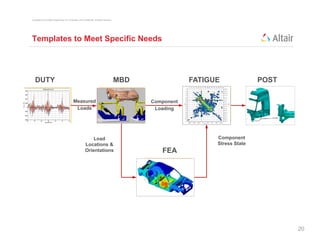

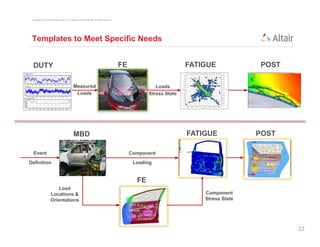

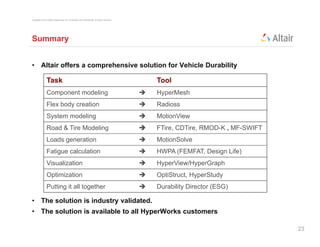

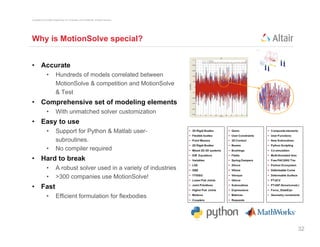

The document outlines an agenda for a vehicle durability workshop discussing HyperWorks software applications. The agenda includes introductions to HyperWorks capabilities like MotionView, MotionSolve, and CD-Tire for durability modeling. It also highlights a customer breakout session featuring presentations from Honda and Fraunhofer on full-vehicle simulations and tire modeling. Application examples are provided showing how customers use HyperWorks for fatigue validation of vehicle components through multi-body dynamics simulations that closely match real-world test data.