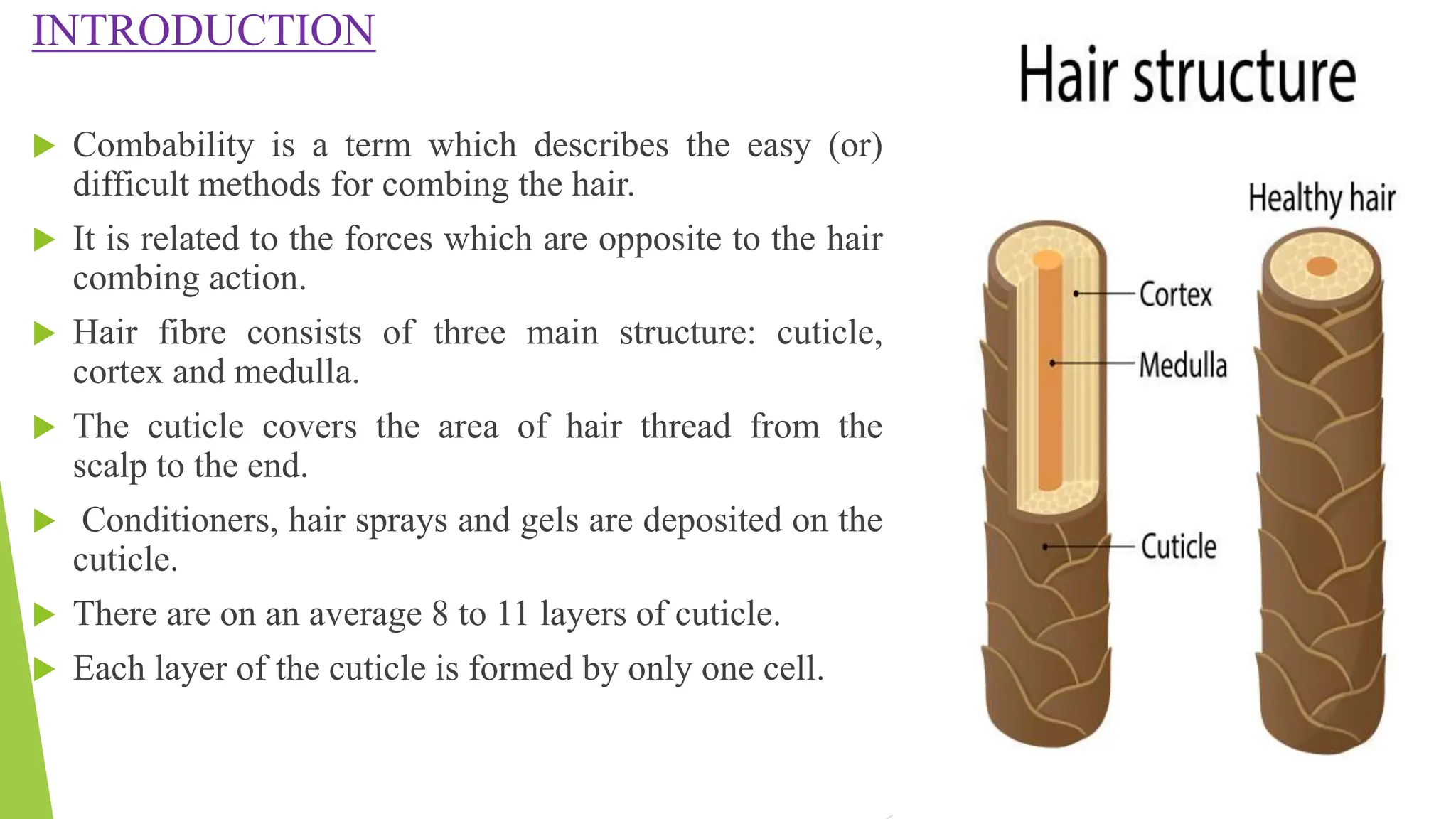

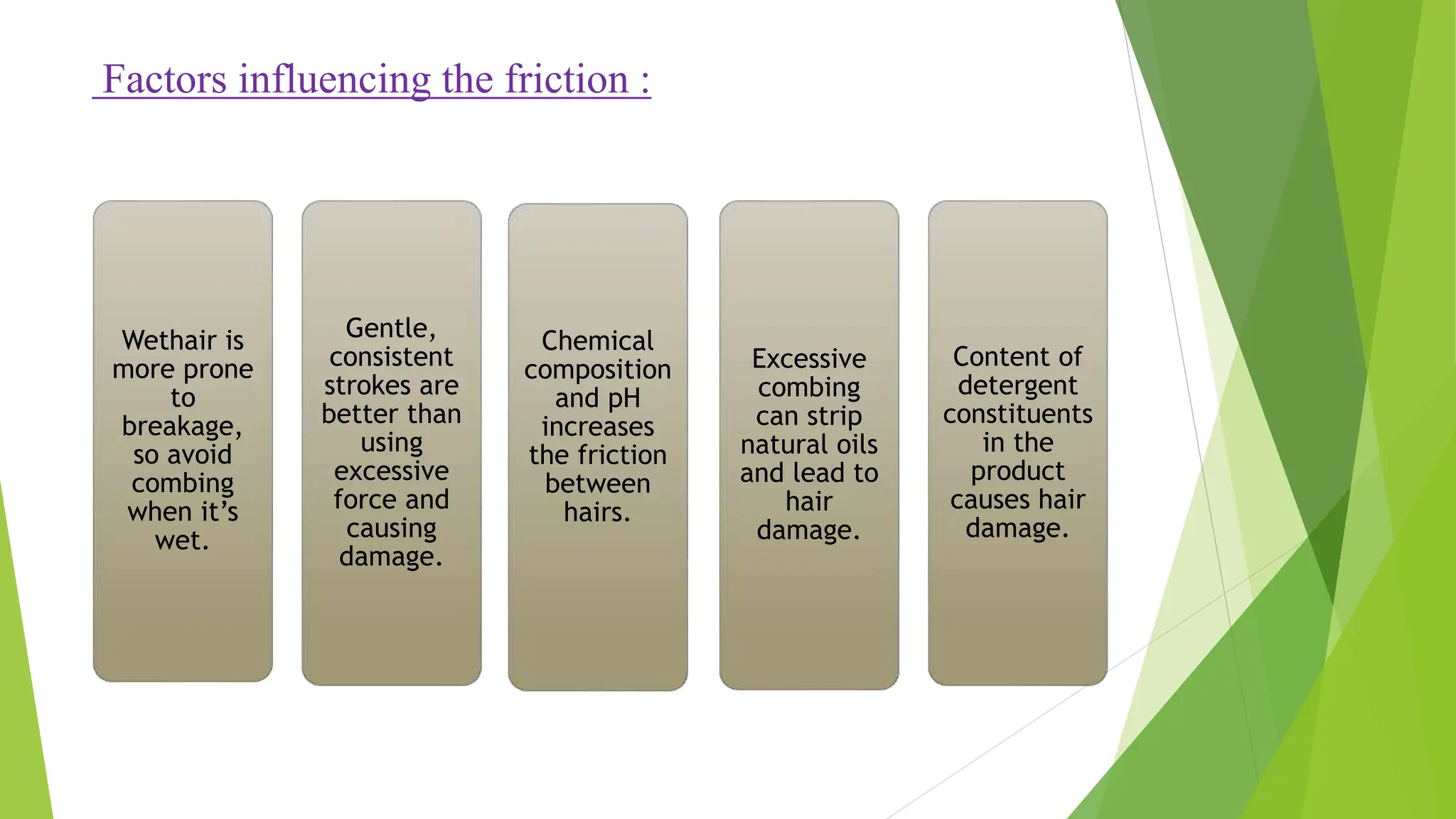

The document discusses the properties of hair combing and the factors influencing its friction, emphasizing the relationship between hair structure and combability. It highlights the benefits of regular combing, the detrimental effects of excessive force or combing wet hair, and methods for evaluating hair properties using advanced techniques such as SEM, AFM, and mechanical assays. Additionally, it outlines the use of piezoelectric sensors for monitoring hair health and suggests that the chemical composition of hair care products can impact hair damage.