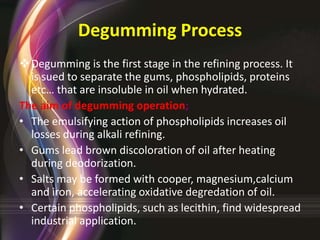

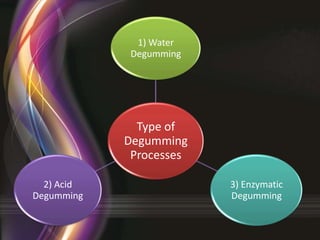

The document discusses the degumming process in oil refining. It aims to remove undesirable components like phosphatides and gums from crude oil. There are three main types of degumming processes:

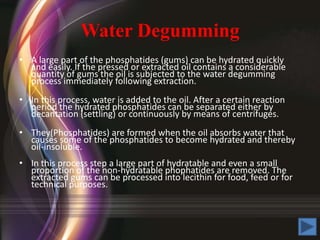

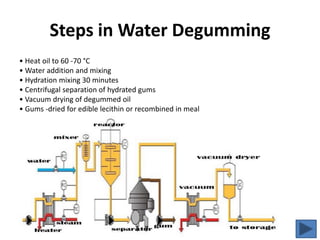

1) Water degumming involves adding water to crude oil to hydrate gums and phosphatides, which are then separated.

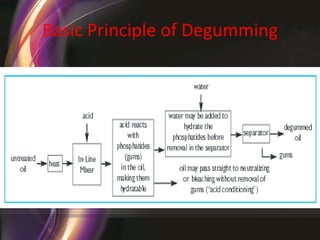

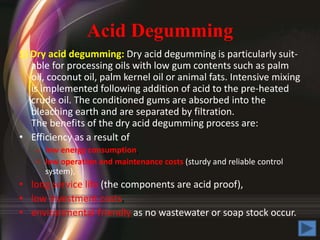

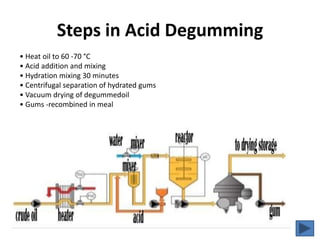

2) Acid degumming uses acid to convert non-hydratable phosphatides into hydratable forms that can be removed. It is done dry or wet with added water.

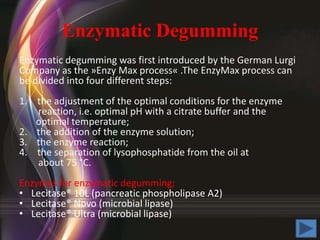

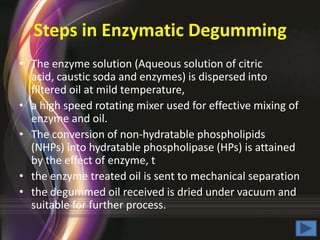

3) Enzymatic degumming uses enzymes like phospholipase to convert non-hydratable phosphatides into hydratable ones that can then be mechanically separated from the