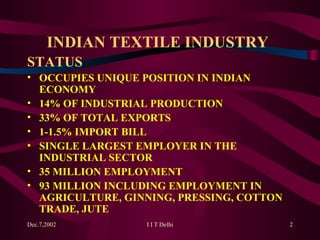

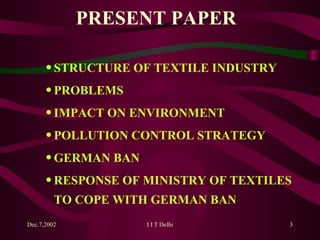

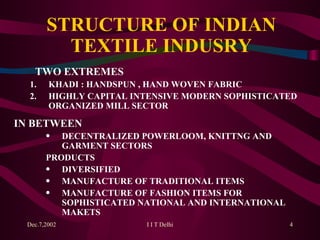

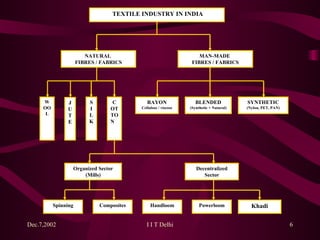

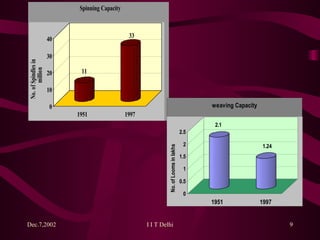

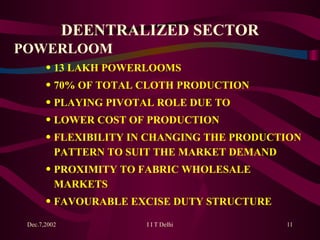

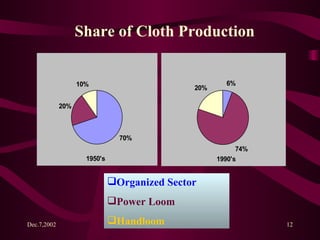

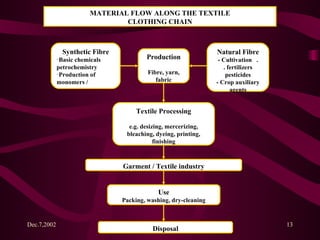

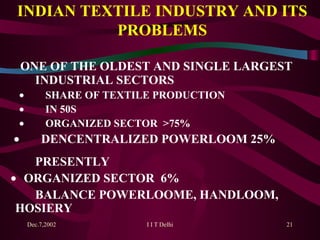

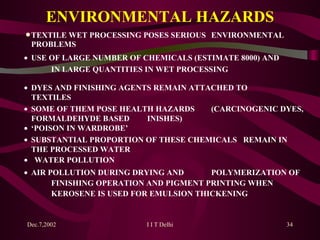

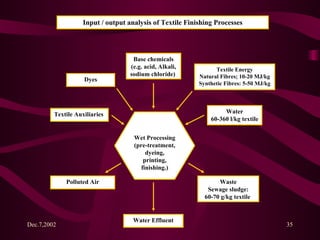

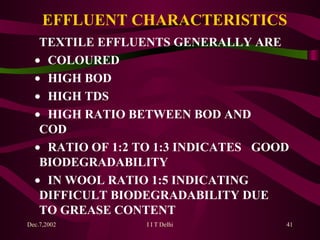

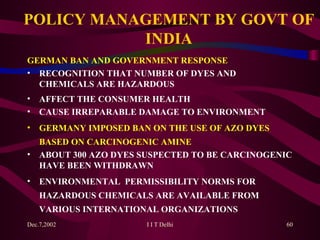

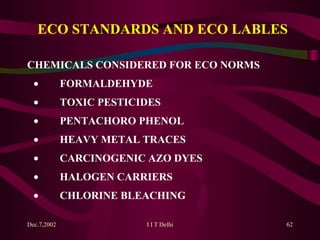

The document discusses the environmental issues faced by the Indian textile industry. It provides details on the structure and size of the industry, which is one of the largest in India. The decentralized sector, which includes powerlooms and handlooms, accounts for the majority of textile production. Wet processing poses serious pollution problems due to the large quantity of chemicals used. Strict environmental regulations have been introduced but enforcement remains a challenge. The industry needs to modernize and adopt cleaner technologies to compete globally in a sustainable manner.