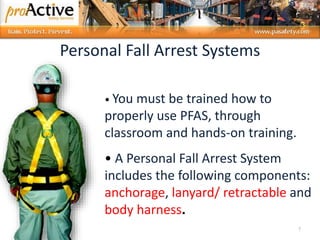

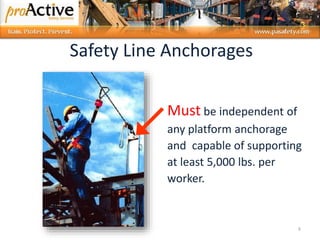

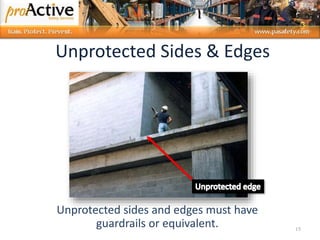

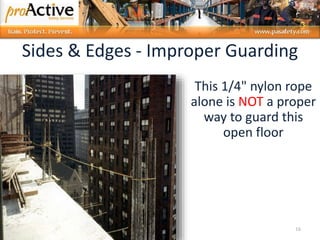

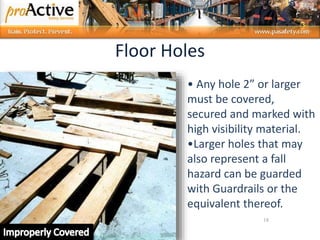

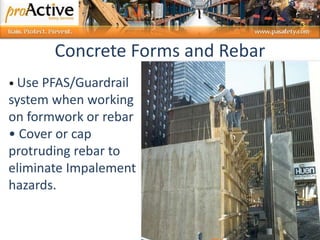

The presentation discusses fall protection and prevention methods in construction, emphasizing that falls are the leading cause of fatalities in the industry. Key topics include assessing fall hazards, types of fall protection systems such as personal fall arrest systems, guardrails, and safety nets, along with the criteria for when these systems must be implemented. The importance of training workers to recognize and minimize fall hazards is also highlighted.