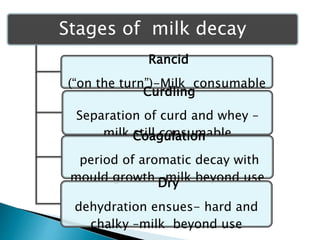

This document discusses microorganisms found in milk and their effects. It notes that milk provides an excellent medium for microbial growth. Both harmless and potentially pathogenic microorganisms can contaminate milk during the milking and storage processes. The main types of microorganisms discussed are bacteria, yeasts, molds, and bacteriophages. Several pathogenic bacterial species are also mentioned. The document outlines factors that influence microbial growth in milk and how their activities can affect milk quality through spoilage. Common spoilage effects and methods of controlling microorganisms in milk are summarized.