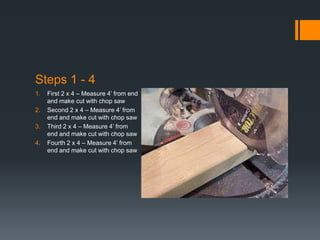

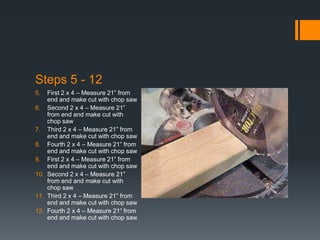

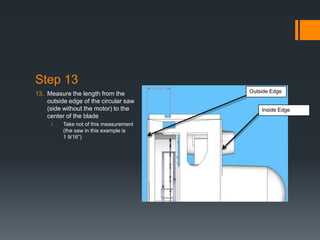

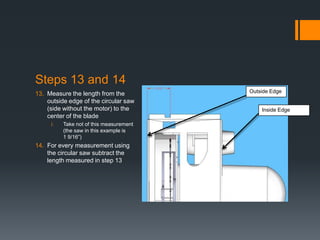

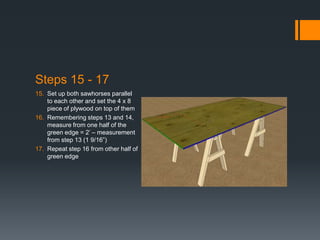

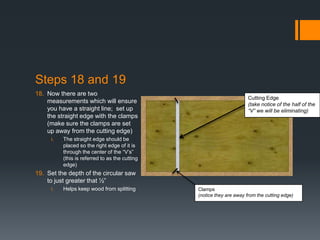

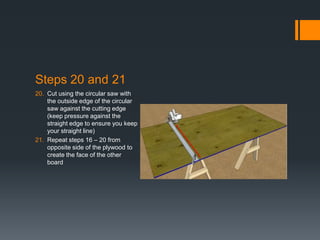

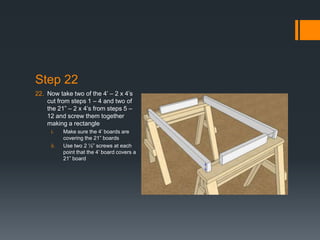

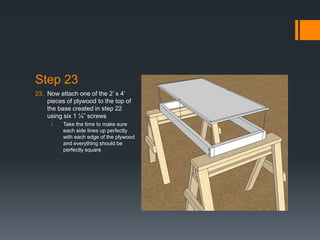

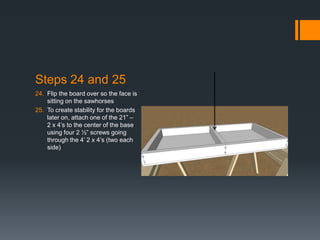

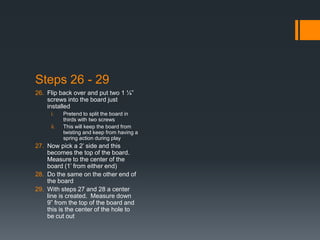

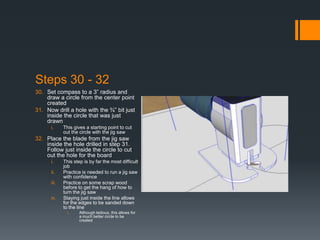

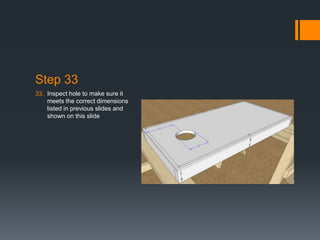

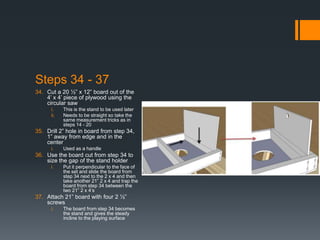

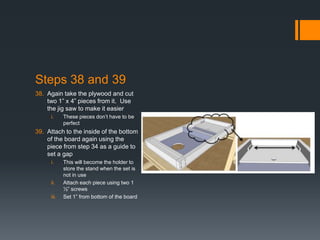

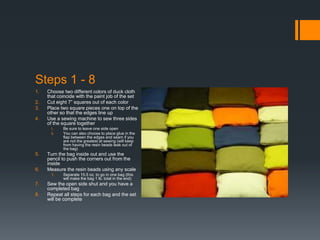

The document provides step-by-step instructions for building a cornhole set and bags. It involves cutting wood boards and plywood sheets to size, assembling the boards into rectangles, attaching them to create two boxes with holes, and finishing with sanding and painting. It also includes cutting and sewing fabric to create bags, filling them with resin beads to weigh 1 pound total. Following all 45 steps results in a complete homemade cornhole set and bags.