This document summarizes an internship presentation given by Nurul Syafiqah Binti Mohd Najib. The presentation covered:

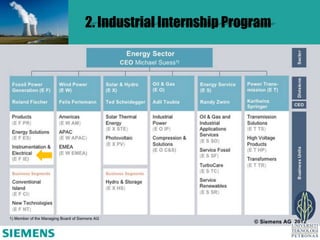

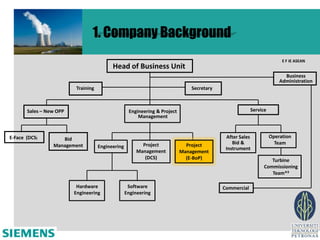

1. An overview of Siemens Malaysia, including its divisions and business areas.

2. Details about the internship program, including a 5-month placement in the office followed by 1.5 months on-site.

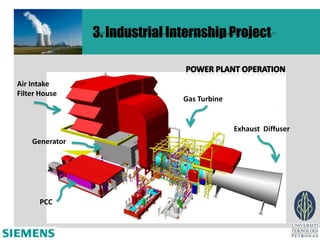

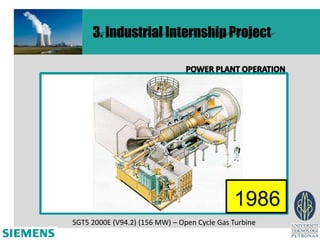

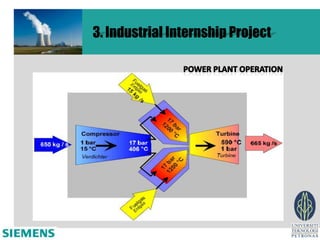

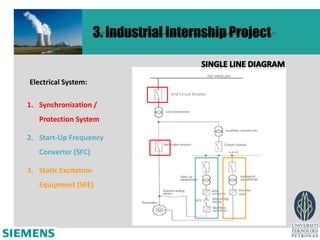

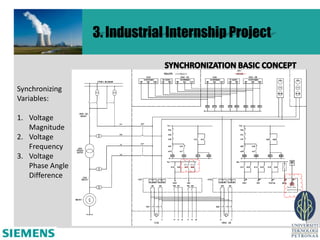

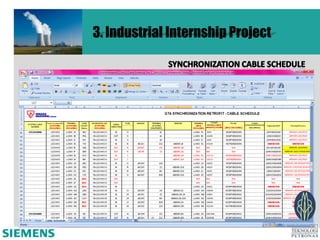

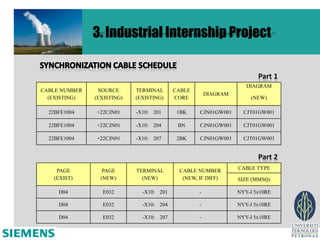

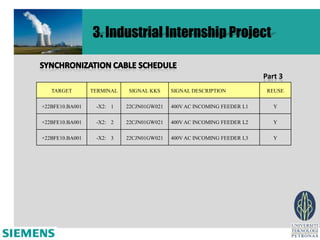

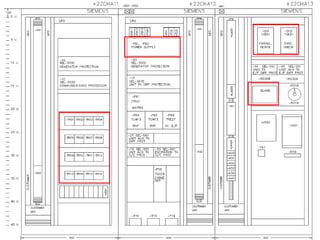

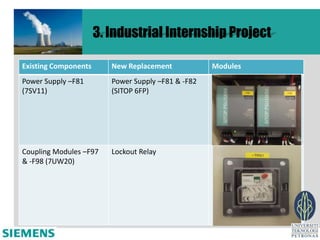

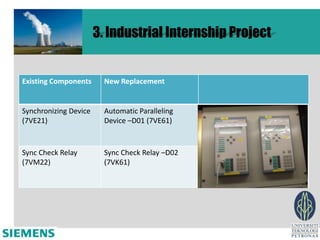

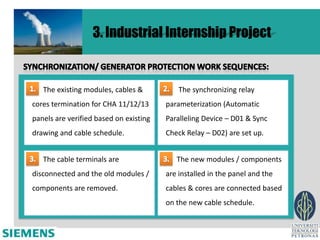

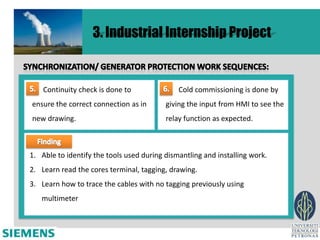

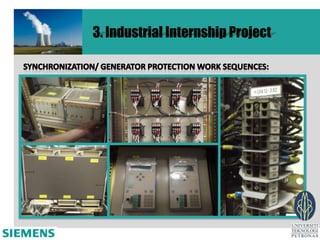

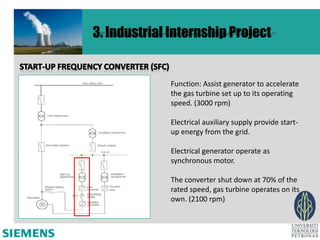

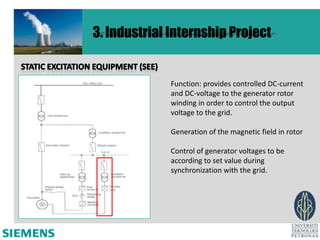

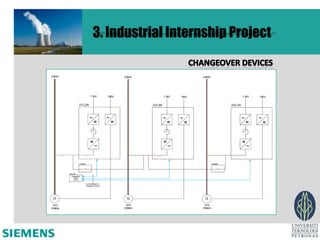

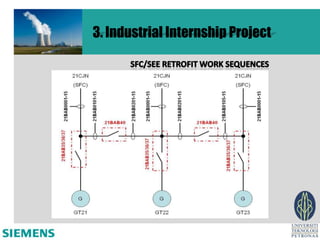

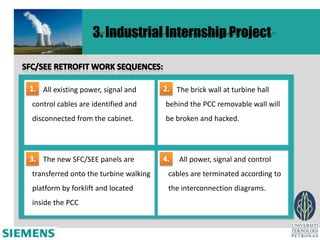

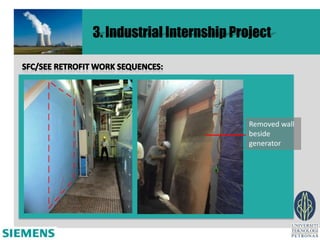

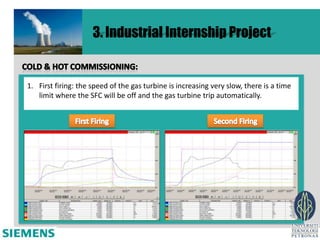

3. The internship project, which involved retrofitting synchronization and generator protection systems at the TNB Putrajaya Power Station. The project exposed the intern to various electrical and commissioning tasks.