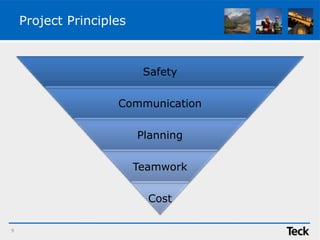

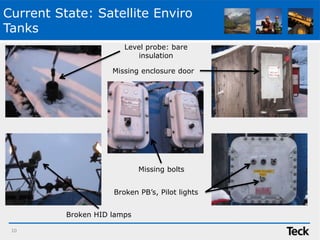

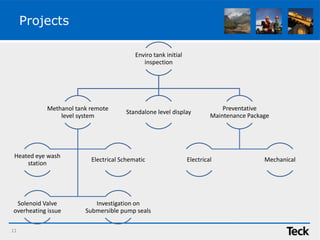

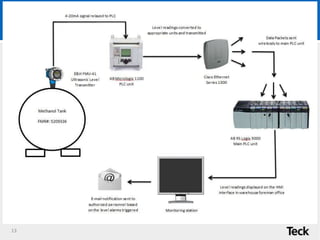

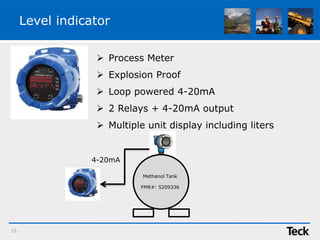

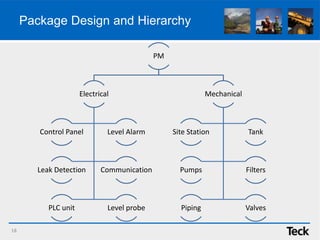

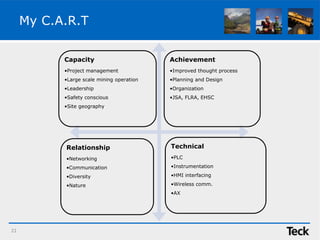

This document summarizes a presentation given by Manir Al-Faisal, an electrical engineering co-op student, about his work experience. It discusses safety issues with traction on icy surfaces that have led to injuries. It then introduces the speaker and his educational and work background, including current projects involving monitoring methanol tank levels, installing standalone displays, and developing preventative maintenance packages. Recommendations are provided to improve the co-op experience and opportunities for permanent positions.