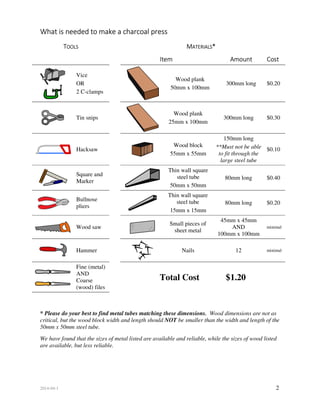

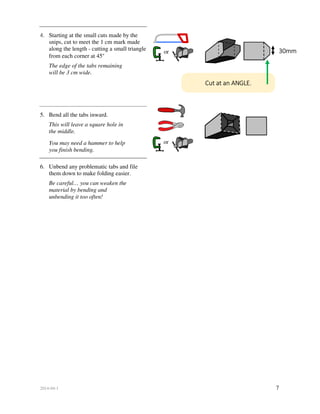

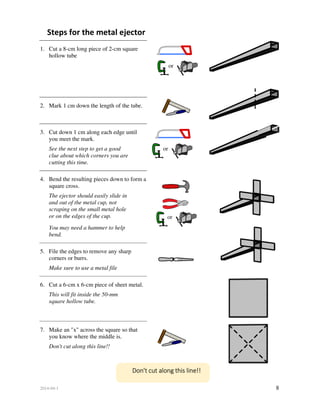

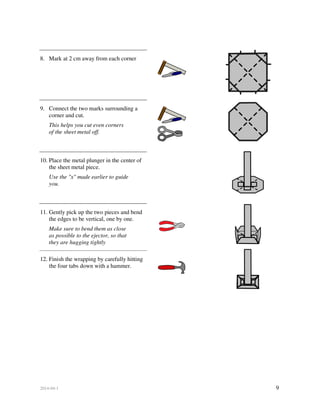

The document outlines a workshop focused on building a charcoal press, where participants learn basic woodworking and metalworking skills to create briquettes from charcoal dust. It includes detailed instructions on setting up the workspace, preparing materials, and step-by-step guides for using tools to construct both the press and its components. Additionally, it promotes hands-on learning and encourages collaborative engagement among participants during the build process.