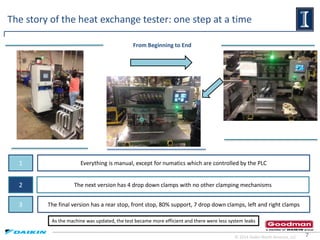

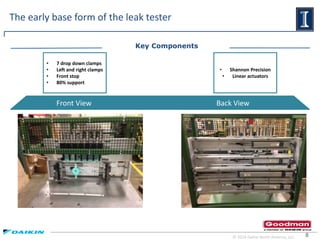

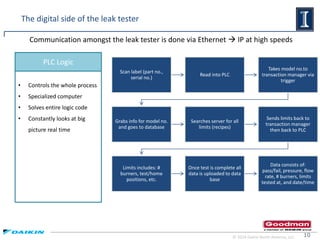

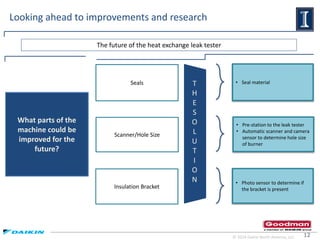

Jeremy French completed a controls engineering internship at Goodman Manufacturing where he worked on various projects including HMIs, control panels, and a heat exchange leak tester. Over the course of the internship, he learned how to troubleshoot machinery issues, input questions to problems, and saw improvements to the leak tester to make the testing process more efficient with fewer leaks. The leak tester uses pneumatics, a PLC, HMI, and control panel to automatically clamp units, conduct tests by measuring pressure and flow, and send results to a database. Potential future improvements include updating seals, adding automatic scanning, and sensors to check for insulation brackets.