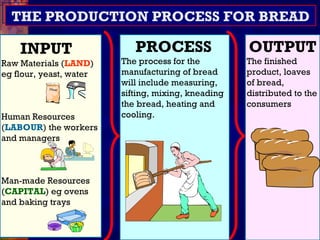

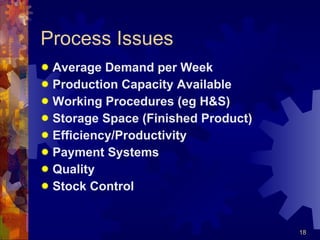

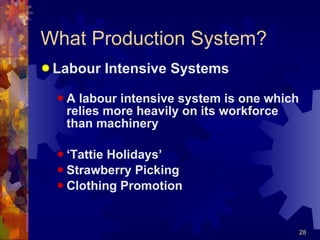

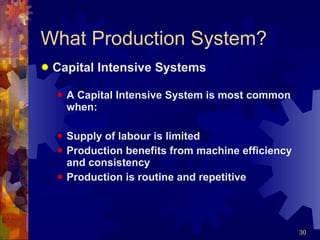

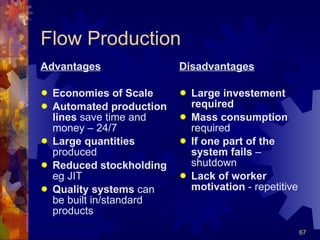

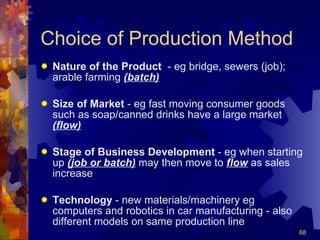

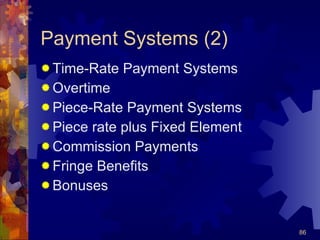

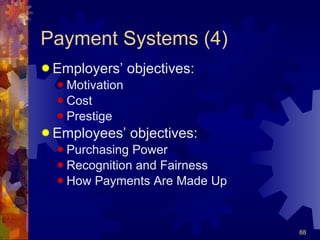

The document discusses various aspects of operations management for a business. It covers topics like the production process, inputs and outputs, production systems, quality control, stock control, purchasing, and total quality management. It provides examples and discusses factors to consider for different aspects of managing the operations and production of goods and services in a business.