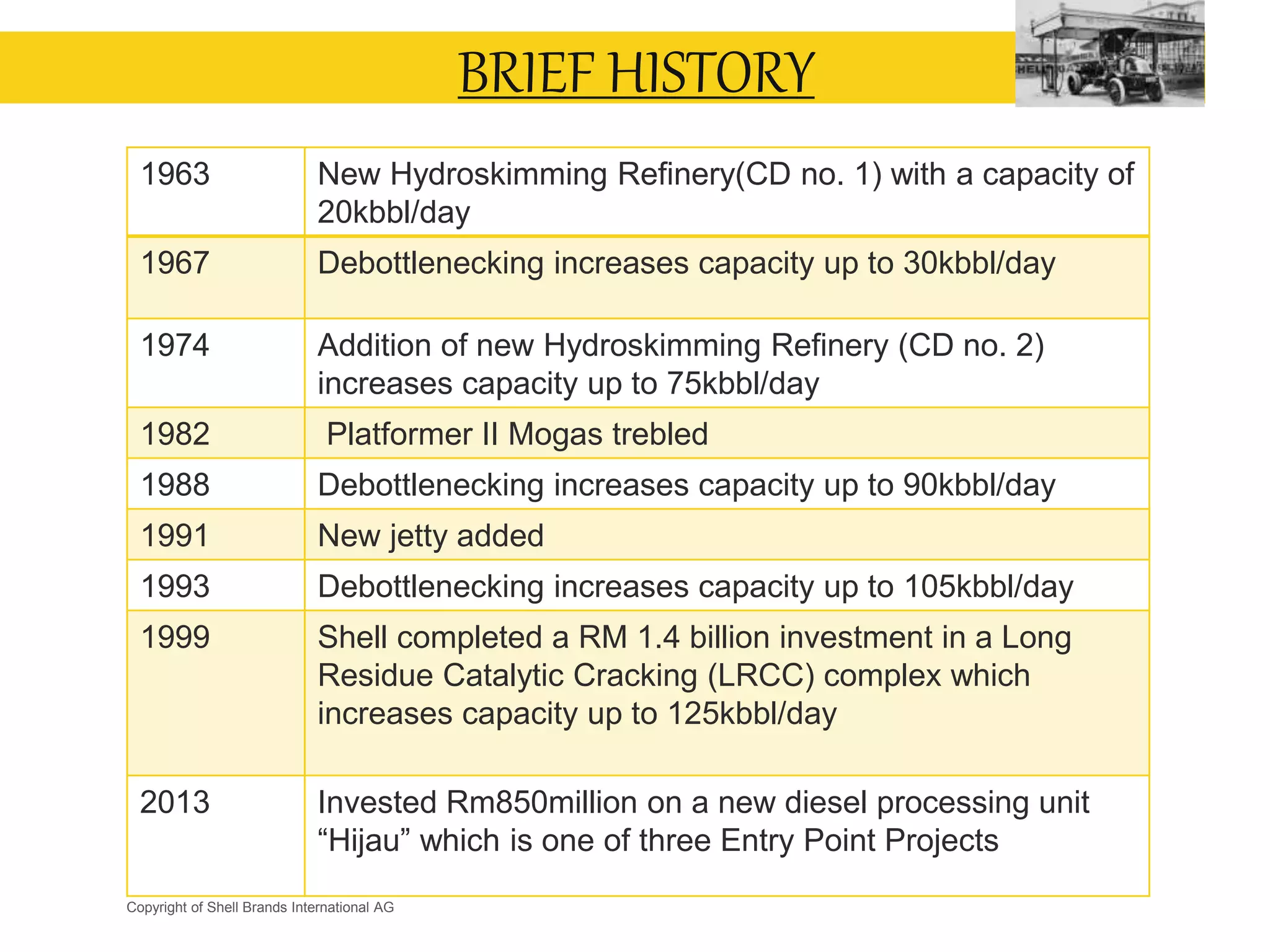

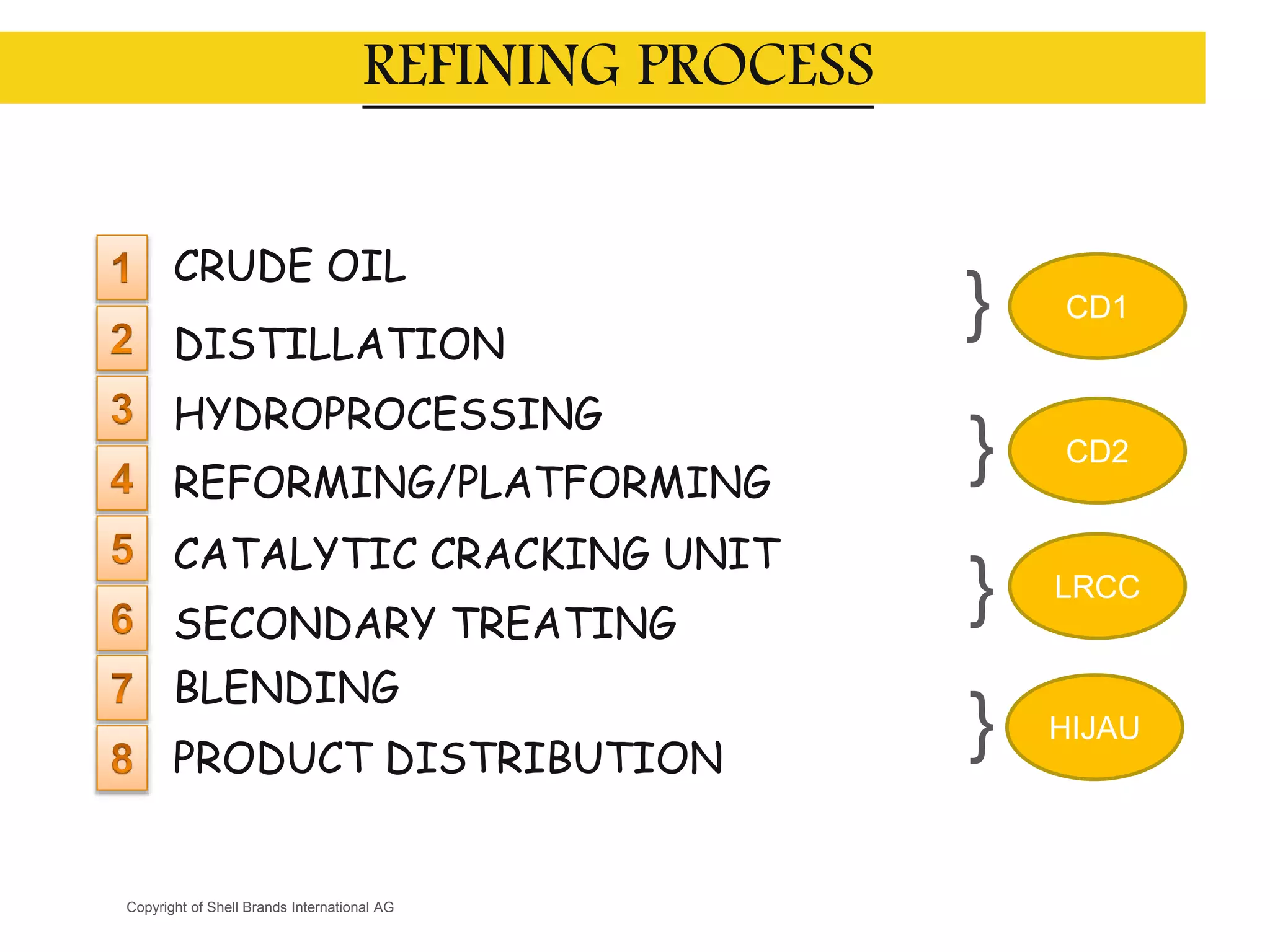

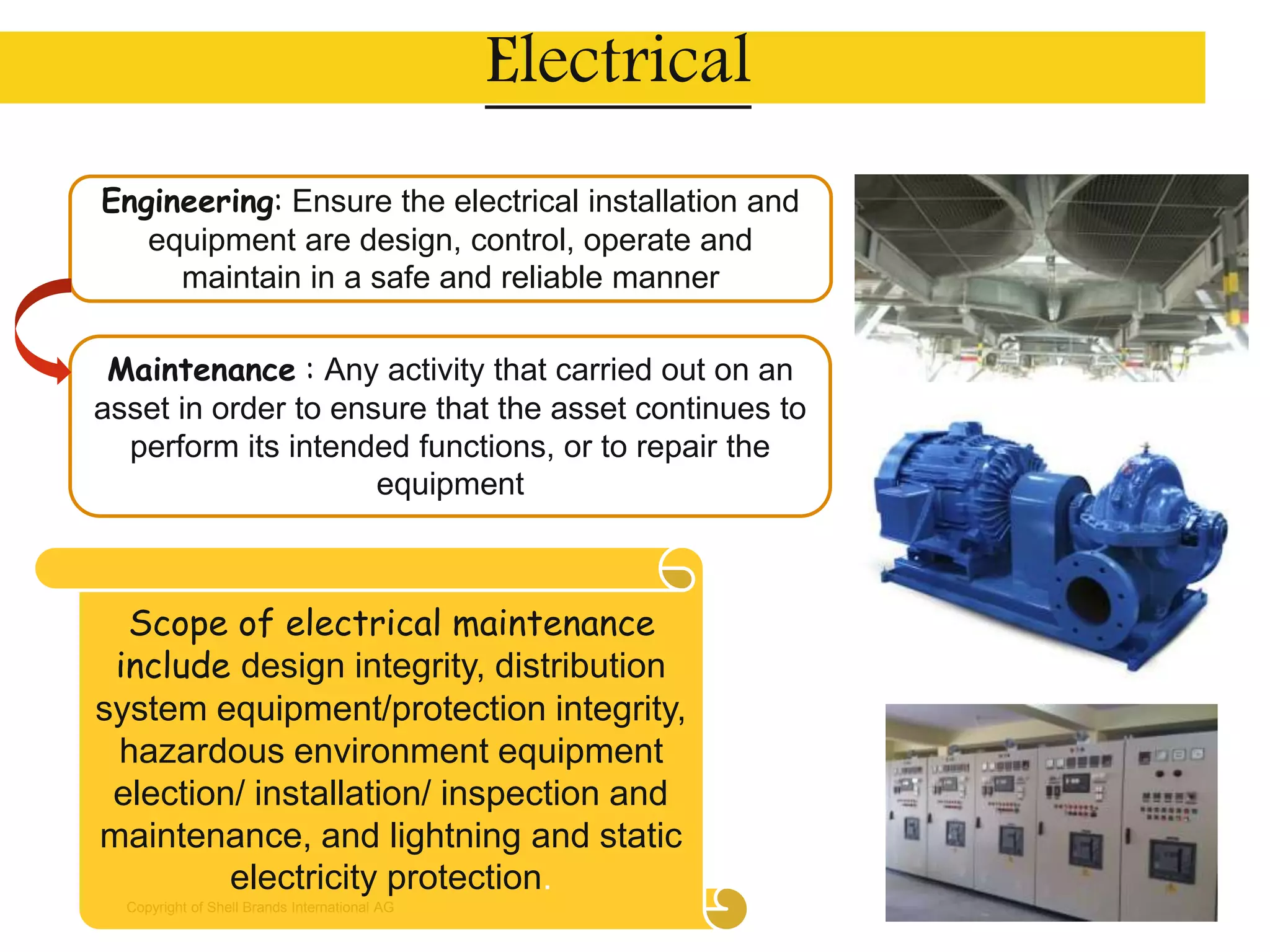

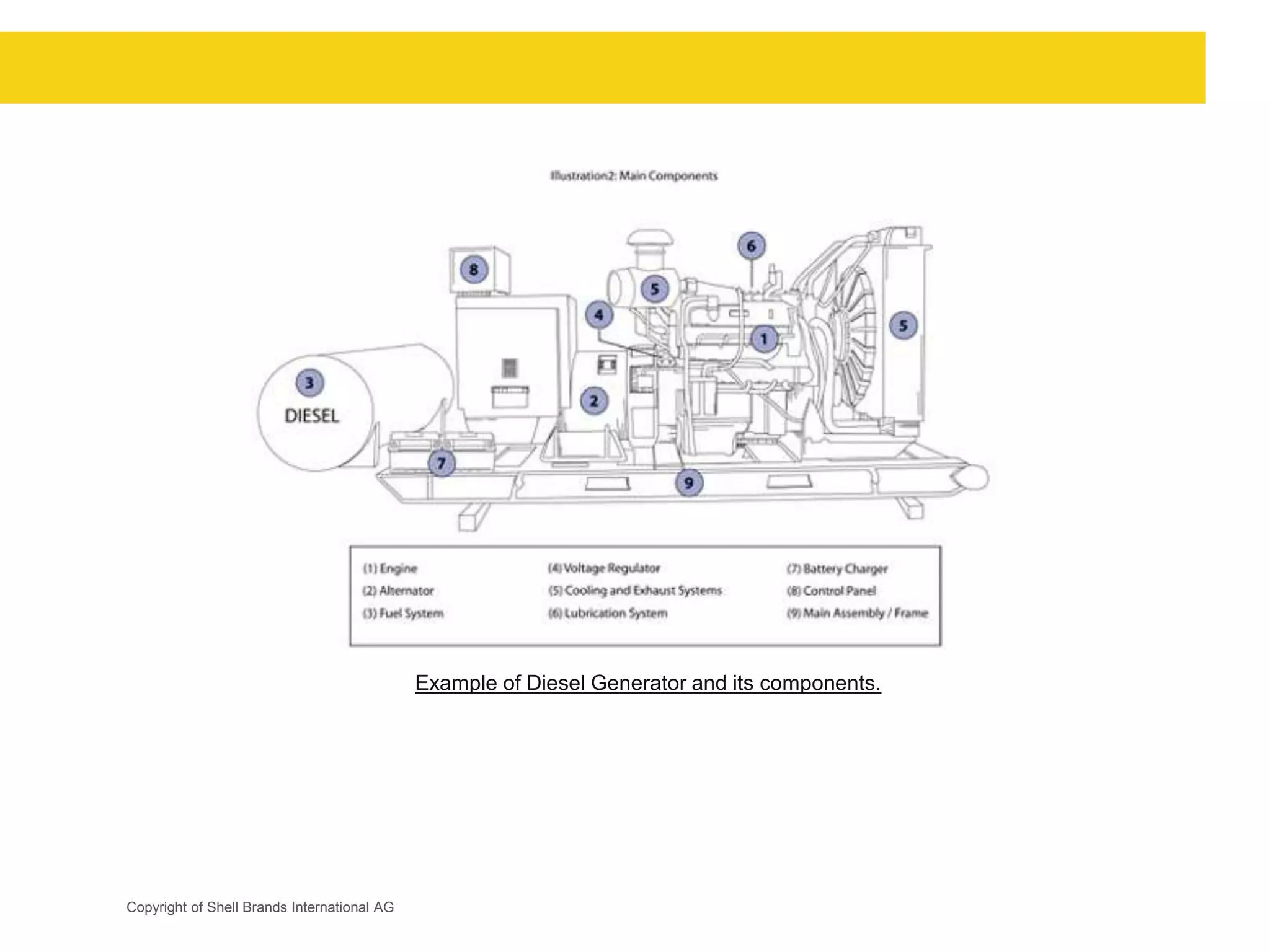

The document outlines the industrial training experience of a student in the electrical engineering department at Shell Refining Company, focusing on objectives, company overview, safety regulations, and work experience. It details the projects undertaken, including the replacement of transformer units and the installation of a cathodic protection system, alongside the skills and knowledge gained during the training. The conclusion highlights the importance of applying theoretical knowledge in practical settings to prepare students for real job challenges.