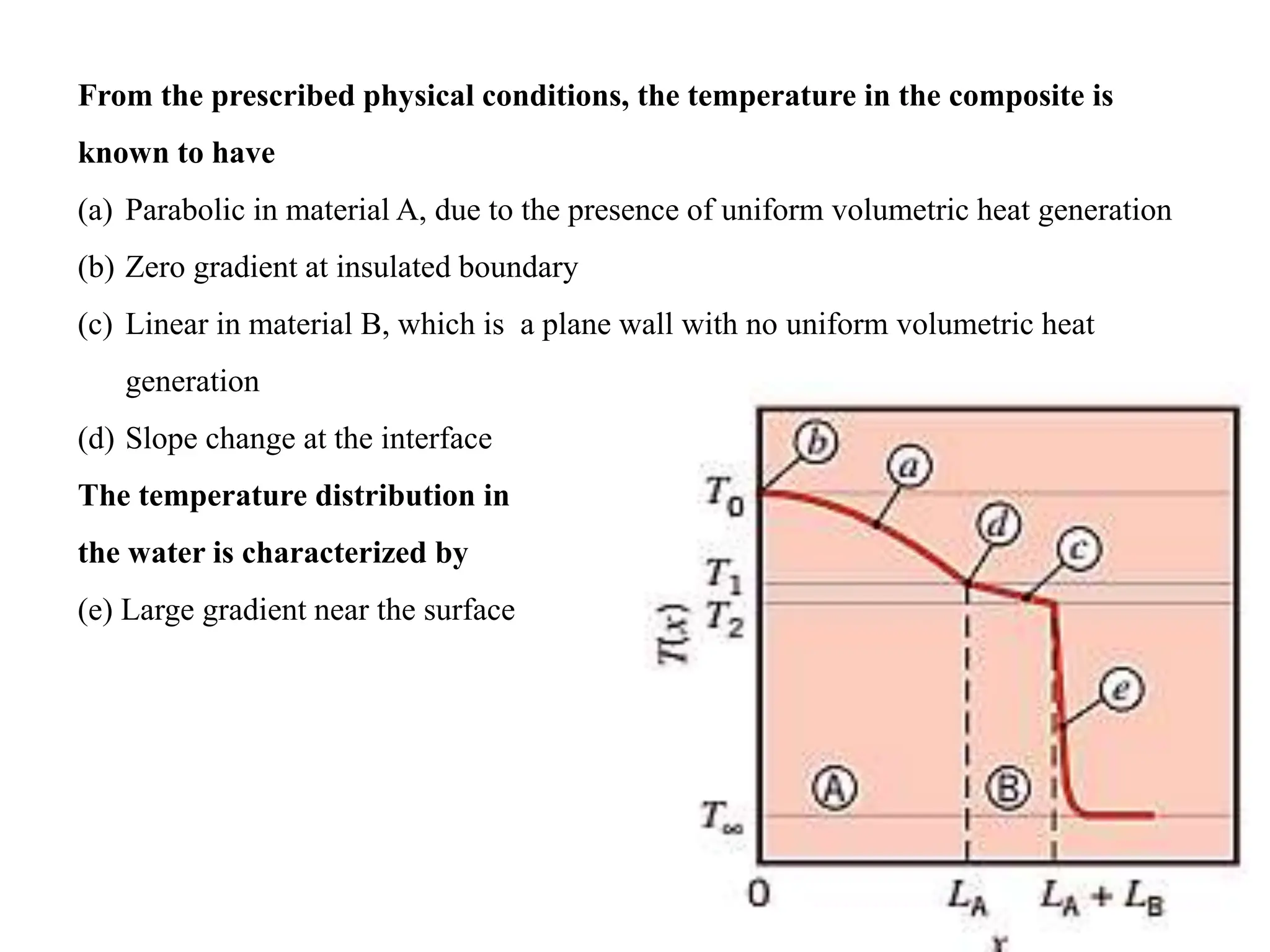

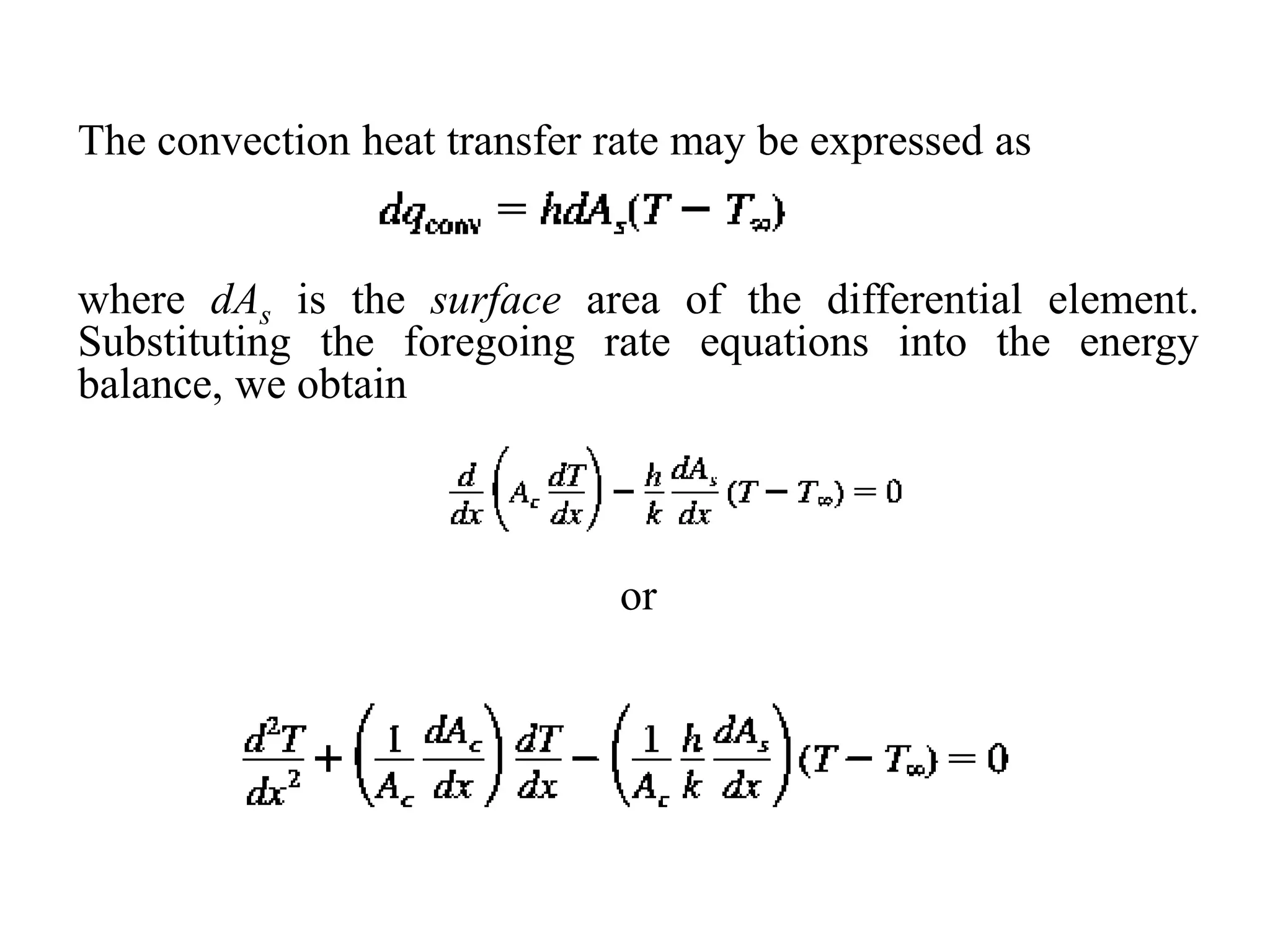

The document discusses steady-state heat transfer involving thermal energy generation from electrical sources, chemical reactions, and radiation absorption. It outlines equations and solutions for temperature distribution in various geometric configurations like plane walls and cylinders, emphasizing boundary conditions and heat flux calculations. The document also addresses methods to enhance heat transfer rates, such as increasing convection heat transfer coefficients or surface areas through the use of fins.