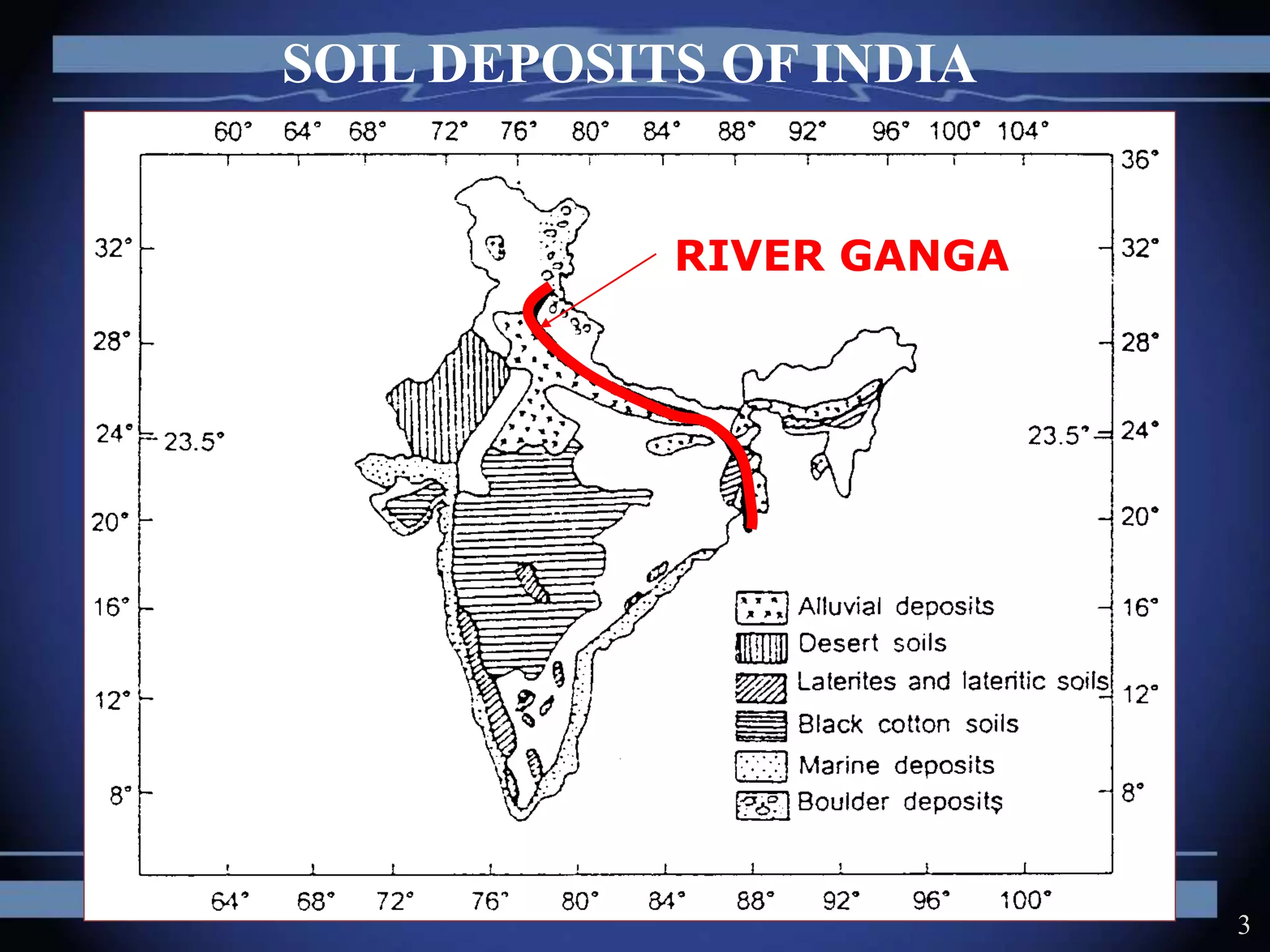

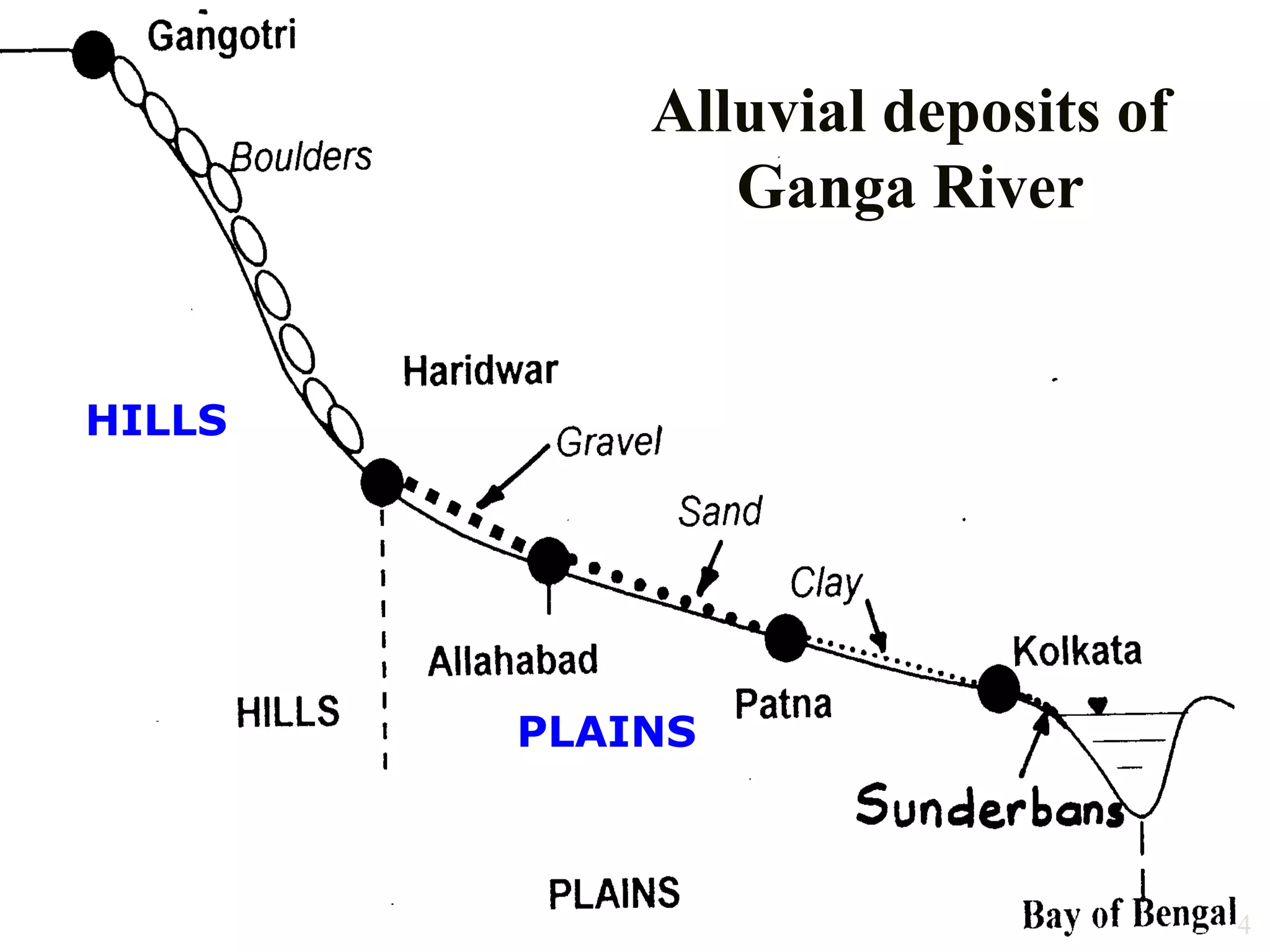

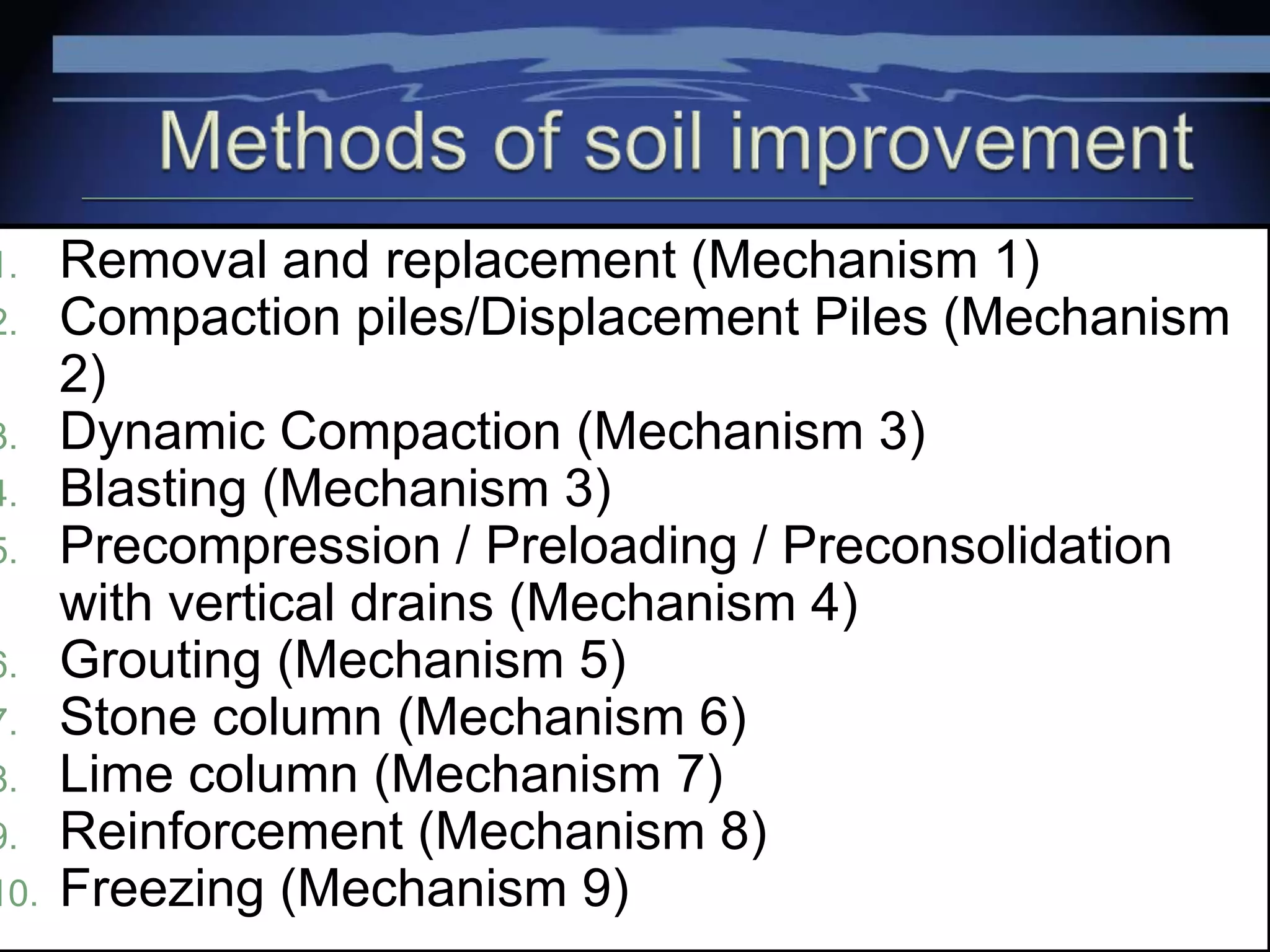

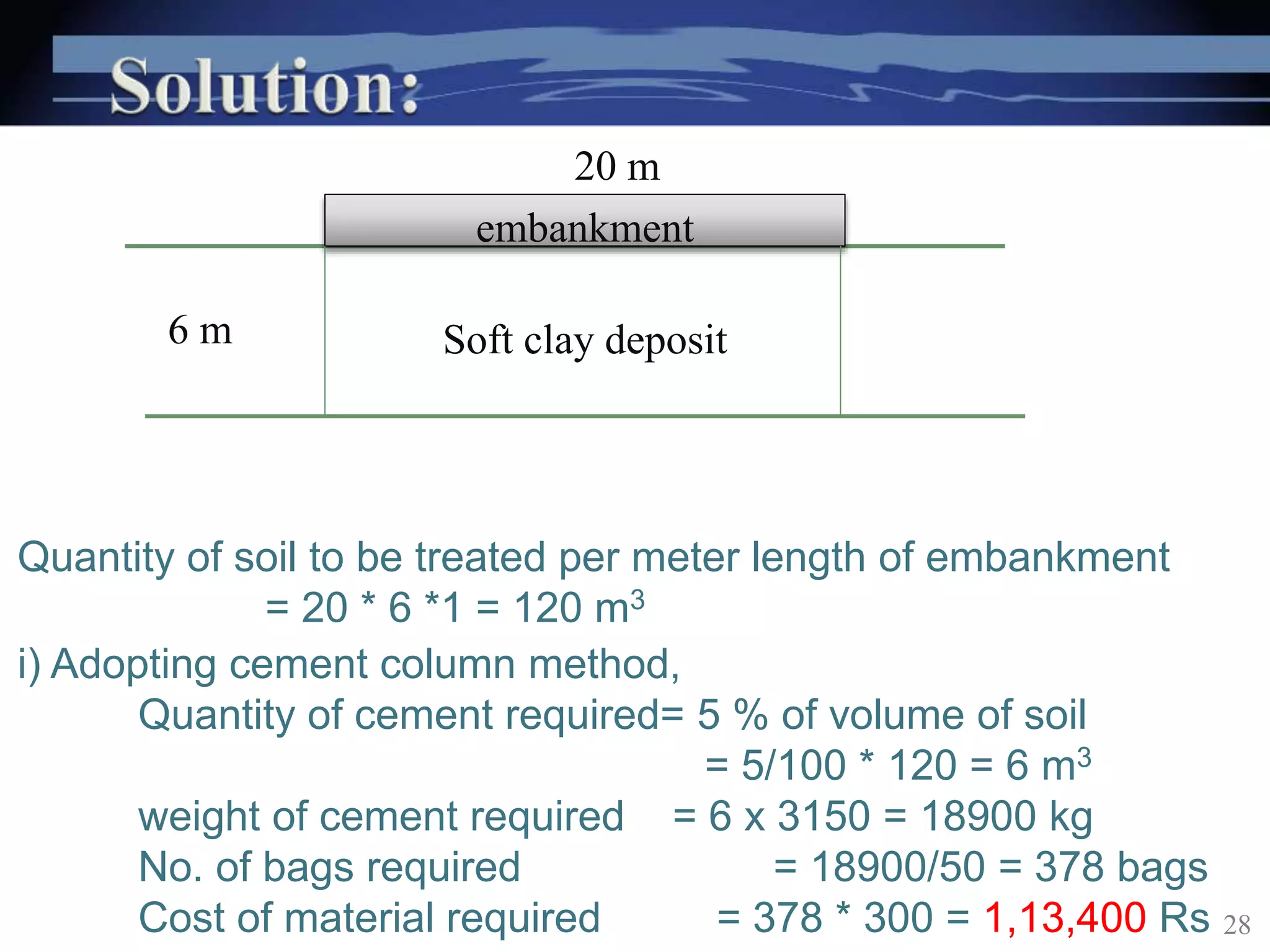

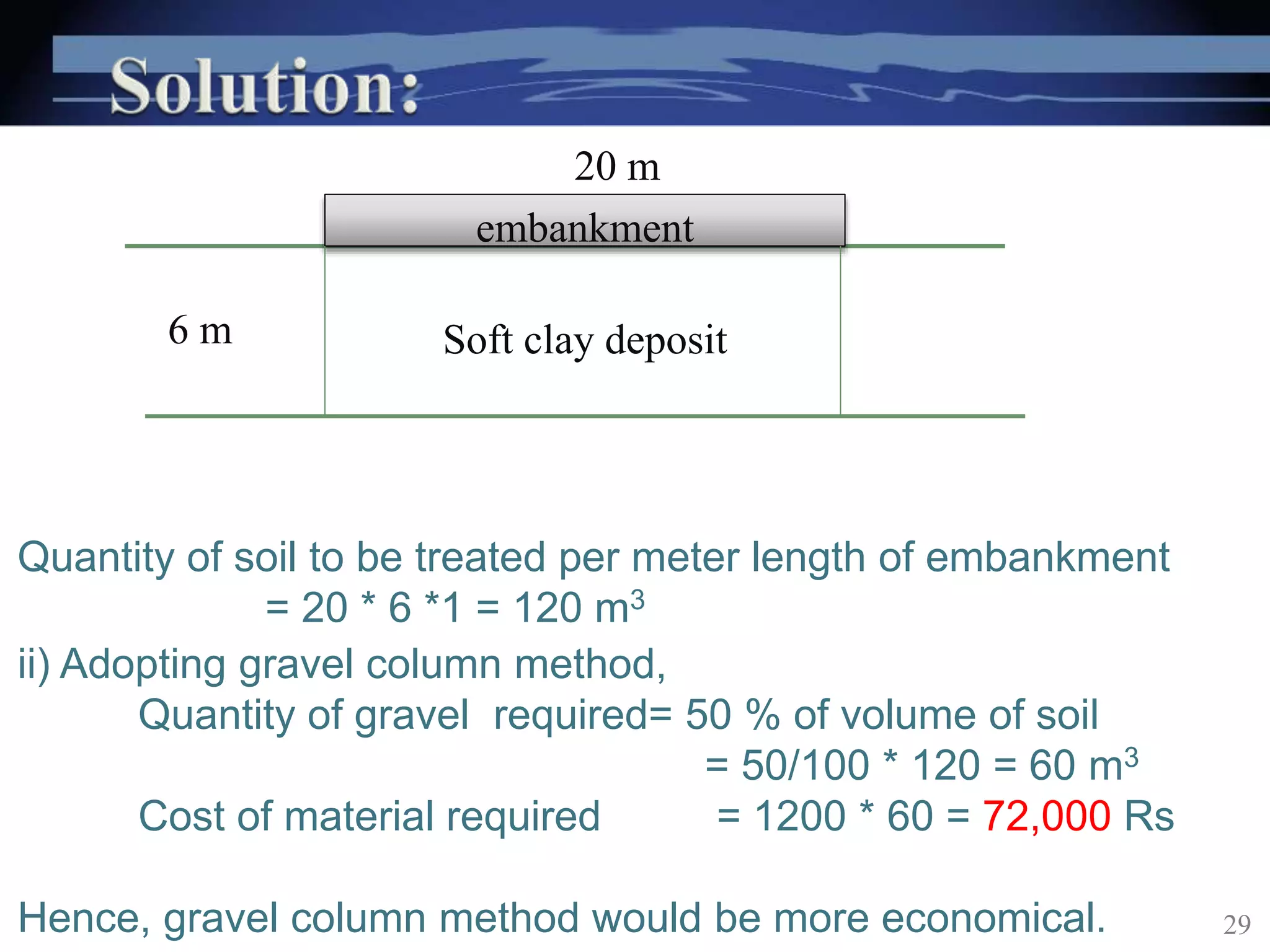

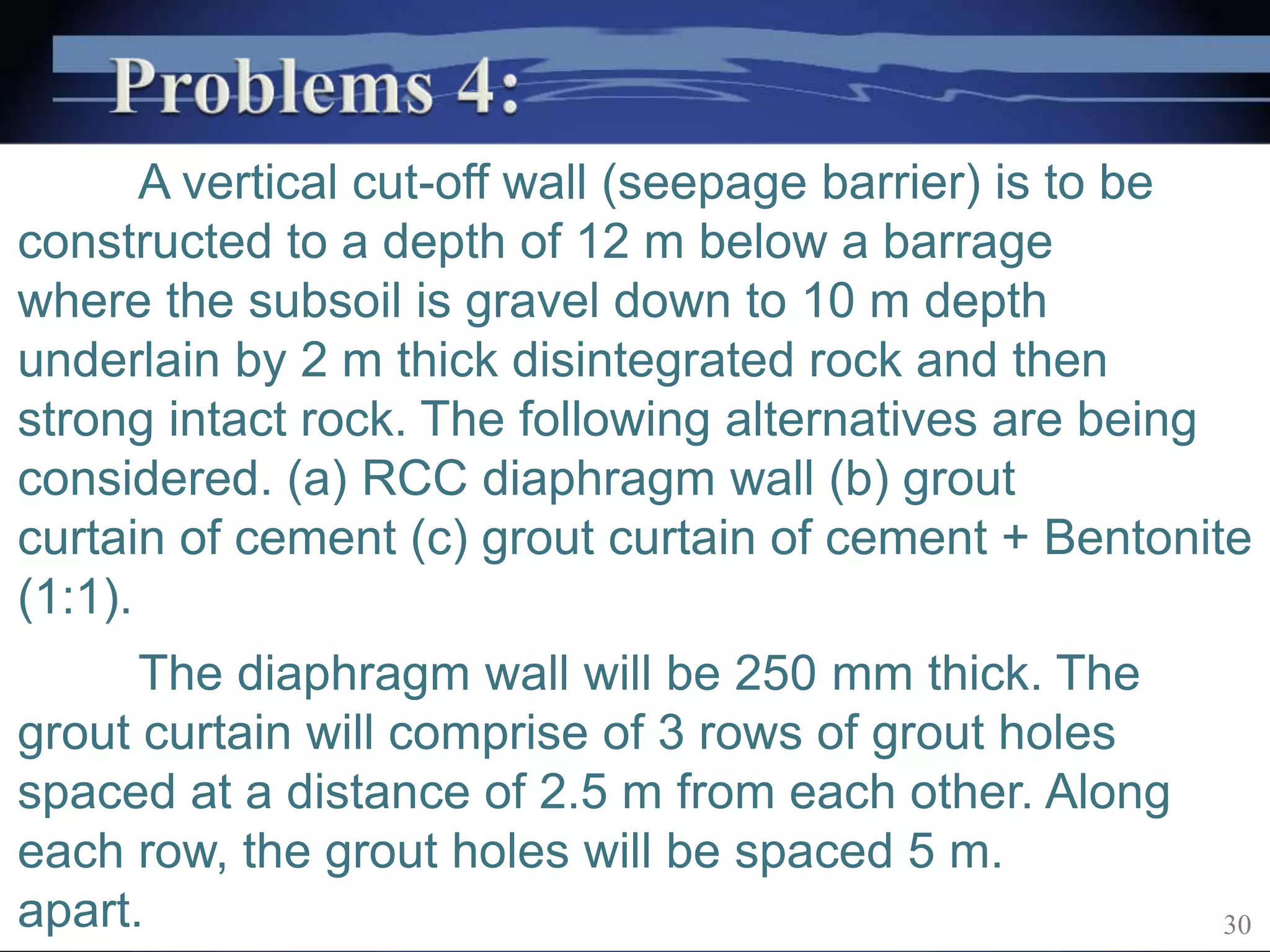

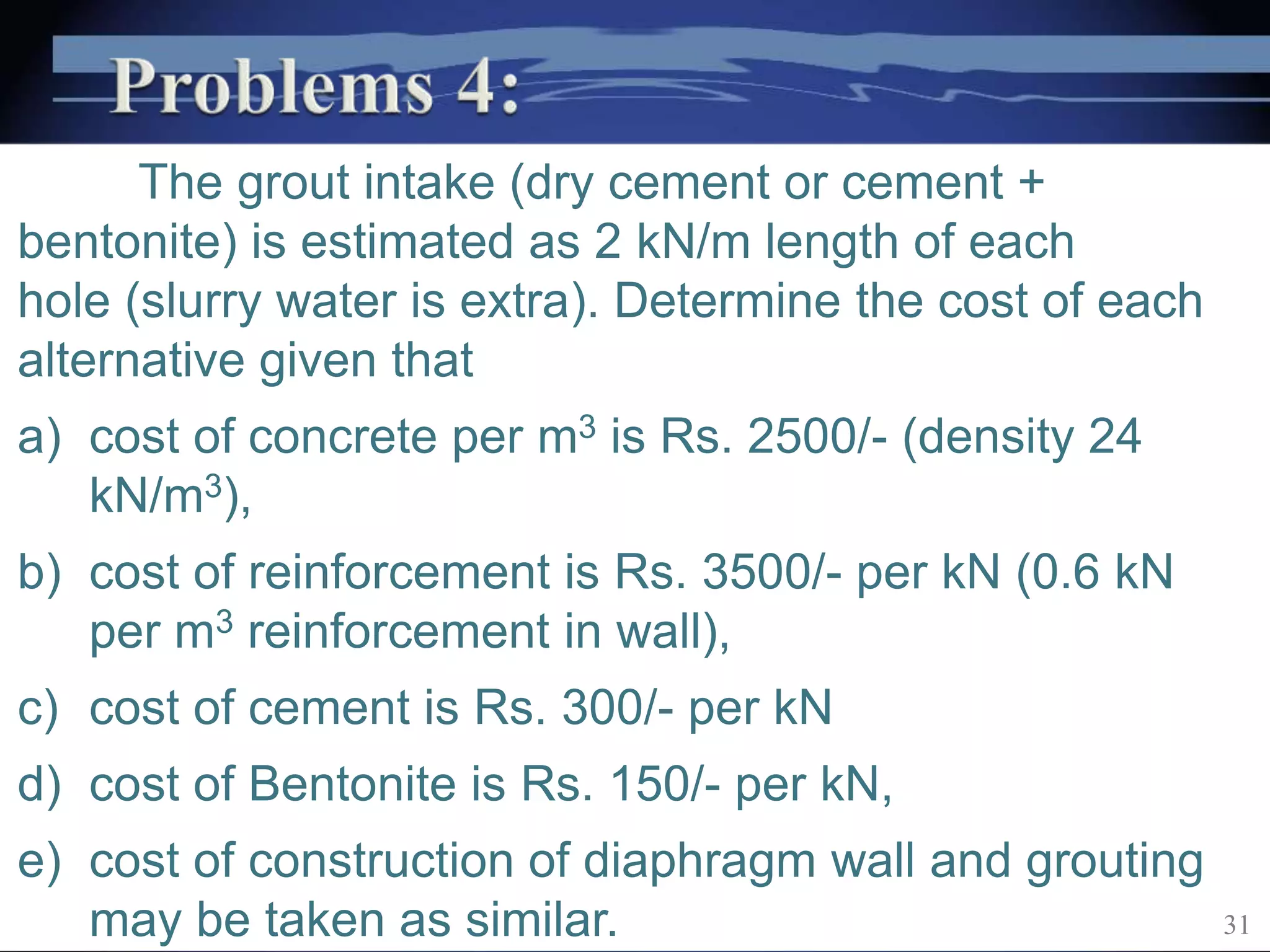

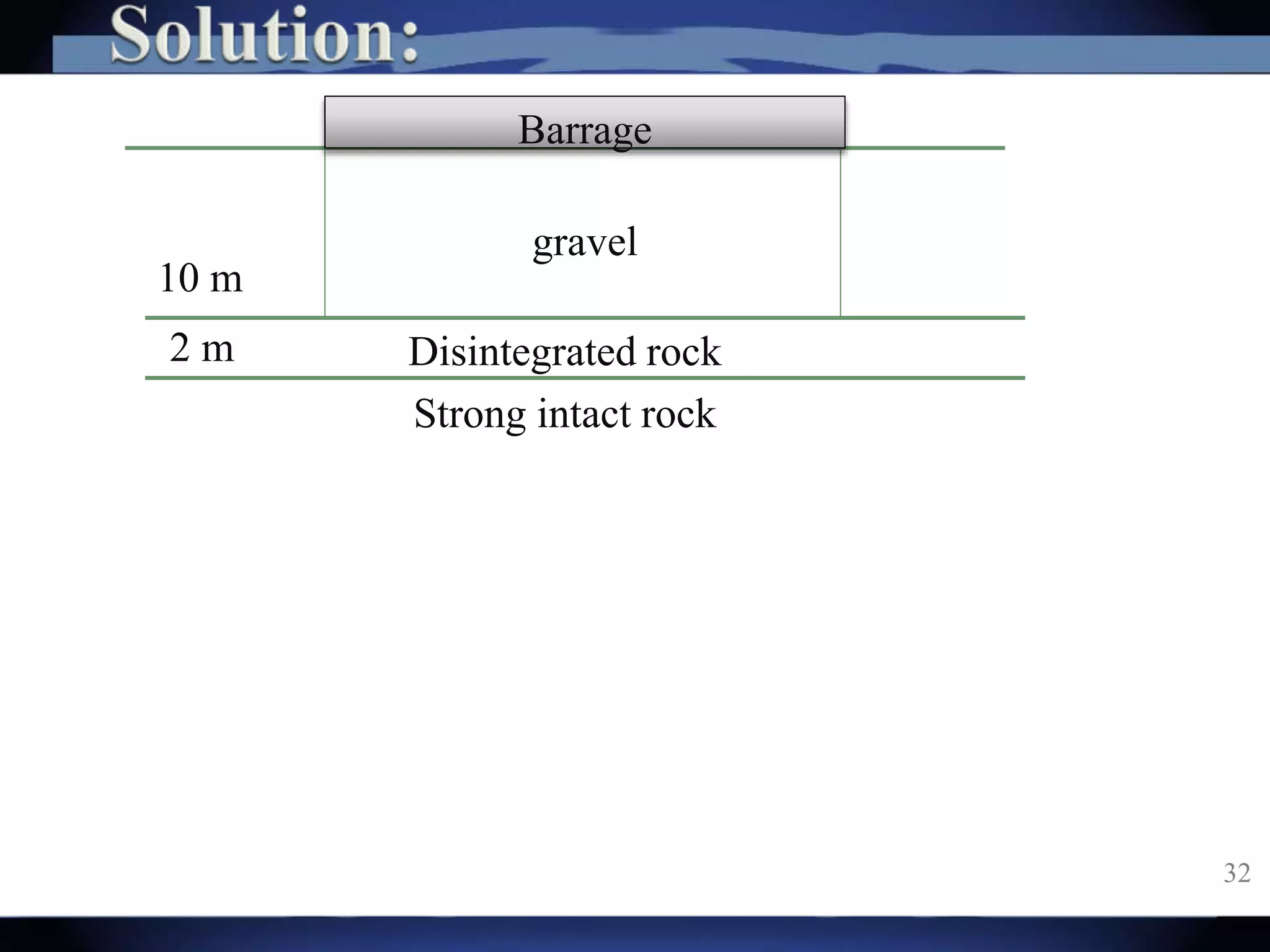

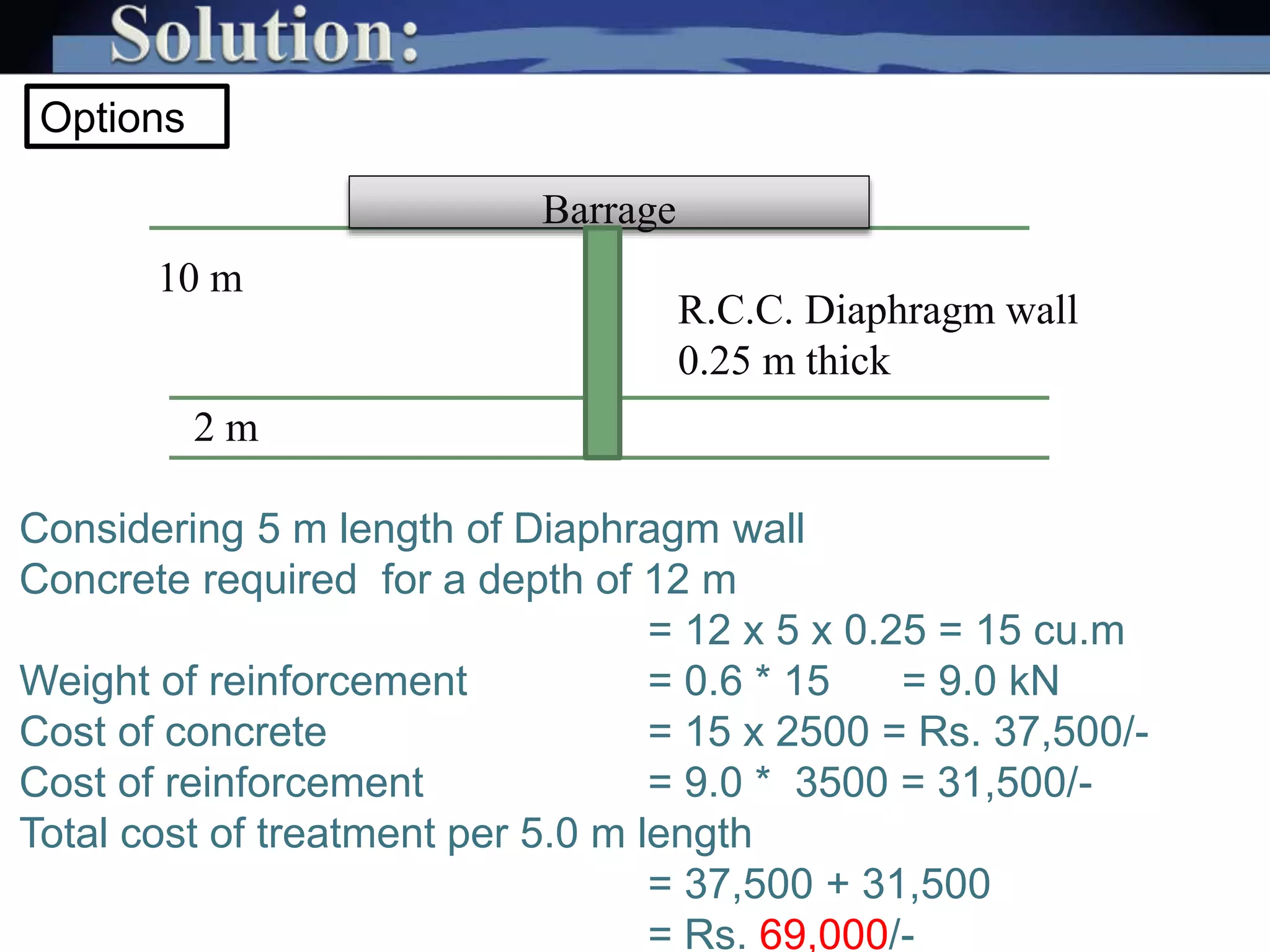

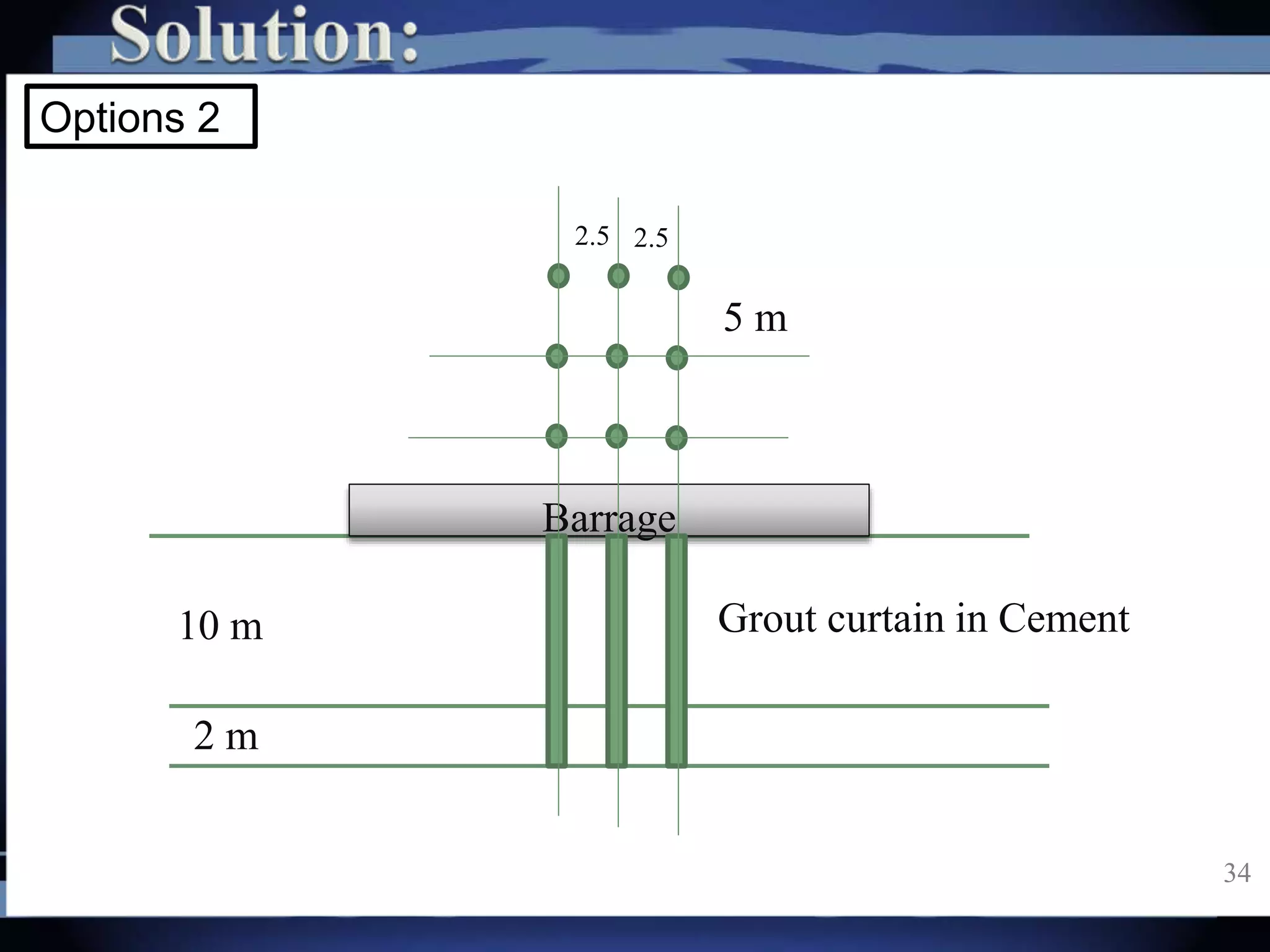

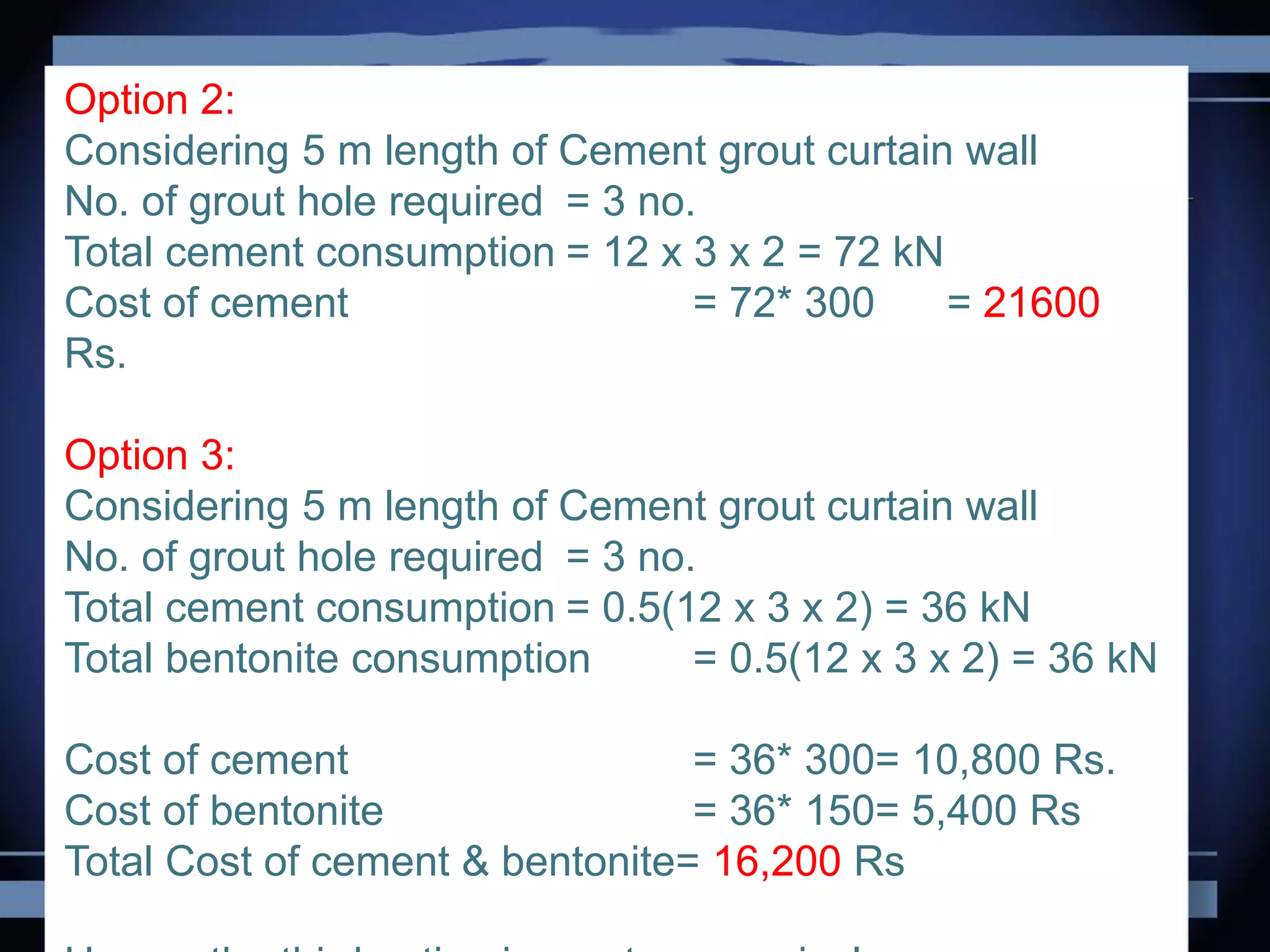

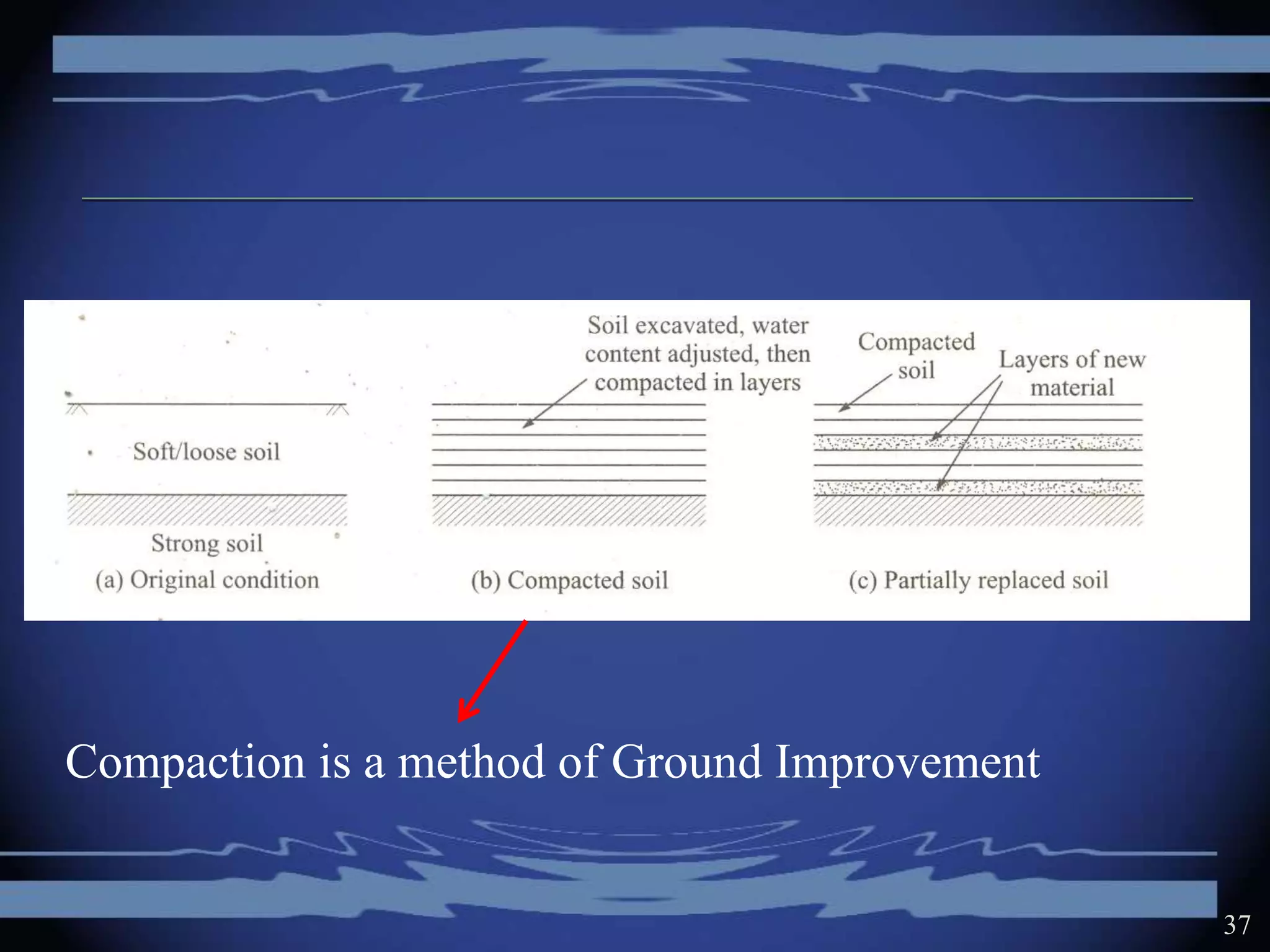

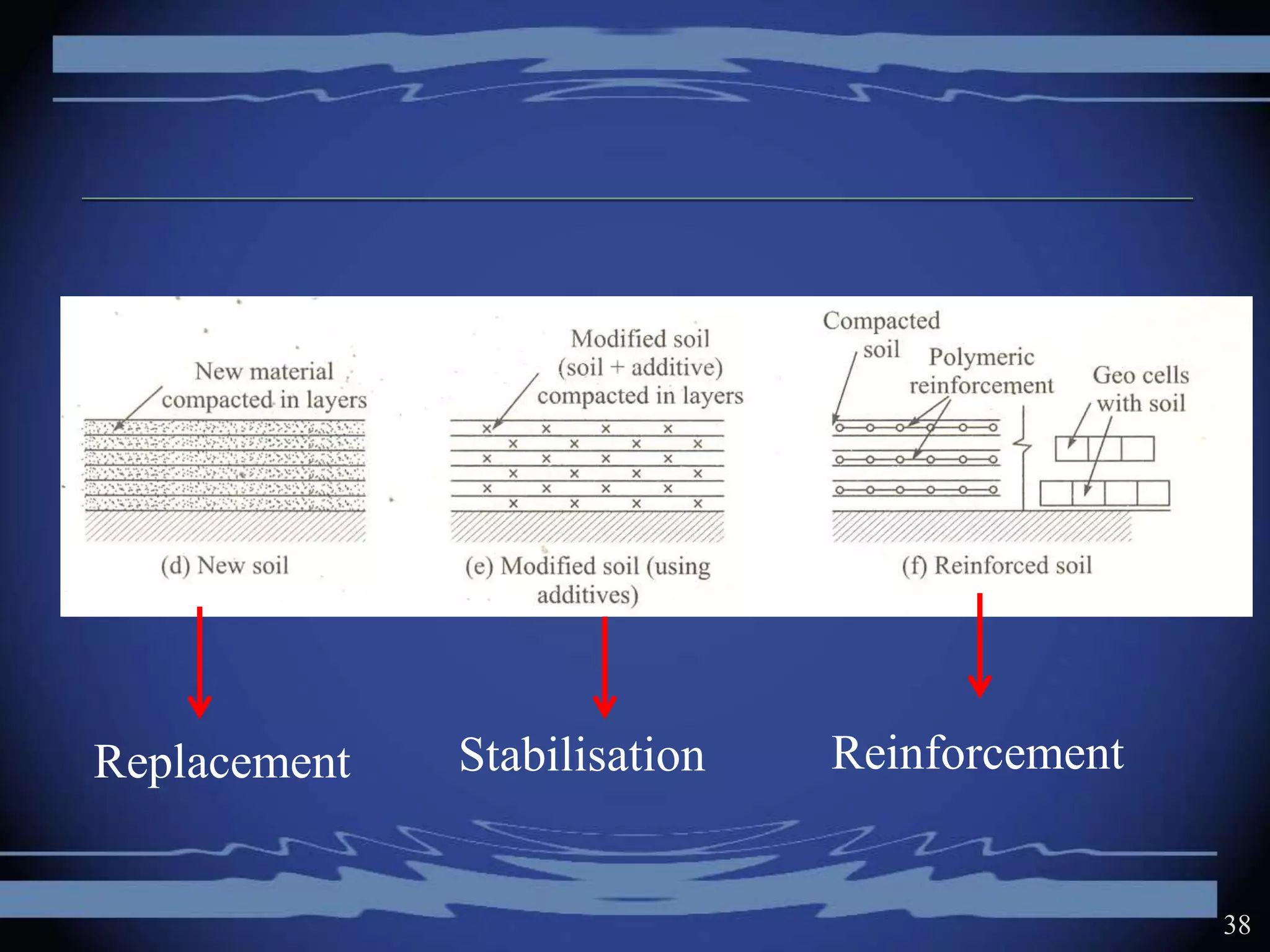

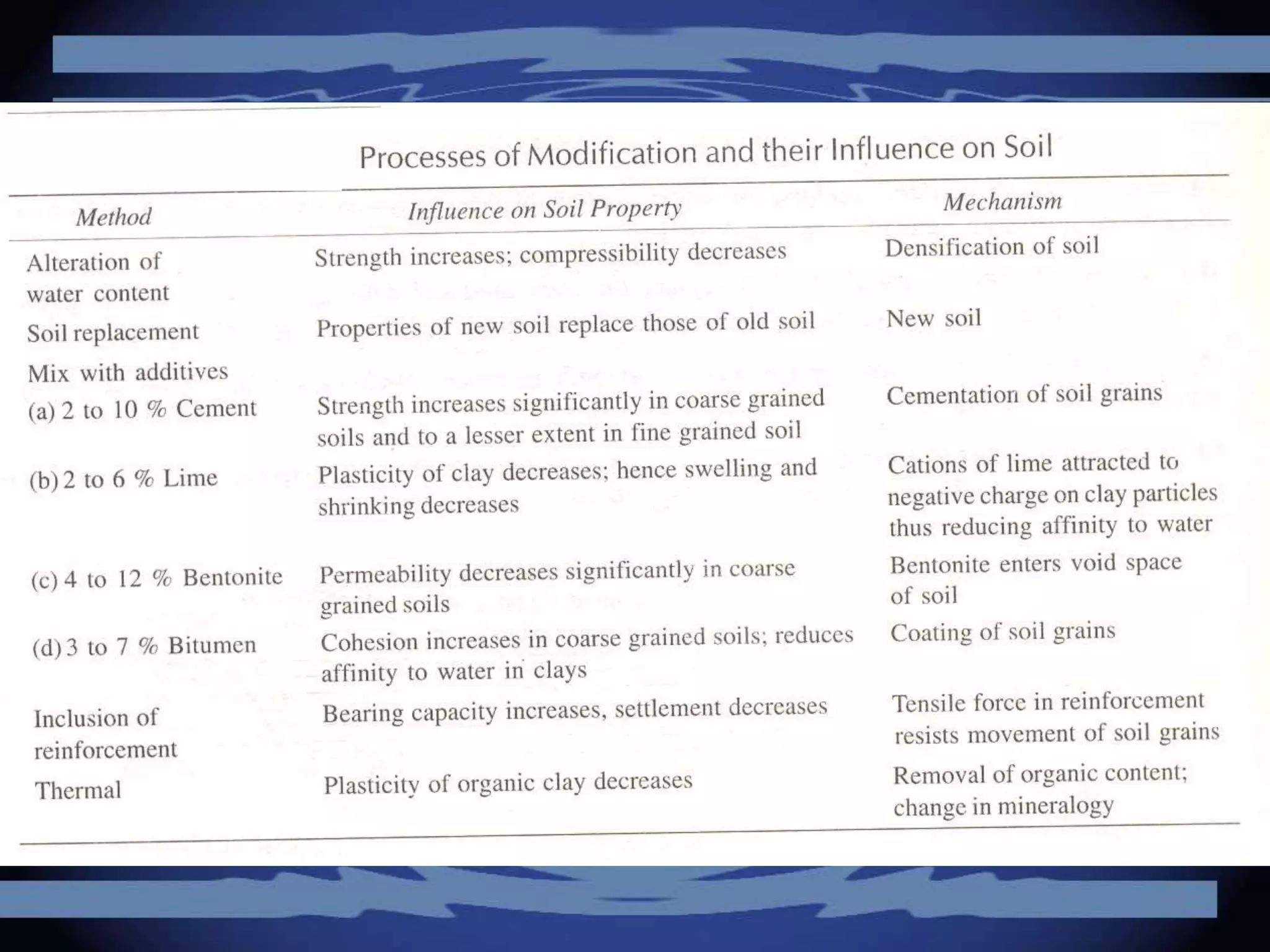

The document discusses ground improvement techniques. It begins by introducing the topic and providing context about the location and author. It then discusses various soil conditions from problematic to ideal and different ground improvement methods. The key ground improvement mechanisms are described along with factors to consider when selecting a method. Examples are provided to estimate costs for improving loose sand and stabilizing soft clay using different techniques. The document provides an overview of ground improvement and considerations for selecting appropriate techniques.