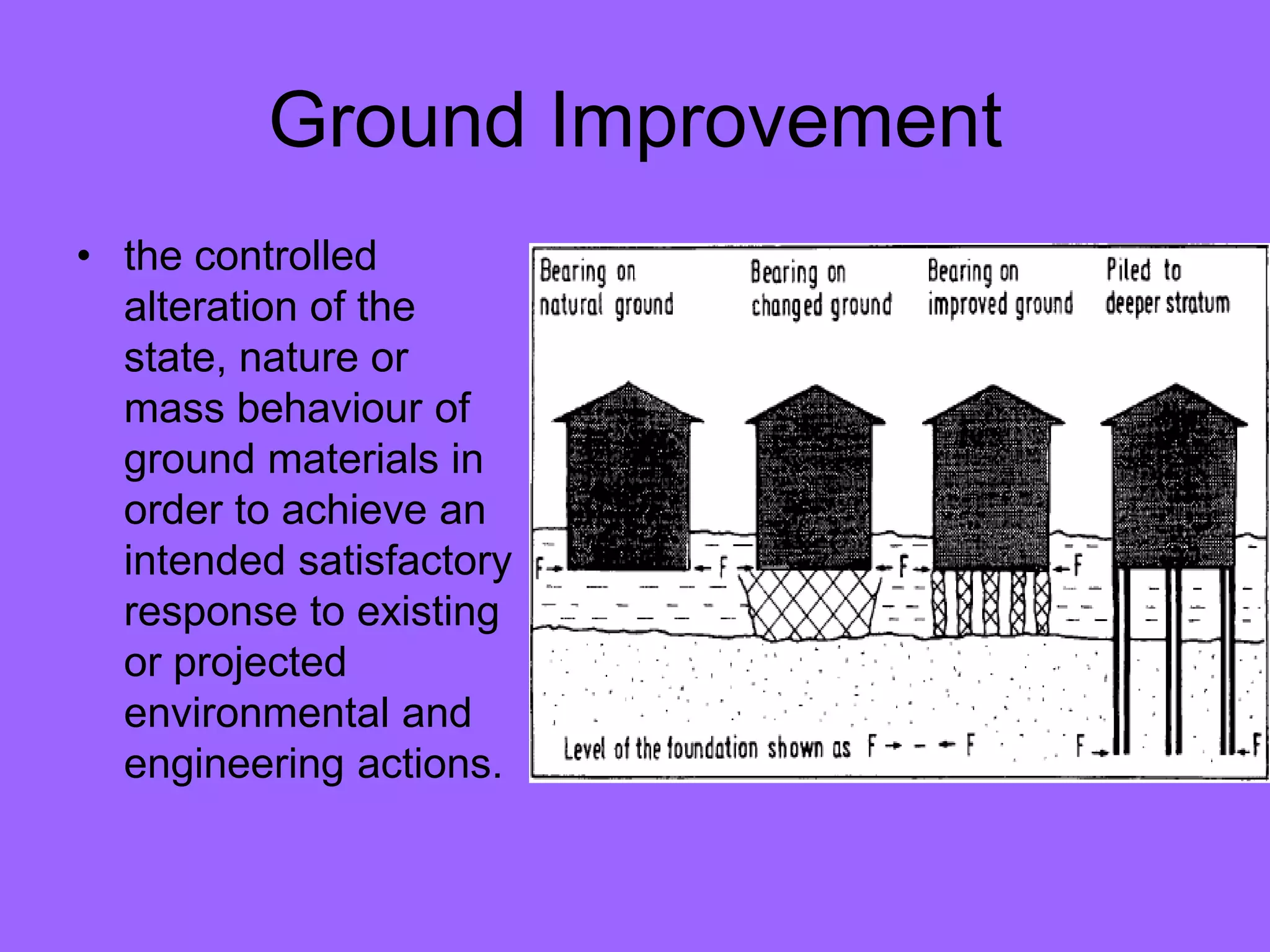

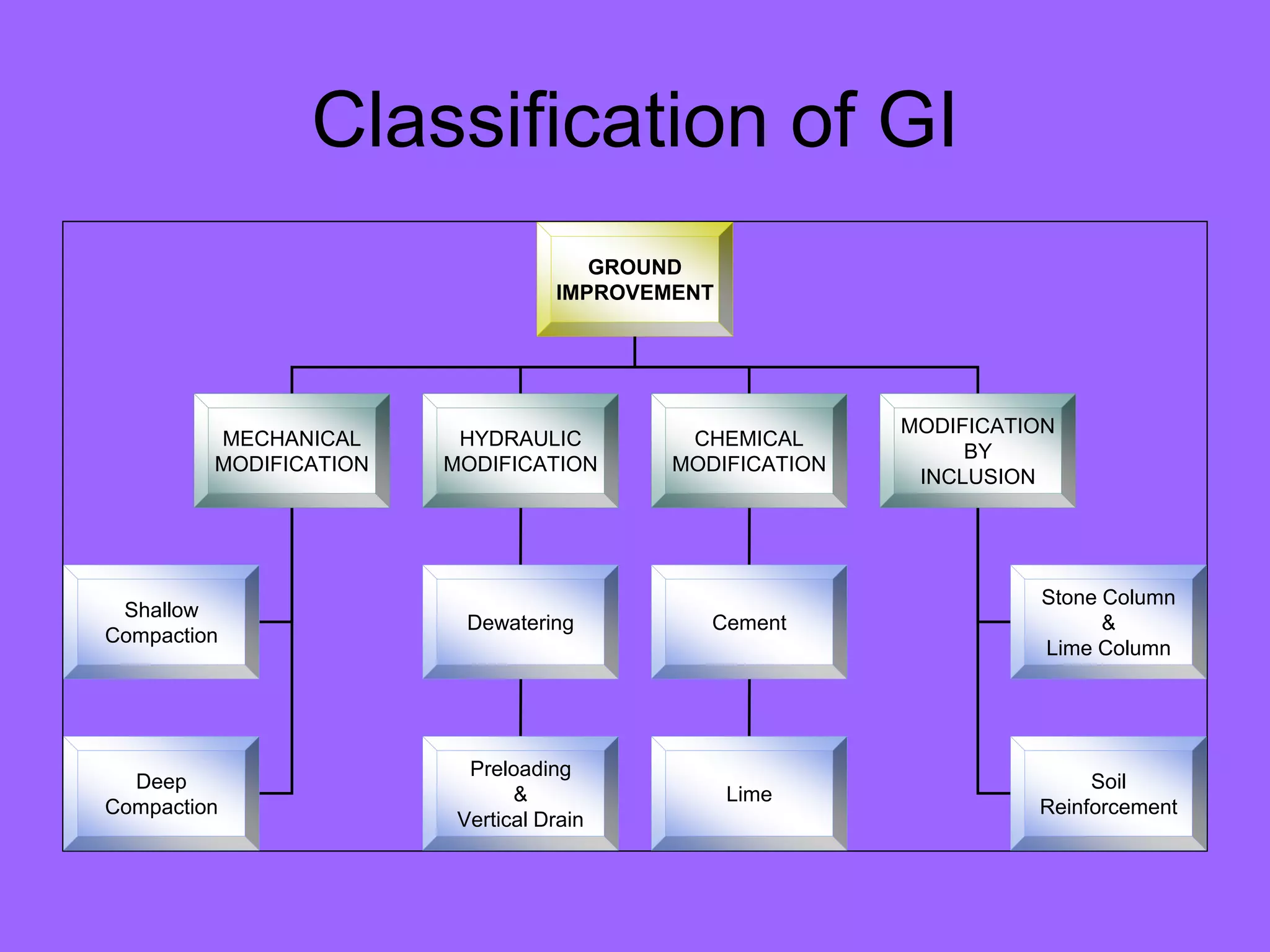

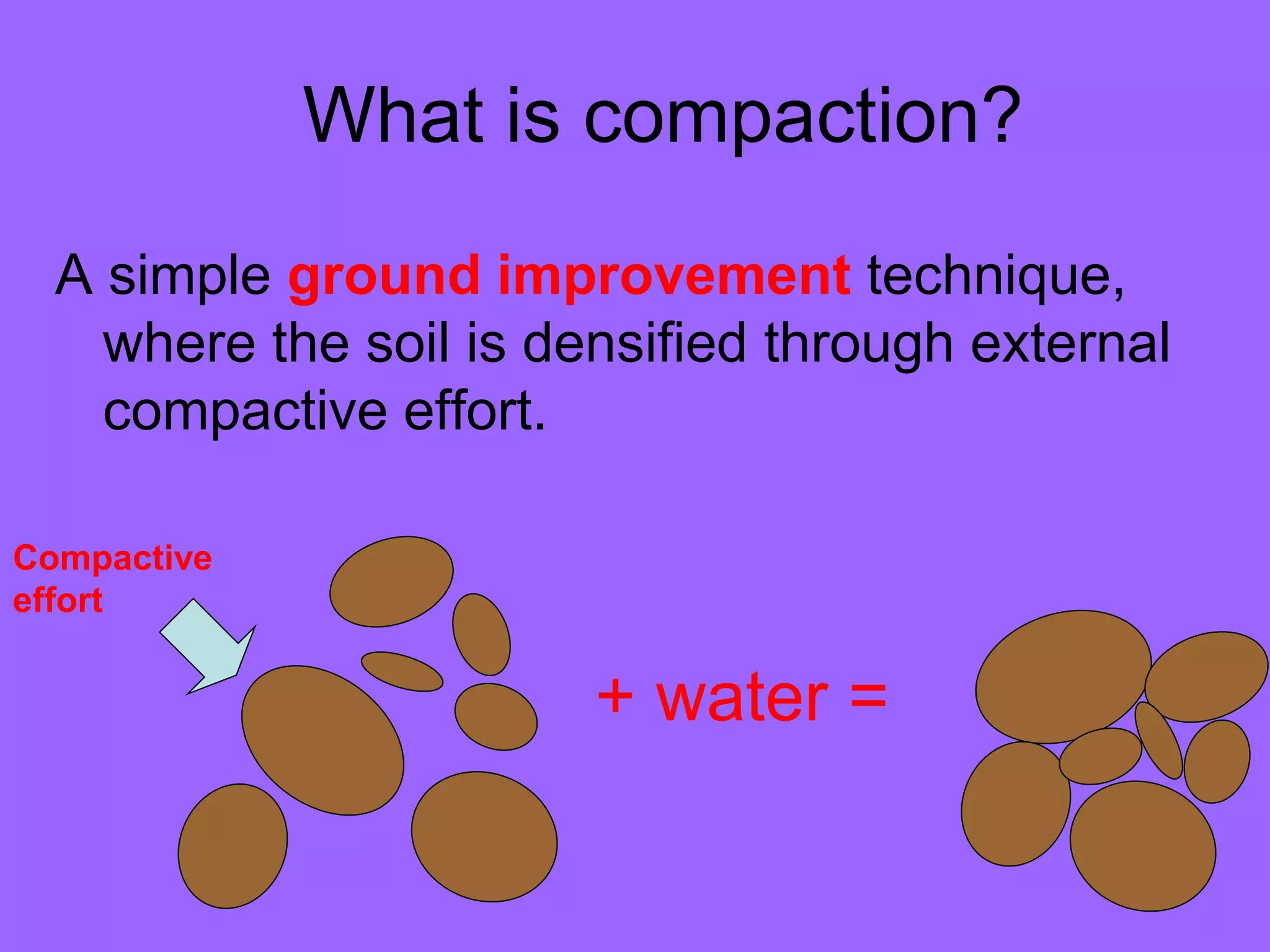

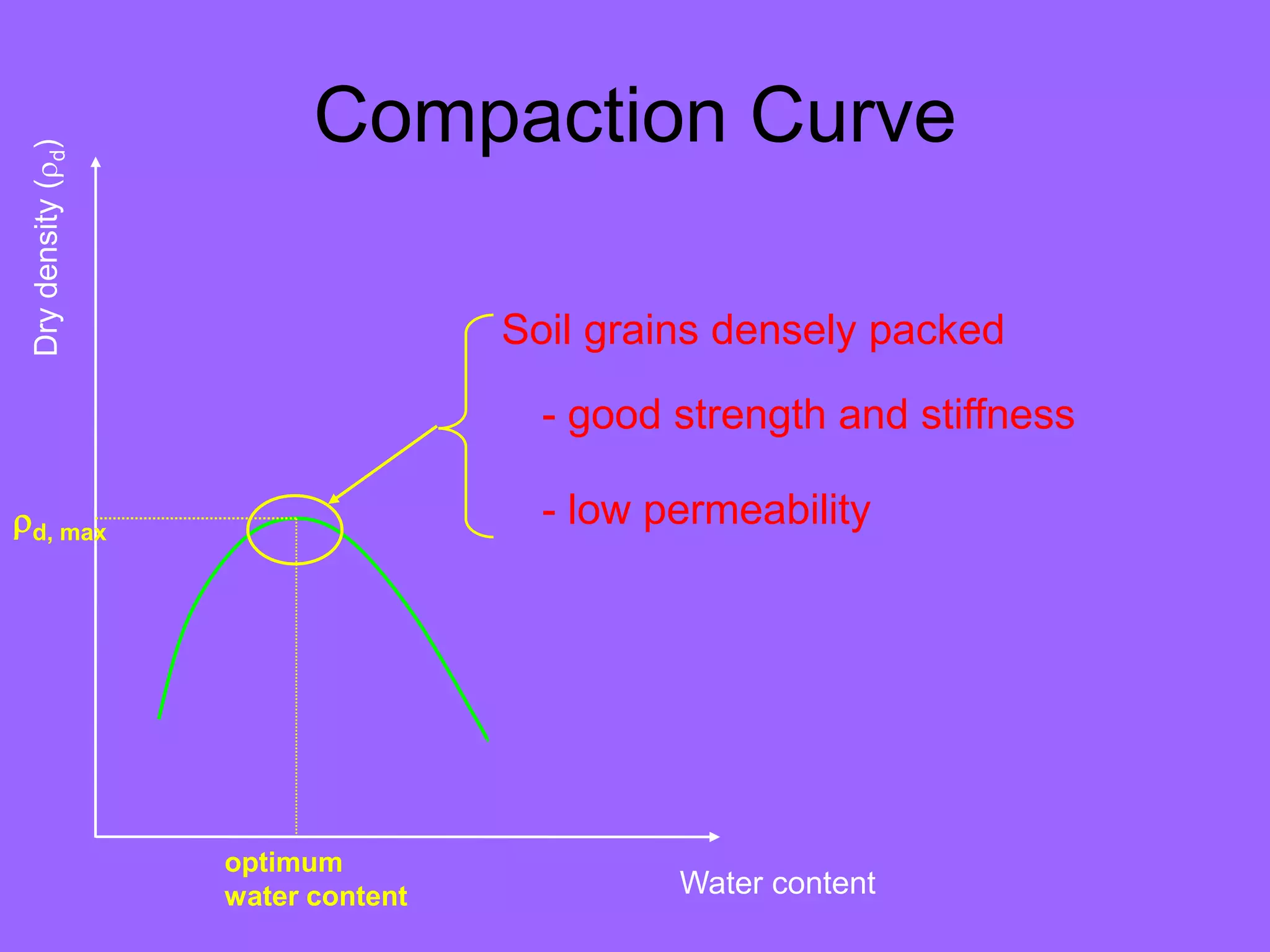

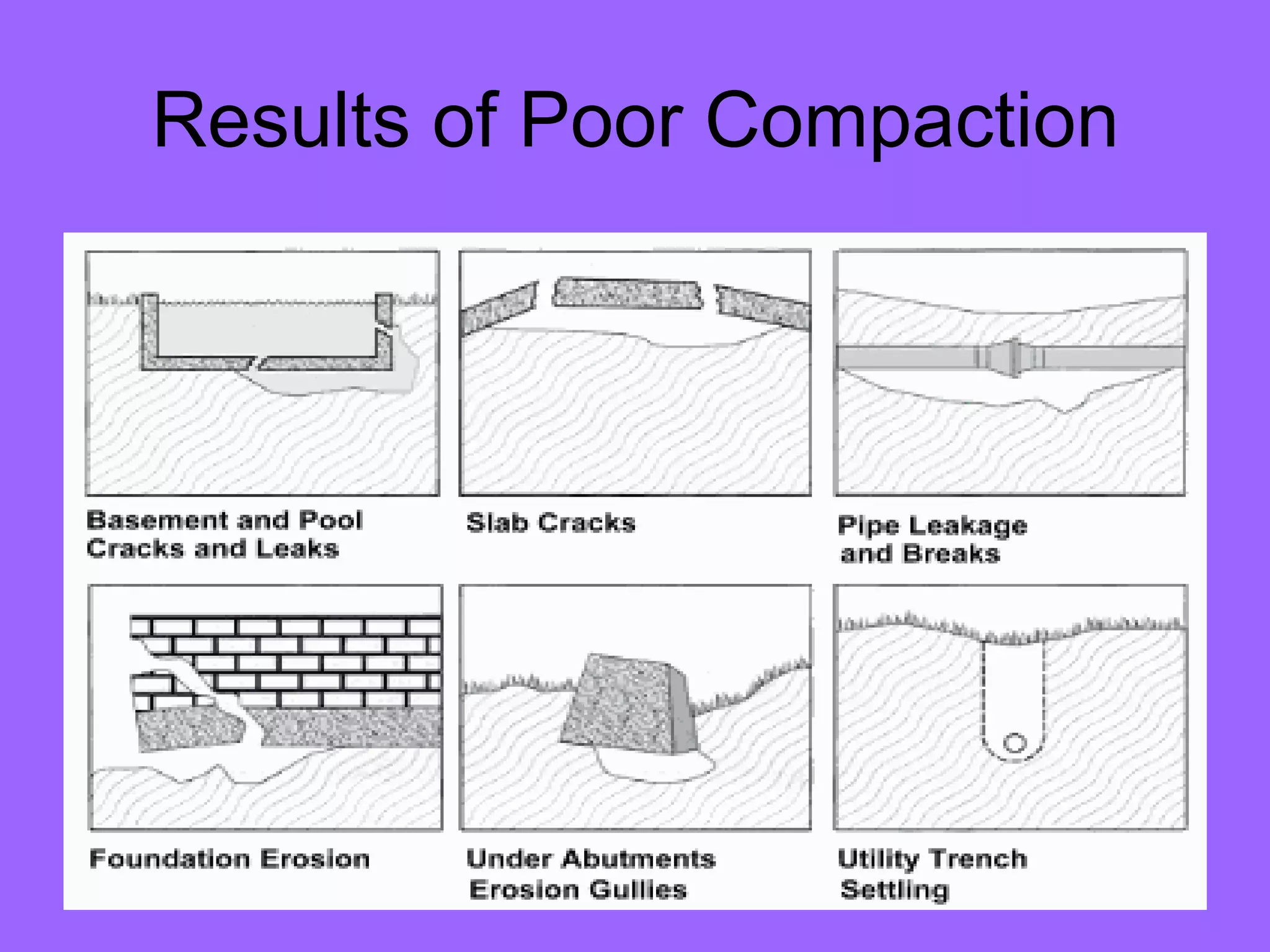

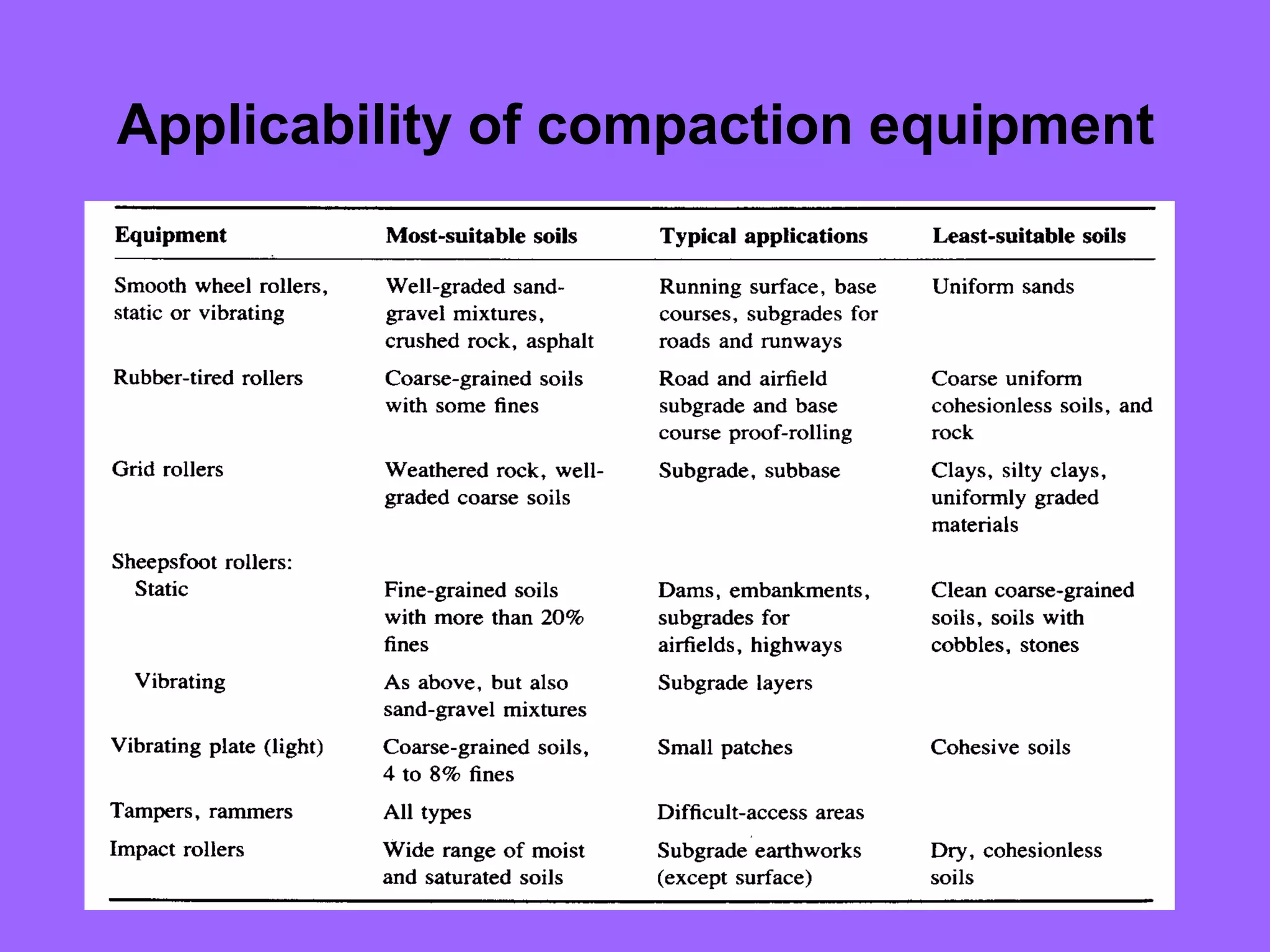

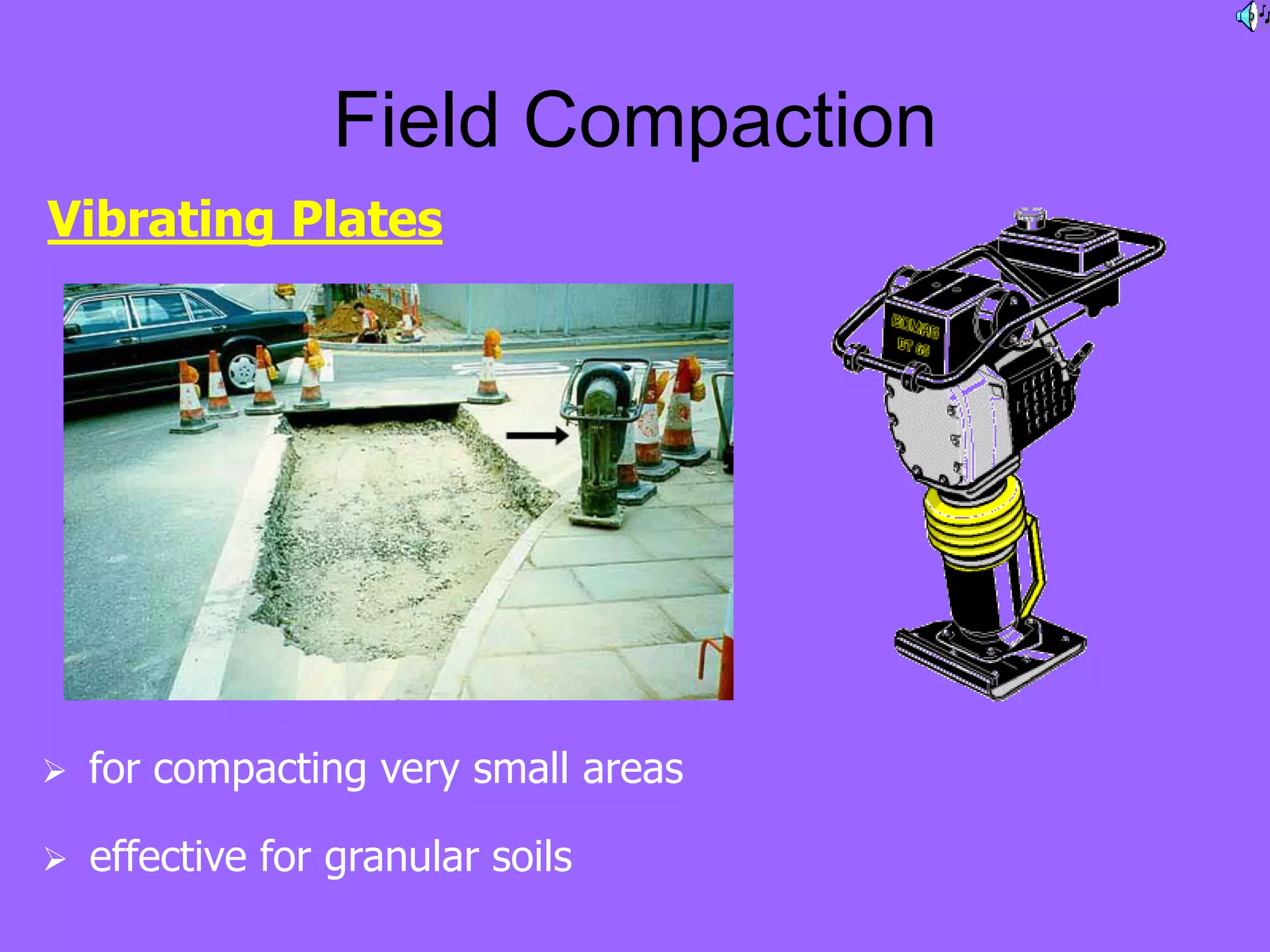

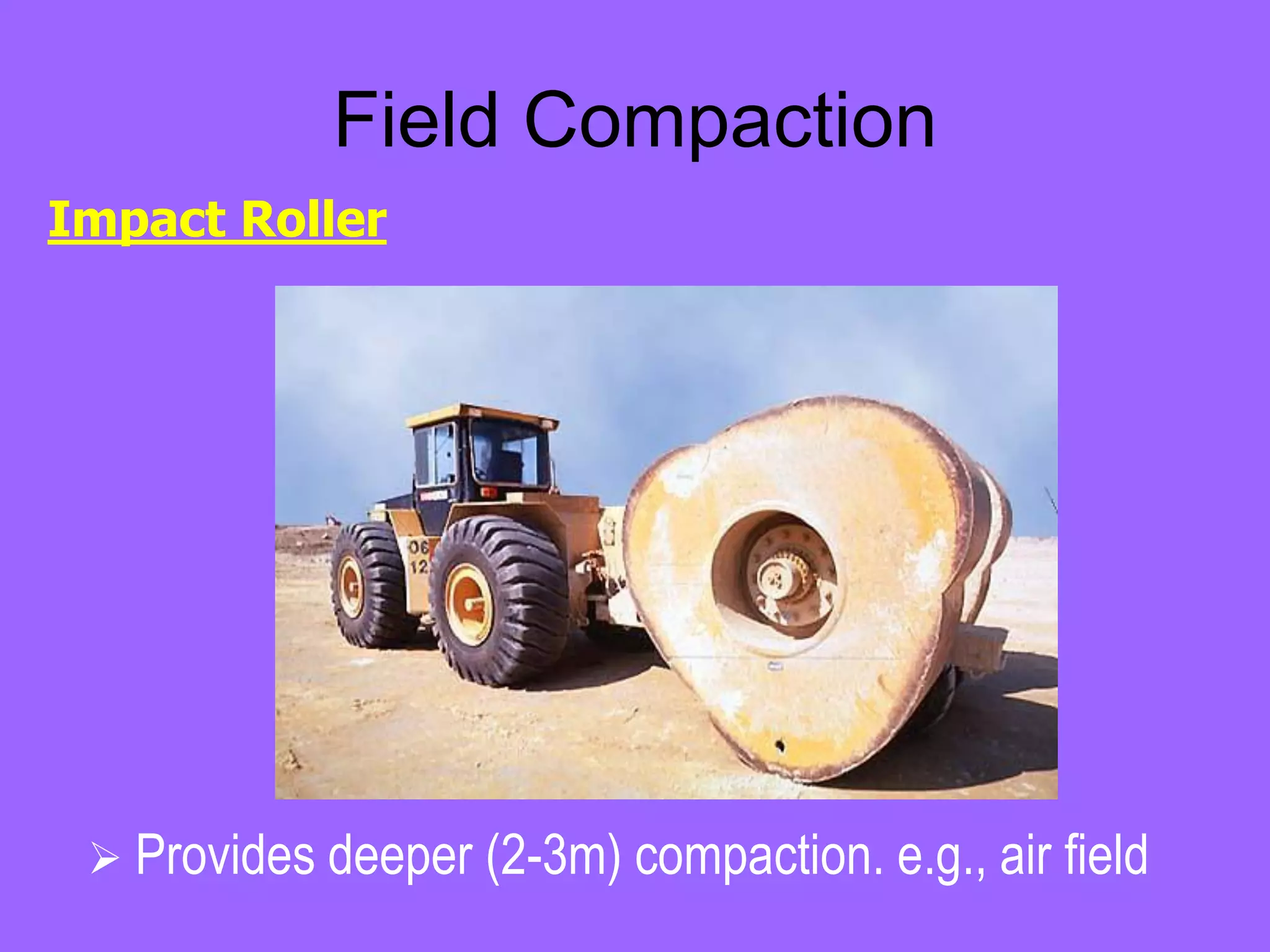

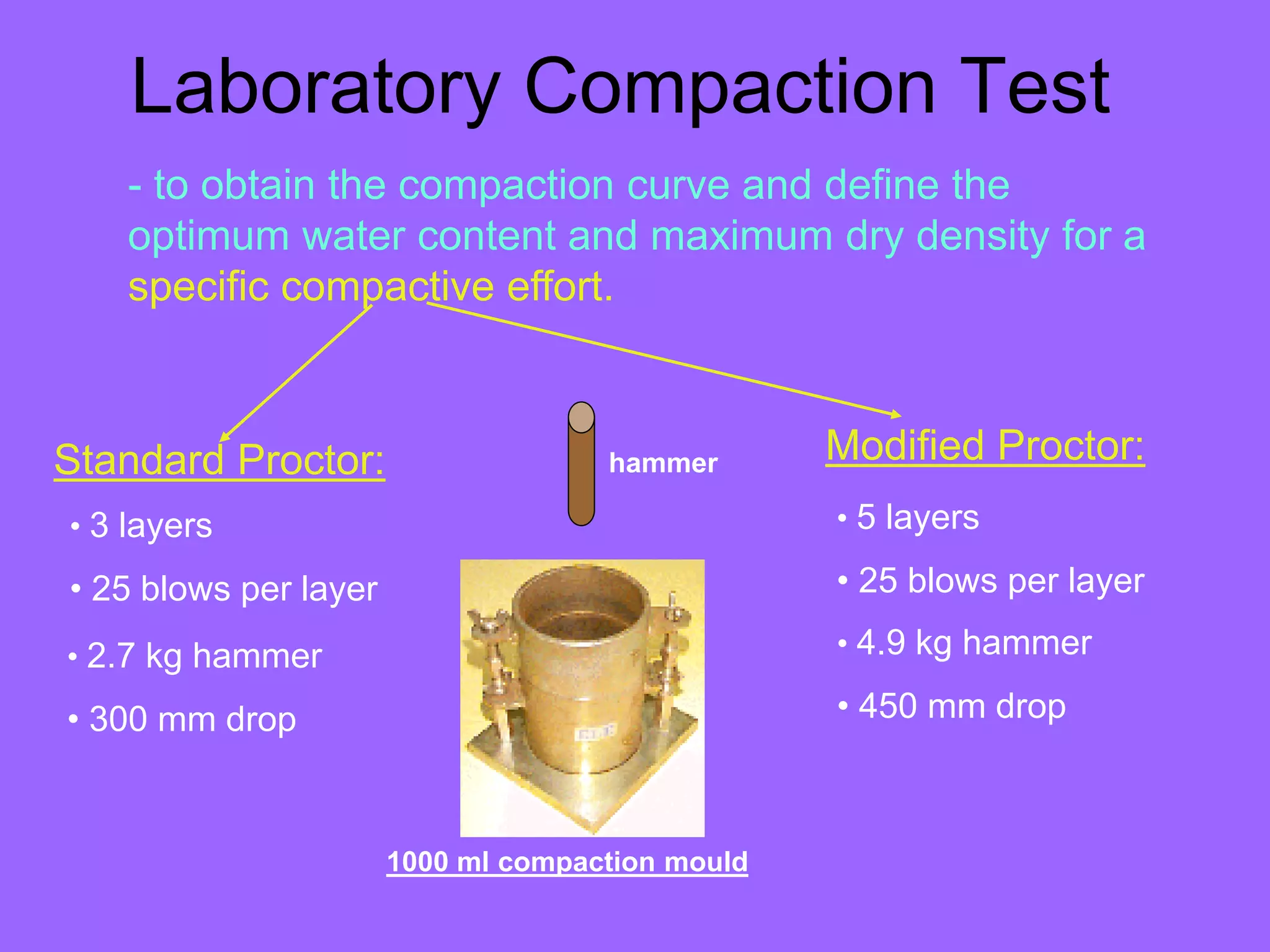

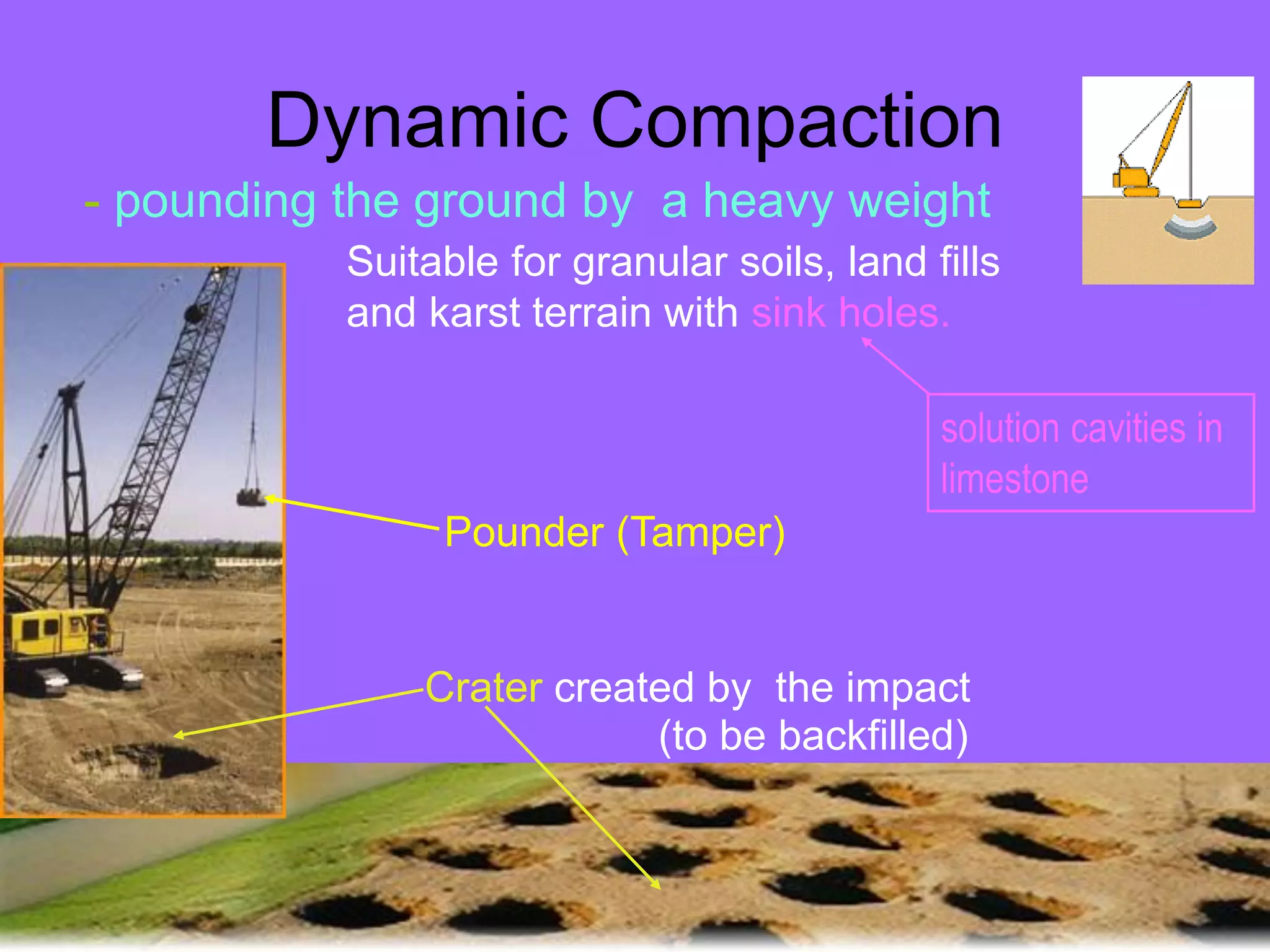

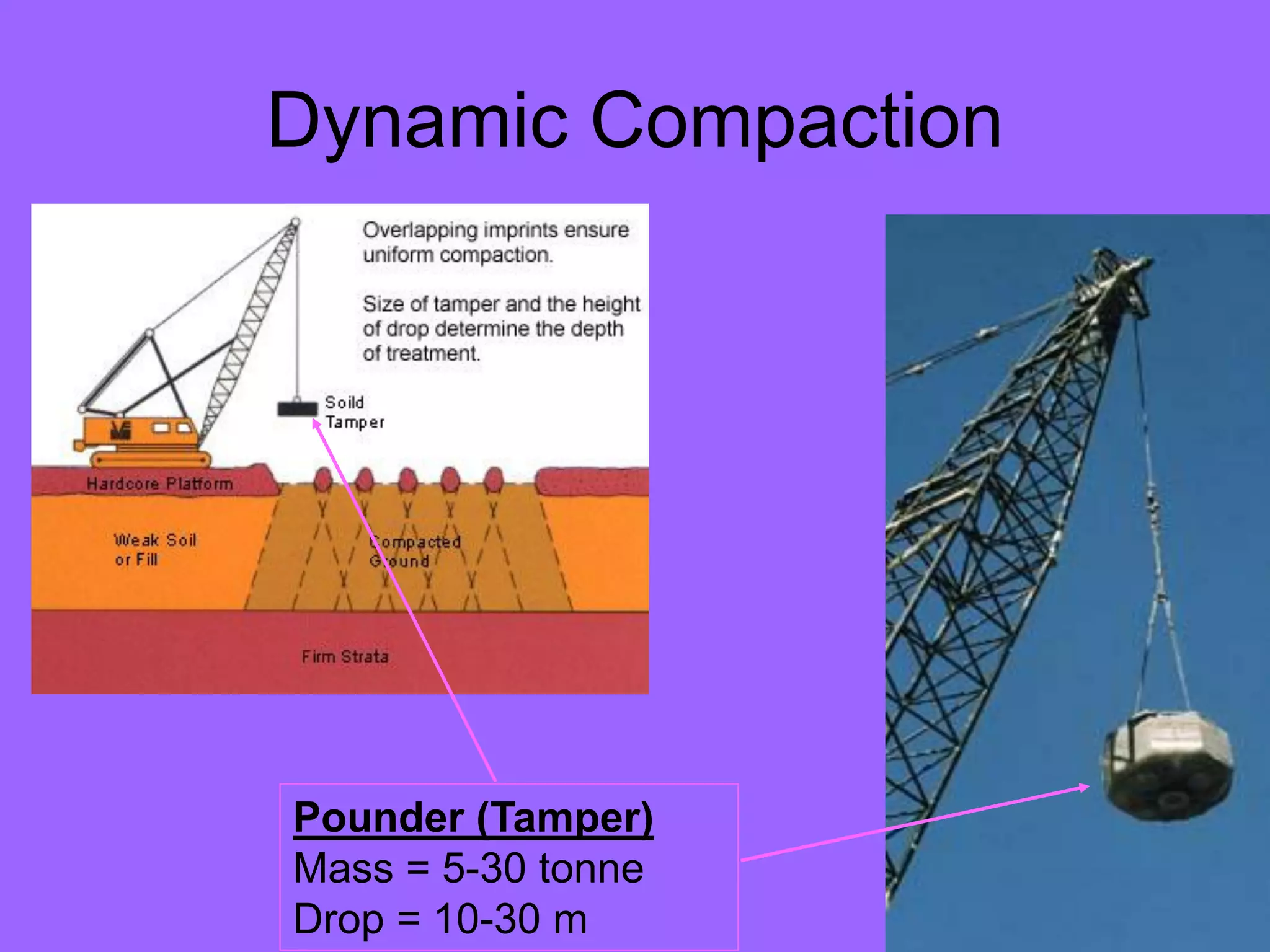

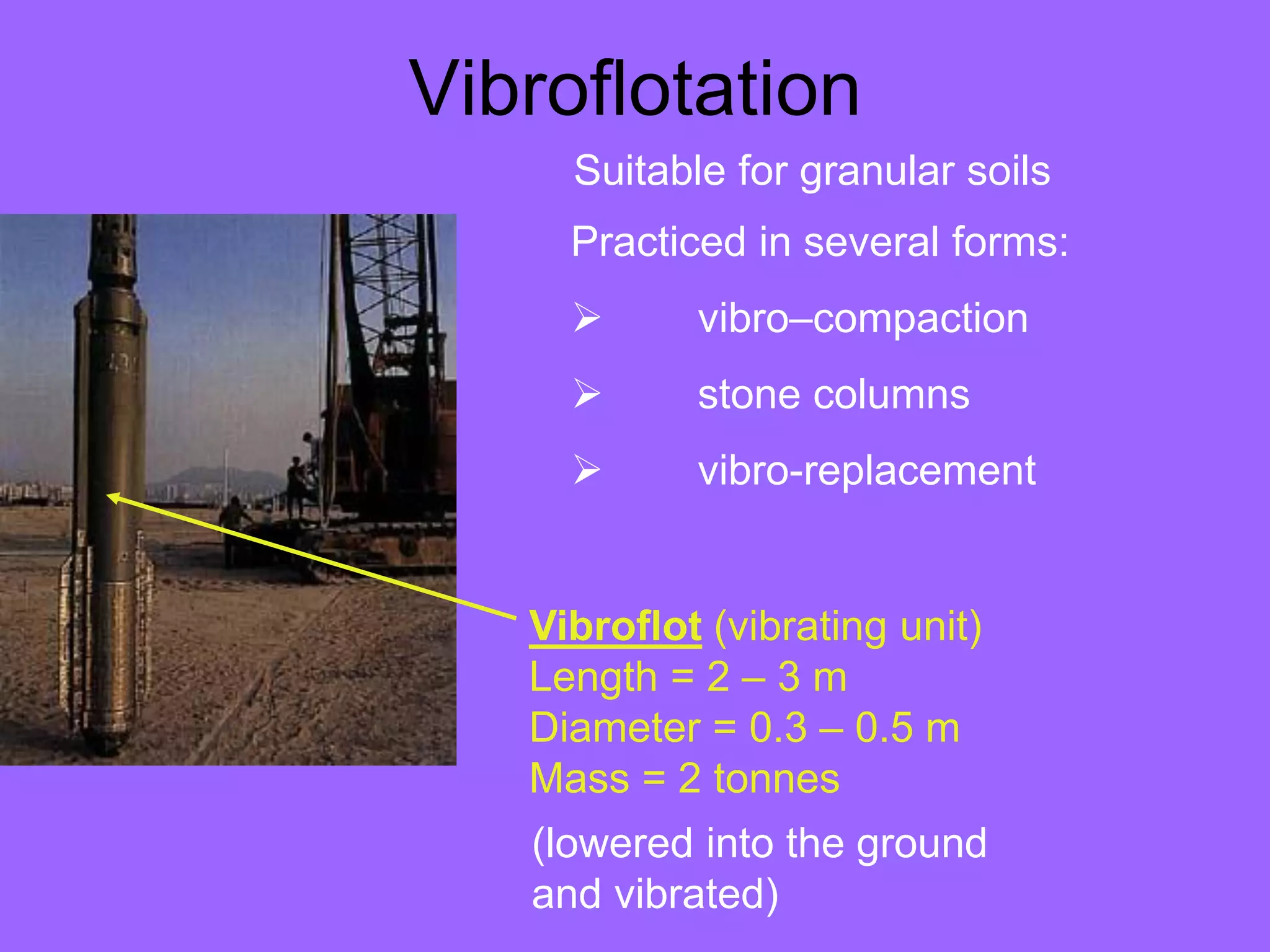

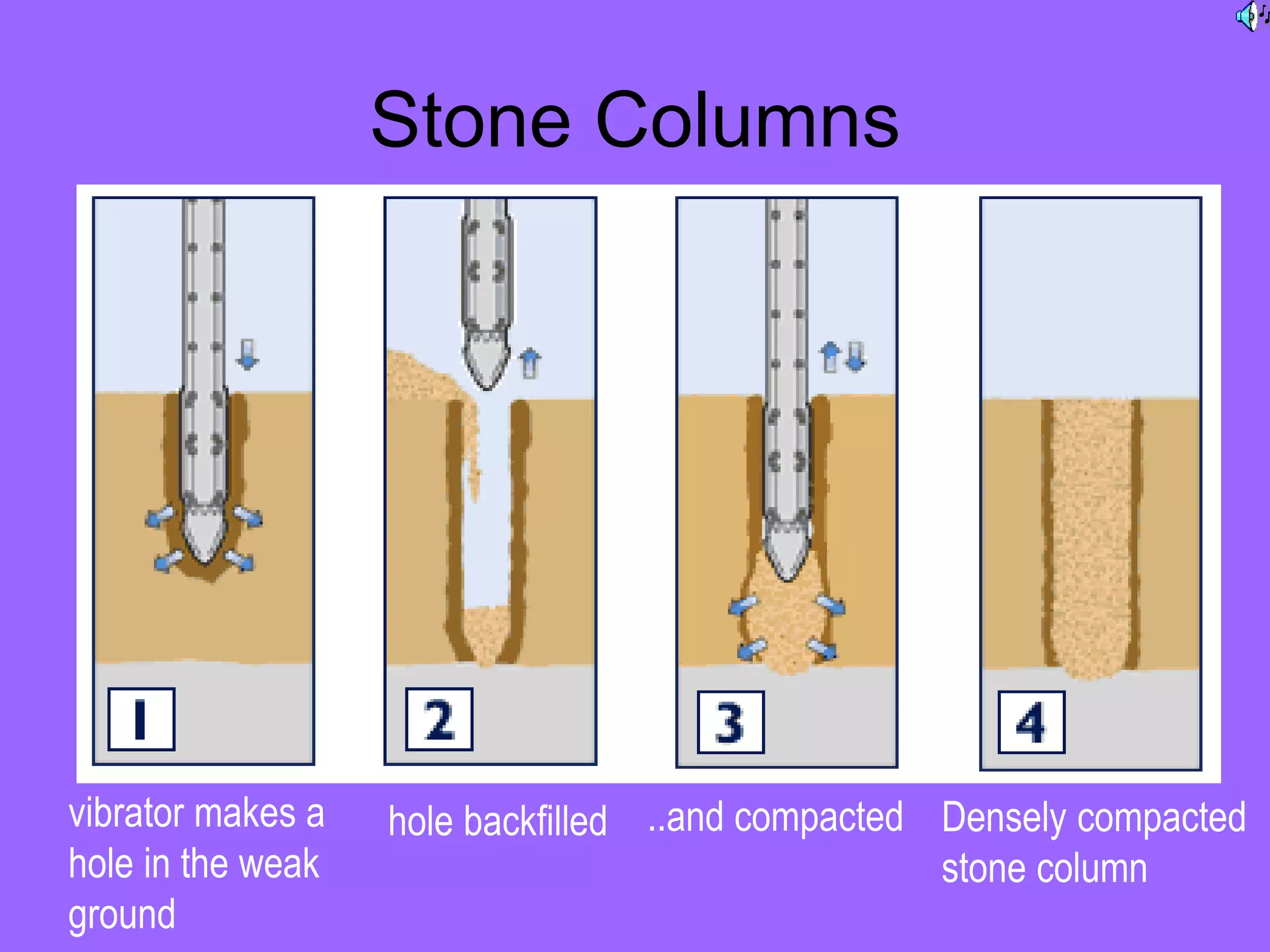

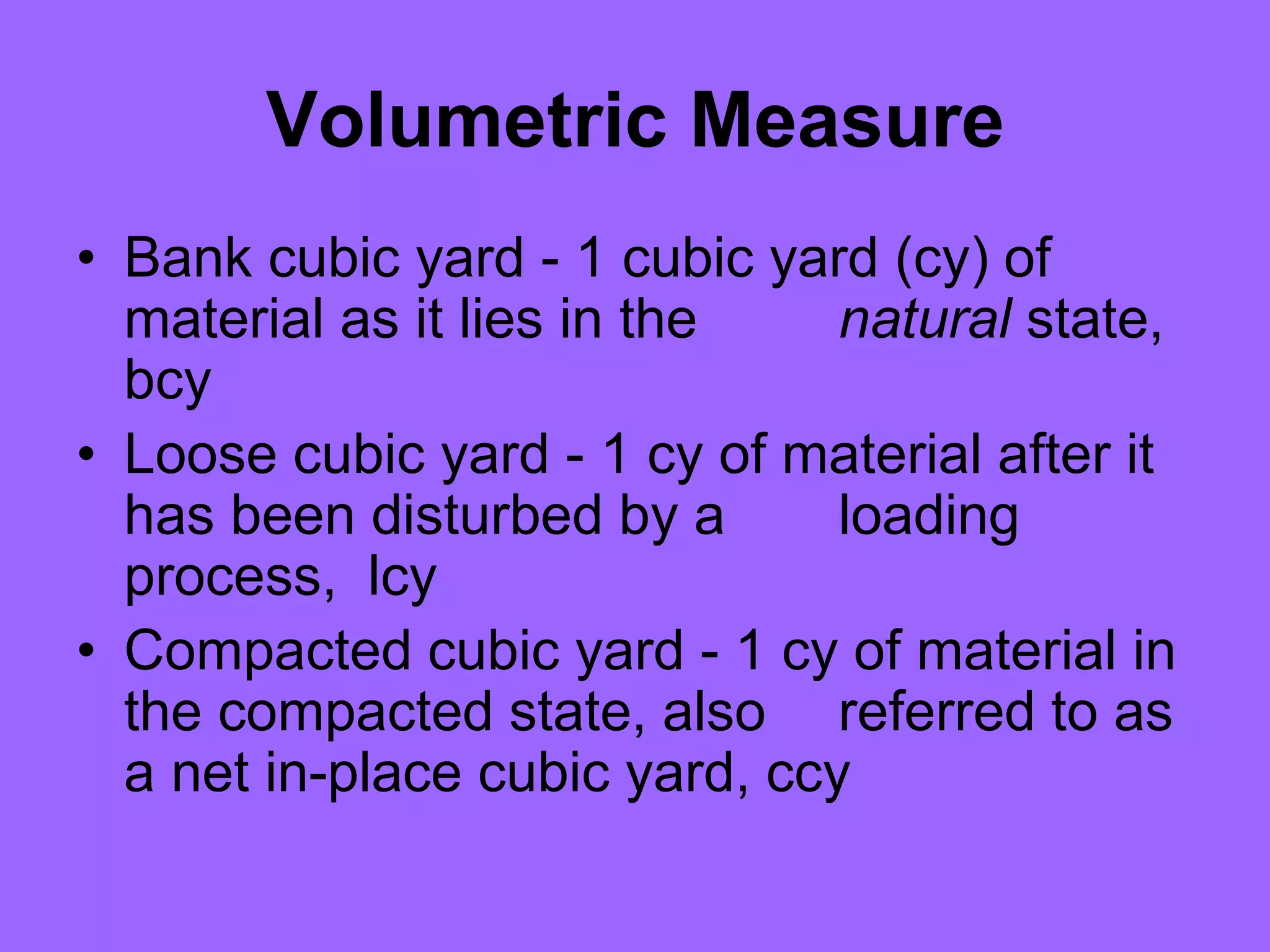

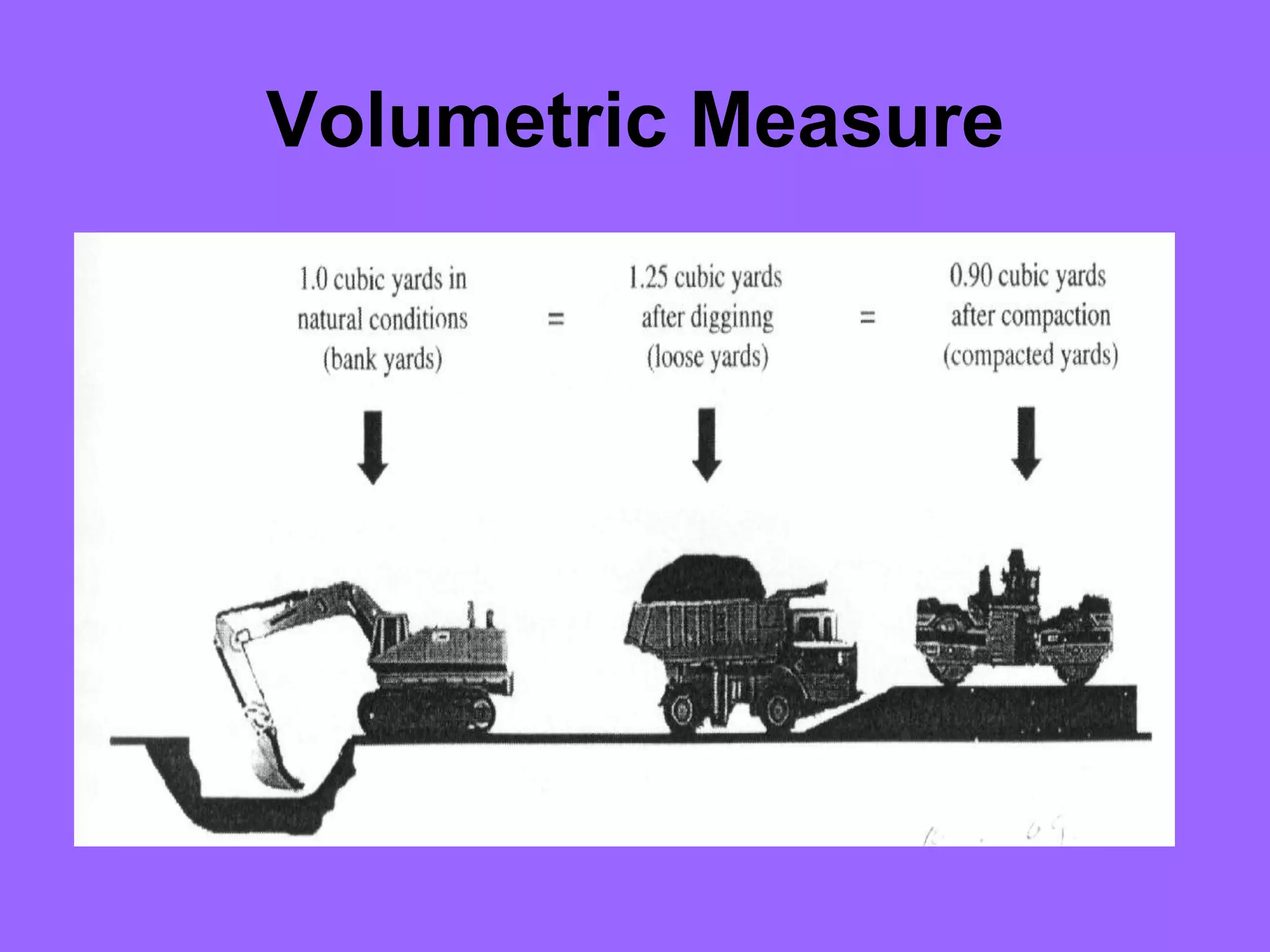

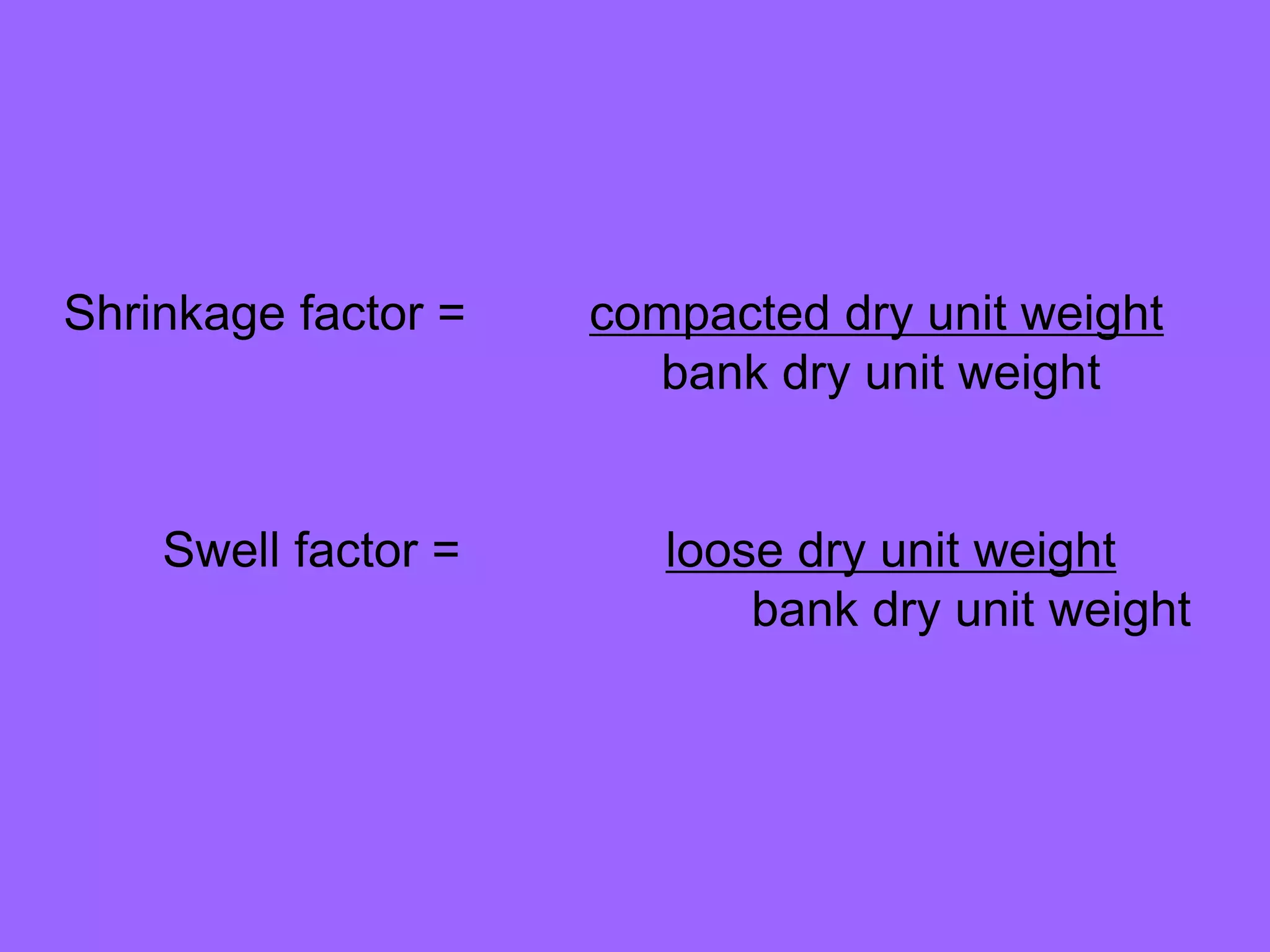

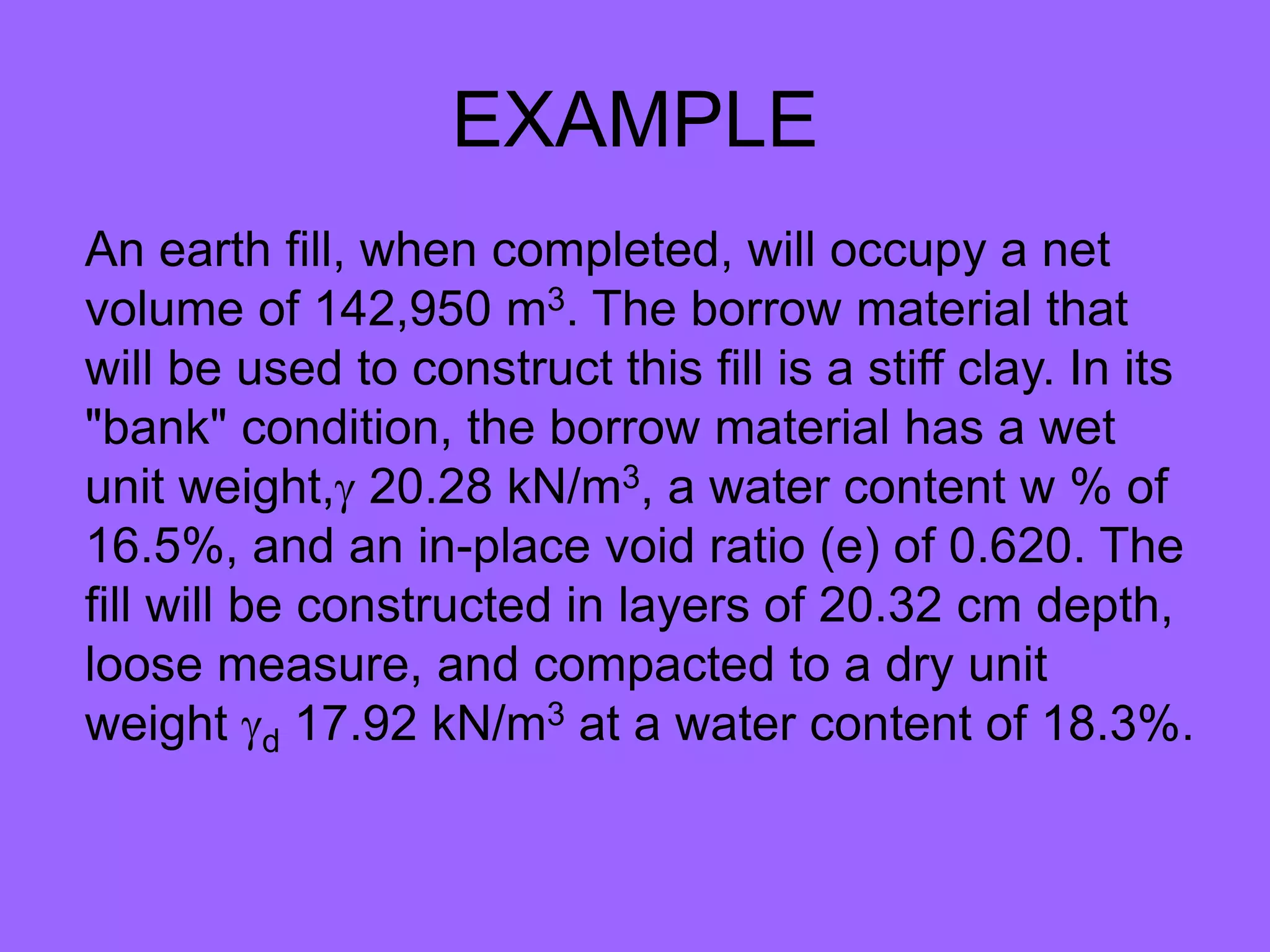

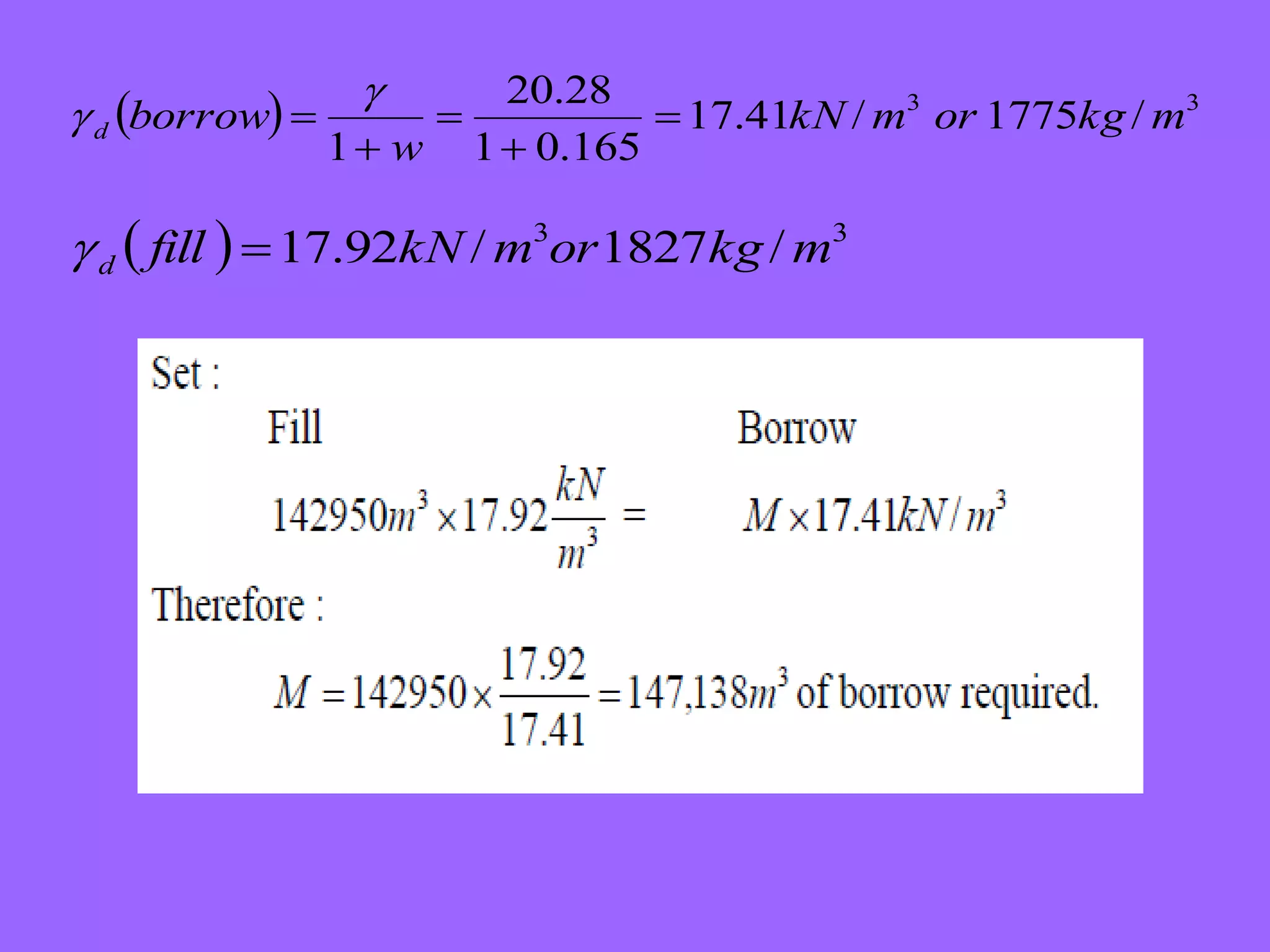

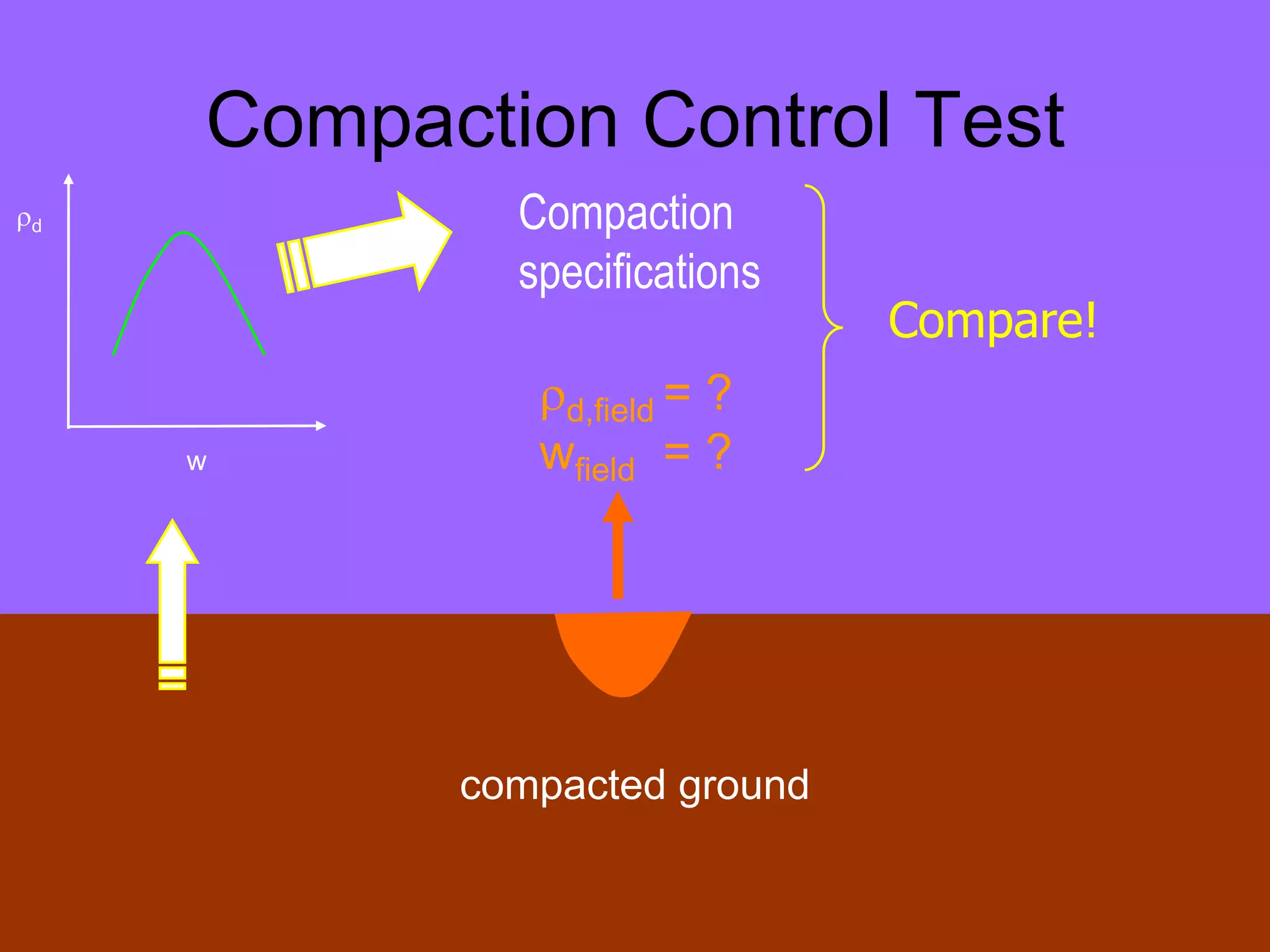

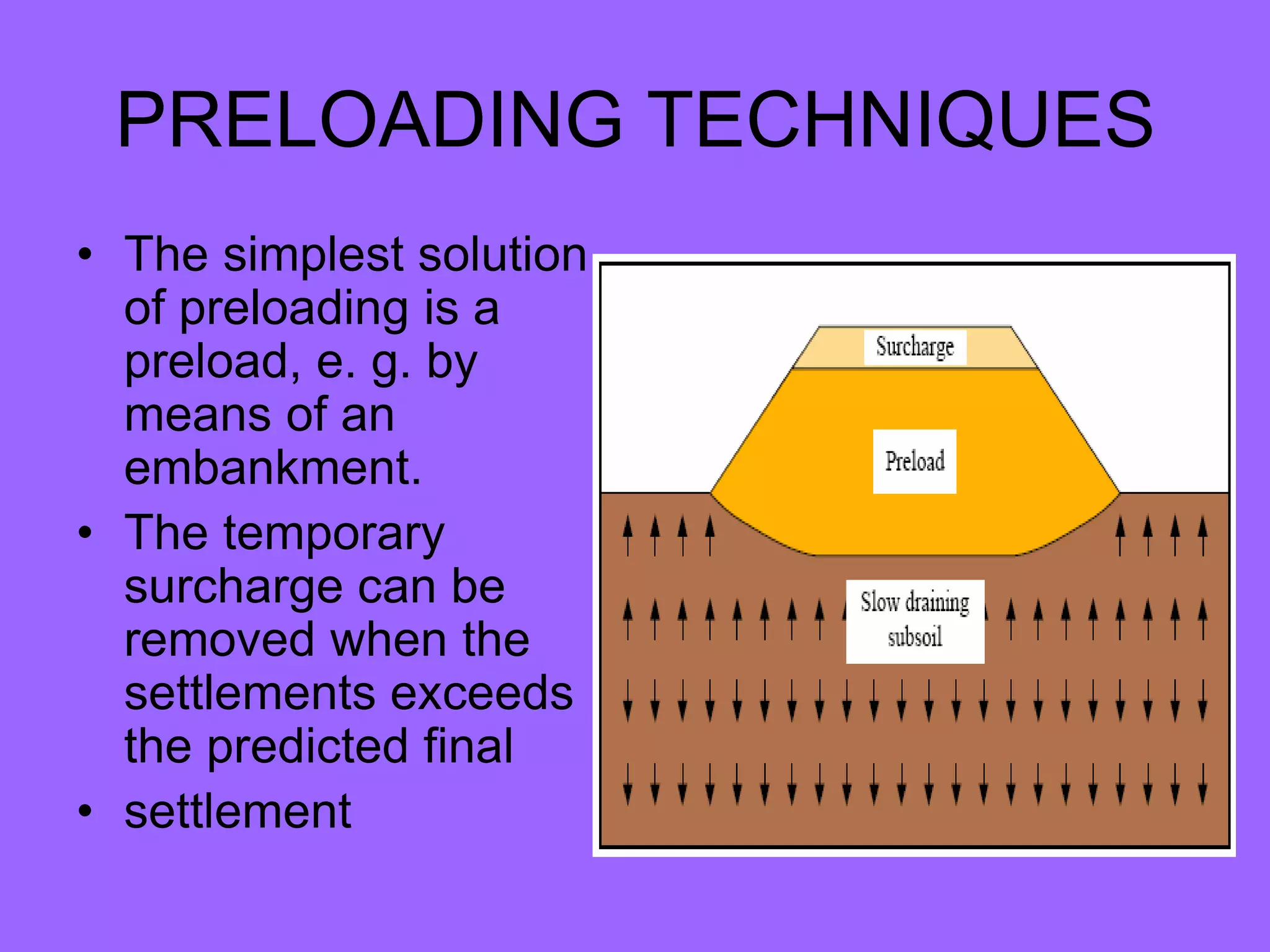

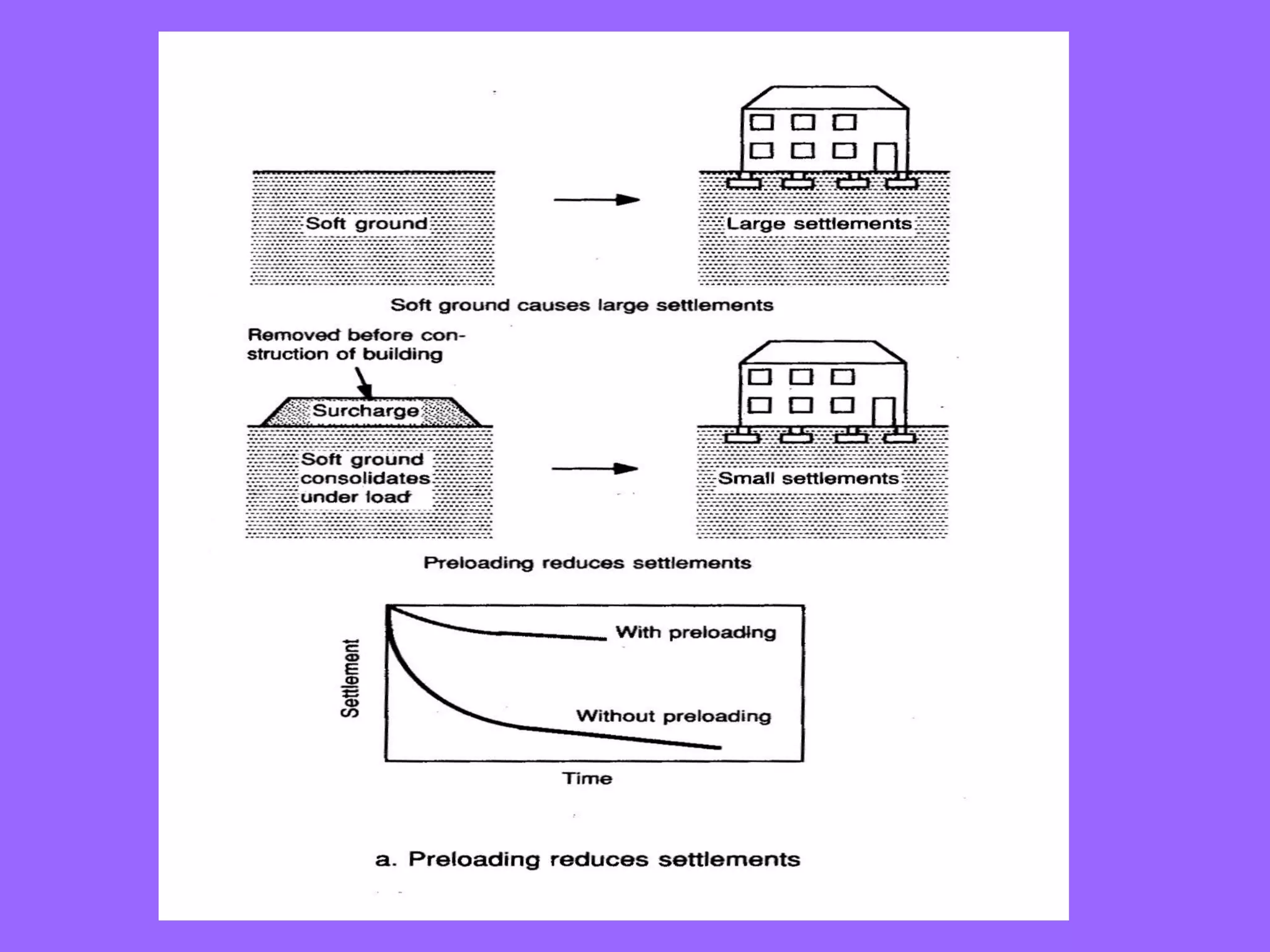

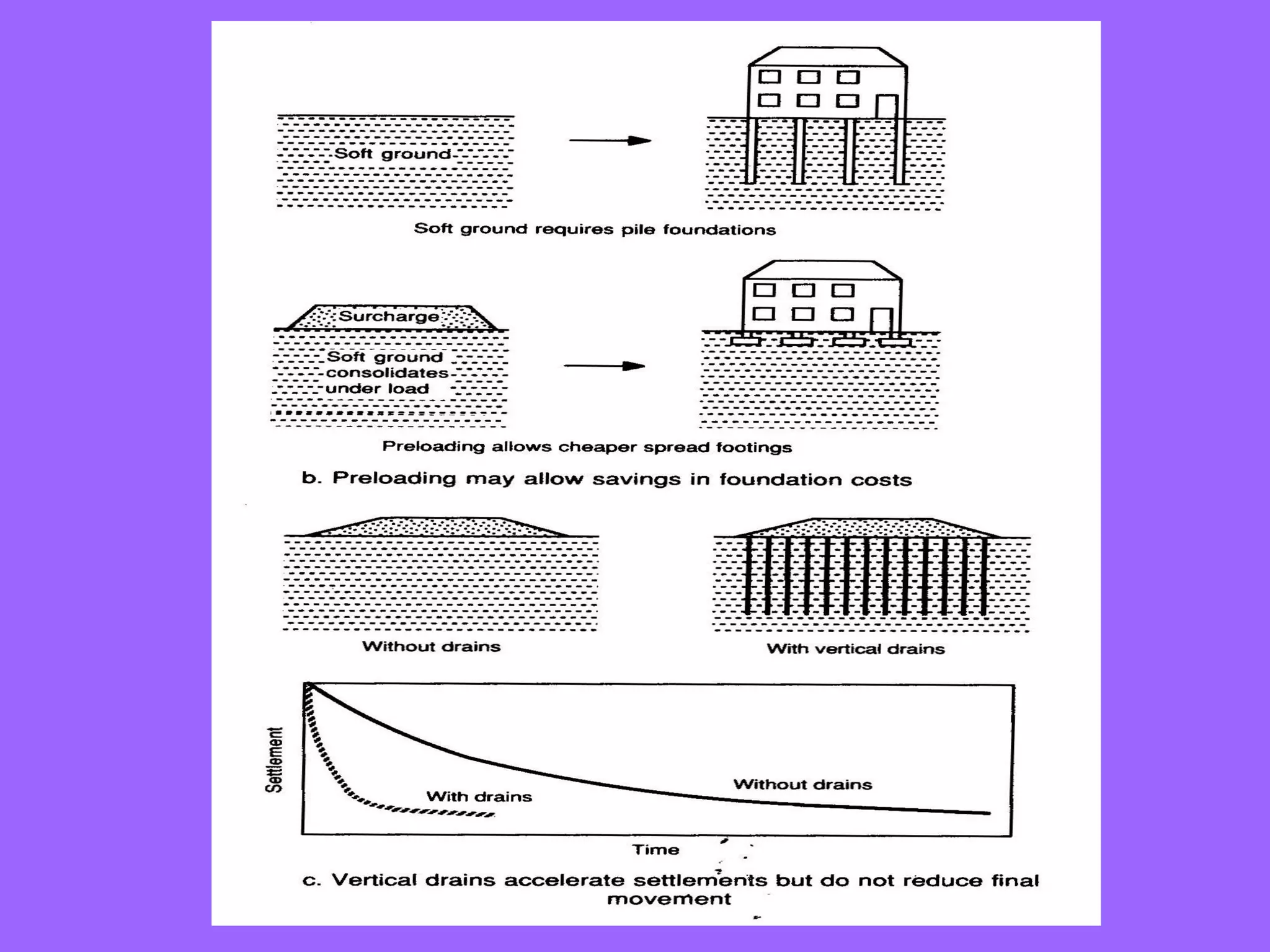

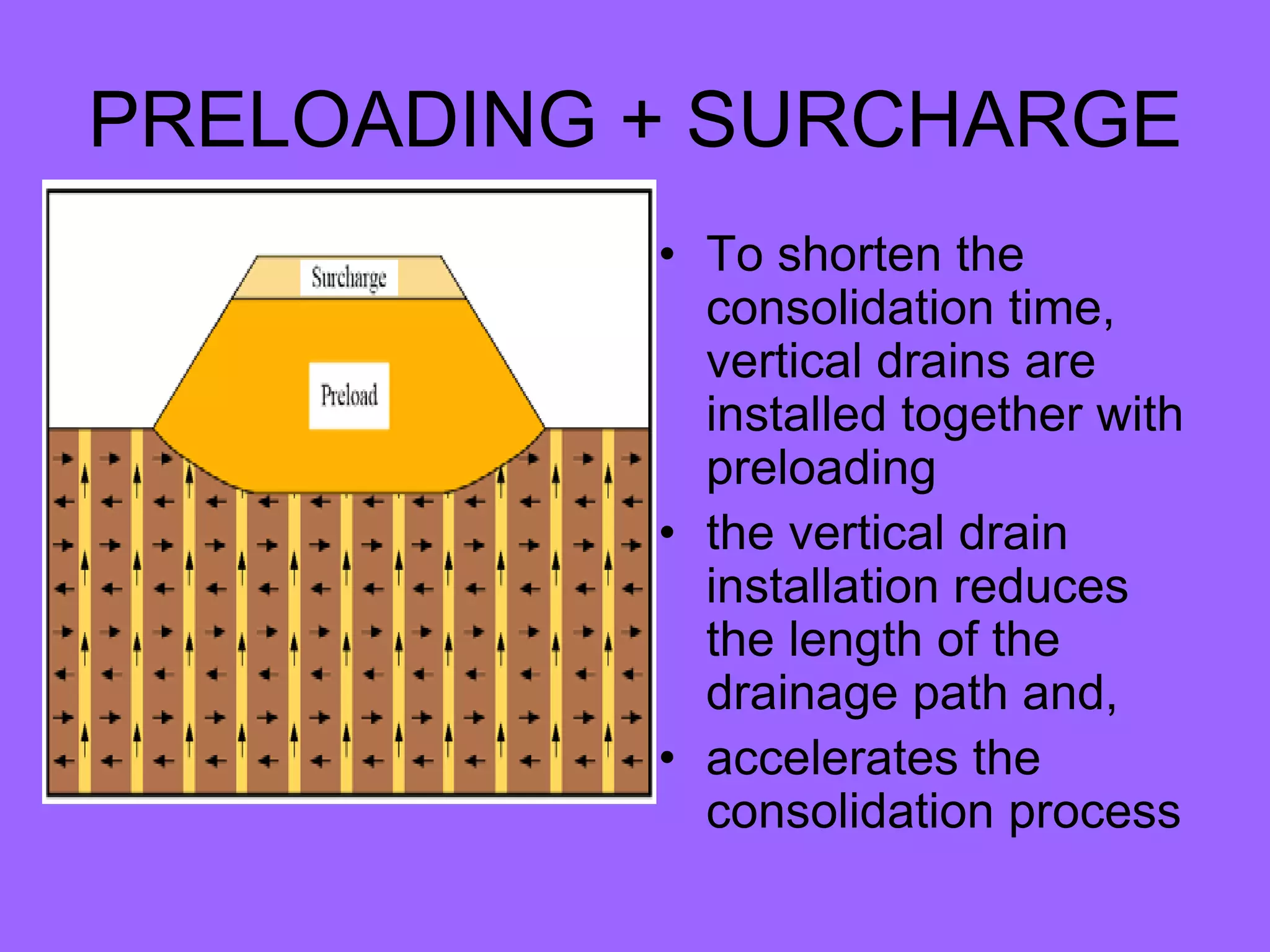

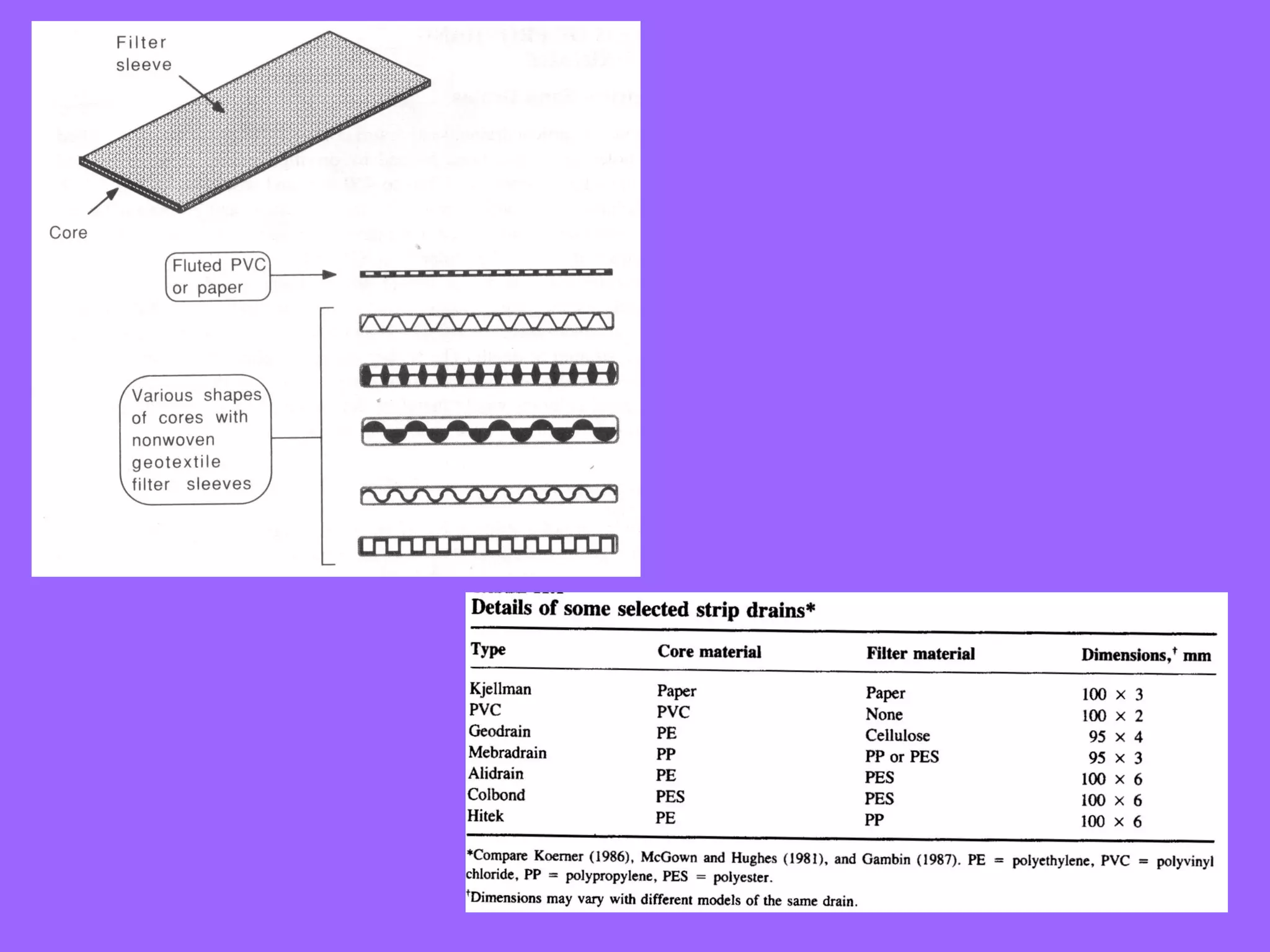

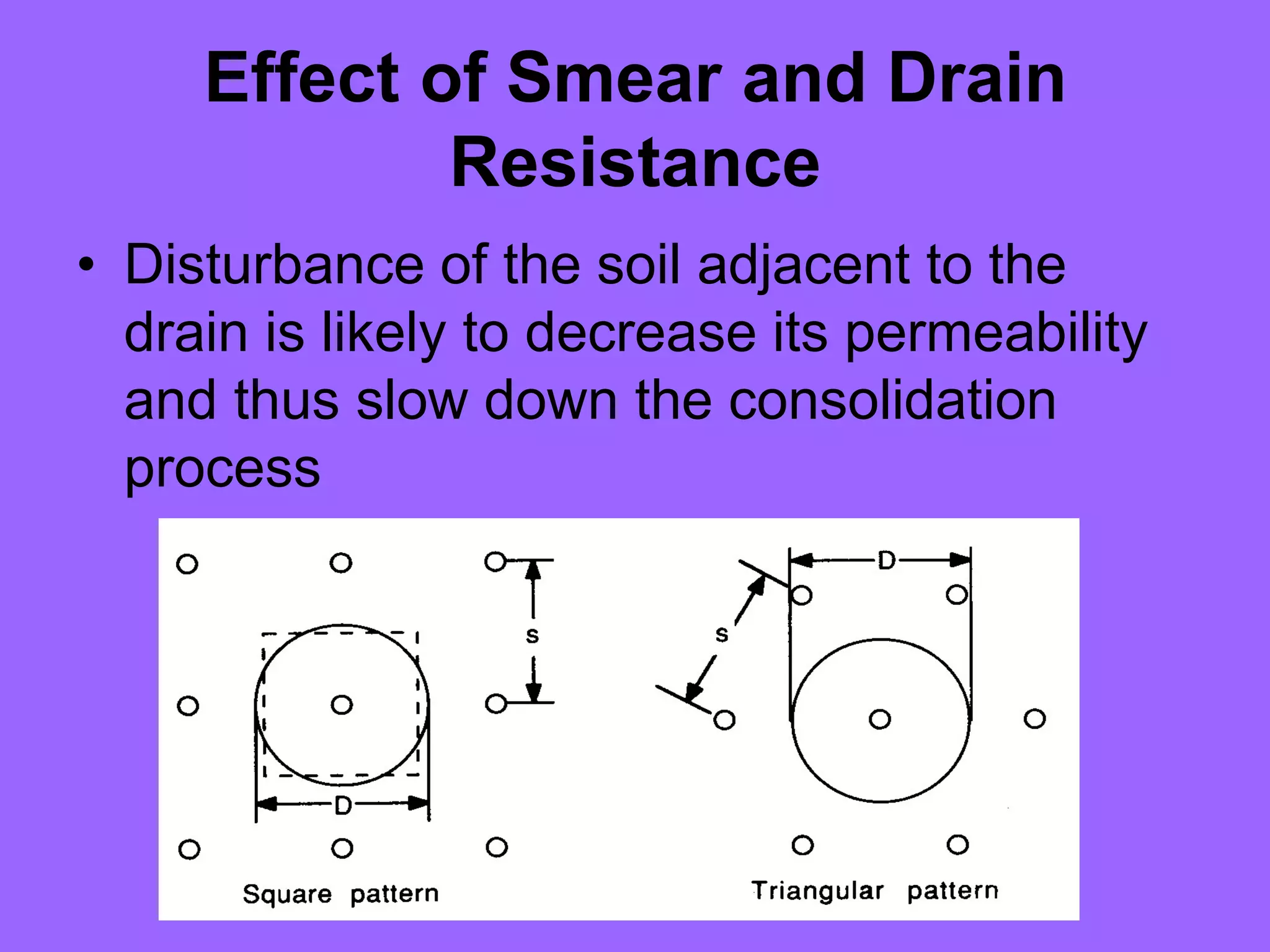

This document discusses different methods for ground improvement (GI), including mechanical, hydraulic, and chemical modification techniques. Mechanical modification techniques aim to densify soils using external forces like compaction. Compaction increases soil strength and reduces compressibility, permeability, and liquefaction potential. Hydraulic modification techniques like dewatering and preloading are used to modify ground conditions by lowering the water table or accelerating consolidation. Preloading combined with vertical drains can shorten consolidation time in fine-grained soils. The document provides examples of different compaction and ground improvement equipment and methods.