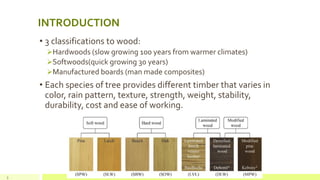

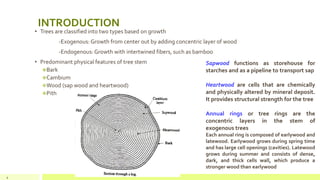

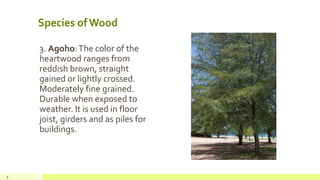

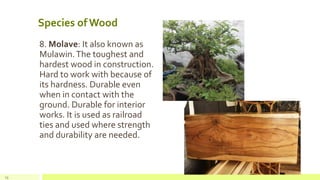

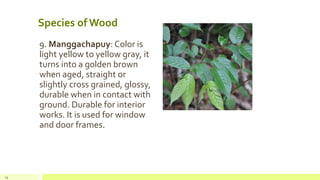

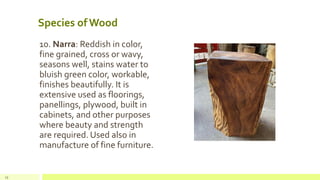

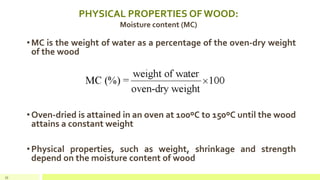

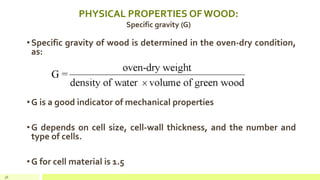

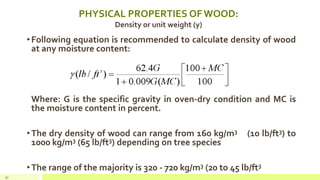

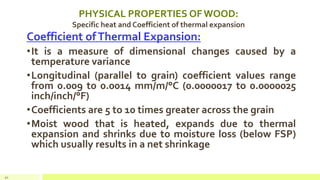

The document provides an extensive overview of wood as a construction material, including its classifications, types, properties, production processes, and applications. It details various species of wood, their characteristics, and uses, along with the physical and chemical properties of wood that affect its performance. Additionally, it discusses engineered wood products and production techniques essential for construction and preservation.