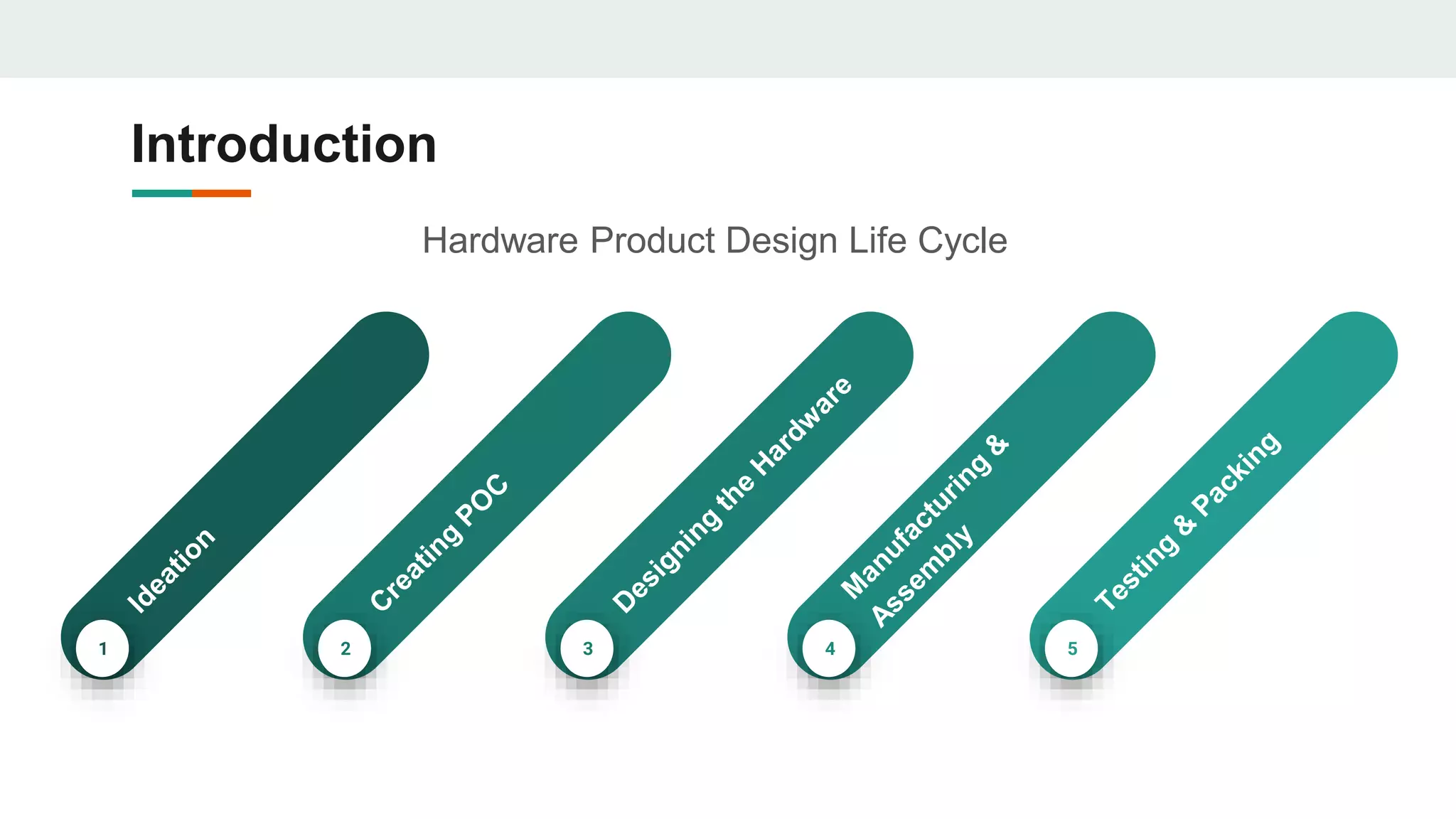

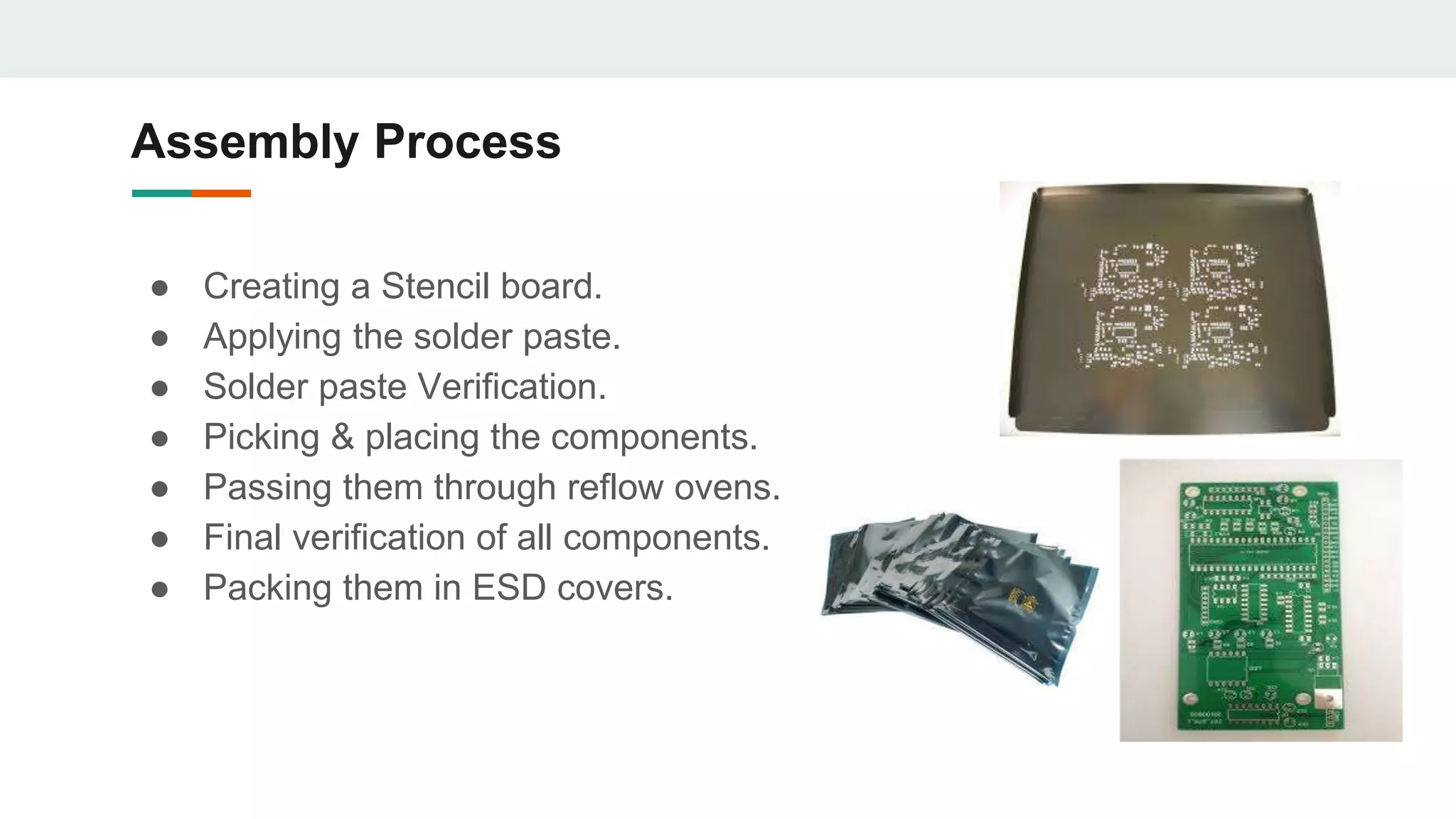

The hardware product design process involves ideating a solution, testing proof of concepts, designing the hardware schematic and layout while ensuring EMC compliance, manufacturing through solder paste application and reflow ovens, assembly including visual inspection and functional testing, and finally certification and product delivery to market.