Internship report on texeurop-bd-ltd

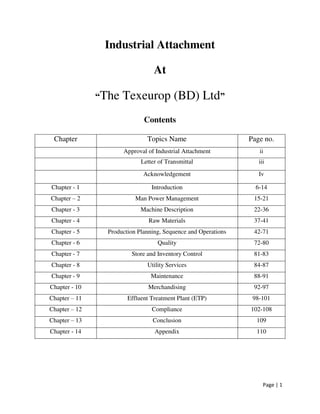

- 1. Page | 1 Industrial Attachment At “The Texeurop (BD) Ltd” Contents Chapter Topics Name Page no. Approval of Industrial Attachment ii Letter of Transmittal iii Acknowledgement Iv Chapter - 1 Introduction 6-14 Chapter – 2 Man Power Management 15-21 Chapter - 3 Machine Description 22-36 Chapter - 4 Raw Materials 37-41 Chapter - 5 Production Planning, Sequence and Operations 42-71 Chapter - 6 Quality 72-80 Chapter - 7 Store and Inventory Control 81-83 Chapter - 8 Utility Services 84-87 Chapter - 9 Maintenance 88-91 Chapter - 10 Merchandising 92-97 Chapter – 11 Effluent Treatment Plant (ETP) 98-101 Chapter – 12 Compliance 102-108 Chapter – 13 Conclusion 109 Chapter - 14 Appendix 110

- 2. Page | 2 LIST OF FIGURE Figure No Figure Name Page Fig-1 Main Building Of Texeurop (BD) Ltd 7 Fig-2 Location Of Texeurop (BD) Ltd 7 Fig-3 Hydro Extractor Machine 28 Fig-4 Silting Machine 28 Fig-5 Stenter Machine 29 Fig-6 Compactor Machine 29 Fig-7 Dizit Board 30 Fig-8 Plotter 30 Fig-9 Pattern Cutting Machine 31 Fig-10 Automatic Spreading Machine 33 Fig-11 Straight Knife Machine 34 Fig-12 Band Knife Machine 34 Fig-13 Circular Knitting Machine 44 Fig-14 Flat Bed Knitting Machine 44 Fig-15 Dyeing Machine 46 Fig-16 Dyeing Laboratory 46 Fig-17 Pattern Making 48 Fig-18 Sample Section Of Texeurop (BD) Ltd 49 Fig-19 Quality Checking In Sample Section 50 Fig-20 Digitizer 52 Fig-21 Plotter 52 Fig-22 Manually Spreading 53 Fig-23 Automatic Spreading 53 Fig-24 Automatic Cutting Machine 54 Fig-25 Manually Cutting By Straight Knife Machine 54 Fig-26 Band Knife Machine 55 Fig-27 Straight Knife Machine 55 Fig-28 Numbering Machine 55 Fig-29 Plain Machine 57 Fig-30 Over Lock Machine 58 Fig-31 Flat Lock Machine 58 Fig-32 Kansai Machine 58 Fig-33 Button Holing Machine 59 Fig-34 Button Attaching Machine 59 Fig-35 Bartack Machine 59 Fig-36 Sewing Floor Of Texeurop (BD) Ltd 60 Fig-37 T-Shirt 61 Fig-38 Polo Shirt 62 Fig-39 Jacket 64 Fig-40 Skip Stitch 66 Fig-41 Open Seam 66 Fig-42 Scissor Cut 66

- 3. Page | 3 Fig-43 Part Shading 66 Fig-44 Broken Stitch 67 Fig-45 Four Point Up Down 67 Fig-46 Pleat 67 Fig-47 Uneven Stitch 67 Fig-48 Initial Check 69 Fig-49 Ironing 69 Fig-50 Spot Lifter 69 Fig-51 Thinner Fluid 69 Fig-52 Washing Of Spot 70 Fig-53 Inspection 70 Fig-54 Hang Tag 70 Fig-55 Metal Detector 70 Fig-56 Prepare Hanger 70 Fig-57 Folding 71 Fig-58 Packing 71 Fig-59 Cartooning 71 Fig-60 Prepare Cartooning 71 Fig-61 Quality Inspection 73 Fig-62 Raw Material Inventory 82 Fig-63 Generator 85 Fig-64 Boiler 86 Fig-65 Air Dryer 86 Fig-66 Air Compressor 86 Fig-67 Water Treatment Process 87 Fig-68 Motors 87 Fig-69 Maintenance Tools 89 Fig-70 Effluent Treatment 99 Fig-71 Equalization Tank 100 Fig-72 Ferrous Tank 100 Fig-73 Polymer Tank 100 Fig-74 Settling Tank 101 Fig-75 Drinking Water 105 Fig-76 Fire Extinguisher 106 Fig-77 Fire Alarm Switch 106 Fig-78 Fire Equipment 107 Fig-79 Hose Rill 107 Fig-80 First Aid Box 107 Fig-81 Gloves 108 Fig-82 Mask 108

- 4. Page | 4 List of table Table No Table Name Page Table-1 Working Hour Analysis 18 Table-2 Worker Man Power Summary 19 Table-3 Total Number Of Machine Is Knitting Section 23 Table-4 Specification Of Circular Knitting Machine 24 Table-5 Specification Of Flat Knitting Machine 25 Table-6 Specification Of Twill Tape Knitting Machine 26 Table-7 List Of Dyeing Machines 27 Table-8 Number Of Machine In Sample Section 31 Table-9 Auto Cutter Machine List 32 Table-10 Cutting Section Machine List 33 Table-11 Machineries In Sewing Section 35 Table-12 Finishing Section 36 Table-13 Different Types Of Yarn 38 Table-14 Raw Material Sources And Costs 39 Table-15 Machinery Of Sample Section 47 Table-16 Sewing Machine Description 57 Table-17 The Point System 79

- 5. Page | 5 Chapter-01 Introduction Serial No. Content Page No. 1.1 Introduction 6 1.2 Location of Texeurop (BD) Ltd 7 1.3 At a Glance 8 1.4 Factory Information 8 1.5 Vision and Mission of the company 9 1.6 Physical Infrastructure 9 1.7 History of project development 10 1.8 Project cost 10 1.9 annual turnover 10 1.10 Final products name 10 1.11 Buyer name of Texeurop (BD) Ltd 11-12 1.12 Achievements 13 1.13 Remarks 14

- 6. Page | 6 1.1 Introduction Texeurop (BD) LTD. an 100% export oriented composite knit textile unit Established with the commitment to care the Global needs for knit and casual clothing. The project has employed the State-of-Art technology in its very pieces of investments. Aiming at the context of the changing Global demand pattern, international environment on trade specially the withdrawal of quota system and GSP and the availability of craftsmanship in the country, the project encompassed the knitting, dyeing and processing of fabrics and ready-made Garments production to be available from one stop service. The project is a new one established in 2004 if compared the with other well established textile factory, but the manpower engaged in the projects to carry out the day to day business are all highly skilled, purely professional, vastly experienced. The unique combination of organized Managerial and Technical term in one hand and latest, advanced and balanced technology on the other hand made the project one of the top to be referred in this field in the country. The best use of continuous development of Human Resources by providing them International Standard Environment and equal opportunity is the keys for achieving comprehensive competence in all the level Organizational Hierarchy. Texeurop (BD) LTD. has been established with the objective and vision to cater the needs of 21st century of world wide knit apparels markets from one stop service being committed to One- time Delivery, Quality Assurance, Price Affordability and Social Accountability .The project is located in Vogra, Joydebpur under the district of Gazipur, about 37 km distance from the International Airport Dhaka, Bangladesh. A well developed Road Communication is there to reach the factory from the Airport as well as from the Dhaka City. The head office of the project is Located in the heart of Dhaka City in Tejgoan Industrial Area.

- 7. Page | 7 1.2 Location of Texeurop (Bd) Ltd: Fig 1: Texeurop (Bd) Ltd Google map view of Texeurop (Bd) Ltd Fig 2: Location of Texeurop (Bd) Ltd

- 8. Page | 8 1.3 At a Glance: Name of the company: Texeurop (Bd) Ltd Company logo : Factory Address : Texeurop (Bd) Ltd : Vogra, Joydebpur Gazipur,Bangladesh Tel : +880-2-9261986, 9261988, 9261993, 9262163-4, 9262701-2, Fax : +880-2-9261582 Email : info@texeuropbangladesh.com Web address : www.texeuropbangladesh.com 1.4 Factory Information: Factory Name : Texeurop (Bd) Ltd factory type :100% Export Oriented Knit Garments. Factory Address : Vogra, Joydebpur Gazipur,Bangladesh Year of Establishment : 2004 Total area of the industry : 12500 sq Meter Factory land area : 10000 sq. Meter Products Manufacturing : T-shirt, Polo shirt, Sweat shirt, Golf shirt, Cardigan, Jogging suit, Short/Trouser, Legging, Fashion dress & Children wears etc.

- 9. Page | 9 1.5 Vision and Mission of the company: Texeurop (BD) Ltd. is a Composite Knit Dyeing Factory that producing & manufacturing Knitted Fabric and Garments with a mission to be one of the leading exporters by providing the good quality knitted garments from Bangladesh to various customers around the globe. The policy of Texeurop (BD) Ltd. to ensure: a. Customer satisfaction by all means. b. Providing quality product as per requirement of the buyer. c. Ensuring quality services in communication & timely delivery of the product. d. To decrease the percentage of rework. e. Evaluate the suppliers on yearly basis. f. Give safe and hygienic working environment to workers. g. Improve continually in the Quality Management System with every year to come. h. Reducing environmental pollution with proper treatment of effluents. i. Providing a better working environment for both employers and employees by strictly following rules & regulation of various complains issues. 1.6 Physical Infrastructure: The mill is built in such a way that there is possibility for further expansion of the mill. The structure such as mill, office buildings, record rooms, guardrooms & dining room etc. are made of solid hard concrete & brick mtls. . The whole area is surrounded by safety brick wall .The main set up for m/c’s are built of corrugated iron & iron sheet, transparent hard plastics with enough ventilation & scope for passing light & air. Total area of the industry : 12500 sq Meter Factory land area : 10000 sq. Meter Building : 8 Storied.

- 10. Page | 10 1.7 History of the Project Development: Texeurop (BD) Ltd. has been established with the objective and vision to satisfy the needs of 21st century of worldwide knit apparels markets from one stop service being committed to One-time Delivery, Quality Assurance, Price Affordability and Social Accountability. Basically Pantex garments factory was the mother textile at Narayangonj of Texeurop (BD) Ltd. from which the factory was expanded with collaboration of European partner. The project is located in Vogra Joydebpur under the district of Gazipur, about 25 km distance from the International Airport Dhaka, Bangladesh. A well-developed Road Communication is there to reach the factory from the Airport as well as from the Dhaka City 1.8 Project Cost: The initial cost of Texeurop (BD) Ltd. establishment is about 400 million Taka. But the gradual enlargement & enhancement of the mill increasing the project cost. So it is very difficult to measurement the actual cost of the project 1.9 Annual Turnover: Annual turnover of the factory is approximately Tk 140 core. 1.10 Final Products Name: a. Basic T - Shirt, d. Long Sleeve T - Shirt, g. Hood Jacket, b. Polo Shirt, e. Knit Jacket, h. Infant Knitwear c. Ladies Jacket, f. Kids Jacket,

- 11. Page | 11 1.11 Buyer Name of TEXEUROP (BD) Ltd.:

- 12. Page | 12

- 13. Page | 13 1.12 Achievements:

- 14. Page | 14 1.13 REMARKS: Texeurop (BD) Ltd is a Modern textile industry. Every facility of a modern textile mill exists in this factory. It has a no. of renowned buyers especially at Europe. So Texeurop (BD) Ltd. is getting popular throughout the Textile sectors and its buyers. This Factory has a good communication system from the capital city Dhaka.

- 15. Page | 15 Chapter-02 Manpower management Serial No. Content Page No. 2.1 Manpower Organogram 16 2.2 Administration Organogram 16 2.3 Organogram Of Production Section 17 2.4 Different Departments 18 2.5 Supporting Department 18 2.6 Information Medium 19 2.7 Shift Change 19 2.8 Responsibilities Of General Manager 19 2.9 Responsibilities Of Production Manager 20 2.10 Responsibilities Of Production Officer 20 2.11 Job Description Of Production Officer 20 2.12 Job Description Of Sr. Production Officer 21 2.13 Responsibilities Of Floor In-Charge 21 2.14 Remarks 21

- 16. Page | 16 2.1 Manpower Organogram 2.2Administration:

- 17. Page | 17 2.3 Organogram of Production Section : Organogram of production section

- 18. Page | 18 2.4 Different Departments: a. Knitting section Knitting Inspection b. Dying section Batch section Dye house Dyeing Lab Quality Control Finishing c. Garments Section Merchandising Sample d. Maintenance Section Electrical Mechanical e. Store Section 2.5 Supporting Departments a. Personnel Administration b. HRD c. Marketing d. Procurement e. Finance and accounting f. Security department Table 1: Working Hour Analysis: Working Day Per Week 06 Day Normal Working Hour Per Day 08 Hour Overtime Hour 02 Hour (If required) Break 01 Hour No. of Shift 03 (Dyeing)

- 19. Page | 19 Table 2: Workers manpower summary: Total no of worker 3392 Total no of staff officer and managers 907 2.6 Information Medium Intercom telephone Oral Fax Mobile Written letters 2.7 Shift Change: There are three shifts in this factory and each shift is of eight hours. Shift is changed after a week on Saturday. Shift Change/ for worker of Security: A Shift – 07:00 – 15:00 B Shift – 15:00 – 23:00 C Shift – 23:00 – 07:00 General shift : 10:00 – 19:00 Office Time 10:00 – 19:00 2.8 Responsibilities of General Manager To discuss with the buyer or party for order To control dyeing and finishing floor. To control lab and Q.C. To control all manpower

- 20. Page | 20 2.9 Responsibilities of Production Manager: To plan the production schedule with capacity and volume of order. To observe dyeing finishing. To supervise senior production officer and production officer. To rectify any kinds of problems during dyeing. To match shade as required. 2.10 Responsibilities Of Production Officer: From getting an order of upper level all responsibilities are on the production officers. They work with a troop of operators, helpers, fitters etc. to finish the production in due time. In the meantime production officers bear all hazards, problems. They have to explain to the manager for any type of production hamper. So, all production activities and its success depend on the production officers. Job Alignment of P.O & S.P.O: Job title: Production officer & Senior Production officer Report to: Production Manager Purpose: To control shift according to the plan made by the production manager Territory: Dyeing section (major) Batching and Finishing section (minor) Role within the organization: Responsible for own shift production with good quality and minimum time. Environment: Production officer has to work under huge stress. He has to work in acute heat under physical and mental pressure. Also he has to work in acute heat all the year round. 2.11 Job Description of Production Officer: Report To: Sr. production officer Job Summary: To plan, execute & follows up the production activities & control the quality production with related activities.

- 21. Page | 21 Duties & Responsibilities: Overall supervision of dyeing, finishing production. Batch preparation & PH check Dyes & chemical requisition issue & check. Write fabrics loading & loading time from m/c. Program making, sample checking, color management. Control the supervisors, operator, asst. operator & helpers of dyeing m/c. And also any other works as & when required by the management. 2.12 Job Description of Sr. Production Officer: Report To: P.M (production) Job Summary: To plan, execute & follows up the production activities & control the quality production with related activities. Duties & Responsibilities: Overall supervision of dyeing, finishing production. Checks the different log books of different areas & report to management. Checks the sensitive parameters of different machine for smooth dyeing. Checks out the plan to control the best output from supervisor & workers. To trained up & motive the subordinates how to improve the quality production. Maintenance of machine & equipment. Any other works & when required by the management. Control the supervisors, operator, asst. operator & helpers of dyeing m/c. 2.13 Responsibilities of Floor In-Charge: To check Lab recipe and Prepare Production Recipe. Batch preparation and pH check. Control of supervisor, operator, asst. operator and helper of dyeing floor. To match shade as required. To find out dyeing and fabric fault as early as possible. 2.14 Remarks: Production runs with the help of mechanical fitters. For any kind of mechanical fault of any machine they fix and work under technical in-charge. Production officers’ takes account of daily production by running after the two supervisors and workers so on.

- 22. Page | 22 CHAPTER – 03 MACHINE DESCRIPTION Serial No Content Page No 3.1 Introduction 23 3.2 Knitting Section 23 3.3 Circular Knitting Machine 23 3.4 Flat Knitting Section 25 3.5 Cloth Knitting Section 26 3.6 List Of Machines 26 3.7 Garments Section 30 3.7.1 Sample Section 30-31 3.7.2 Cutting Section 32-34 3.7.3 Machineries Is Sewing Section 35 3.7.4 Finishing Section 36 3.8 Remarks 36

- 23. Page | 23 3.1 Introduction: Texeurop (BD) LTD. is an integrated computerized company. It has total 20 dyeing machines among of them 10 machines are known as sample dyeing machine on the basis of their production capacity. The machines are controlled by high skilled operators. On the other hand Knitting section contains 18 machines, among of them 13 are circular knitting machine and another 5 are flat bed machines. 3.2 Knitting Section: Process requirements: In Texeurop (BD) Ltd. three types of machines are used for producing and inspecting knitted fabrics. These are:- 1. Circular knitting machine (Single& Double Jersey Machine) 2. Flat knitting Machine (Cuff & Collar). 3. Fabric inspection machine And the whole knitting section is divided in four sections, 1. Circular knitting section 2. Flat knitting section 3. Fabric inspection section 4. Store section Table 3 Total no of machine at a glance: M/c type Total no of machine Ground total Single jersey 13 45 Rib 04 Fleece 06 Auto Stripe 04 Flat bed 15 Twill tape 03 3.3 Circular Knitting Section. This section contains 27 circular knitting machines. Circular knitting machines are of different types, made by different manufacturer and also have different specifications. In this section body fabric for knitted garments is produced. The different specifications of different machines are given one after another

- 24. Page | 24 Table 4 :Specification of circular knitting machine M/c no Brand of machine Origin of machine M/c type Dia (inch) Gauge No of needle No of feeder 01 JIUNN LONG Taiwan Rib 36 18 2040*2 72 02 JIUNN LONG Taiwan Rib 34 18 1920*2 68 03 JIUNN LONG Taiwan Rib 34 18 1920*2 68 04 JIUNN LONG Taiwan Rib 32 18 1800*2 62 05 - 08 JIUNN LONG Taiwan Single jersey 36 24 1740 69 09-10 JIUNN LONG Taiwan Single jersey 34 24 1812 72 11 JIUNN LONG Taiwan Single jersey 24 24/20 1872 75 12 JIUNN LONG Taiwan Single jersey 28 24 2112 84 13-15 JIUNN LONG Taiwan Single jersey 30 24 2256 90 16-17 ORIZI O Italy Single jersey 30 28 1680 72 18-19 GOAN G LIH Taiwan Fleece 36 20 2256 102

- 25. Page | 25 20-21 GOAN G LIH Taiwan Fleece 34 20 2136 96 22 GOAN G LIH Taiwan Fleece 30 20 1860 84 23 GOAN G LIH Taiwan Fleece 30 20 1860 84 Auto Stripe 24-26 Lisky Taiwan Single jersey 4 color 28 24/22 1344 70 27 Lisky Taiwan Single jersey 4 color 36 24/28 1420 90 3.4 Flat Knitting Section: Generally collar, cuff of knitted garments is produced in this section. In this section there are 5 flat knitting machines, all of them are same type and also have same specification. The specification of all machines is given below Table 5: Specification of flat knitting machine Serial no Machine brand Country of origin Maximum width Machine type Machine gauge No of feeder 01 -05 JIUNN LONG Taiwan 68” V-Bed 14 8 06-15 JIUNN LONG China 40” V-Bed 14 8

- 26. Page | 26 Table 6: Specification of Twill tape knitting machine Serial no Machine brand Country of origin No of head 01-03 Nobletex China 10 3.5 Cloth Inspection Section: In cloth inspection section one machines is available. Specification of this machines is given below Type Cloth Inspection Machine Manufacturer name Uzu fabric Inspection Country Thailand Model No. UZ 900.31 3.6 List of Machines Department Machine type No. of machine Grey Fabric Store & inspection Fabric inspection machine 1 Batching Turning machine 02 Over lock machine 03 Dyeing floor Sample dyeing machine all are high pressure 10 Winch dyeing machine (Atmospheric) Bulk 08 Winch dyeing machine (High temperature) Bulk 05 Dark Room Light Box 03 Lab Dip Machine 03

- 27. Page | 27 Lab Electric Pipet 02 Electric Balance 02 Spectrophotometer(Data Color) 01 Computer 01 Printer 01 Philips Hot Iron 01 Washing Machine 01 Tumble Dryer 03 GSM Cutter 03 Crock meter (wet & dry Rub) 01 PH Meter 01 Dryer 01 Washing Section Washing Machine 07 Hydro Extractor 01 Tumble Dryer 03 Finishing Section Hydro extractor 01 Squeezer 01 Slitting & Dewatering machine 02 Dryer(tube) 01 Tube Compactor 01 Open Compactor 02 Stenter 02 Stenter (Mahlo) 01

- 28. Page | 28 Calendar 01 Brushing machine 01 Sueding Machine 01 Some machine picture used in finishing section: Fig 3:Hydro extractor machine Fig 4: Silting machine

- 29. Page | 29 Fig 5 : Stenter Machine Fig 6 : Compactor Machine

- 30. Page | 30 3.7 Garments section: Here the machines are categorized by the concerned section. These are section of the Texeurop Bd Ltd garments section. 3.7.1 Sample section 3.7.2 Cutting section 3.7.3 Sewing section 3.7.4 Finishing section 3.7.1 Sample section : CAD Room CAD room has the following machine: 01. Dizit board-copy the hand marking pattern Fig 7:Dizit board 02. Printer: a. Consumption(mini print) b. Plotter(big print) Fig 8:Plotter Machine

- 31. Page | 31 03.Pattern cutter machine: Brand: Winda Fig 9 :Pattern cutter machine 04.Software a. Gerber technology Table 8 : Total number of machine used in sample section SL NO Machine type No of Machine Description O1 Pain machine (lock stitch) 57 1 needle 02 Over lock machine 27 4 thread (2 needle,2 looper) 03 Flat lock machine 22 3,4,5 thread 04 Button hole machine 1 1 needle 05 Button attaching machine 1 1 needle 06 Bartact machine 1 1 needle 07 Snap machine 1 08 Prequitting machine 2 2/4 needle 09 Rib cutting machine 1 10 Feed of the arm 1 11 Kansai special(chain stitch) 2 Special 12 Kansai special(back tap) 1 Special 13 Kansai special(smoke Machine) 7 Special =124

- 32. Page | 32 3.7.2 Cutting section In cutting section following machines are use- 1. Cutting m/c Completely manual: Hand operated scissor. Manually operated powered knife: Straight knife Band knife Computerized cutting machine: Garber Cutting machine (no of machine 2) 2. Spreading machine Brio 1000(no of machine 4) Konsan (no of machine 1) Equipment’s in cutting section Cutting table Perforated paper Marker Auto sticking m/c Gsm tester Gsm cutter Electric balance Cutting Department equipped with Auto Spreading & Auto Cutting Machine: Table 9 :Equipped with state of the art automatic spreading and CNC technology cutting machine made by Gerber Machine Specification Brand Auto Cutter Automatic Fabric Cutting Machine with clearing Belt Gerber Spreader Automatic Fabric Spreading Machine with Spreading Processor Brio 1000 Konsan

- 33. Page | 33 Fig 10: Automatic Spreading Machine and Automatic Cutting Machine Table 10 :Cutting section machine list : Type Brand Machine Quantity Computer hp 2 CAD Machine Winda digitizer 1 CAD Machine Winda plotter 1 CAD Machine Winda laser cutting machine 1 Straight knife cutting machine BLUISTER 15 Band knife Cutting Machine BLUISTER 2 Sticker machine 10

- 34. Page | 34 Fig 11 straight knife cutting machine Fig 12 band knife cutting machine

- 35. Page | 35 3.7.3 Machineries in sewing section: Table 11 :sewing section machine SL No Sewing Machine Quantity Brand 1 1-Needle Lockstitch 551 JUKI,BROTHER,SUNSTA R,PUFF 2 1-Needle Chain Stitch 25 JOJE,FEIYUE 3 Vertical Trimmer 50 JUKI,SUNSTAR 4 2-Needle Lockstitch 22 SUNSTAR 5 2-Needle Chain Stitch 50 KANSAI, JOJE,FEIYUE 6 Multi Needle Chain Stitch 46 KANSAI 7 4-Thread Over lock (With Electrical Chain Cutter) 451 JUKI,PEGASUS,KANSAI 8 2-Needle Piping (Back tape) 25 PEGASUS,KANSAI 9 2/3-Needle Covering Stitch (Flatlock) 461 JUKI,PEGASUS,KANSAI 10 Zig-Zag Machine 10 JUKI,SUNSTAR 11 Bartack Machine 110 JUKI,BROTHER,SUNSTA R 12 Button Hole Machine 63 JUKI,BROTHER 13 Button Swing Machine 65 JUKI,BROTHER 14 Smocking Machine(12 & 33 Needle) 15 KANSAI 15 Pico ting machine 11 KANSAI

- 36. Page | 36 3.7.4 Finishing Section: Table 12 :In finishing section following machines are use: Serial No Finishing Machine Quantity Brand 01 STEAM IRON 158 VEIT,SLIVER STAR,NISHO 02 VACCUM TABLE 148 VEIT,SLIVER STAR,NISHO 03 METAL DETECTOR 3 CINTEX 04 NEEDLE DETECTOR 12 CINTEX,HASHIMA 05 HAND METAL DETECTOR 5 KM,HASHIMA 06 STRAPPING MACHINE 2 TOYO 07 SPOT REMOVING MACHINE 12 UZU 08 TAG ATTACHER MACHINE 6 ARTEKA TOTAL 346 3.8 Remarks: Texeurop BD ltd is a well-planned factory. Everything which is necessary is available here is a well-furnished factory.

- 37. Page | 37 CHAPTER-04 Raw Material Serial No. Content Page No. 4.1 Raw material 38 4.2 Different Types of Yarn for Knitting 38 4.3 Raw materials sources and costs 39 4.4 Grey Fabrics 40 4.5 Grey fabric sources 40 4.6 Garment accessories 40 4.7 Different types of trimmings item 41 4.8 Remarks 41

- 38. Page | 38 4.1 Raw material: Raw material is a unique substance in any production oriented textile industry. It plays a vital role in continuous production and for high quality fabric. Types of raw materials: 1. Yarn 2. Grey fabric 3. Dyes 4. Chemical 4.2 Different Types of Yarn for Knitting: Table 13 : Different Types of Yarn for Knitting: Generally used yarn Count Cotton 10S ,18 S ,20 S ,24S , 26S , 28S , 30S , 32S , 34S , 38s ,40S Polyester 75D, 100D Spandex yarn 20D,40D, 70D Grey Mélange (C-90% V-10%) 24S , 26S Ecru Mélange (C-85% V-15%) 24S , 26S , 28S Anthra Mélange (C-65% V-35%) 24S , 26S , 28S PC (65%Polyester & 35% cotton) 24S , 26S , 28S , 30S CVC 24S , 26S , 28S , 30S

- 39. Page | 39 4.3 Raw materials sources and costs Table 14: Raw material sources and costs Yarn Types. Yarn Count Source of Yarn Price of Yarn 100% Cotton, Combed. 40/s Shinha Tex $ 3.55/kg 100% Cotton, Carded. 40/s Rahmat Tex $ 2.90/kg 100%Cotton, Combed. 34/s Akij Tex $ 3.08/kg 100%Cotton, Carded. 34/s Shamim Tex $ 2.70/kg 100% Cotton, Carded. 32/s Shamim Tex $ 2.56/kg 100% Cotton, Carded. 30/s Akij Tex $ 2.55/kg 100%Cotton, Combed. 30/s Akij Tex $ 2.95/kg 100%Cotton, Combed 30/s Keya Tex $ 3.00/kg 100%Cotton, Combed. 26/s Akij Tex $ 2.90/kg 100% Cotton, Carded. 26/s Keya Tex $ 2.45/kg 100% Cotton, Carded. 24/s Akij Tex $ 2.45/kg

- 40. Page | 40 100%Cotton, Combed. 24/s Akij Tex $ 2.85/kg 100%Cotton, 20/s Keya Tex $ 2.90/kg Combed Grey mélange(85% Cotton +15% viscose) 34/s Shamim Tex $ 3.05/kg Grey mélange (”) 26/s Shamim Tex $ 2.85/kg Spandex ( Lycra) 20/d Korea,Chine&Taiw an $ 08-18/kg 4.4 Grey Fabrics: Following types of grey fabrics are dyed- Single jersey Double jersey Single jersey with lycra Interlock Single Lacoste Double Lacoste Rib Lycra rib 1 x 1 rib & others Collar & cuff Polyester fabrics Single Pique Double Pique Terry Fleece 4.5 Sources: Dyeing department of Texeurop (BD) Ltd. receive grey fabric from knitting department of this company. According to buyer order, store officer receive the grey fabric and he maintains the delivery of finished fabric 4.6 Garment accessories/Basic accessories: 1. Thread 2. Zipper 3. Interlining 4. Button for example: Snap button, Plastic button, .Metal button. 5. Label: Main label , Size Label, Wash care label

- 41. Page | 41 6. Motif: Leather, Plastic, batch Metal 7. Pocketing fabric 8. Lining 9. Velcro 10. Elastic 11. Cord 12. Ribbon 13. Toggles 14. Rivet 15. Collar bone. 4.7 Different types of trimmings items are mentioned in the following: 1. Sewing Thread, 2. Button, 3. Rivet, 4. Stopper, 5. Interlining, 6. Lining, 7. Metal Badge, 8. Elastic, 9. Zipper, 10. Shoulder Pad, 11. All types of Label such as main label, care label, size label etc. 12. Hook and Loop, 13. Twill Tape, 14. Velcro Tape 15. Lace. 4.8 Remarks Texeurop (BD) Ltd. Fabrics Ltd is very careful & conscious about its raw materials. The raw materials are always collected from those suppliers who supply the dyes & chemicals of higher quality. The best Quality Raw Materials are selected to ensure and satisfy the Buyers requirements

- 42. Page | 42 Chapter-05 Production Planning, Sequences and Operations Serial No. Content Page No. 5.1 Different Sections in Texeurop(Bd) Ltd 43 5.2 Knitting Department 43 5.3 Flat bed knitting machine 43 5.4 Dyeing section 45 5.5 Sample section 46 5.6 Machinery of sample section 47 5.7 Sampling Process Flow Chart 47-49 5.8 Sample Procedure in Texeurop(Bd) Ltd 50 5.9 The details attached to the garments sample 51 5.10 CAD Section 51 5.11 Digitizer 52 5.12 Plotter 52 5.13 Cutting section 53-55 5.14 Process flow chart of fabric cutting department 56 5.15 Types of sewing machine 57 5.16 Sewing machine description 57-59 5.17 Types of sewing thread 60 5.18 Accessories used in sewing 60 5.19 Sewing operational sequence of a T Shirt 61 5.20 Operational Sequence of Polo Shirt 62-63 5.21 Operation Sequence of Jacket 64-65 5.22 Sewing defects Finishing Section 66-67 5.23 Line balancing 68 5.24 Steps in line balancing 68 5.25 Finishing section 68 5.26 Process Flow Chart of Garments Finishing 68 5.27 Finishing item 69-71

- 43. Page | 43 5.1 Different Sections in Texeurop (Bd) Ltd Knitting section Dyeing section Sample section CAD section Cutting section Sewing section Finishing section Folding, Packing and Cartooning section 5.2 Knitting Department: Knitting Dept. is well equipped with the latest model of “Pailung” auto stripe machines with 6 color facility and “Lisky” circular & flat knitting machines with all necessary equipments to produce all kinds of circular knitted fabric in Light & Heavy Jersey (Single Jersey & Double Jersey), Pique, Rib, Interlock, Felpa, Sweat fabric, with Spandex attachment facility in different dia, gauges & weights. 5.3 Flat Bed Knitting Machine: Flat Bed Knitting Machine produces flat pieces. Most common knitting machine for hobbiests and boutique producers. Garments produced from a flatbed knitting machine normally have side seams.; It is not possible to knit in the round on a flatbed knitting machine. Flatbed knitting machines cannot work purl stitches or garter stitch automatically. A flat bed knitting machine comprising a flat elongate bed on which is retained a plurality of parallel, latchable, needles equally spaced along the length of the bed and each movable relative to the bed in a direction lengthwise of the needles and transverse of the bed length.

- 44. Page | 44 Fig 13: Circular knitting Machine Fig 14: Flat Bed Knitting Machine

- 45. Page | 45 5.4 Dyeing section: Lab is considered to be the heart of dyeing section. Shade Matching and recipe calculation for the bulk production are the primary task of dyeing lab. TEXEUROP(BD) Ltd. has a well decorated dyeing lab. The first step of shade matching is to find out the primary colors percentage to form the shade given by the buyer. Data color is being used for this purpose. The second step is to prepare recipe for lab dyeing and the final step is making necessary adjustments in recipe for bulk dyeing. In dyeing floor, there are 9 sample machines to perform test dyeing. There are 17 bulk dyeing machines for performing scouring Bleaching and dyeing. After unloading from the bulk machine the fabric is being fed in the Squeezer to remove water. Then the fabric is being fed in to the dryer. The GSM and Shrinkage are maintained by STENTER, TUBE TEX, FABCON etc. BRUSHING, SUIDING machines are being used for special finishing purposes like removing crease marks. Fig 15: Dyeing Machine

- 46. Page | 46 Fig 16: Dyeing Laboratory 5.5 Sample section: Sample is a product which represents a group of product or lot or a batch in order to assess their quality, style or design or any other characteristic of the product. Based on the samples, the buyer will give approval or comments for any alteration in design or style or quality. Samples will reflect the quality and workmanship of the exporter or manufacturer. Broadly garment samples are categorized as development samples and production samples. Samples that is made in development stage are as following: Proto sample Fit sample Photo shot sample Size set sample Pre-production sample In production stage factory need to submit few more samples that includes: Top of production sample Shipment sample

- 47. Page | 47 5.6 Machinery of sample section: Table 15 : Machinery of sample section SL NO MACHINE TYPE NO OF MACHINE DESCRIPTION O1 PAIN MACHINE (LOCK STITCH) 57 1 NEEDLE 02 OVERLOCK MACHINE 27 4 THREAD (2 NEEDLE,2 LOOPER) 03 FLAT LOCK MACHINE 22 3,4,5 THREAD 04 BUTTON HOLE MACHINE 1 1 NEEDLE 05 BUTTON ATTACHING MACHINE 1 1 NEEDLE 06 BARTACT MACHINE 1 1 NEEDLE 07 SNAP MACHINE 1 08 PREQUITTING MACHINE 2 2/4 NEEDLE 09 RIB CUTTING MACHINE 1 10 FEED OF THE ARM 1 11 KANSAI SPECIAL(CHAIN STITCH) 2 SPECIAL 12 KANSAI SPECIAL(BACK TAP) 1 SPECIAL 13 KANSAI SPECIAL(SMOKE MACHINE) 7 SPECIAL 5.7 Sampling Process Flow Chart:

- 48. Page | 48 1. Tech Pack Receiving: This is the first stage of the sampling processes. In this stage Tech Pack or the Technical pack is received from the buyer, via merchandiser. Tech pack contains all the specifications to produce a garment. 2. Pattern making: The second stage is pattern making. In Texeurop (Bd) Ltd. Pattern is being made manually by pattern master often. Then the manually formed pattern is taken into CAD section and Digitizer is being used to input the pattern in WINDA. Finally with the help of plotter Patterns are being made by CAD section executives. This patterns contains information about materials, tolerance etc. Fig 17:Pattern Making 3. Sample Making: Sample making is the ultimate goal of this department. After making the pattern, the sample is made by using the pattern set. 4. Size Setting: After making the sample, size is set according to the Tech Pack. If there is any fault, the sample is redone. 5. Pre-Production (PP) Meeting: After the buyer has inspected the sample, preproduction meeting is called. In this meeting buyer or his agent, merchandiser, sample manager, all remain present. They decide on how to and when to start the production. If the decision Okayed, the sample is ready to go for final production. 6. Grading of Sample: After finalizing the sample. Grading is done. There may be several grades of a single design. The grading is done to separate the samples and patterns from each others. 7. Marker: After grading the samples. The design is inputted into the marker software. This software specifies how to set the pattern in the actual fabric. By using the marker software efficiently, fabric can be saved. Texeurop (bd) ltd. uses winda for marker making. 8. Cutting: After making the marker the pattern is delivered to the cutting unit and fabric is cut for final production.

- 49. Page | 49 9. Print or embroidery (if required): If tech pack contains print or embroidery instructions then those should be completed in the cutting fabrics according to the tech pack. 10. Sewing: Sewing is another important section to approve the sample by the buyer in the very shot. Here, garments are sewn according to measurement chart. It should be noted that, during sewing extra care should be taken to make fault free sample garments. 11. Finishing: Ironing or pressing has done in the garments here according to the measurement chart. 12. QC check: After completing all the above processes, quality controller inspects the sample garments here by following the tech pack which is provided by the buyer. 13. Send to the buyer for approval: After checking the sample garments by the quality controller (QC), garments sent to the buyer for approval. If it’s approved by the buyer then garments merchandiser can start the next processes for the garments production Fig 18: Sample section of Texeurop(BD) ltd

- 50. Page | 50 5.8 Sample Procedure in Texeurop (Bd) Ltd : Buying office reference merchandiser Merchandiser to pattern section Pattern making Sample fabric cutting Sample sewing Quality inspection Ironing Final qualify inspection 5 measurement Folding & packing Send to buyer Buyer approval/ buyer rejection Production pattern Fig 19: Quality check in sample section

- 51. Page | 51 5.9 The details attached to the garment sample: After the confirmation of order, each sample sent to buyer has the following details attached to it with the help of a tag. It contains the details pertaining to both what the buyer has demanded and what supplement fabric/trim etc. they have used (if applicable). Ref no. Color Fabric Composition Garments size Style no 5.10 CAD Section: Computer aided design (CAD) has brought a revolution in textile industry. The time consuming and cumbersome process of textile designing has been made easier by CAD. Now thoughtful and innovative designs are available to the textile designers and textile manufacturers at the click of a mouse. Though CAD is costly but the use of CAD is increasing day by day in our country. Because markers made by CAD can be transferred via email which saves both time and money. Besides Using CAD also help to minimize the waste of fabric by increasing the marker efficiency. Uses of CAD: In apparel industry CAD software is used for Pattern making Grading of pattern Marker making Digitizing manual patterns. There are number of CAD software suppliers who have developed CAD systems. Gerber and winda both are being used in Texeurop (bd) ltd

- 52. Page | 52 5.11 Digitizer: Digitizer is an input device for converting analog to digital data using a single pointing device. The pointing device can either be a cursor, puck, stylus or mouse. Texeurop (bd) ltd Uses winda digitizer. Fig 20: Digitizer 5.12 Plotter: The first step is to complete marker plan in computer. In the final step plotter is being used to print all pattern pieces on marker paper according to the marker plan. Texeurop (bd) ltd uses winda Plotter. Fig 21: Plotter

- 53. Page | 53 5.13 Cutting Section: Cutting is considered to be the most important section in garments manufacturing industry. Because Cutting section provides higher opportunity to make profit compared to other section by reducing wastage. In this section garment parts are being cut according to patterns. In garments cutting department, a process flow chart has to maintained to send the right measurement parts in the next process for making quality garments. Fig 22: Manually Spreading Fig 23: Automatic Spreading Machine

- 54. Page | 54 Fig 24: Automatic Cutting Machine Fig 25: Manually Cutting by Using Straight Knife Cutting Machine

- 55. Page | 55 Fig 26: Band knife cutting machine Fig 27:Straight knife cutting m/c Fig 28: Numbering

- 56. Page | 56 5.14 Process Flow Chart of Fabric Cutting Department: Receiving patterns from pattern department Receiving Cutting ratio from merchandiser Marker making Receiving Fabric from the store Fabric Checking Fabric Spreading Marker placing on to the lay Cutting the fabric Numbering Checking Sorting and Bundling Sending to next process

- 57. Page | 57 5.15 Types of Sewing Machine: There are different types of sewing machine and each type has its own application in assembling different types of garments. The common machines are: Plain machine Flat lock machine Over lock machine Kansai Machine Button holing machine Button attaching machine Bar tack machine 5.16 Sewing Machine Description: Table 16 :sewing machine description Machine Properties and Uses Fig 29: Plain Machine One needle, Two needle, Three guide One hook Two thread One magnate guide Bottom hemming Belt top stitch Zipper joint Flap make Flap top stitch Loop tack stitch Belt joint stitch

- 58. Page | 58 Machine Properties and uses Fig 30: Over Lock Machine Properties 5 threads 4 tensioners 2 knifes (up/down) 2 needles for 5 threads 1 Needle for 3 threads 3 loppers for thread 2 loppers for 3 thread Uses Over lockstitch Fig 31: Flat Lock Machine Properties: 4 tensioners 3 threads Contain a holder 2 needles Uses: Zigzag stitch Knit hemming Loop making Fig 32: Kansai machine Properties 2 needles 4thread 8 tensioners 21 lopper point (used two loppers Depends on distance of stitches) Uses Back yoke stitch Back belt stitch

- 59. Page | 59 Machine Properties and uses Fig 33: Button holing machine Properties: 2 threads 1 needle 2 tensioners Contains bobbin case, hook & knife Uses: To create hole for button attaching in garment Fig 34: Button attaching machine Properties: Button attached by lock stitch doesn’t look neat however it provides greater safety. Uses: To attach the button. Fig 35: Bartack machine Properties: Bartack machine provides forward and backward stitching in short length (about 6cm) and sew a dense tack Bartaks containing 18-72 stitches, has options to change stitch density Uses: Secure pocket corners Secure open end of button hole Decorative purposes

- 60. Page | 60 5.17 Types of sewing thread: Cotton Polyester Silk linen 5.18 Accessories used in sewing: Sewing thread Plastic/coconut button Snap button Woven label Hang tag/price tag Zipper Barcode +size label Name label Size label Lock pin Poly sticker Twill tape Satin tape (hanger loop) Lace Reflective tape Elastic Main label Fig 36: Sewing floor

- 61. Page | 61 5.19 Sewing operational sequence of a T Shirt: Fig 37: T Shirt Sl. No. Process Machine Type No. of Needle No. of Thread Production /hour 1 Shoulder tape join Over lock 2 4 100-120 Pcs 2 Neck join with rib Over lock 2 4 100-120 Pcs 3 Rib cut Plain m/c 1 2 100-120 Pcs 4 Neck closing Flat lock 1 2 100-120 Pcs 5 Back tape piping Flat lock 1 2 100-120 Pcs 6 Can tuck Plain m/c 1 2 100-120 Pcs 7 Front neck top sin Flat lock 1 2 100-120 Pcs 8 Back neck top sin Flat lock 1 2 100-120 Pcs 9 Size label Plain m/c 1 2 100-120 Pcs 10 Shoulder scissoring Scissor 100-120 Pcs 11 Sleeve tuck Plain m/c 1 2 100-120 Pcs 12 Sleeve join Over lock 2 4 100-120 Pcs 13 Side seam Over lock 2 4 100-120 Pcs 14 Sleeve tuck Plain m/c 1 2 100-120 Pcs 15 Hem tuck Plain m/c 1 2 100-120 Pcs 16 Bottom hem Flat lock 3 6 100-120 Pcs 17 Sleeve hem Flat lock 3 6 100-120 Pcs 18 Security tuck Plain m/c 1 2 100-120 Pcs 19 Care label joining Plain m/c 1 2 100-120 Pcs

- 62. Page | 62 5.20 Operational Sequence of Polo Shirt: Fig 38: Polo Shirt Lining join with collar part by heat pressing Collar marking for open stitch Collar inside open stitch Collar marking Collar ¼ top seam Collar cutting Band Rolling Band join with Collar Band top seam 1/6 Placket Lining placket make Placket Rolling Placket joint Placket top seam 1/6 Placket Pattern top seam Placket pattern top seam Box Sewing Pocket Rolling Pocket iron Pocket marking

- 63. Page | 63 Pocket joint with body Yoke joint with back part Yoke ¼ top seam Back & front part matching Number shoulder joint Solder top seam Collar Making Collar & body number matching Collar joint with body part Collar top seam jointing point Sleeve marking Sleeve over locked Sleeve joint with body part Sleeve marking for batch Sleeve batch joint (left & right side) Body marking Batch joint with body part Label make Label Iron Main label joint in back side Sleeve opening tuck Body hem sewing Care label sewing Side Joint Band Tuck Band

- 64. Page | 64 tape joint Band top seam Sleeve chap tuck Inspection 5.21 Operation Sequence of Jacket: Fig 39: Jacket Contrast join with the pocket by pressing Pocket rolling Number matching with body & Pocket Pocket join Zigzag top seam over Pocket Numbering & gathering back & front pants Solder join Top seam on the solder join line Collar make Chain stitching on collar marking line Collar Join Collar over locked in joining line

- 65. Page | 65 Numbering sleeve and body part Sleeve joins with body Zigzag top seam on Arm hole Zipper piping Side sewing /body sewing by over lock Zigzag top seam (side sewing line) Bottom hem tuck sewing Tuck bottom hem with body parts Arm hole tuck Bottom hem top sin zigzag Cuff making Cuff join Cuff top seam zigzag Zipper join with body part Collar tape part join with zipper side Collar taping part join with body part Zipper top seam Collar top seam Label join with body part Quality Table

- 66. Page | 66 5.22 Sewing defects: Needle damage Skip stitches Thread Breakages Broken Stitches Seam Grin Seam Puckering Pleated Seam Wrong stitch density Uneven stitch density Staggered stitch Improperly formed stitches Sewing Defect: Fig 40: Skip stitch Fig 41 : open seam Fig 42 : Scissor cut Fig 43 : Part Shading

- 67. Page | 67 Fig 44: Broken Stitch Fig 45: Four point up – down Fig 46: Pleat Fig 47: Uneven Top Stitch

- 68. Page | 68 5.23 Line balancing: Line balancing is the allocation of sewing machine according to style and design of garment. It depends of that what type of garment we have to produce. 5.24 Steps in line balancing: Now-a-days, Standard Minute Value (SMV) is used as a tool for the line balancing, production control and the estimation of efficiency. In a similar way, the time taken to do a job for making garments like shirt/trouser/blouse/dresses could depend upon a number of factors like : The length of the shirt/trouser/blouse/dress; The number of stitches per inch; The presentation of item; The pricing of garment. 5.25 Finishing Section: Garments finishing means mainly applies of pressing, folding & packing of garments. It is the last section of garments manufacturing department. 5.26 Process Flow Chart of Garments Finishing: Sewn garments received in finishing section Initial quality check Spot removing if there’s any spot Ironing or pressing Inspection Hang tag attaching Folding Poly bag Metal check Packaging or cartooning

- 69. Page | 69 5.27 Finishing item: Price ticket Hang tag Poly bag Back board Neck board Collar inside Butter fly (Single, Double) Tag pin Tissue paper Draw string and stopper Images of Finishing section: Fig 48: Initial Check Fig 49: Ironing Fig 50: Spot Lifter Fig 51: Thinner Gun (spot remover)

- 70. Page | 70 Fig 52: Washing spot Fig 53: Inspection Fig 54: Hang tag Fig 55: Metal Detector Fig 56: Prepare Hanger

- 71. Page | 71 Fig 57: Folding Fig 58: Packing Fig 59: Cartooning Fig 60: Prepare carton

- 72. Page | 72 Chapter – 6 Quality Serial No. Content Page No. 6.1 Quality 73 6.2 Quality control 73 6.3 Total quality control 73 6.4 Quality assurance 74 6.5 On Line Quality Control System 74 6.6 Off line quality assurance system 74 6.7 Equipment’s used for test 75 6.8 AQL (Acceptable Quality Level) 75 6.9 Quality inspection and control in RMG industry 75-77 6.10 Quality control of sewing thread 78 6.11 Quality Control in Zipper 78 6.12 Fabric inspection method: 78 6.13 Calculation of total points per yards 79 6.14 Textile Care Symbols 80 6.15 Remarks 80

- 73. Page | 73 6.1 Quality: In manufacturing, Quality is a measure of excellence or a state of being free from defects, deficiencies and significant variations. According to ISO 9000 quality is “degree to which a set of inherent characteristics fulfils requirement”. 6.2 Quality control: Quality is of prime importance in any aspect of business. Customers demand and expect value for money. As producers of apparel there must be a constant endeavor to produce work of good quality. Quality control is “The systems required for programming and coordinating the efforts of the various groups in an organization to maintain the requisite quality”. In the garment industry quality control is practiced right from the initial stage of sourcing raw materials to the stage of final finished garment. For textile and apparel industry product quality is calculated in terms of quality and standard of fibers, yarns, fabric construction, color fastness, surface designs and the final finished garment products. However quality expectations for export are related to the type of customer segments and the retail outlets. The motto of Texeurop (BD) LTD. is to manufacture quality apparels and so the executives of quality control section make no compromise with quality Fig 61: Quality Inspection 6.3 Total quality control: Total quality control means the application of management principles to all areas of business from design to delivery instead of confining them only to production activities Objectives: To maximize the production of goods within the specified tolerances correctly the first time. To achieve a satisfactory design of the fabric or garment in relation to the level of choice in design, styles, colors, suitability of components and fitness of product for the market.

- 74. Page | 74 6.4 Quality assurance: quality assurance refers to the planned and systematic activities implemented in quality system so that quality requirements for a product or service will be fulfilled. It is the systematic measurement, comparison with the standard, monitoring f processes and associated feedback loop that confers error prevention. This can be contrasted with the quality control, which is focused on process output. Quality assurance system consists of two types. They are: Online quality assurance system Off line quality assurance system 6.5 On Line Quality Control System: This type of quality control is carried out without stopping the production process. During the running of production process a set up is automatically performs and detects the fault and also takes corrective action. Online quality control comprises with the raw material quality control and the process control. Raw material control: Texeurop (Bd) Ltd always very concern about the quality of the product. So, they knit grey fabric from the best quality yarn & utilizes technical evaluation in every stage of the production, as we know the quality product depends on the raw material quality. Process control: The method chosen for process must be provided with the necessary accurate parameters. Here the specific gravity, water level, residual hydrogen per oxide etc. at each stage is checked. In every stage Ph should be maintained sincerely. 6.6 Off line quality assurance system: This type of system consists of quality measuring system when the production process completed. All off line tests for finished fabrics (dyeing and finishing section) can be grouped as follows: Physical Chemical Physical tests: Following physical tests are carried out in offline quality assurance system. Thread per inch Fabric weight Width test Tensile strength Tear strength Seam slippage Abrasion resistance Pilling resistance Thermal stability Crease resistance Stretch ability & growth recovery Smoothness appearance

- 75. Page | 75 Chemical tests: Following chemical tests are carried out in offline quality assurance system. Fastness to washing Fastness to light Fastness to heat Fastness to actual laundering Fastness to sea water Fastness to chlorinated water Fastness to water spotting Fastness to perspiration 6.7 Equipment’s used for test: various types of machineries and equipment are used during testing. Following equipment’s are the main instruments for testing. Spectrophotometer with software (data color) Martindale abrasion tester Light box Sample dyeing machine Iron Electric balance Crock meter Data color 6.8 AQL (Acceptable Quality Level): A certain proportion of defective will always occur in any manufacturing process. If the percentage does not exceed a certain limit, it will be economical to allow the defective to go through instead of screening the entire lot. This limit is called the “Acceptable Quality Level” (AQL). Normally for Garment industry, the AQL levels of 2.5, 4.0 and 6.5 are followed. 6.9 Quality inspection and control in RMG industry: The various Garments manufacturing where in-process inspection quality control are done are mentioned below:

- 76. Page | 76 In Sample making section In- Marker making section Inspection in fabric spreading section Inspection in fabric cutting section Inspection in fabric sewn section Inspection in pressing & Finishing section Quality Control in Sample Section: Maintaining buyer specification standard Checking the sample and its different issues Measurement checking Fabric color, GSM, Fastness properties required checking Quality Control in Marker Making: To check notch or drill mark Fabric length must be higher than marker length Fabric width must be higher than marker length Matching of grain line Check pattern size and dimension Matching of check and stripe taking into consideration Consider garments production plan Cutting table length consideration Pattern direction consideration Quality Control in Fabric Spreading: Fabric spreading according to correct alignment with marker length and width Maintain requirements of spreading Matching of check and stripe Lay contains correct number of fabric ply Correct Ply direction To control the fabric splicing Tension control Quality Control in Fabric Cutting: The dimension of the pattern and the cut piece should be same and accurate Cut edge should be smooth and clean Notch should be cut finely Drill hole should have made at proper place

- 77. Page | 77 No yarn fraying should occur at cut edge Avoid blade deflection Maintain cutting angle More skilled operator using Quality Control in Sewing Section: Input material checking Cut panel and accessories checking Machine is in well condition Thread count check Special work like embroidery, printing panel check Needle size checking Stitching fault should be checked Garments measurement check Seam fault check Size mistake check Mismatching matching of trimming Shade variation within the cloth Wrong placement of interlining Creased or wrinkle appearance control Quality Control in Finishing Section: Proper inspection of the garments including measurement, spot, dirt, impurities Water spot Shade variation check Insecure or broken chain or button Wrong fold Proper shape in garments Properly dried in after pressing Wanted wrinkle or fold in lining Get up checking Collar closing Side seam Sleeve placket attach Cuff attach Bottom hem Back yoke

- 78. Page | 78 6.10 Quality Control of Sewing Thread: A slender, strong strand or cord, especially one designed for sewing or other needlework. Most threads are made by plying and twisting yarns. A wide variety of thread types are in use today, e.g., spun cotton and spun polyester, core-spun cotton with a polyester filament core, polyester or nylon filaments (often bonded), and mono filament threads. Following Features of Sewing Thread are considered: Thread Construction/Ticket number Thread count Thread Ply Number of twist Thread balance Thread Tenacity Thread Elongation Sew ability Imperfection Thread color Package Density Winding Yardage 6.11 Quality Control in Zipper: A zipper, zip, or zip fastener, is a commonly used device for temporarily joining two edges of fabric. It is used in clothing (e.g., jackets and jeans), luggage and other bags, sporting goods, camping gear (e.g. tents and sleeping bags), and other items. Following Factors are being considered in Zipper: Proper dimension of zipper The top and bottom end should correctly have sewn The tape and color of zipper should be uniform Slider has to be locked properly The slider should move properly 6.12 Fabric inspection method: 4 Point System is being used in TEXEUROP (BD) LTD. for fabric inspection. Within this system, fabric rolls are graded for defects. Each defect receives a certain number of points, and after inspection, of course you hope for the lowest number of points possible.

- 79. Page | 79 Table 17 : The point system is as follows: Size of Defects Penalty Points Length of Defects in Fabric (either length or width) Defects up to 3 inches 1 Defects > 3 inches <6 inches 2 Defects > 6 inches <9 inches 3 Defects > 9 4 Holes and opening (Largest Dimension) 1 Inch or less 2 Over 1 Inch 4 6.13 Calculation of total points per yards In 4-point system fabric quality is evaluated by unit points/100 sq. yards. Points / 100 sq. yd. = (Total points in roll * 36 * 100)/ (Fabric length in yards * Fabric width in inches). Normally fabric roll containing 40 points per 100 square yards are acceptable.

- 80. Page | 80 6.14 Textile Care Symbols: 6.15 Remarks: No wearers will buy a garment with poor quality and visible defects. So buyers and retailer knowingly do not purchase a product that does not meet the quality requirement. That is why maintaining quality is very important for any garments manufacturing industry.

- 81. Page | 81 Chapter 7 Store and Inventory Control Serial No. Content Page No. 7.1 Raw Materials Inventory 82 7.2 Finished goods inventory 82 7.3 Types of Inventory Control Systems 82 7.4 Remarks: 83

- 82. Page | 82 7.1 Raw Materials Inventory: Texeurop (Bd) Ltd has raw materials inventory contains: Carded yarn Combed yarn Chemicals for wet processing Dyes ETP chemicals WTP chemicals Knitted fabric Woven fabric Fig 62: Raw material inventory 7.2 Finished goods inventory: Texeurop (Bd) Ltd has one finished goods inventory for storing cartoons. Texeurop (Bd) Ltd also has a inventory for spare parts which contains gear, spark plug, lubricating oil etc. required for maintenance operation. 7.3 Types of Inventory Control Systems: There are two main types of inventory control systems that we could consider using. The main difference between the two is how often inventory data is updated. Perpetual inventory system: In this system inventory data is entered continuously. Once an order is placed or received the data is updated right away. Compared top periodic inventory system, a perpetual inventory system is superior because it allows real-time tracking of sales in addition to monitoring individual inventory levels for each item. However, the calculated inventory levels obtained from a perpetual inventory system may steadily deviate from the actual inventory levels due to theft or unrecorded transactions. It is therefore vital to periodically compare the physical inventories to the actual on-hand quantities and adjust accordingly.

- 83. Page | 83 Periodic Inventory System: In this system, inventory data is not kept consistently up to the date. Instead, inventory information is update after a particular interval of time. This method is not as efficient as the perpetual system. It is perpetual inventory system which is being used in Texeurop (Bd) ltd. 7. 4 Remarks: Texeurop (BD) Ltd. has individual stores for raw materials, finished goods and spare parts. The store of dyestuff and chemicals are not so clean. There is not enough space to store the finished goods. It requires increasing the store.

- 84. Page | 84 Chapter 8 Utility Services Serial No. Content Page No. 8.1 Generator 85 8.2 Boiler 85 8.3 Air compressor and Compressed Air Dryer 86 8.4 Water treatment process 86-87

- 85. Page | 85 8.1Generator: A generator is a machine that converts one form of energy into another, especially mechanical energy into electrical energy, as a dynamo. An industrial generator normally uses diesel or gas as its fuel. In Texeurop (Bd) ltd. there are two gas generators and a diesel generator. The capacity of each gas generator is 1030kw and the capacity of diesel generator is 500kw. The brand name of the gas generator is Caterpillar. Fig 63: Generator The maintenance of the gas generator is performed in every 1000hrs. It is essential to change the spark plug in each 1000hrs.Each gas generator has 16 cylinders. Air cylinders suck air to perform the ignition along with gas. The price of gas generator of 1030kw is around $375,000. 8.2 Boiler: Boiler is a closed vessel or arrangement of vessels and tubes, together with a furnace or other heat source, in which steam is generated from water. There are two types of boiler water tube boiler and fire tube boiler. In Texeurop (Bd) ltd. there is a fire tube boiler. It is 12tons boiler and the capacity of the boiler is 7200kg per hour. Steam pressure is around 10bar. The boiler also has safety valve to prevent explosion.

- 86. Page | 86 Fig 64: Boiler 8.3 Air compressor and Compressed Air Dryer: An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e. compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. In Texeurop (Bd) ltd there are two Air Compressors. A compressed air dryer is used for removing water vapor from compressed air. In Texeurop (Bd) ltd there is one compressed air dryer. Fig 65: Air Dryer Fig 66: Air Compressor 8.4 Water treatment process: In Texeurop (Bd) ltd. there are two deep tube wells by the side of the water treatment plant. There are also two submersible pumps in the deep tube well one is 100-meter-deep and another one is 140 metes deep. The water from the deep tube well goes to the reserve tank.

- 87. Page | 87 Then the water goes to the first processing tank. First and Second tanks are filled with stone. The third tank is filled with resin. The resin is used to remove the hardness of water. Fig 67: Water treatment plant There is another tank filled with salt water which is used to remove the remaining iron layer from the water. It would require more chemical for wet processing section if the industry had no water treatment plant. Besides water contaminated by iron is harmful for all metal pipe and machine. By the help of motor the treated water is being delivered to the workstation. Fig 68: Motors Backwash facility is also available in Texeurop (Bd) ltd. The backwash is performed in every 8- 12 hours. The regeneration process is being performed in every 40-48 hours after

- 88. Page | 88 Chapter 9 Maintenance Serial No. Content Page No. 9.1 Maintenance 89 9.2 Objectives of Maintenance 89 9.3 Types of Maintenance 89 9.4 Preventive Maintenance 89 9.5 Break down Maintenance 89 9.6 Maintenance of Equipment 90 9.7 Weekly maintenance 90 9.8 Monthly maintenance 90 9.9 Different types of machine for maintenance 91 9.10 Picture of maintenance tools 91

- 89. Page | 89 9.1 Maintenance: Maintenance is the process by which equipment’s are looked after in such a way that they can give the best possible service. All the machines and machine parts of knitting, dyeing and garments are maintained with extreme care. Texeurop (Bd) ltd has a maintenance department with skilled engineers, fitters & operators. 9.2 Objectives of Maintenance: 1. To keep the factory plants, equipment’s, machine tools in optimum working condition. 2. To increase production & improve quality by minimizing the downtime of the machine. 3. To modify the machine tools to meet the need for production. 4. To ensure specified accuracy to product & time schedule of delivery to customer. 9.3 Types of Maintenance 9.4 Preventive Maintenance: Preventive maintenance is a predetermined activity to ensure on time inspection & checking of facilities & uncover conditions that may lead to production breakdown. Maintenance is done according to routine once in a month. Schedule maintenance varies, time in time & also depends on situations according to type of machines. 9.5 Break down Maintenance: Break down maintenance is done instantly when problem arises in the machine. In this case, repairs are made after the equipment is out of order and it cannot perform its normal functions. So the defects are then rectified & problems are solved by the maintenance department. Maintenance Preventive Maintenance Mechanical Maintenance Electrical Maintenance Break Down Maintenance Electrical Maintenance Mechanical Maintenance

- 90. Page | 90 9.6 Maintenance of Equipment • Pie or cake pan for soaking parts in cleaning fluid • Small screw driver • Large screw driver • Small adjustable wrench • Hammer (optional) • Small oil can (clean) for cleaning fluid • Cleaning brush (narrow, nylon) • Paring knife (or pocket knife) • Long needle or small crochet hook • Tweezers • Cleaning cloths • Fabric to test stitching 9.7 Weekly maintenance: 1. All belt tight/adjusting 2. All bearing cleaning 3. Gear oil checking/ranking 4. Fan filter cleaning 5. Panel board cleaning 9.8 Monthly maintenance: 1. Checking all control panels 2. Lubrication of all motors bearing 3. All cable terminal tighten 4. Cleaning and maintenance

- 91. Page | 91 9.10 Different types of machine for maintenance: Cutting section: Fabric inspection Cutter m/c Spreader m/c Numbering m/c End cutter m/c Fusing m/c Sewing section: Single needle lock stitch m/c Double needle lock stitch m/c Single needle chain stitch m/c Double needle chain stitch m/c Over lock m/c Multi needle m/c Flat lock m/c Feed off the arm m/c eyelet hole m/c Button hole m/c Finishing section: Thread sucking m/c Tag gum m/c Needle detector m/c Spray gum Rivet m/c 9.11 Image of maintenance tools: Fig 69: Maintenance Tools

- 92. Page | 92 Chapter 10 Merchandising Serial No. Content Page No. 10.1 Merchandising 93 10.2 Merchandiser: 93 10.3 Types of Merchandising: 93 10.4 Objectives of Merchandising: 94 10.5 Process Flow Chart of Merchandising 94 10.6 Fabric consumption: 95 10.7 Function of the merchandiser 96 10.8 Open Account 96 10.9 Documentation for shipment: 96 10.10 FOB 97 10.11 CIF 97 10.12 Remarks 97

- 93. Page | 93 10.1 Merchandising Merchandising is the department which mediates marketing and production departments. It is the methods, practices, and operations used to promote and sustain certain categories of commercial activity. It includes directing and overseeing the development of product line from start to finish. In marketing and merchandising department, a team of merchandisers and marketers work together under a profit controls head. Merchandisers handle the foreign buyers. The teams are made according to the buyers being handled. 10.2 Merchandiser: Merchandiser The person who is related in merchandising is called merchandiser. The merchandiser coordinates with the design team to effectively present the product or product line. He or she develops colors and specifications, and performs market research to determine the most effective ways to sell and promote the product. This person needs strong communication and negotiation skills and visual and analytical abilities. He or she also needs to be a creative and innovative thinker. 10.3 Types of Merchandising: Two type of merchandising done in garment exports 1. Marketing merchandising. 2. Product merchandising. 1. Marketing Merchandising: Main function of marketing merchandising is Product Development Costing 1. Product Merchandising: Product merchandising is done in the unit. This includes all the responsibilities from sourcing to finishing i.e. first sample onwards, the products merchandising work start and ends till shipment.

- 94. Page | 94 10.4 Objectives of Merchandising: To try to get garments order inquiry from buyer through various sources. To find out the consumptions of fabrics & accessories. To make costing on the garments inquiry. Procurement of raw materials. Follow up. Regular correspondence with buyer, suppliers and related personnel. Help and follow up in commercial activities. Arrange tests & inspections. To do shipment 10.5 Process Flow Chart of Merchandising Received PDF sheet Consumption Costing Negotiation with buyer Order received Purchase order sheet received L.C opening Purchase fabric & accessories Time and action setting Approval for bulk production Related work to production planning Start bulk production Inspection Handover to buyer nominated agents

- 95. Page | 95 10.6 Fabric consumption: Body Section, Cpd= L×W×12×GSM÷10000000 =107. 69×69.O8×12×145÷10000000 =1.29kg Sleeve CPD =22.86×25.4×12×145÷10000000 =0.1010kg Neck =69.85×2.54×12×145÷10000000 =0.031kg Bottom hem =58.42×2.54×12×145÷10000000 =0.0258kg Total fabric =1.29+0.1010+0.031+0.0258 =1.447×1.06 Flat lock (3thread) =(28+40+27.5×19)” =2023.5” Over lock (3thread)=(41+20+20×16)” =1472” Over lock thread =(27.5×18)” =495” Total thread consumption = 2023.5"+1472" + 495" =101"

- 96. Page | 96 10.7 Function of the Merchandiser: When an export order is placed to a merchandiser, He or she has to schedule the following main functions to execute the order perfectly on time: Fabric requirement calculations Accessories requirement calculation (e.g. thread, button, interning, label, polybag, carton etc.) Sourcing of yarn & fabrics Sourcing of accessories Possible date of arrival of fabrics & accessories in the garments factory Costing Garments production planning with the help of production DGM. Pre –shipment inspection schedule 10.8 Open Account: An open account transaction means that the goods are shipped and delivered before payment is due, usually in 30 to 90 days. 10.9 Documentation for shipment: Packing list Commercial invoice ERC (export registration certificate) Bank account. Bill of Lading.

- 97. Page | 97 10.10 FOB: FOB: (Free on Board) is simply the Supplier delivers the goods to his nearest Port and hands them over to the Freight Forwarder nominated by the Buyer. Buyer then pays the freight and arranges Insurance 10.11 CIF: CIF: (Cost Insurance Freight) means that the Supplier delivers the goods to his own Freight Forwarder who then ships the goods to the destination Port. 10.12 Remarks: Merchandisers are the key player for generating business for any manufacturing plants/company. To maintain a good relationship between all the departments and to get the best output from each department

- 98. Page | 98 Chapter 11 Effluent Treatment Plant (ETP) Serial No. Content Page No. 11.1 Effluent Treatment Plant (ETP) 99 11.2 Process flow chart of Effluent Treatment Plant 99 11.3 Primary Filtration 100 11.4 Cooling and Mixing 100 11.5 Neutralization Tank 100 11.6 Coagulant Bath 100 11.7 Settling tank 101 11.8 Pressure Filter 101 11.9 Carbon Filtration 101 11.10 Discharge to Drain 101 11.11 Remarks 101

- 99. Page | 99 11.1 Effluent Treatment Plant (ETP): ETP is essential to purify the waste water which comes from different types of manufacturing industry like textile, ternary, dyes and chemical manufacturing industry, pharmaceuticals etc. Different environment saving organizations are trying to protect the environment from the harmful effect of effluent. Different waste has different characteristics which pollute the water. Texeurop (Bd) Ltd. has an enormous ETP facility. Fig 70: Effluent Treatment Plant 11.2 Process flow chart of Effluent Treatment Plant: Effluent Primary Filtration Cooling and Mixing Neutralization (by acid or alkali) Chemical Coagulation Setting and separation of sludge Pressure Filtration Discharge

- 100. Page | 100 11.3 Primary Filtration: It is the first stage of effluent treatment plant, where effluent is come from dyeing. Here primary filtration is performed to remove the solid particles. Fig 71: Equalization Tank 11.4 Cooling and Mixing: In this stage different types of effluent are mixed and cool down by the help of a motor run by a fan. 11.5 Neutralization Tank: After cooling and mixing, effluent is transferred to the neutralization tank by the help of a pump. Here acid or alkali is mixed to neutralize the effluent. A PH meter is placed in the neutralization tank. 11.6 Coagulant Bath: After neutralization of effluent, effluent is transferred to a coagulant bath. Here coagulant is added to the effluent. Fig 72: Ferrous Tank Fig 73: Polymer Tank

- 101. Page | 101 11.7 Settling tank: In here, effluent separates from water and is found in the lower level of the tank. Effluent is like as sludge. Fig 74: Settling Tank 11.8 Pressure Filter: Here filtration is done under pressure. A certain amount of pressure is created here. 11.9 Carbon Filtration: It is an optional filter process which is currently not available in Texeurop (Bd) Ltd. 11.10 Discharge to Drain: After completion of all the process, the effluent becomes purify and safe to drain to the environment. 11.11 Remarks: The Government has made ETP use mandatory for all textile industry having dyeing section.

- 102. Page | 102 Compliance Chapter 12 Serial No. Content Page No. 12.1 Human resource management 103 12.2 Administration department 103 12.3 Flow Chart of Administration Department in Garments Industry 103 12.4 Compliance 104 12.5 Compliance of Texeurop (Bd) Ltd. 104 12.6 Health 105 12.7 Toilet 106 12.8 Fire 106 12.9 Safety guard 107 12.10 Remarks 108

- 103. Page | 103 12.1 Human Resource Management: Human resource management is the process of hiring and developing employees so that they become more valuable to the organization. Human Resource Management includes conducting job analyses, planning personnel needs, recruiting the right people for the job, orienting and training, managing wages and salaries, providing benefits and incentives, evaluating performance, resolving disputes, and communicating with all employees at all levels. Examples of core qualities of HR management are extensive knowledge of the industry, leadership, and effective negotiation skills. 12.2 Administration department: An administration department is responsible for providing administrative aid in five areas of a business: information management systems, human resources, payroll, acquisition and communication. The goal of the administration department is to keep all departments within a business operating at maximum capacity. The administrative offices associated with a garments manufacturing facility are typically proportional to the size of the manufacturing operation. 12.3 Flow Chart of Administration Department in Texeurop (Bd) Ltd Planning Organizing Staffing Directing Controlling Budgeting

- 104. Page | 104 12.4 Compliance: Compliance means conformity of certain standard. Texeurop (Bd) Ltd. is an ISO 9001:2008 certified company. Besides it has certifications of Oeko-Tex Standard 100 Class1, BSCI, SOCOM, SEDEX and WRAP. Texeurop (Bd) Ltd. strictly follows compliance of ILO. Some contents of compliance with ILO and Bangladesh Labor Laws are given below. … No child labors. No forced labor. Transport facilities for worker Hours of work. Voluntary over time. Intervals for rest. Weekly holidays Annual leave. Festival holidays & leaves with bonus. Maternity protection. Worker’s welfare committee. Mineral drinking water. Sanitary facilities First aid box Canteen services. Day care center. Health care activities for the worker & employ company doctor. Fire extinguisher each & every floor & conduct fire drill at least 12 times a year. Other safety department (no discrimination) Compensation cases department. The development of compliance programmer. Environmental developer. Smoking free zone Disciplinary Practices/ Harassment. Freedom of association and right to collective bargaining. Welfare facilities. 12.5 Compliance of Texeurop (Bd) Ltd.: .Here is a list of compliance in which some points are maintained fully and some are partially. Compensation for holiday Leave with wages Health register Time care

- 105. Page | 105 Accident register Workman register Equal remuneration National festival holiday Overtime register Labor welfare Weekly holiday fund Sexual harassment policy Child labor abolition policy Anti-discrimination policy zero abasement policy working hour policy Hiring /recruitment policy Environment policy Security policy Buyers code of conduct Health and safety committee Canteen 12.6 Health: Drinking water at least 4.5 l/day/employee Cup availability Drinking water supply Water cooler, heater available in canteen Drinking water signs in native language and English locate min 20 feet away from work place Drinking water vassal clean at once in a week Water reserve at least once a week Fig 75: Drinking Water

- 106. Page | 106 12.7 Toilet: Separate toilet from women and men A set of proper policy and lock facility Urinal accommodation Effective water sewage system Toilet soap Water tap Dust bins Toilet white washed one in every four months Daily cleaning log sheet No-smoking signs Ladies/Gents toilet signs both in native language and English. Disposal of wastes and effluent. 12.8 Fire: Sufficient fire extinguisher and active Access are without hindrance Fire signs in both languages Photo of fire certified person Emergency exit Fig 76: Fire extinguisher Fig 77: Fire alarm switch

- 107. Page | 107 Fig 78: Fire Equipment Fig 79: Hose Rill Fig 80: First Aid Box 12.9 Safety guard: Metal glows on good condition Rubber mats & ironers First trained employees Ironers wearing sleepers Motor/needle guard Eye guard Mask Nurse Doctor Medicine Medicine issuing register Welfare officer First aid box

- 108. Page | 108 Fig81: Gloves Fig82: Mask 12.10 Remarks: Maintaining compliance is very important for garments manufacturing industry as it helps to attract buyers and provide necessary assistance to keep the workplace healthy.

- 109. Page | 109 12.11 Conclusion: Now a day’s Textile field becomes very competitive and the buyers want 100% quality product. For this reason it is very important to know about the latest technologies in textile sector. To produce a quality product, as a textile engineer we must have a vast knowledge about the production parameters and how to produce a high quality product. We have completed our industrial attachment successfully by the grace of almighty Allah. Industrial attachment sends us to the expected destiny of practical life. The completion of the four weeks Industrial attachment at Texeurop (BD) Ltd. we have got the impression that factory is one of the most modern export oriented knit composite complex in Bangladesh. Though it was established only a few years ago, it has earned “very good reputations” for its best performance over many other export oriented textile mills. During our training period, talking with the clients of this factory we knew that the mill is fulfilling the country’s best export oriented white finished fabric as well as very good colored fabric due to its modern machinery & good management system. Factory is settled with utility to give all convenient supports to the productions for twenty-four hours. It had self-power generator system to satisfy total power consumptions of the mill. We are enough fortunate that we have got an opportunity of having a training in this mill. During the training period we are received co-operation and association from the authority full & found all man, machines & materials on appreciable working condition. All stuffs & officers were very sincere & devoted their duties to achieve their goal. We tried our best to collect all necessary information but it is true that within this short period it is quite impossible to achieve 100% success but as a whole this industrial training was a satisfactory one and once again wed would like to thank the authority of Texeurop (BD) Ltd. as well as our honorable teachers far their altruistic help and advice. We are fortunate enough that we have got an opportunity to have training in this mill. During the training period we have received enough co-operation and association from the authority and found all personnel. All stuffs and officers were very sincere and devoted their duties to achieve their goal.

- 110. Page | 110 Appendix MD= Managing Director COO= Chief Operating Officer GM = General Manager AGM = Assistant General Manager DGM= Deputy General Manager PM= Production Manager PO= Production Officer SPO= Senior Production Officer WRAP= World Wide Responsible Apparel Production LED=Light Emitting Diod R&D= Research and Development IE= Industrial Engineering CAD= Computer Aided Design PC= Polyester Cotton CVC= Chief Value of Cotton G/M= Grey Melange PP= Pre-production TOP= Top of Production AQL= Acceptable Quality Limit QA= Quality Assurance CIF= Cost Insurance Freight FOB= Free on Board STT = Salt Saturated Tank SPI= Stitch per inch LC= Letter of Credit