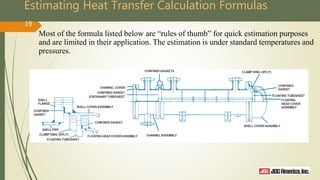

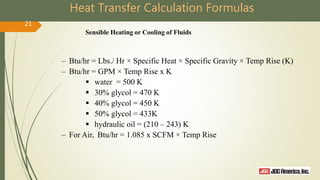

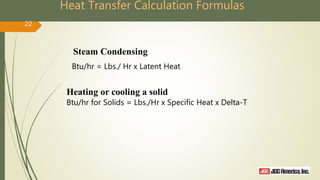

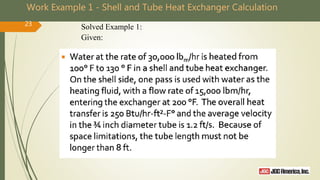

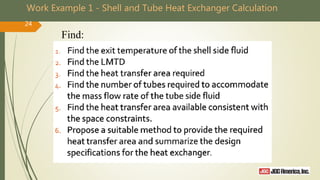

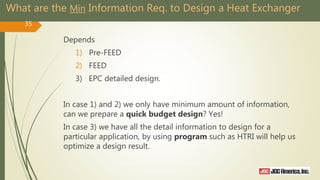

The document provides an overview of heat exchanger calculations and heat transfer principles, including conduction, convection, and radiation. It details various types of heat exchangers and their operational principles, including shell and tube, plate and frame, and others, along with heat transfer calculation formulas and worked examples. Additionally, it discusses essential factors for designing heat exchangers, such as fluid properties and operational parameters.

![“Quick” Heat Transfer Calculation Formulas – for Estimation

General

Liquid:

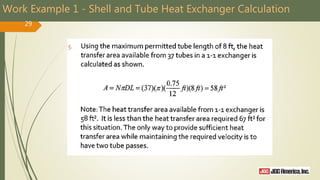

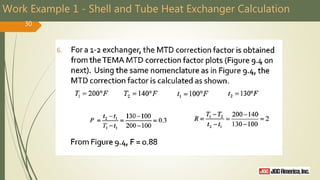

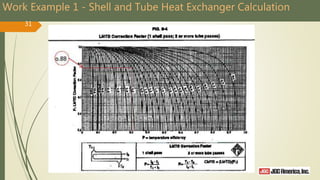

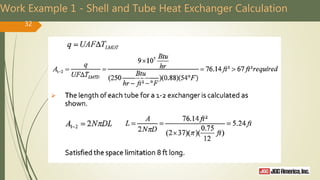

20

–

Btu

hr

= kW × 3412 = HP × 2544

–

Lbs

hr

= GPM x Density 8.022 = GPM × 501.375 × Specific Gravity

Specific Gravity = Density/62.4 Psia = Psig+14.7

–

Btu

hr

= Tons of Refrigeration × 12000

–

Btu

hr

= Evaporative Cooling Tower Tons x 15000

– SCFM of air = [ACFM x (psig + 14.7) x 528] / [(Temp + 460) x 14.7]

– SCFM of air = Lbs/ Hr of air / 4.5 (at atmospheric temperature and pressure)](https://image.slidesharecdn.com/heatexchangertraining02-161205230322/85/Heat-exchanger-training-02-25-15-20-320.jpg)

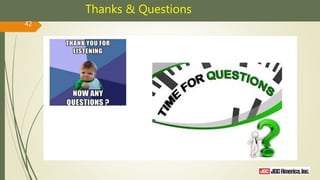

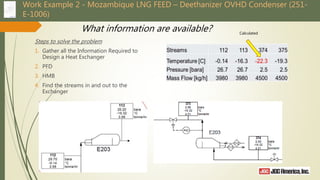

![Approach of a Temperature Difference (ATD)

Condensate Supply Temp. (°C) = achieve T (-16) – rise T (-3) – ATD (-3) = -22.3 (°C)

38

Streams

Hot Side Cold Side

112 113 374 375

Temperature [C] -0.14 -16.3 -22.3 -19.3

Pressure [bara] 26.7 26.7 2.5 2.5

Mass Flow [kg/h] 3980 3980 4500 4500](https://image.slidesharecdn.com/heatexchangertraining02-161205230322/85/Heat-exchanger-training-02-25-15-38-320.jpg)

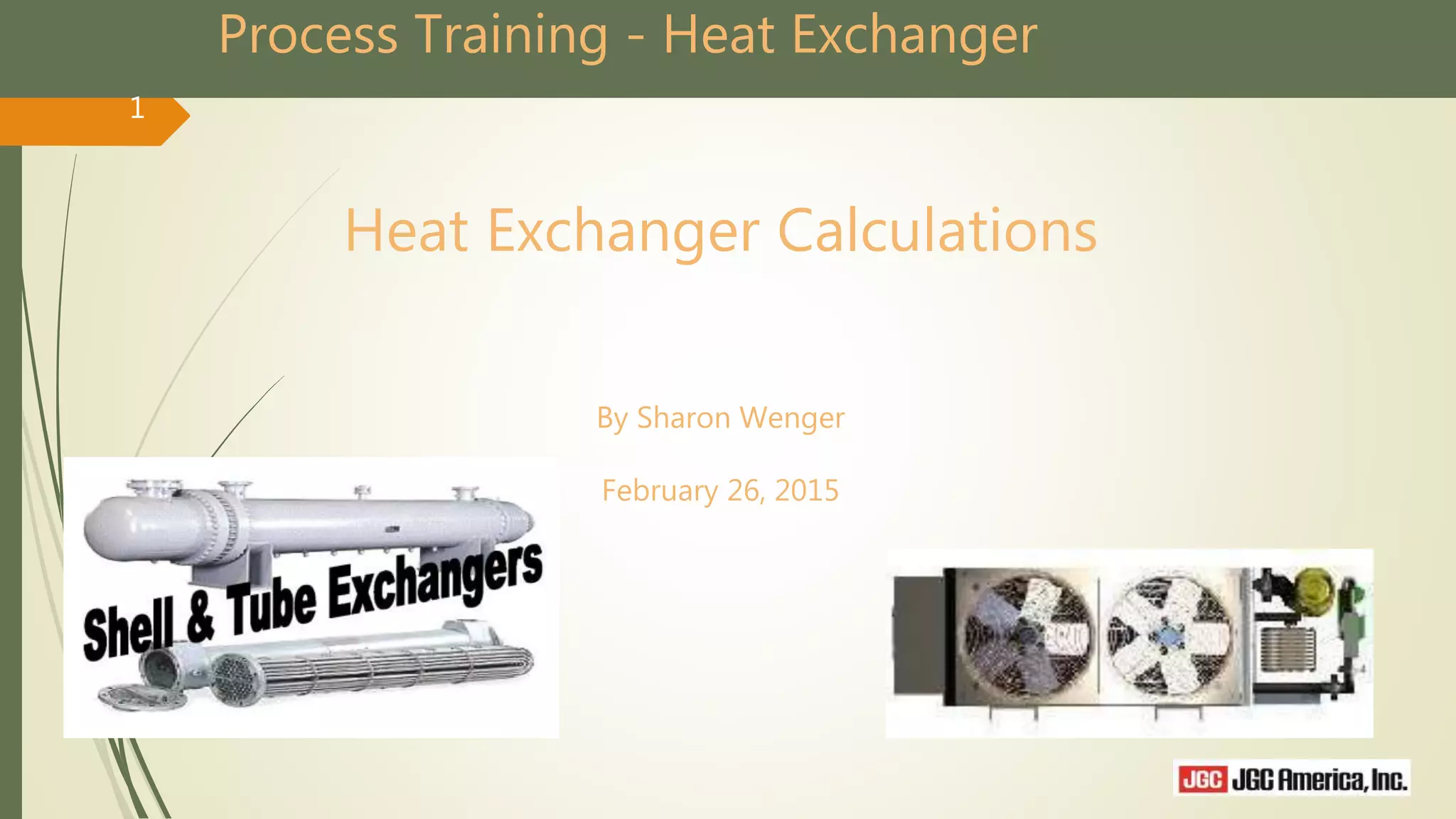

![Calculate Heat Exchanger Duty Required

39

Streams 1 2 3 4

Temperature [C] tc1

tc2

Th1

Th2

-0.14 -16.3 -22.3 -19.3

Pressure [bara] 26.7 26.7 2.5 2.5

Mass Flow [kg/h] 3980 3980 4500 4500

ΔTLM

(°C) 11.35

UA (Kw/°C) 33 - 40 From Go-By

For UA = 33 Q (Kw) = 375

For UA = 40 Q (Kw) = 454

Result UniSim Results

Q = UA ΔTLM](https://image.slidesharecdn.com/heatexchangertraining02-161205230322/85/Heat-exchanger-training-02-25-15-39-320.jpg)