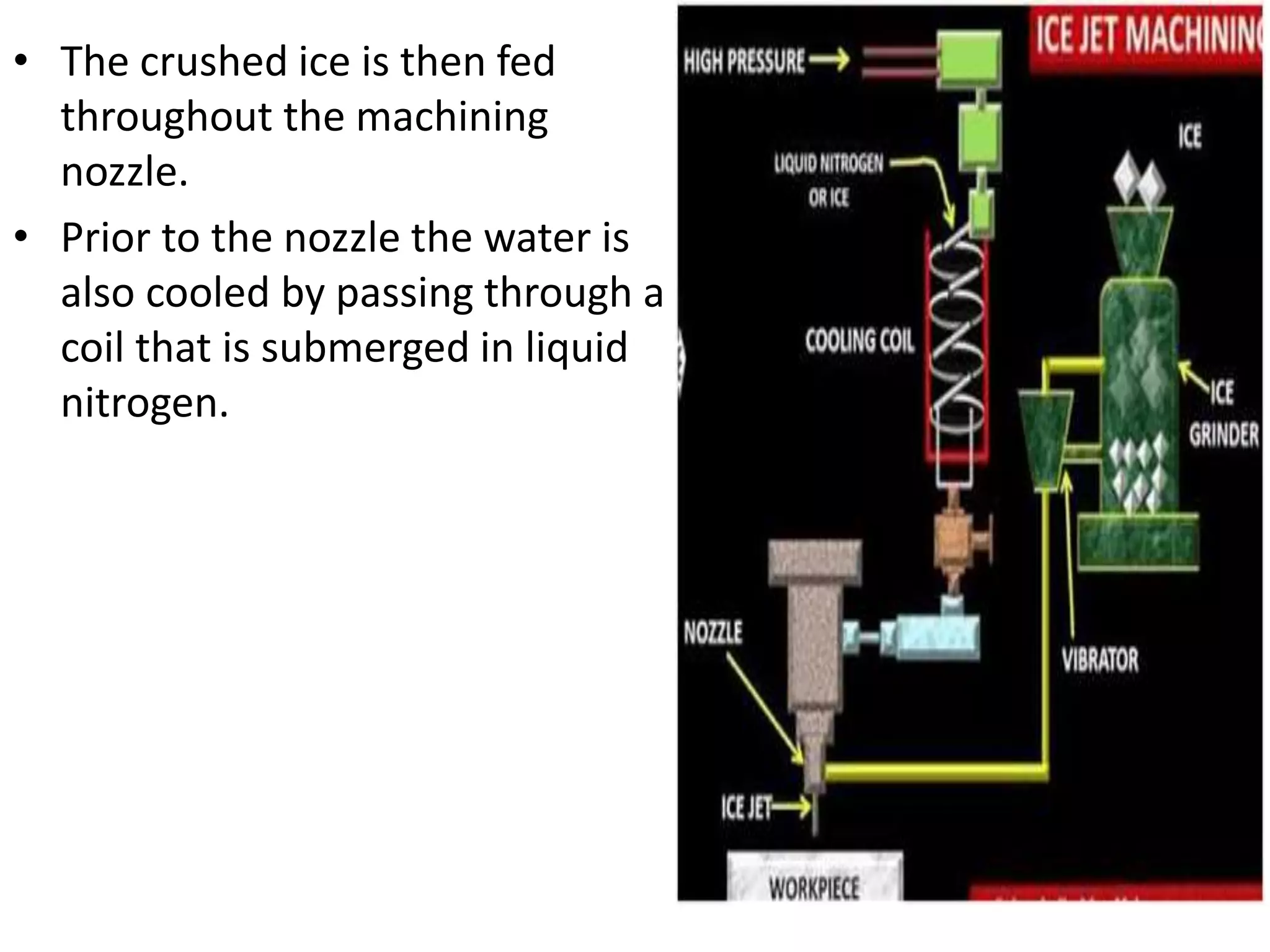

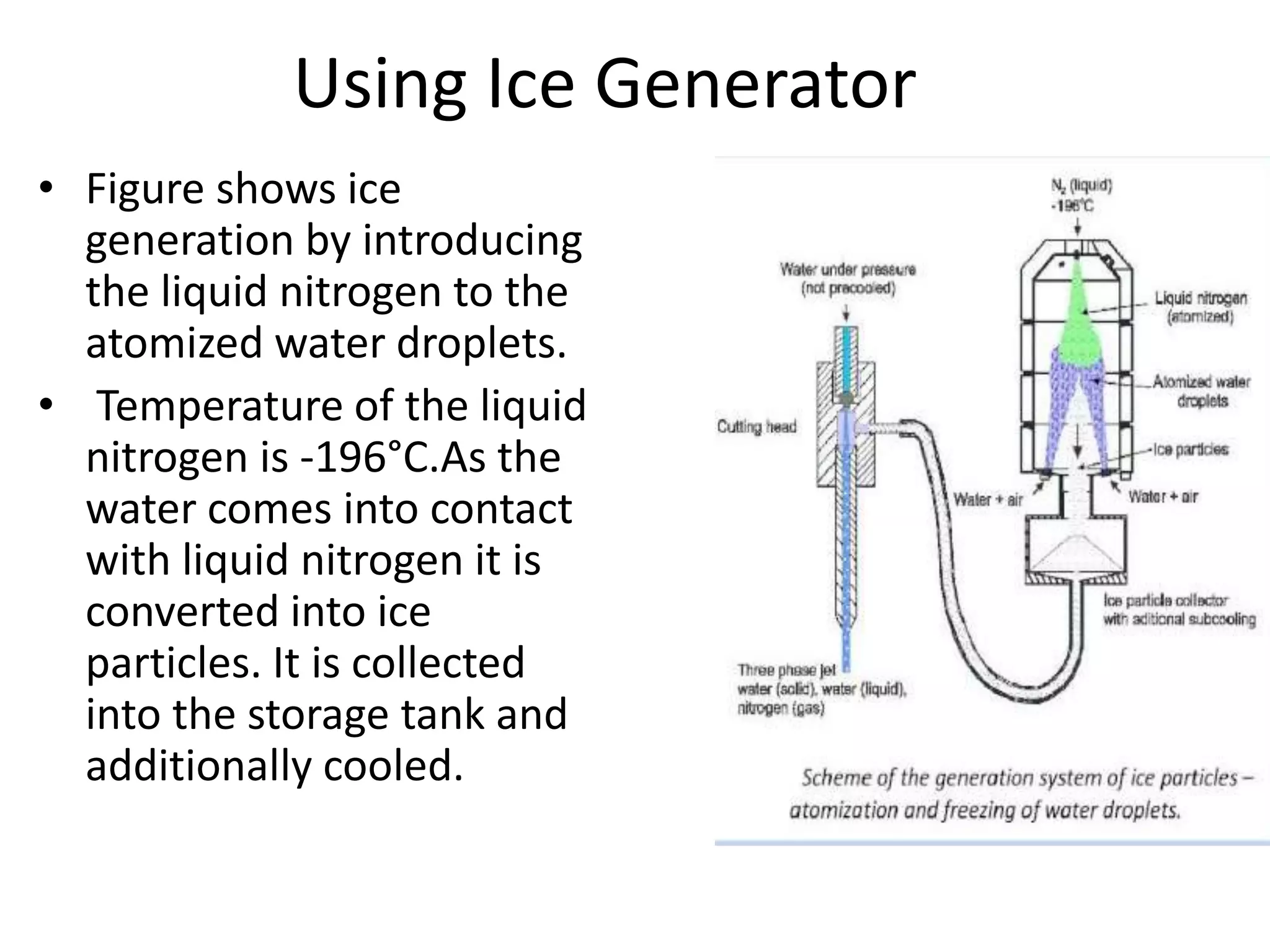

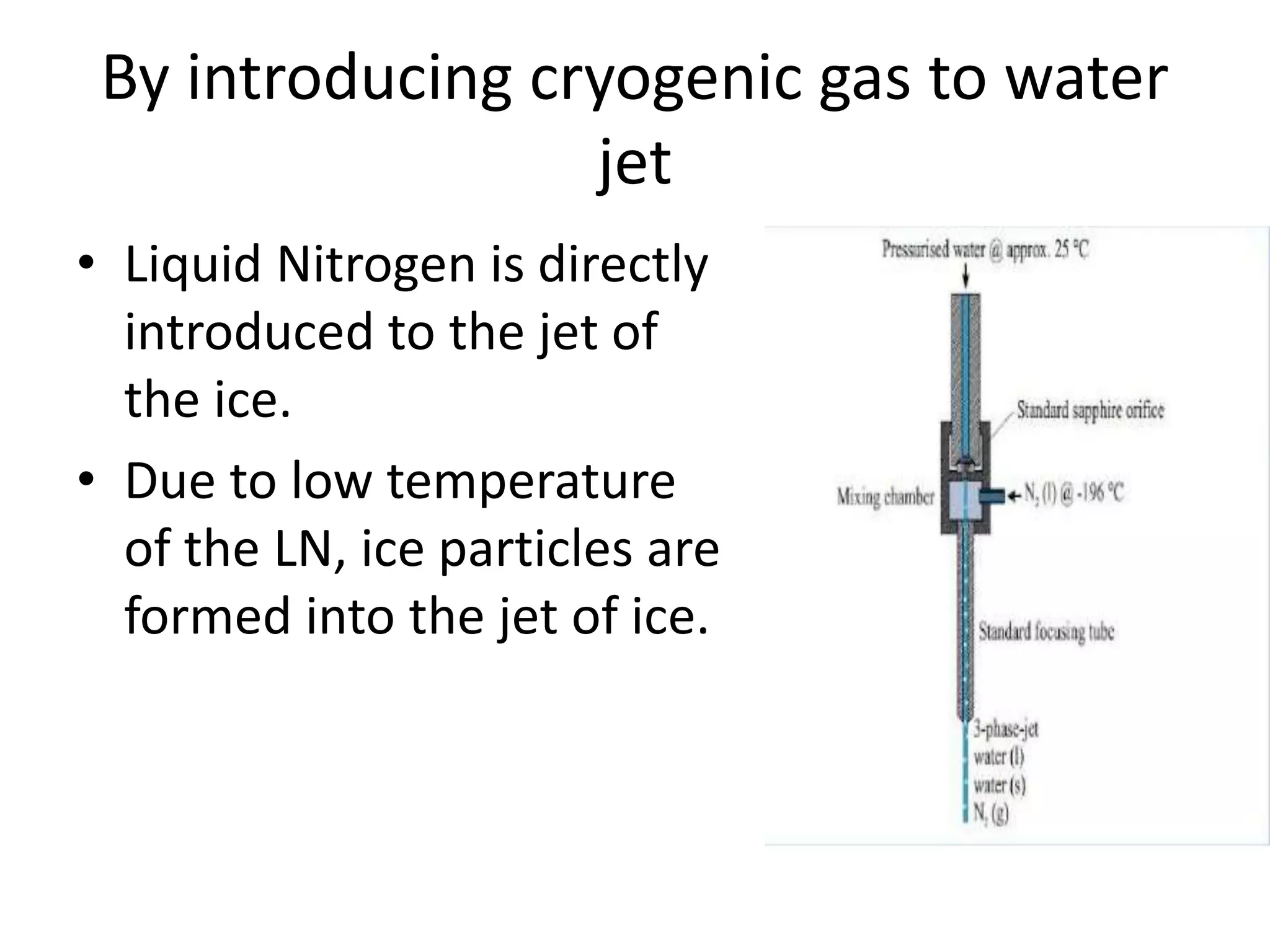

This document discusses ice jet machining, which is a non-abrasive machining process that uses ice particles instead of abrasives. It begins by introducing abrasive water jet machining and describes how ice jet machining is derived from this by substituting ice particles. The document then covers the ice jet machining process, including how ice particles are generated and introduced into the water jet. It discusses the advantages of using ice particles over abrasives, such as eliminating waste water treatment. Finally, it lists some applications for ice jet machining in industries where contamination must be avoided.