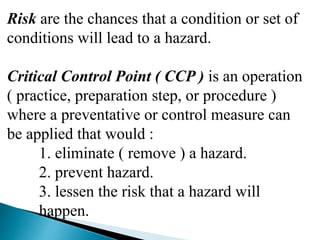

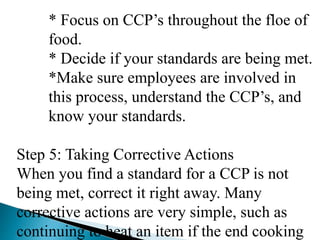

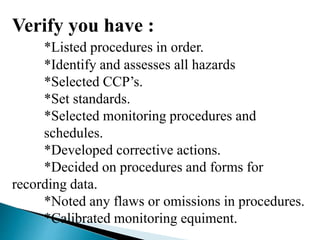

This document provides an overview of developing a food safety system using Hazard Analysis and Critical Control Points (HACCP). It discusses the 7 principles of HACCP for identifying potential food hazards and establishing controls. Key steps include identifying hazards, establishing critical control points, setting standards, monitoring procedures, corrective actions, record keeping, and verifying the system is working properly. Regular training of employees is important for an effective HACCP food safety system.