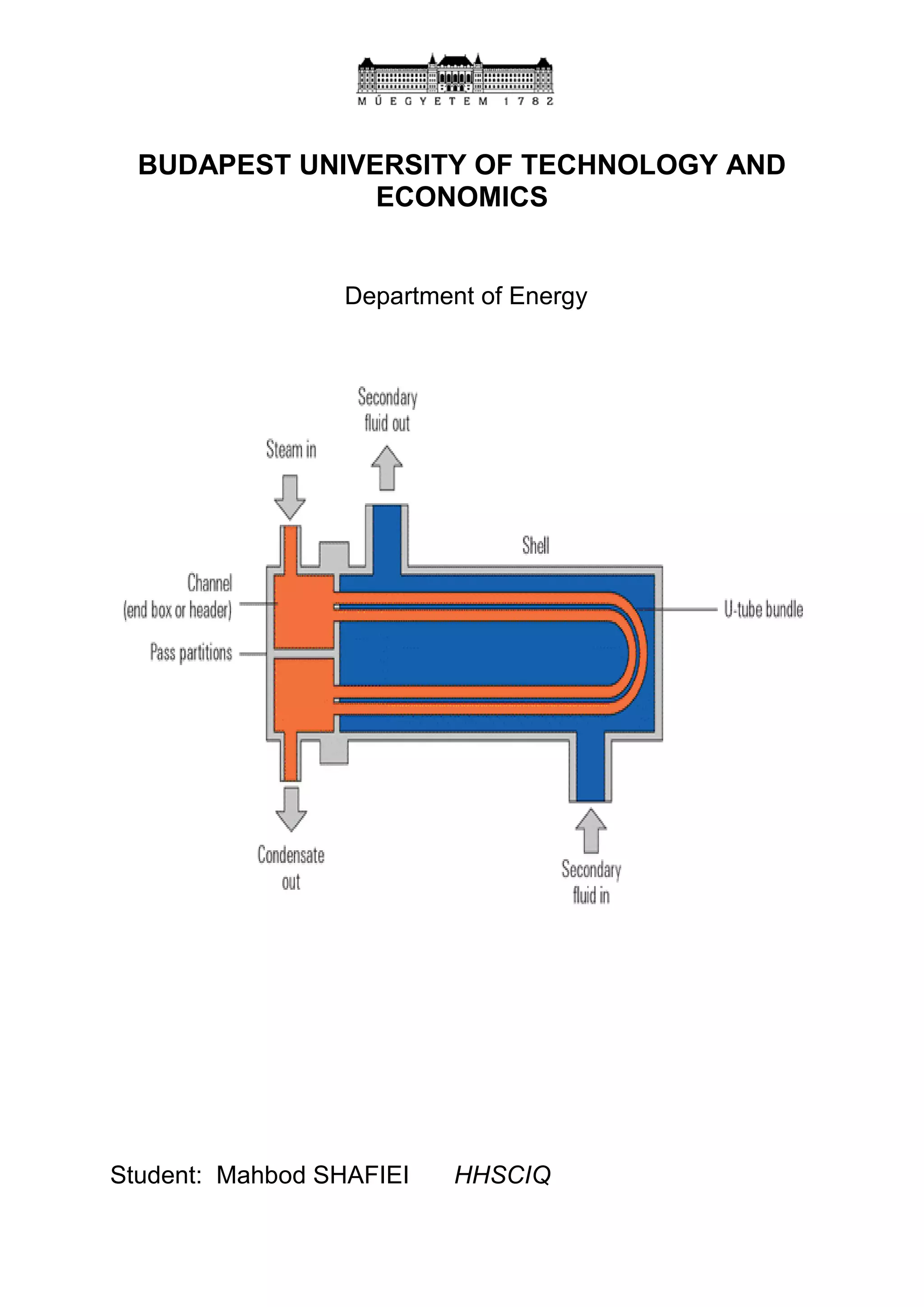

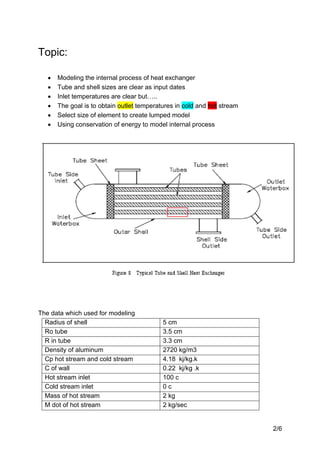

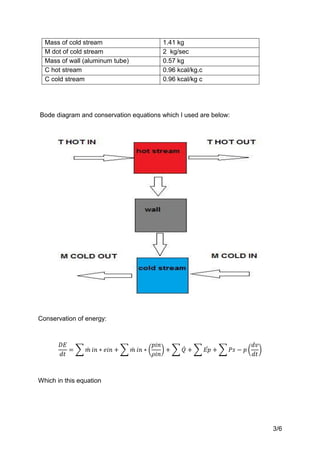

The document discusses modeling the internal process of a heat exchanger. It provides input data on the sizes of the shell and tubes, inlet temperatures of the hot and cold streams, and mass flow rates. The goal is to use conservation of energy equations to model the internal heat transfer and calculate the outlet temperatures of the hot and cold streams. Parameters like the radius and thickness of the tube, densities, heat capacities, and inlet temperatures are given as inputs to develop a lumped model of the heat exchanger and determine the temperatures at each point using energy balance equations.