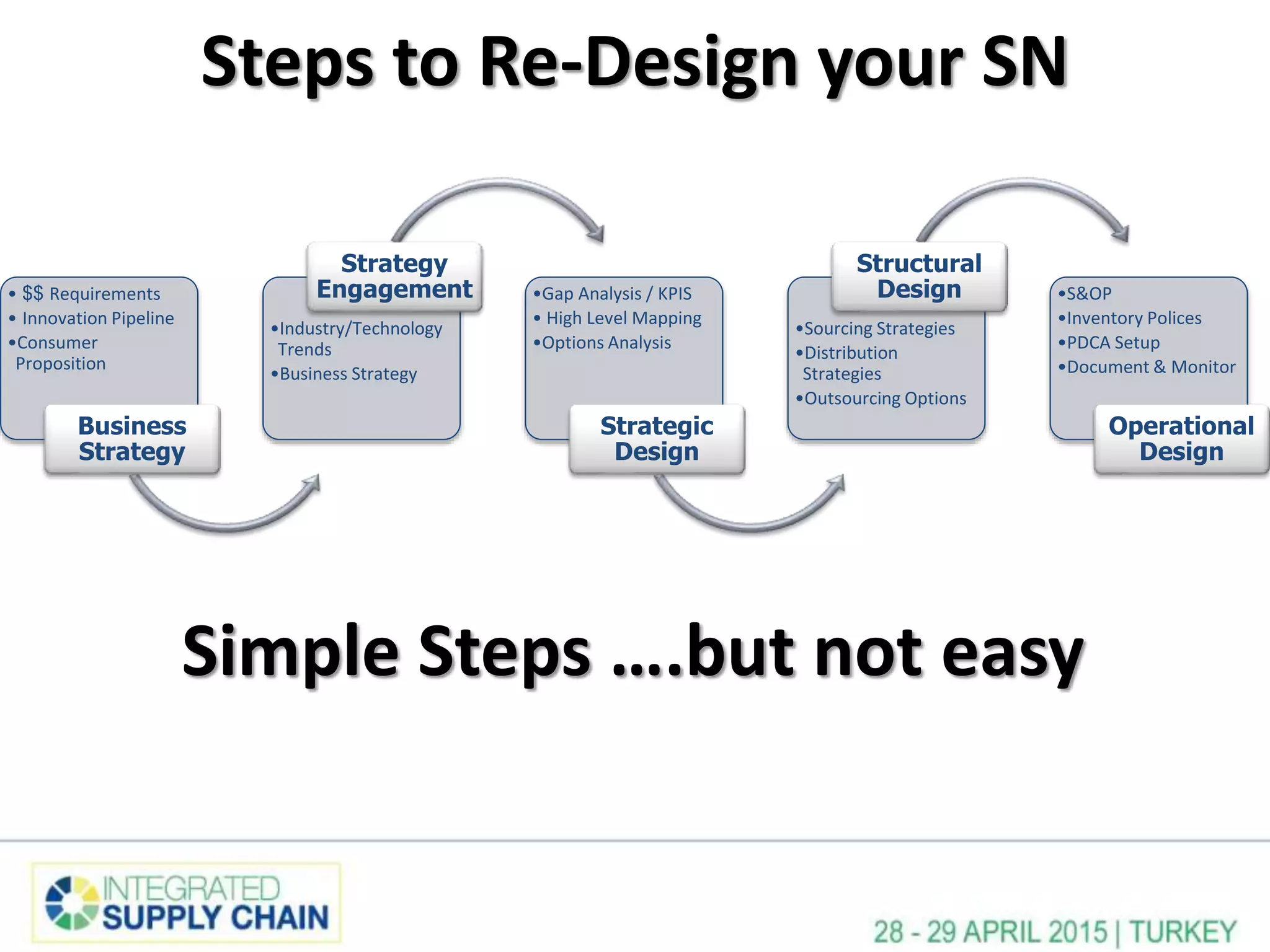

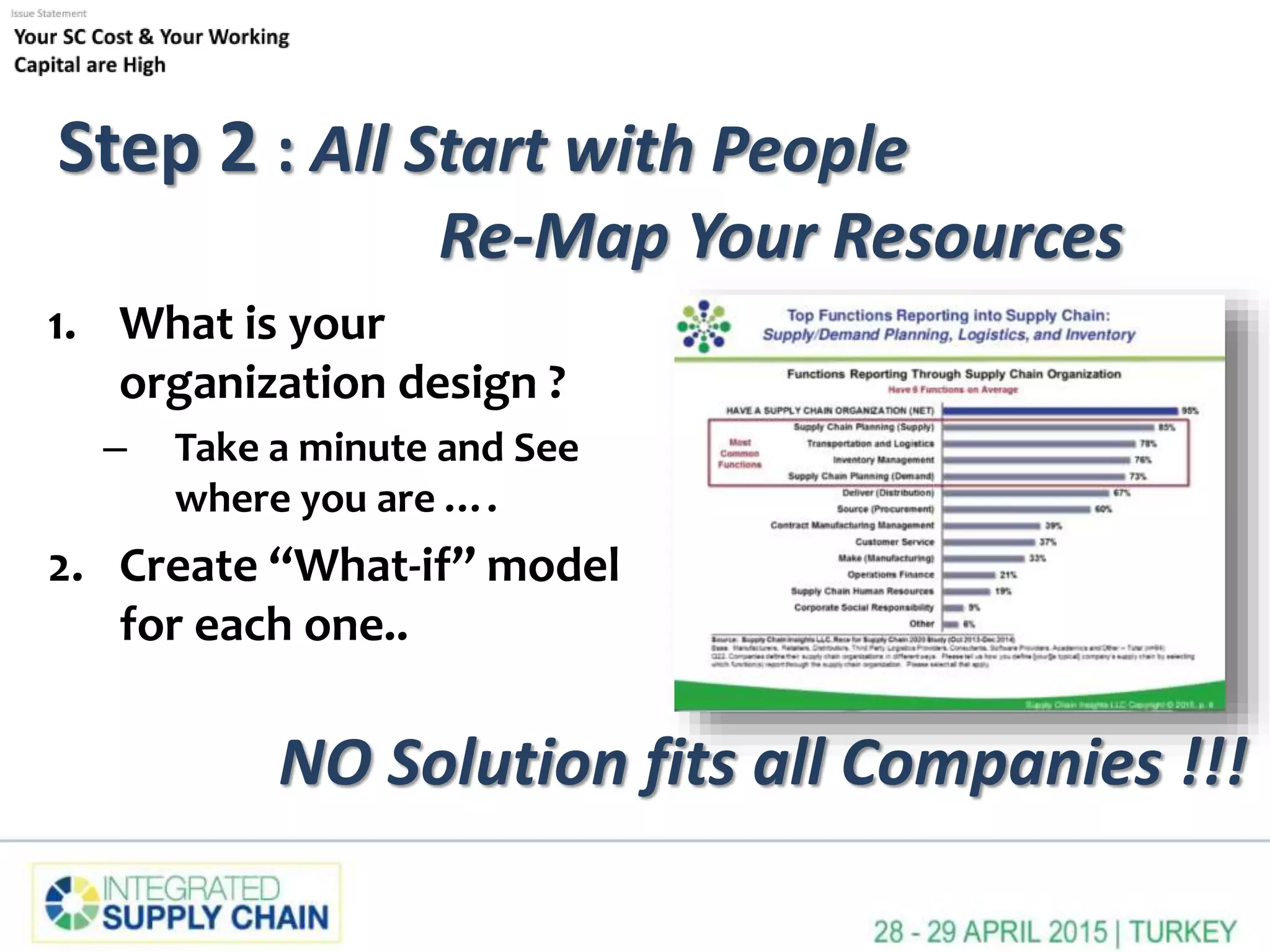

This case study focuses on supply chain network design to enhance flexibility and responsiveness while cutting costs. It outlines step-by-step strategies for redesigning supply chains, emphasizing the importance of organizational assessment, resource mapping, and key performance indicators. The document also highlights the roles of sourcing, distribution, and sustainability in optimizing supply chain efficiency.