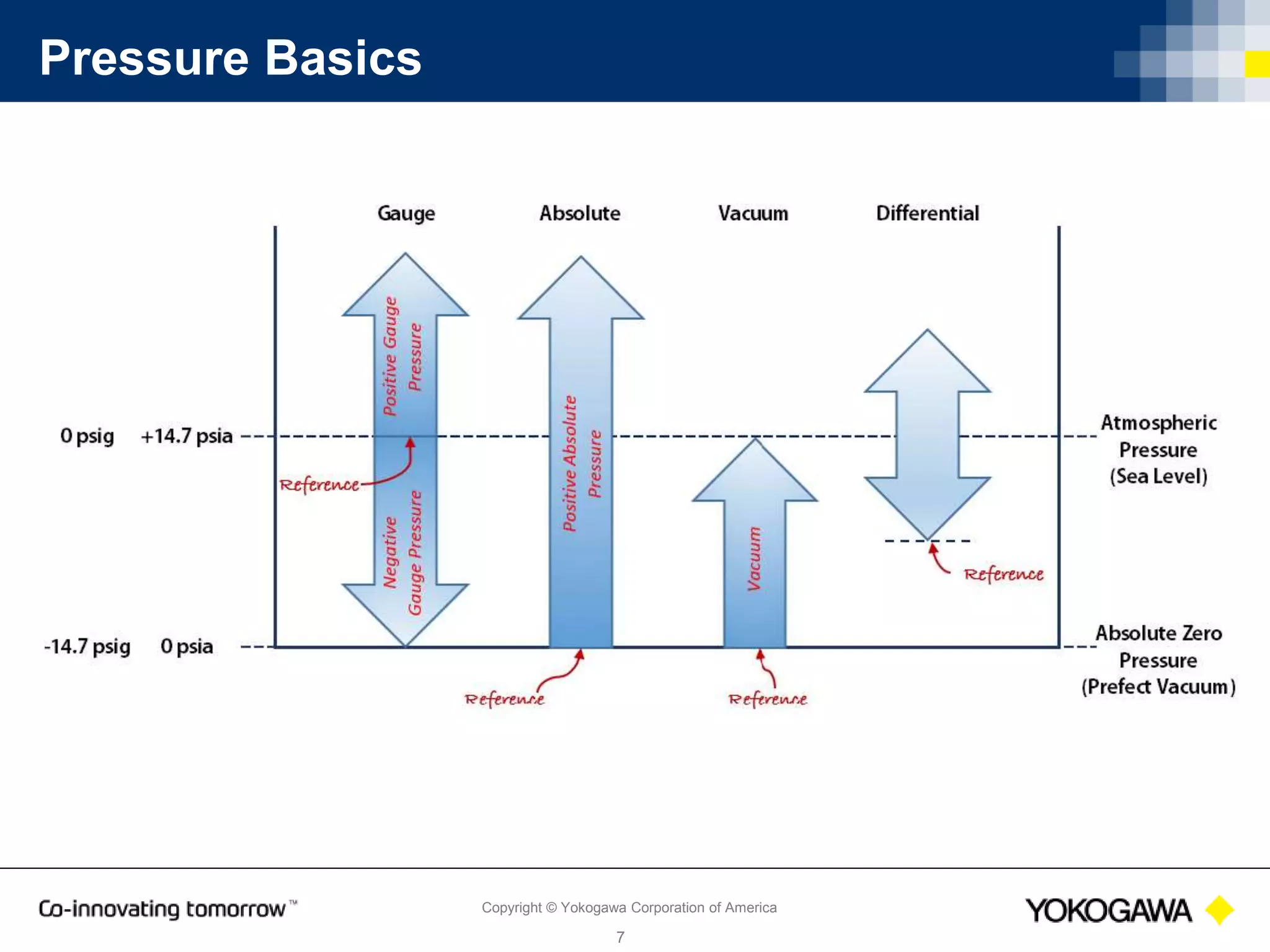

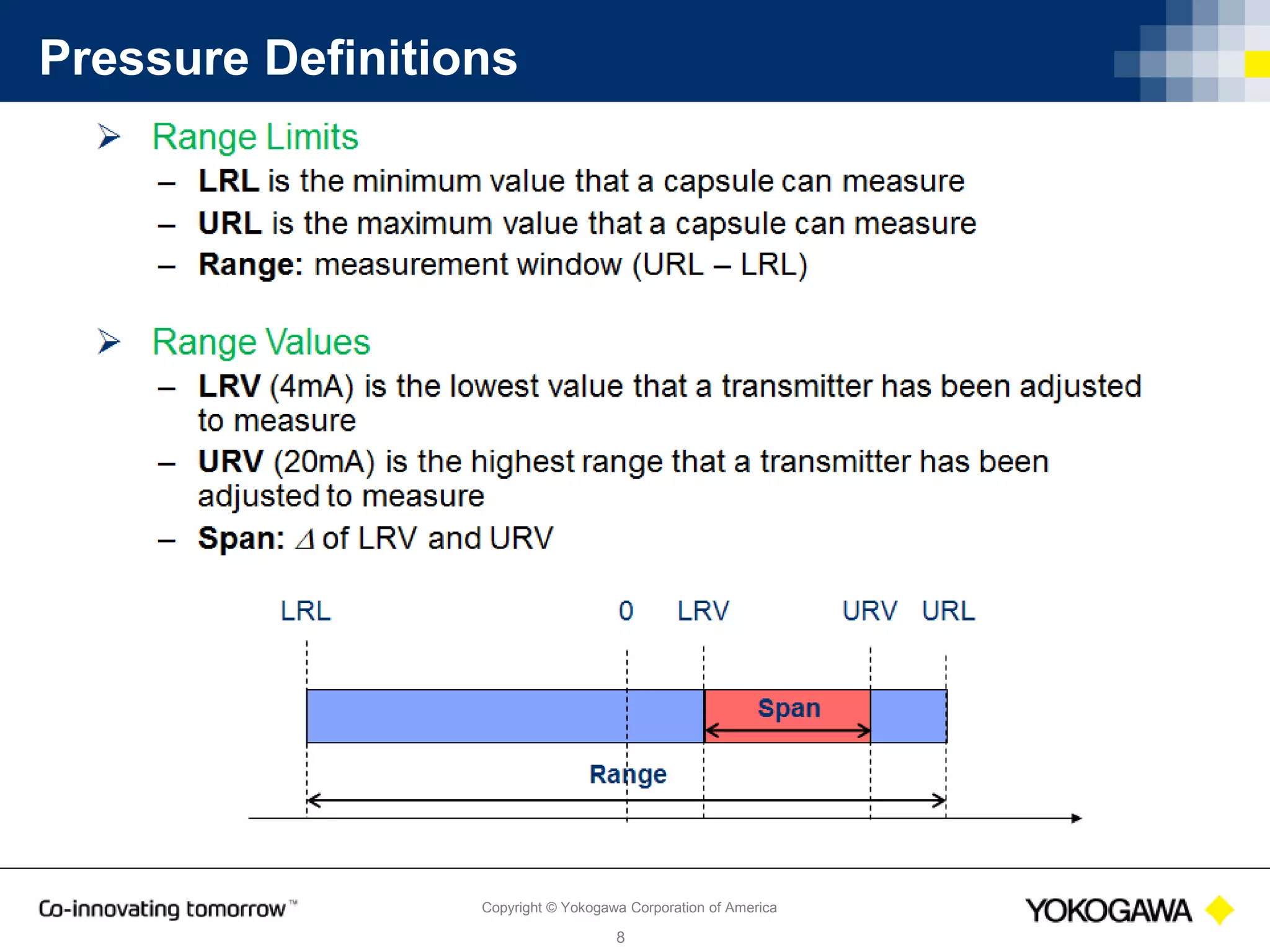

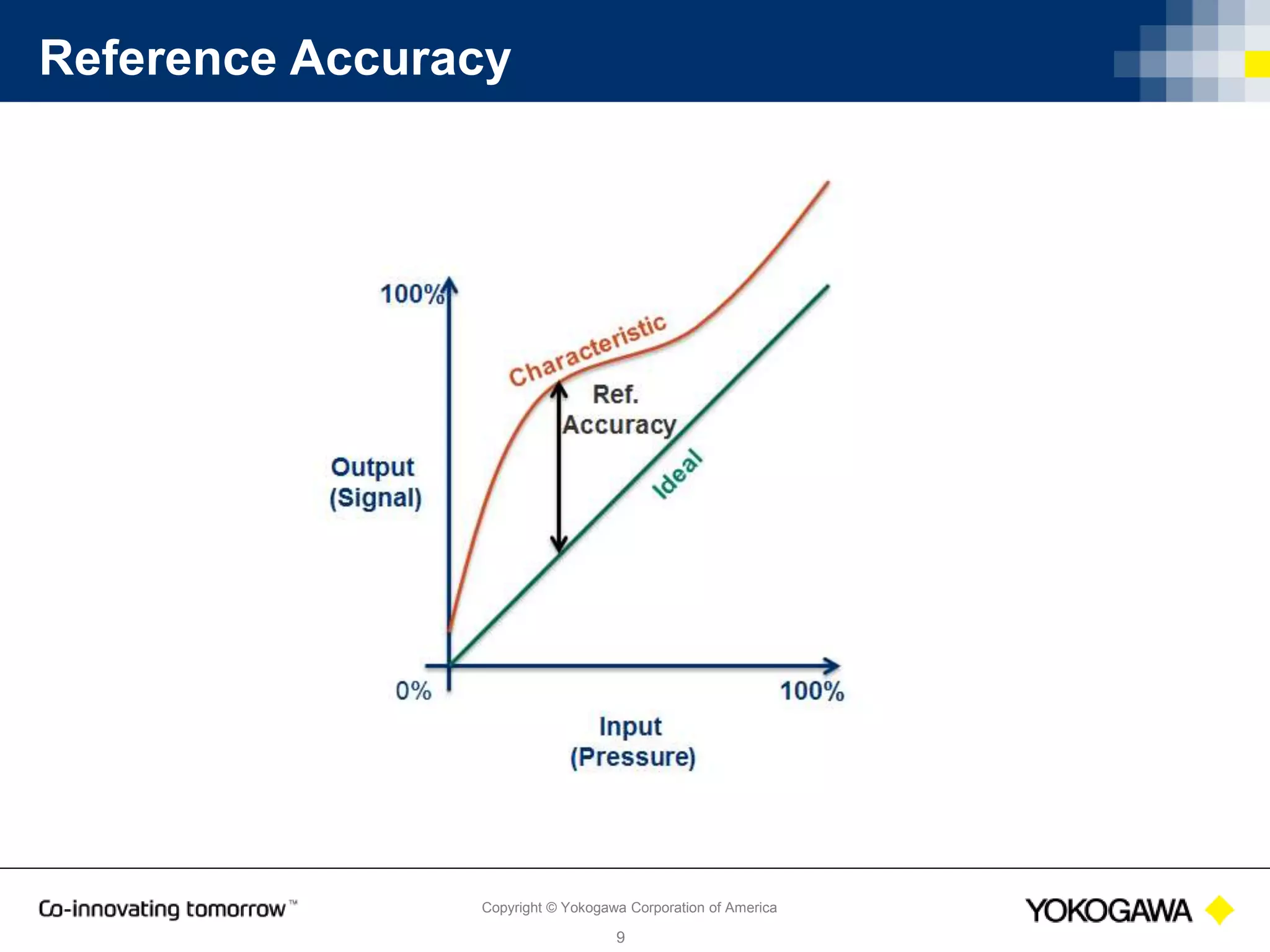

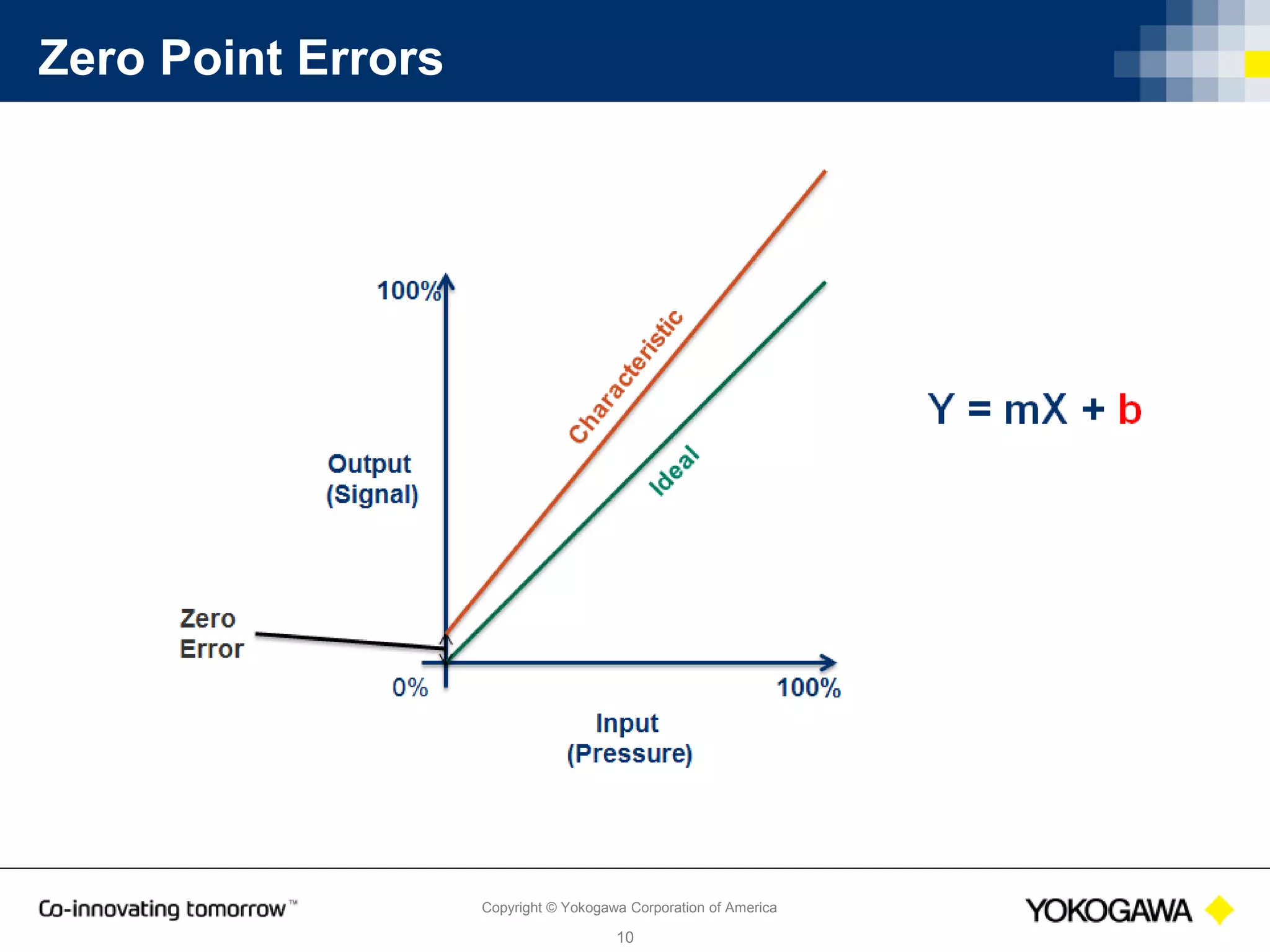

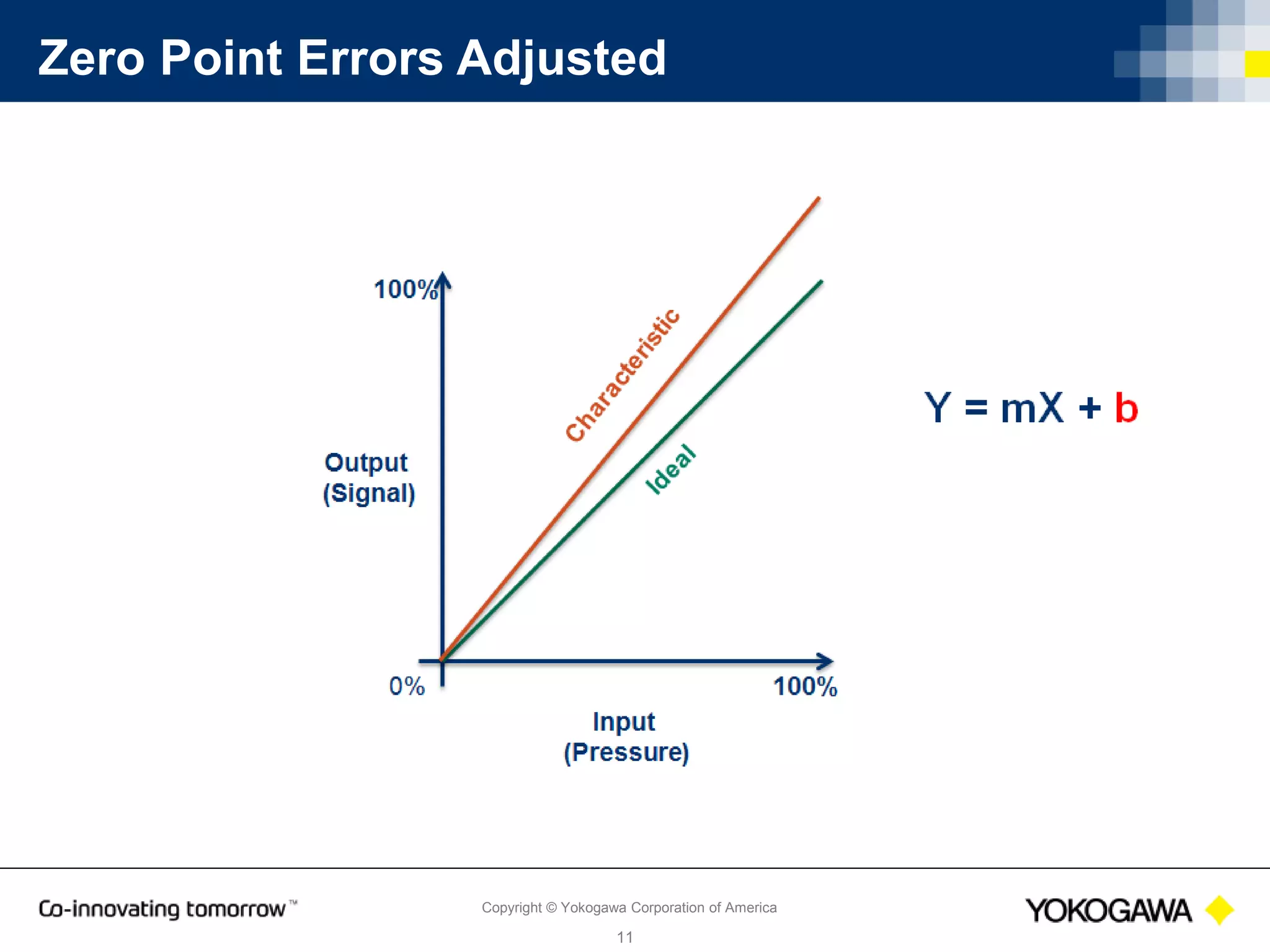

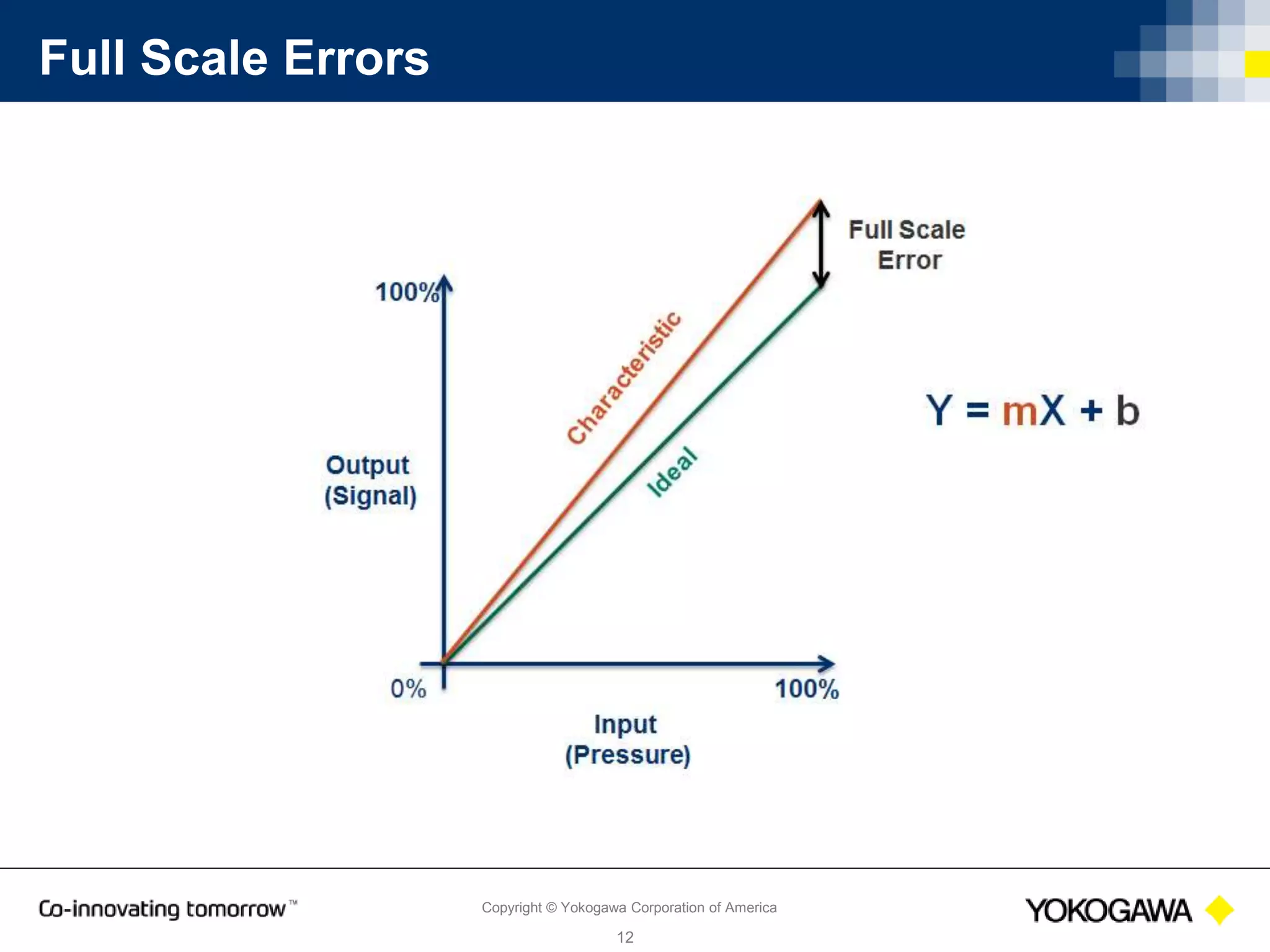

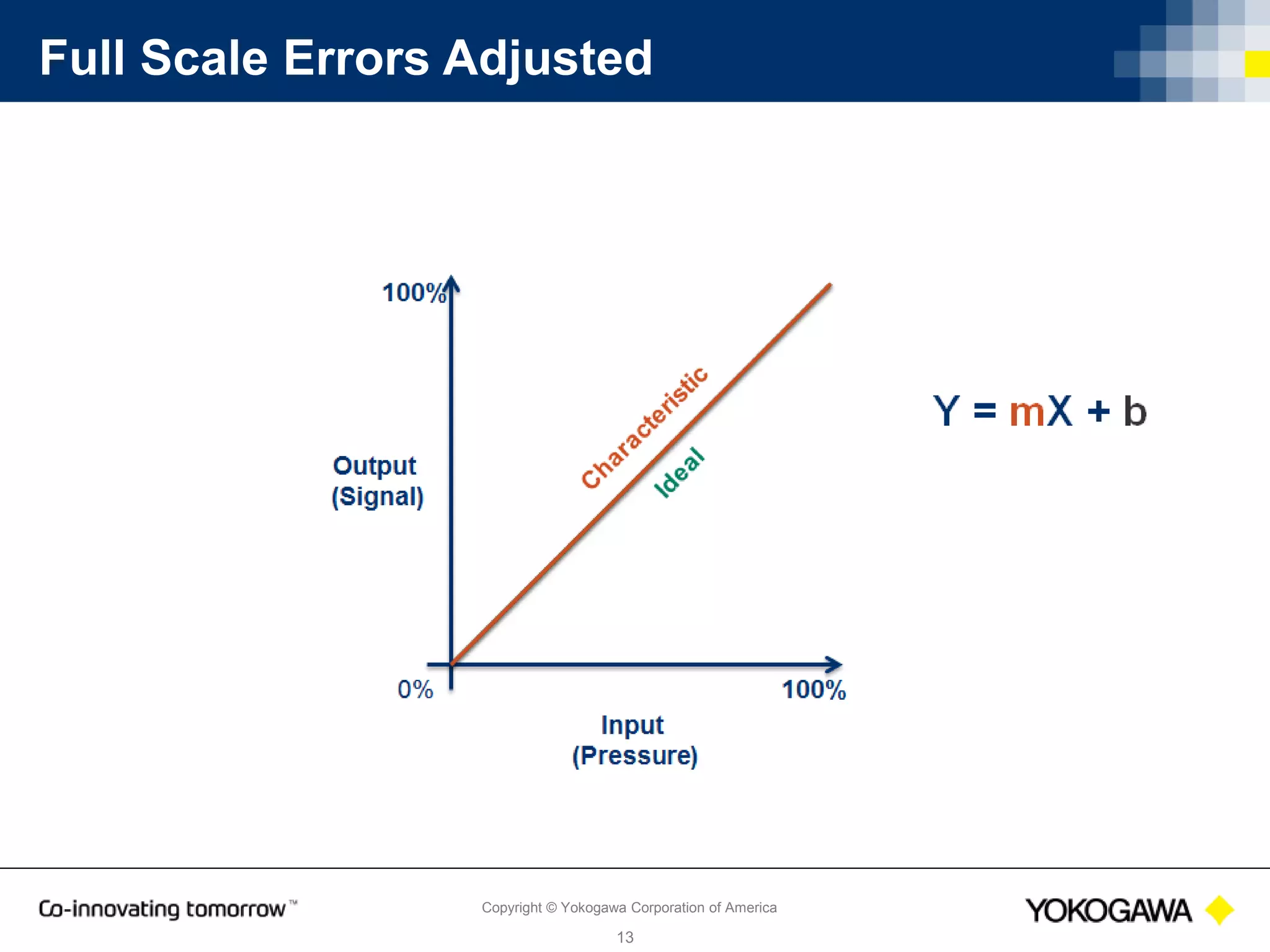

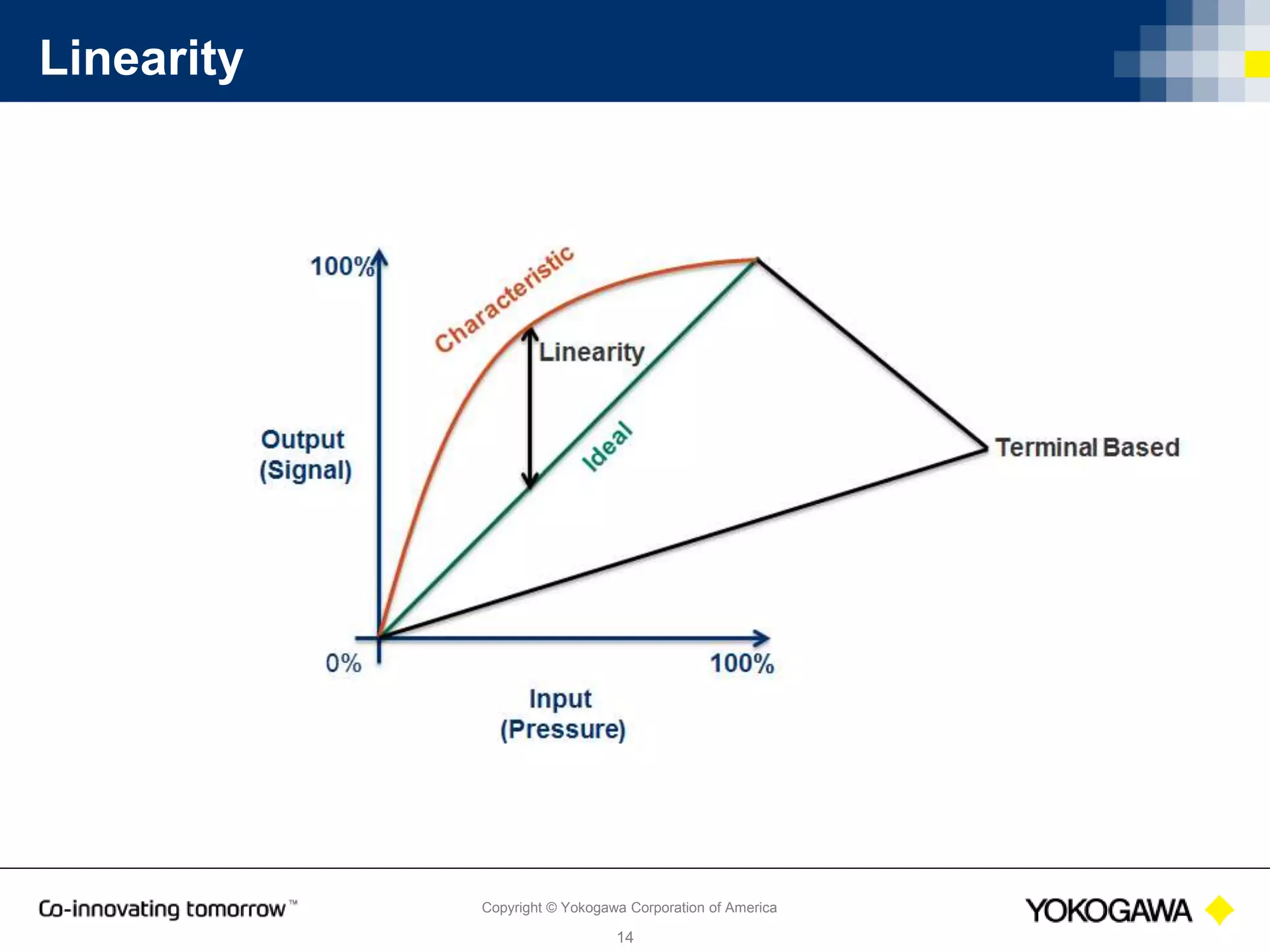

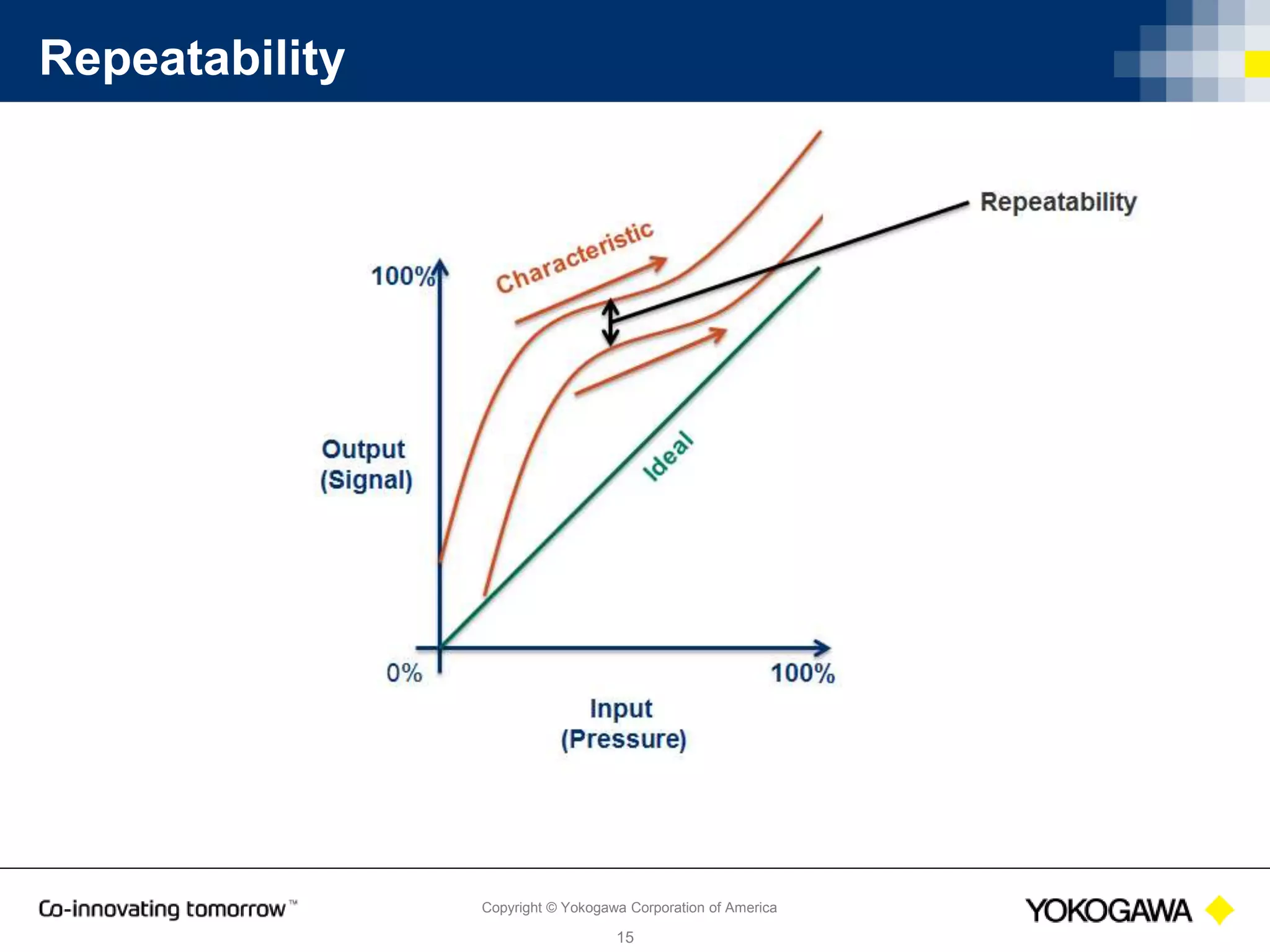

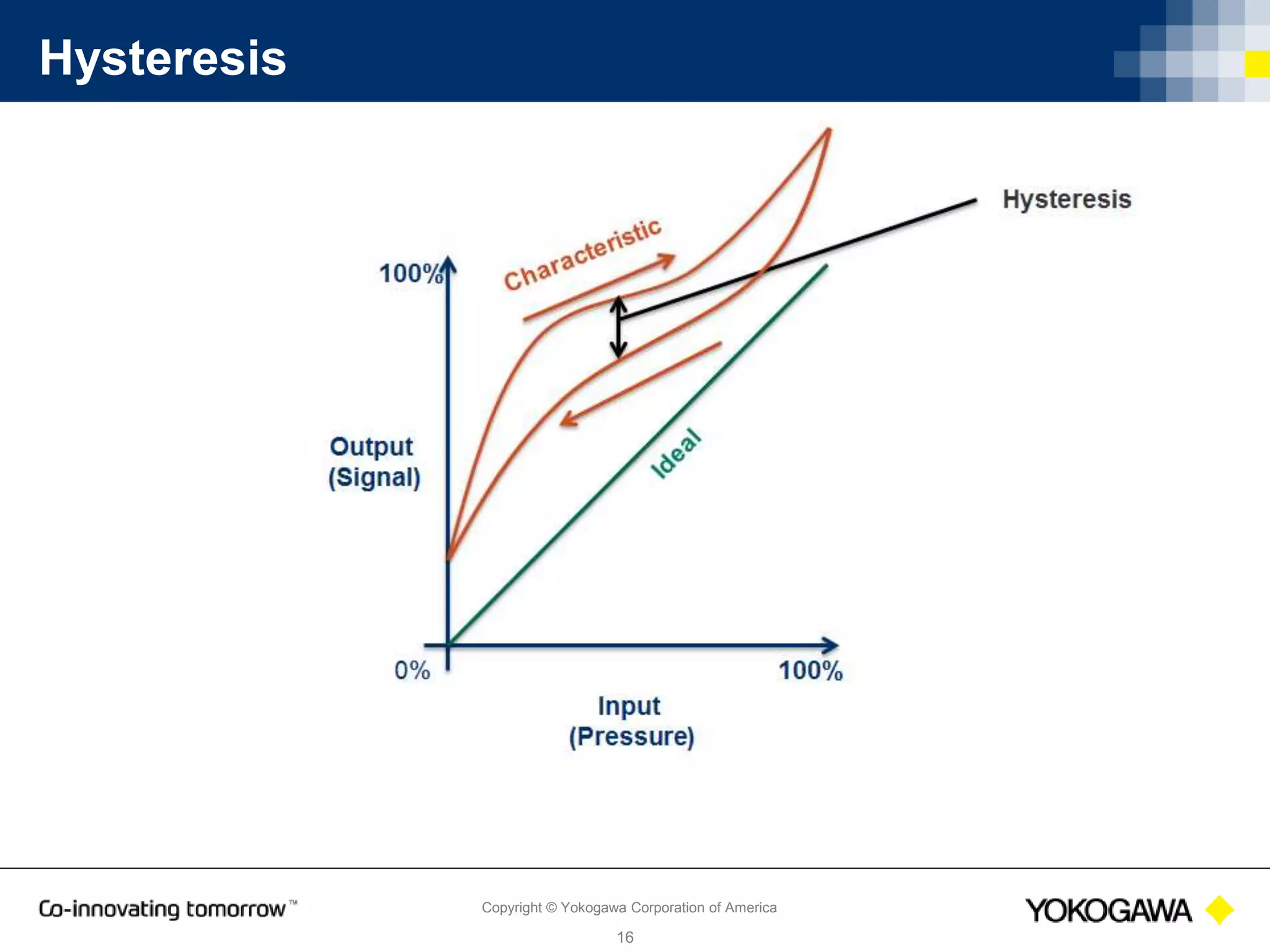

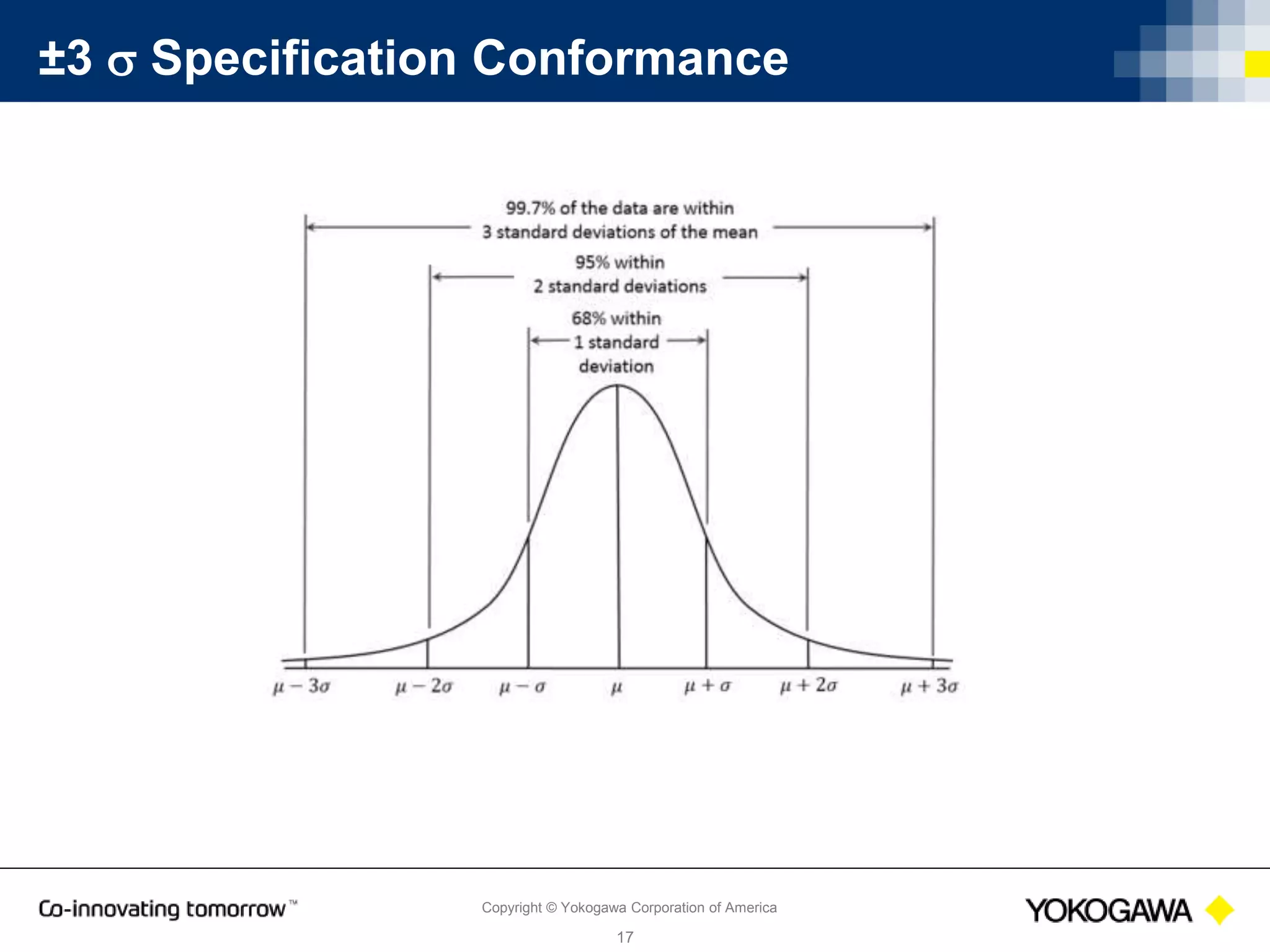

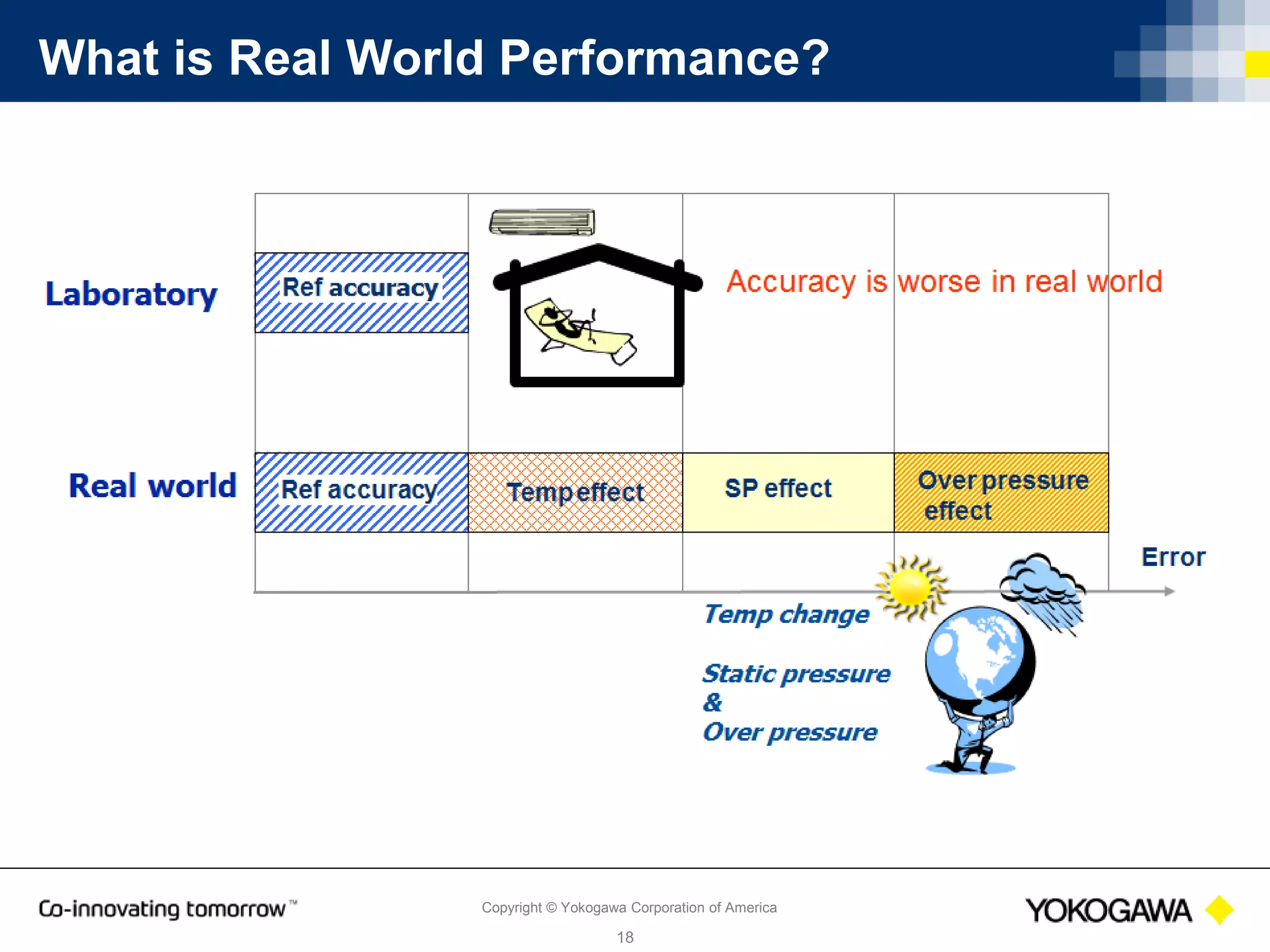

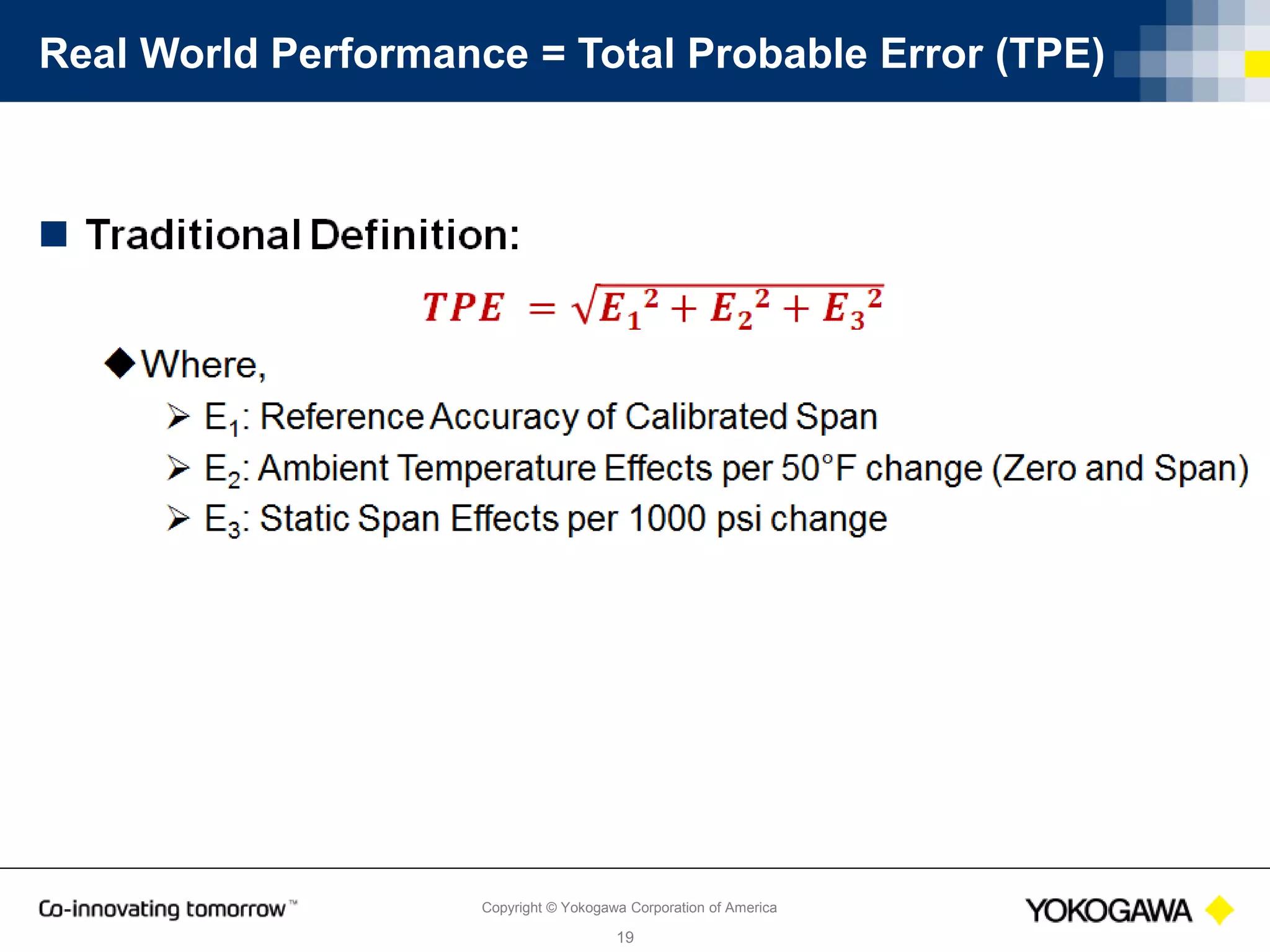

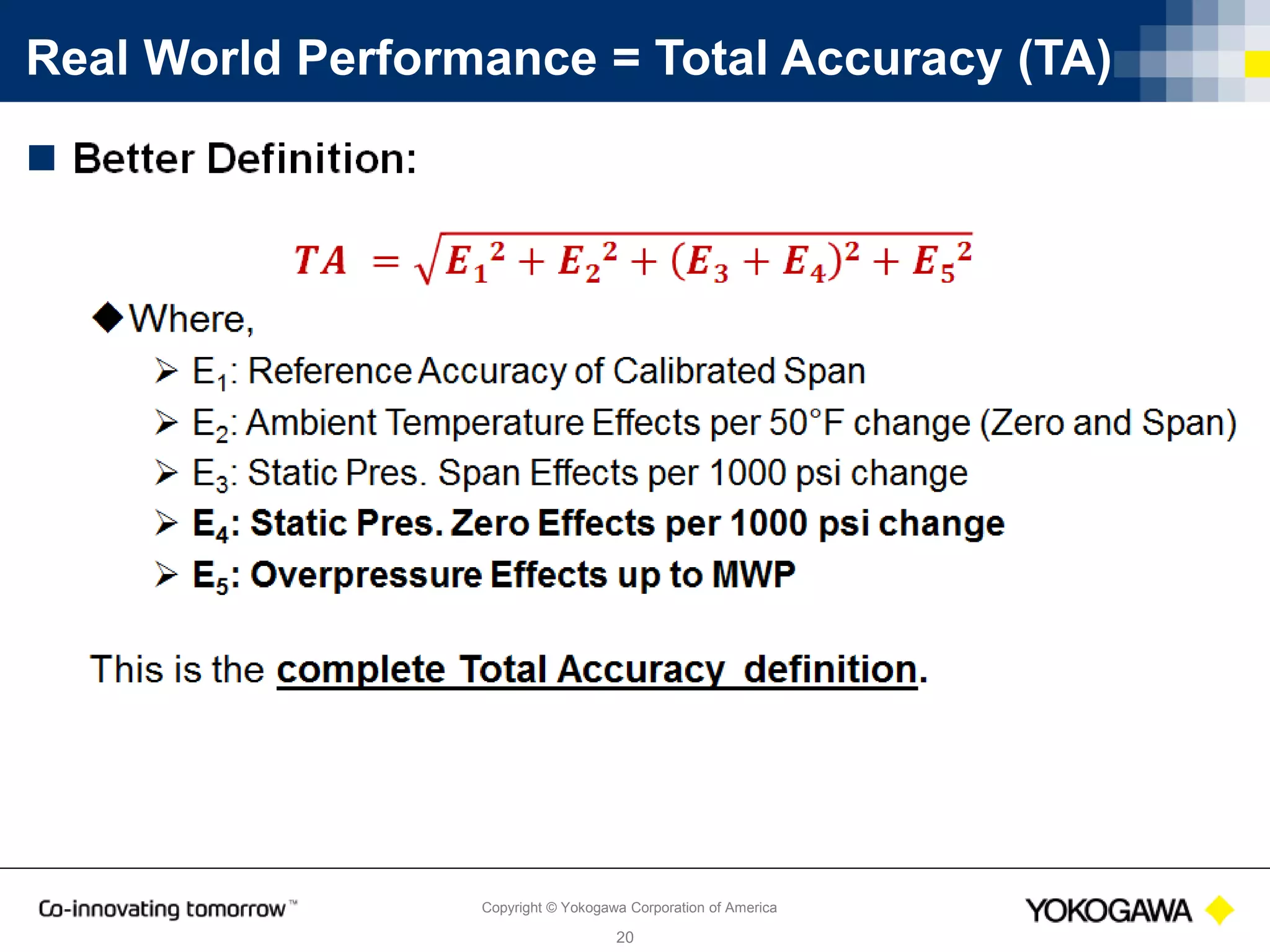

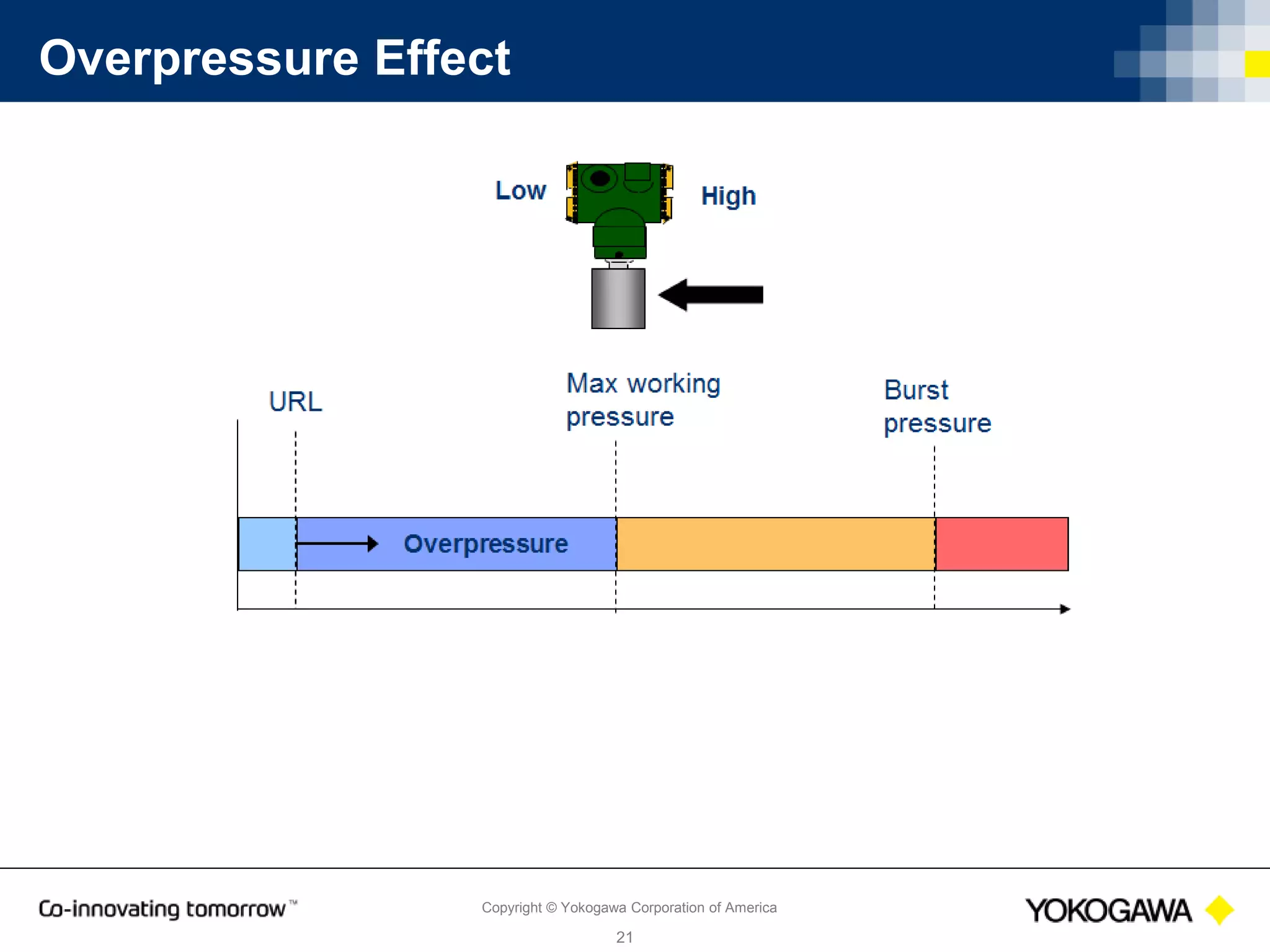

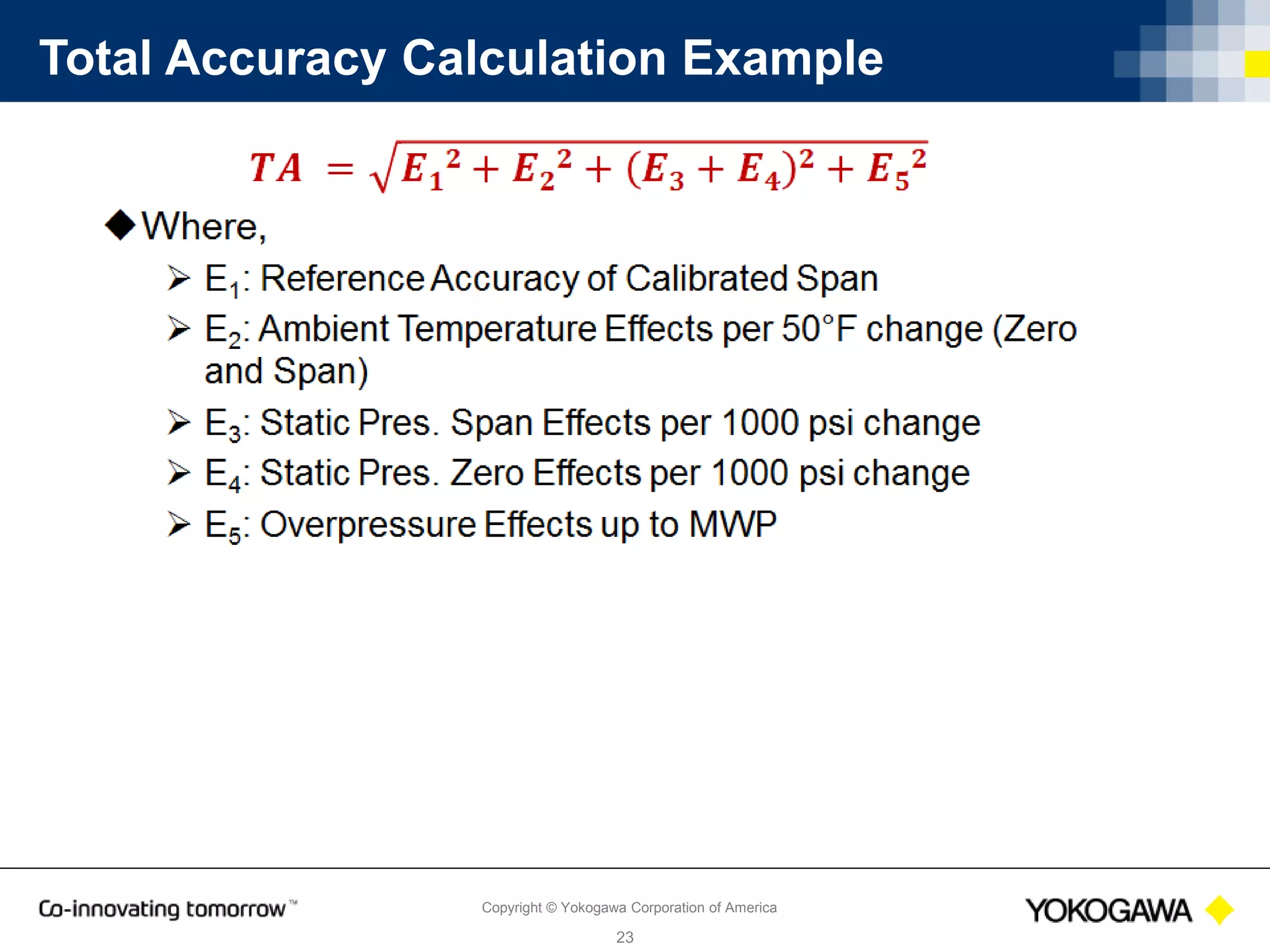

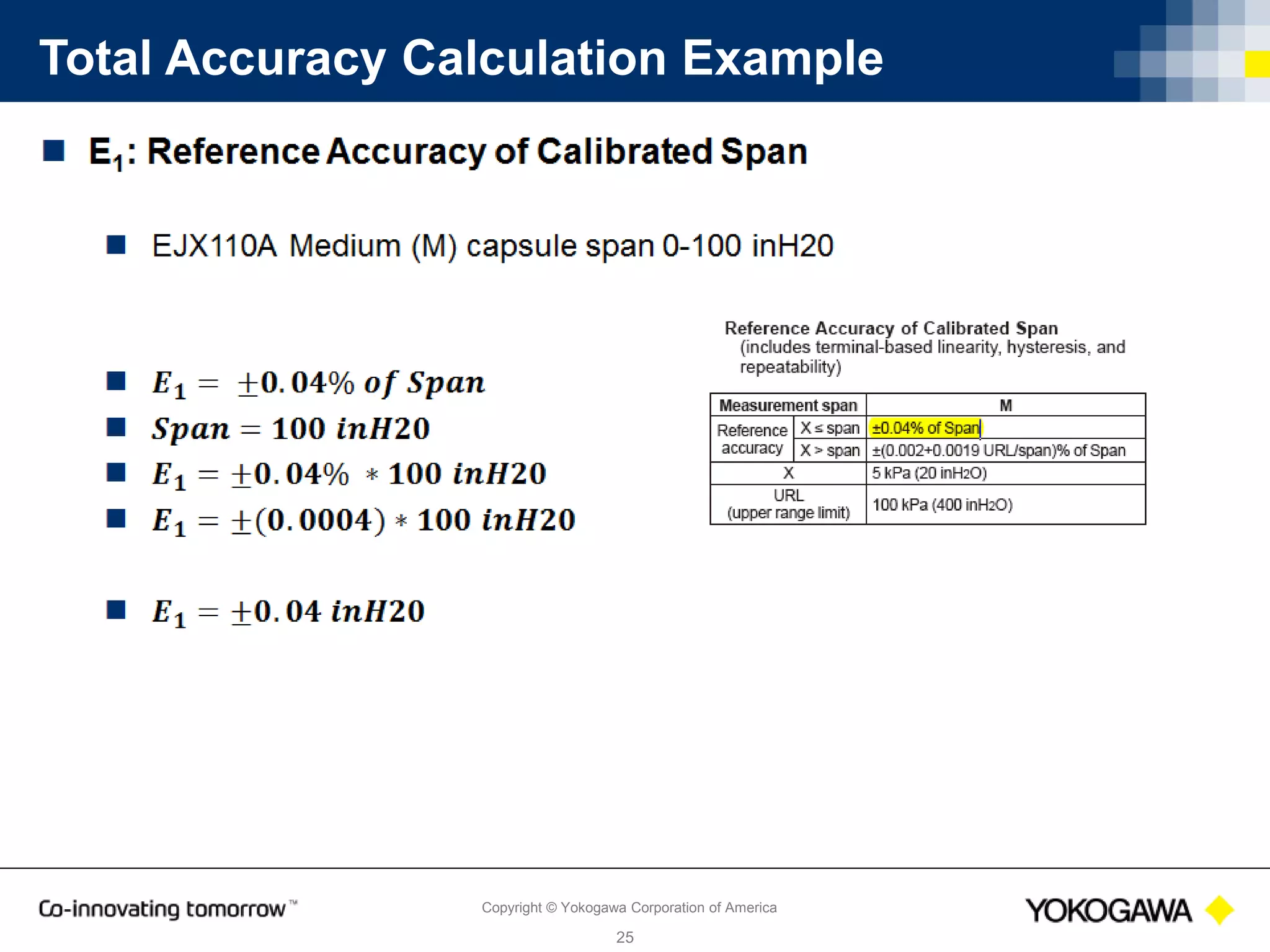

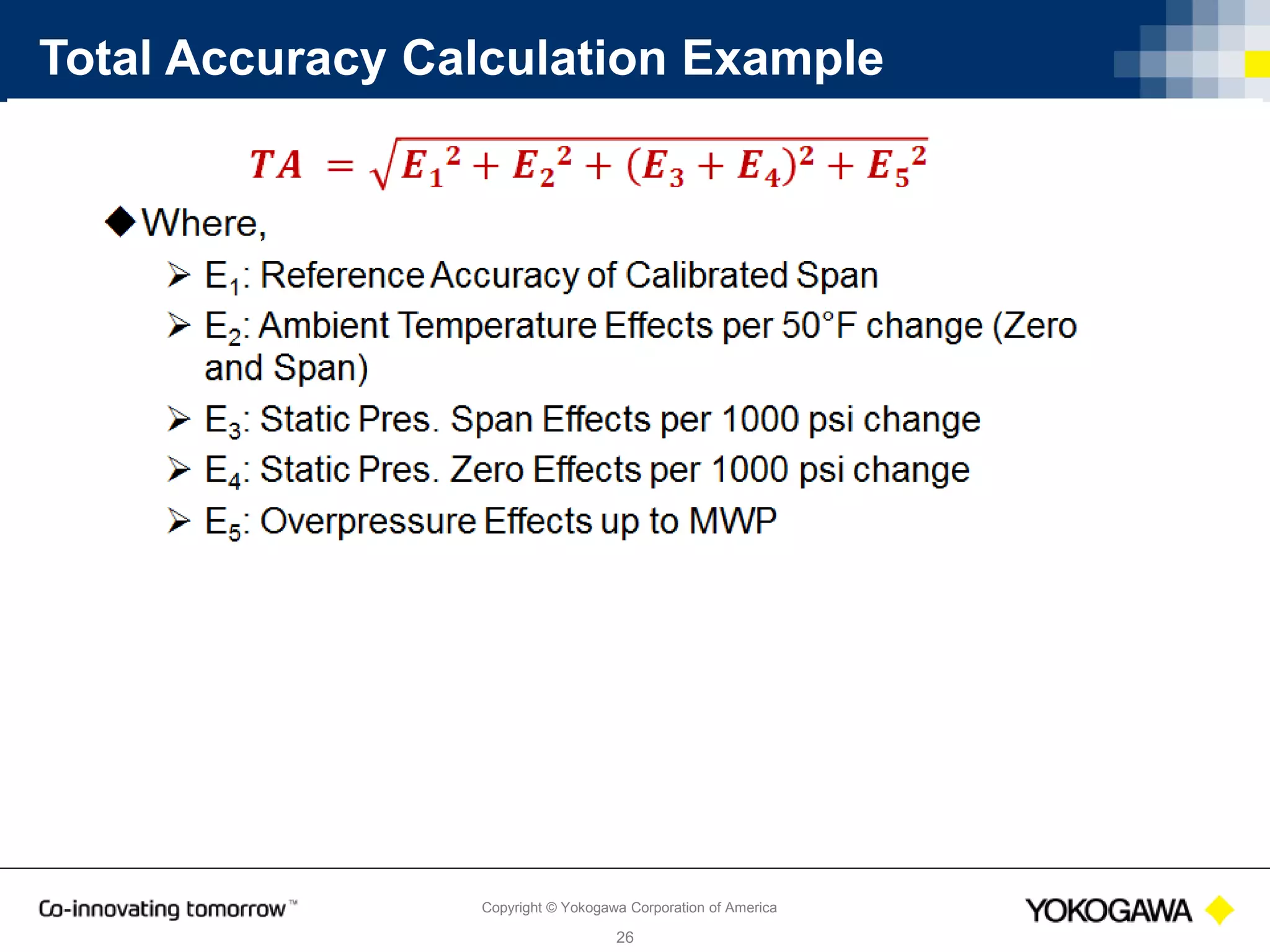

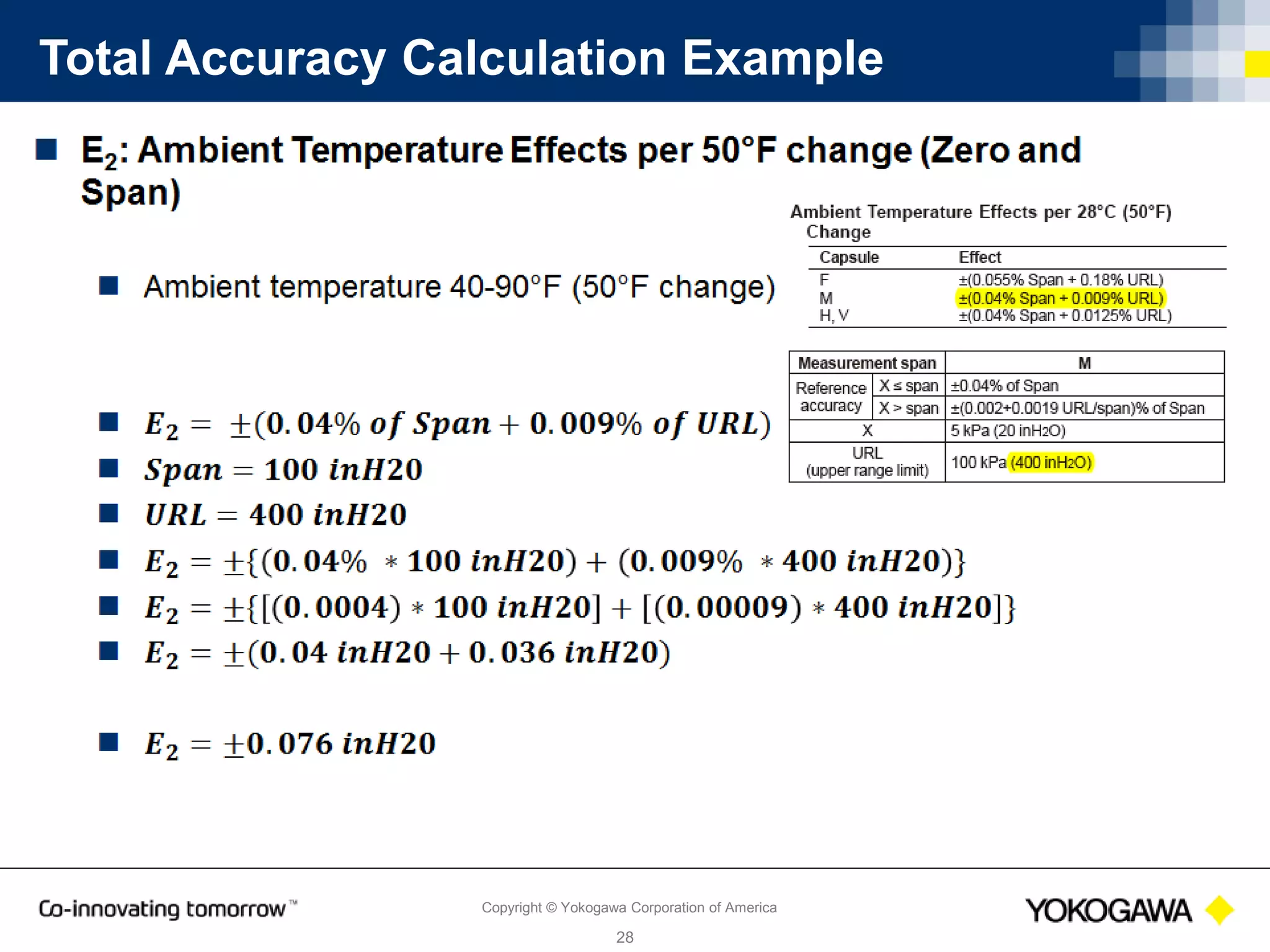

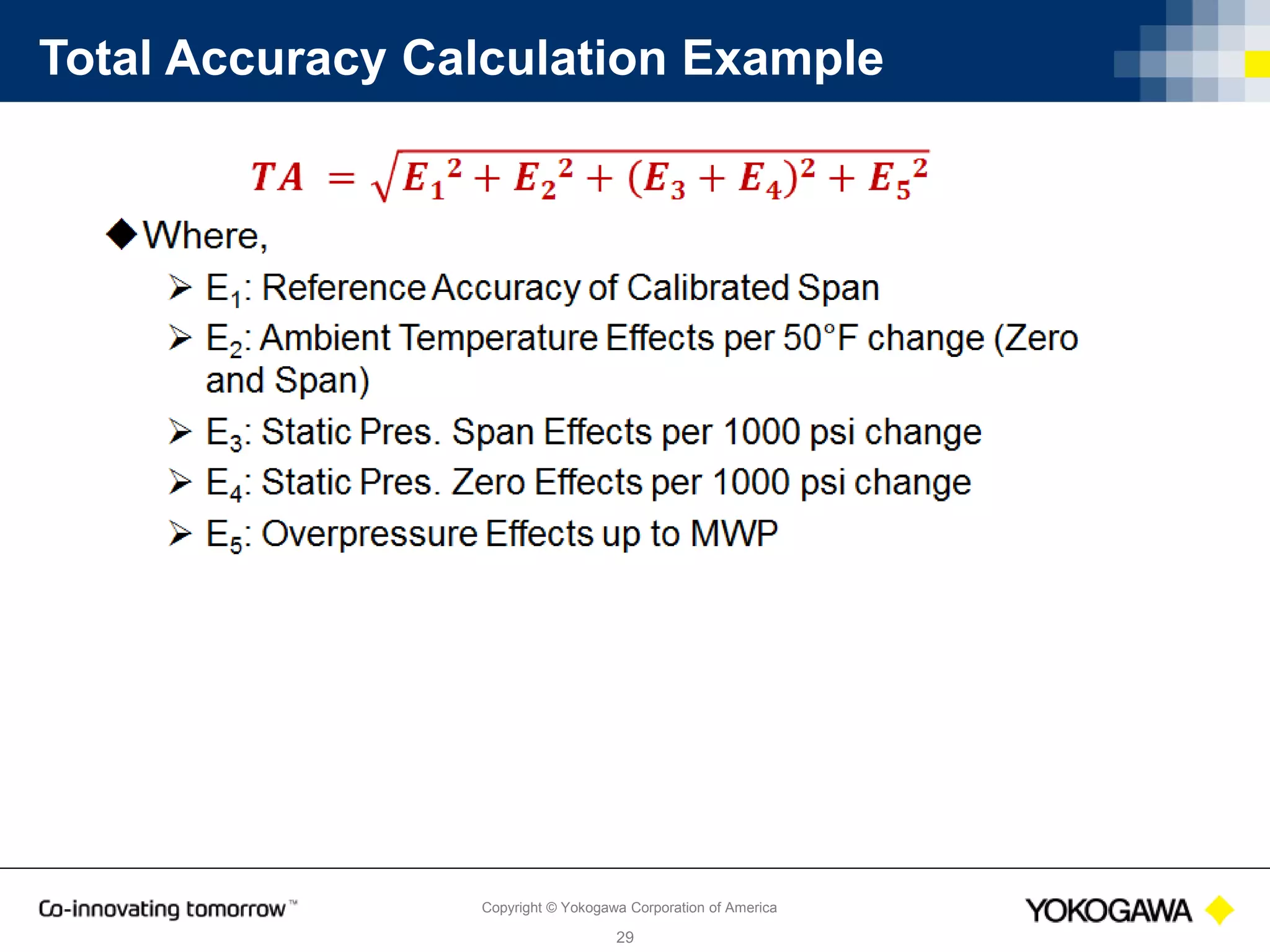

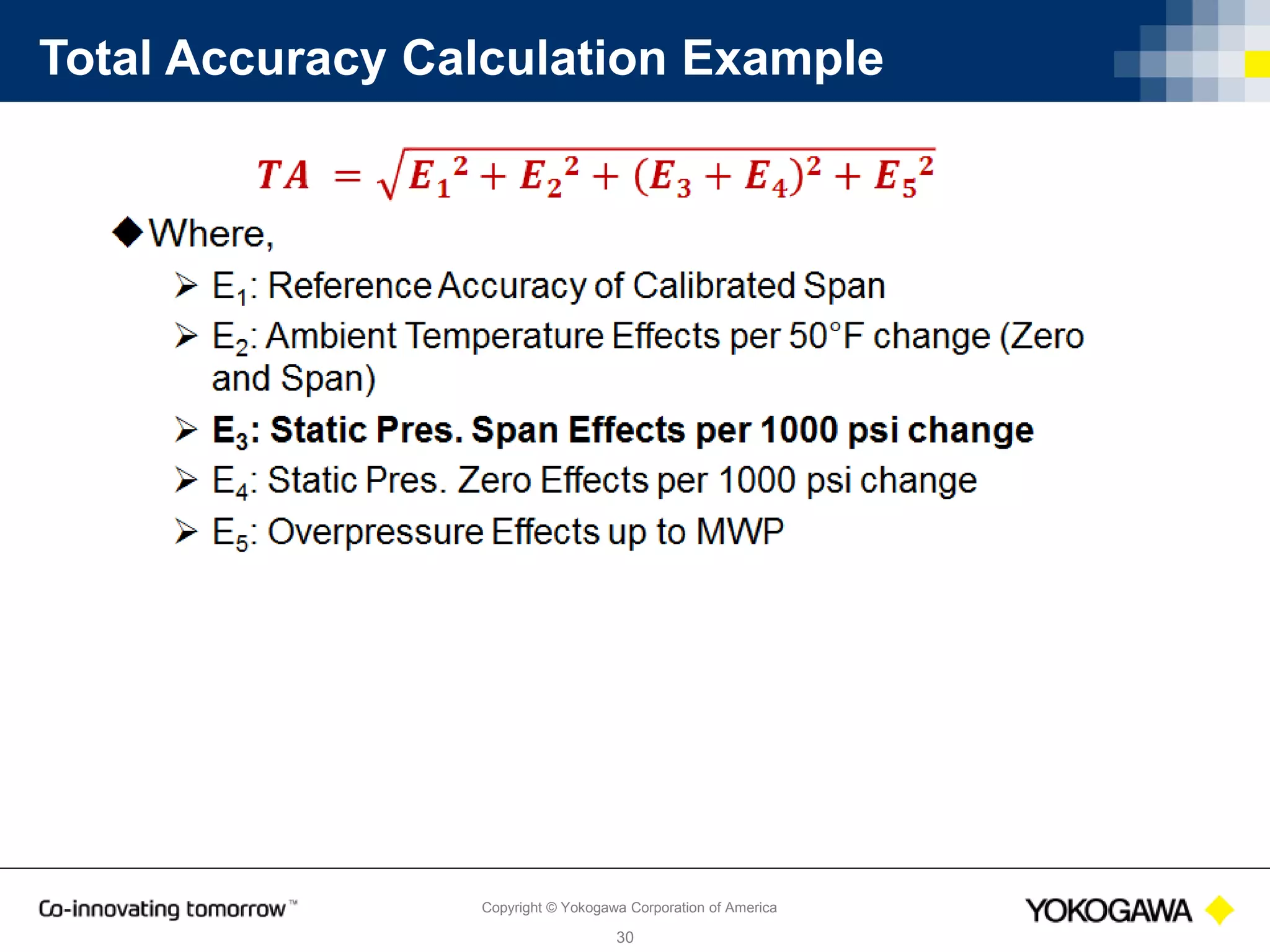

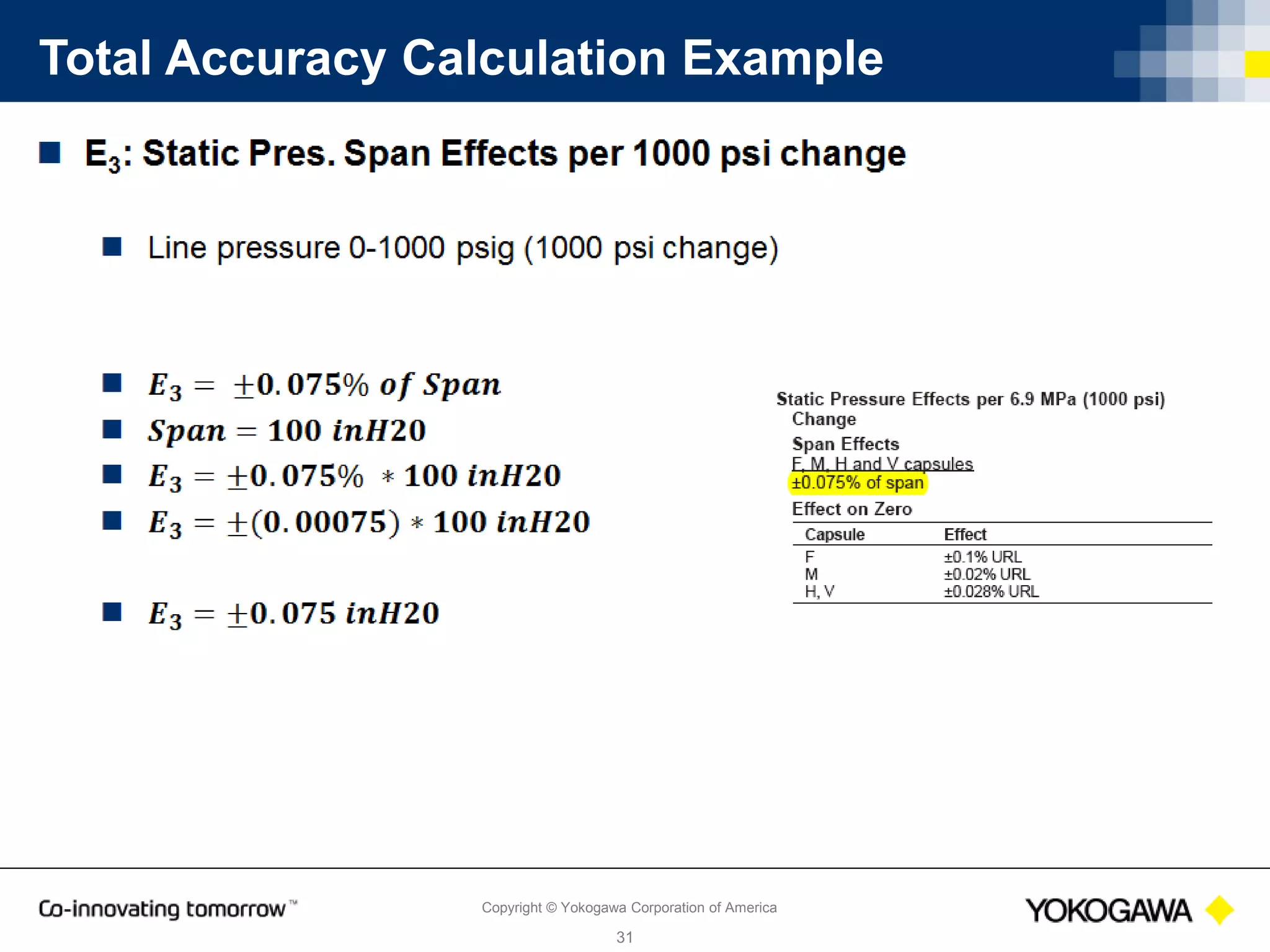

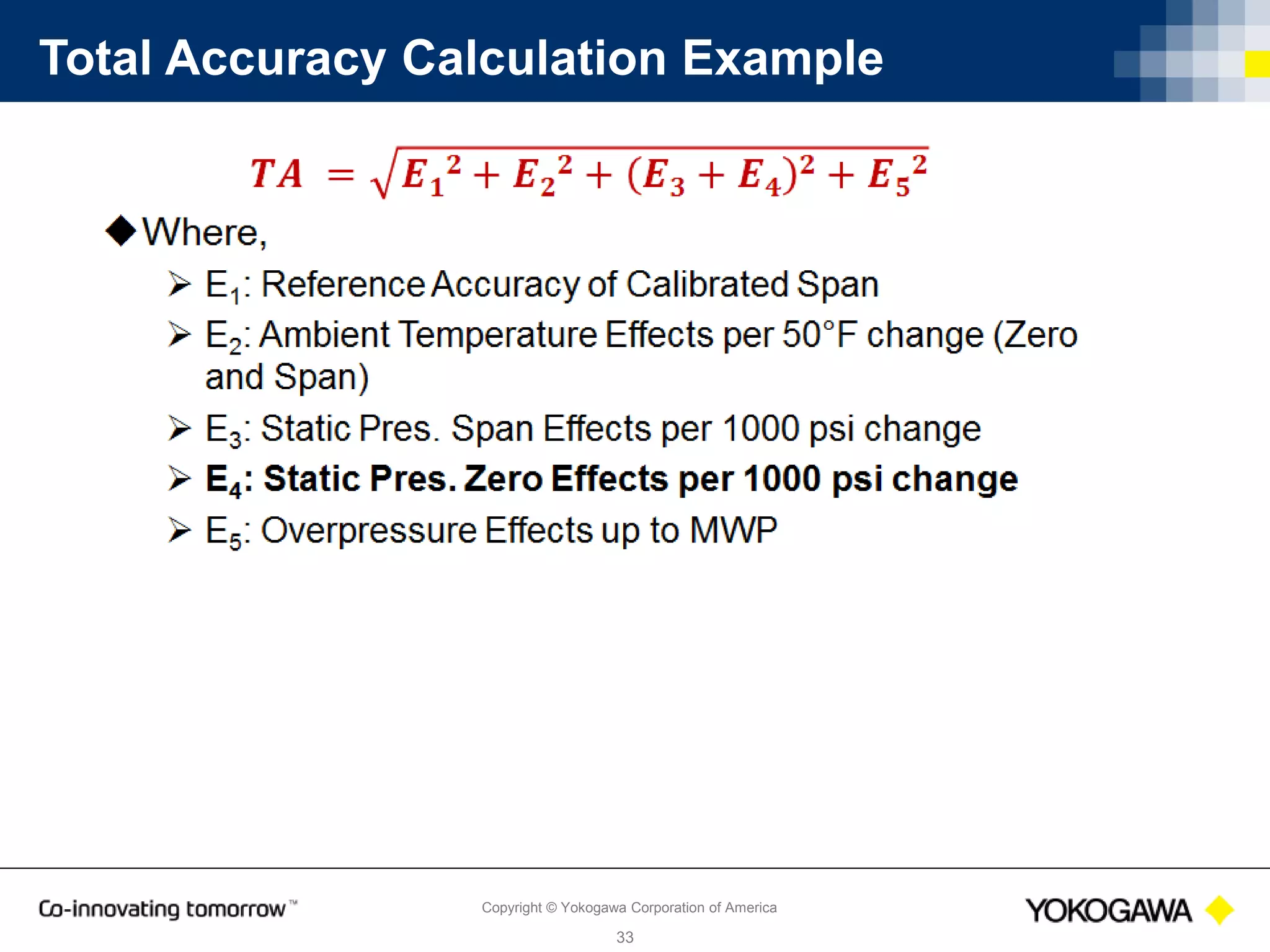

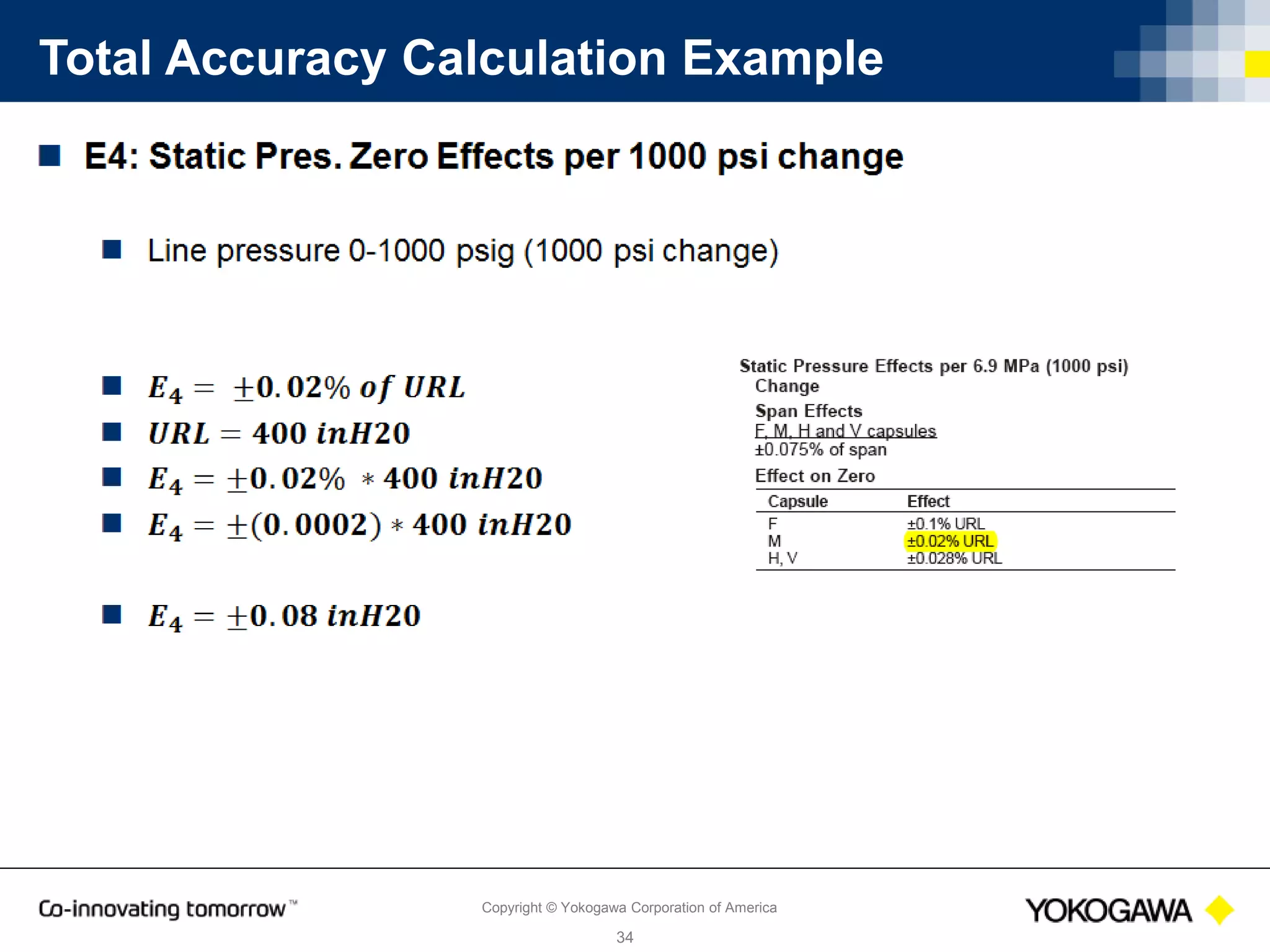

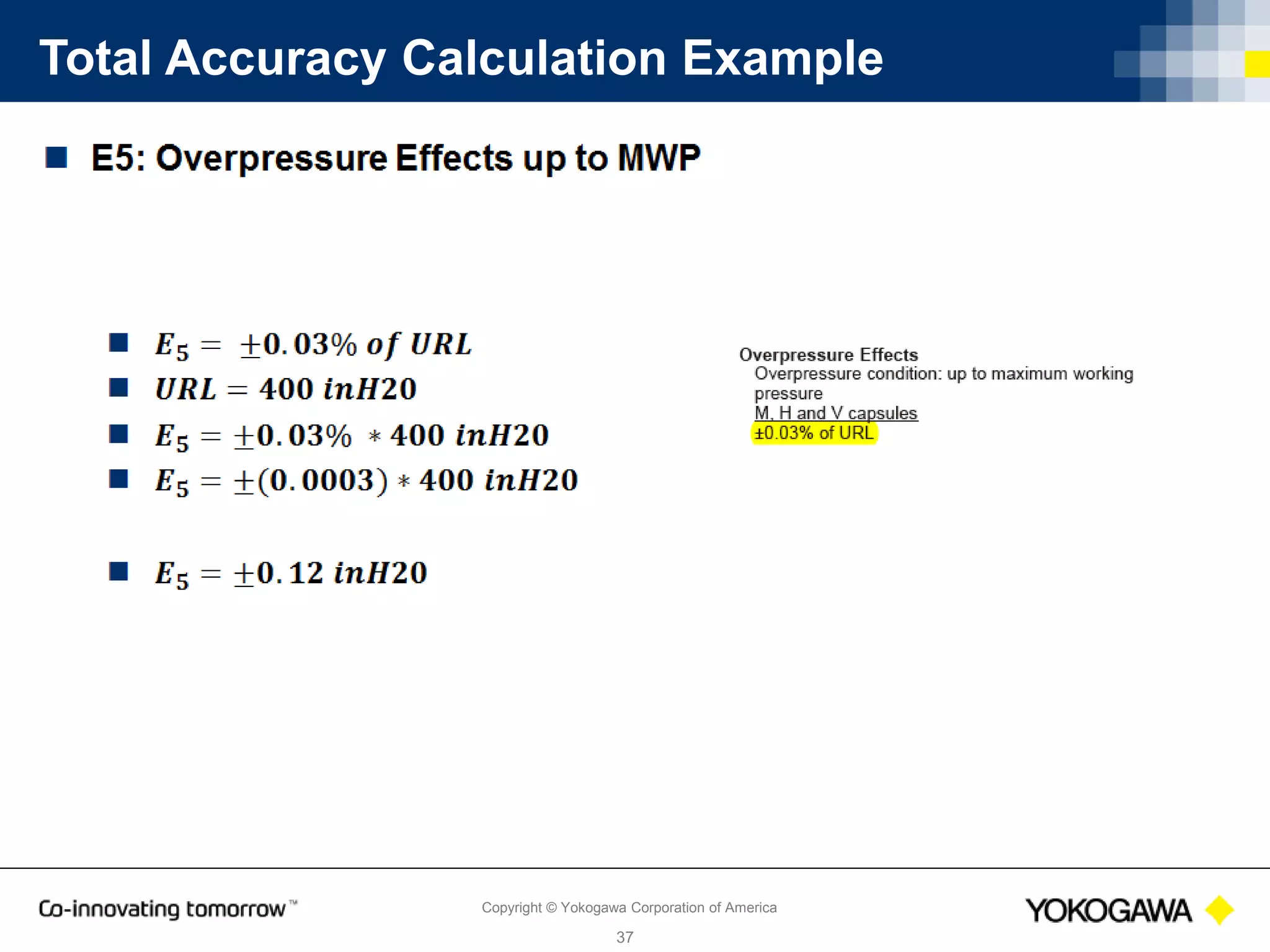

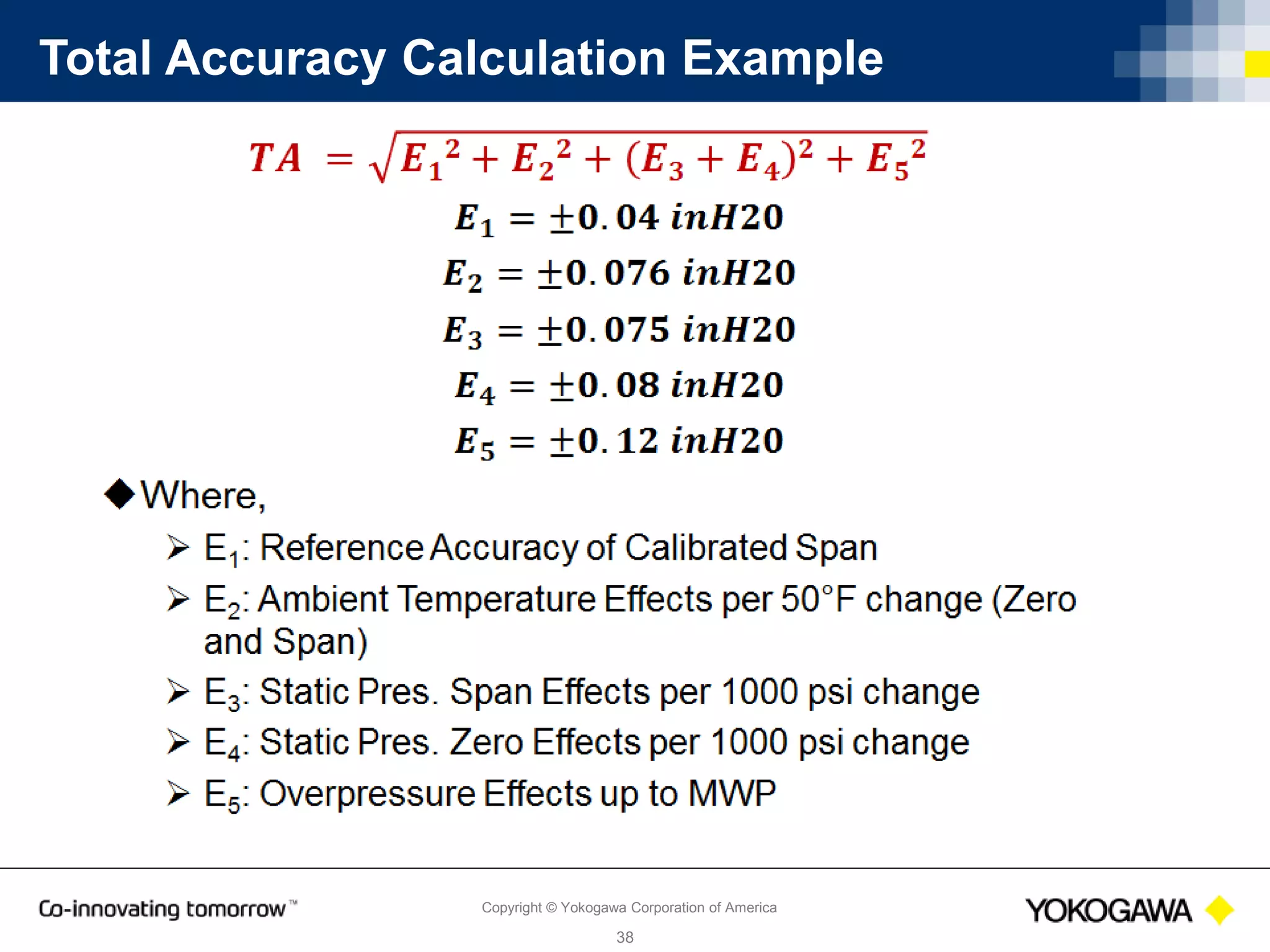

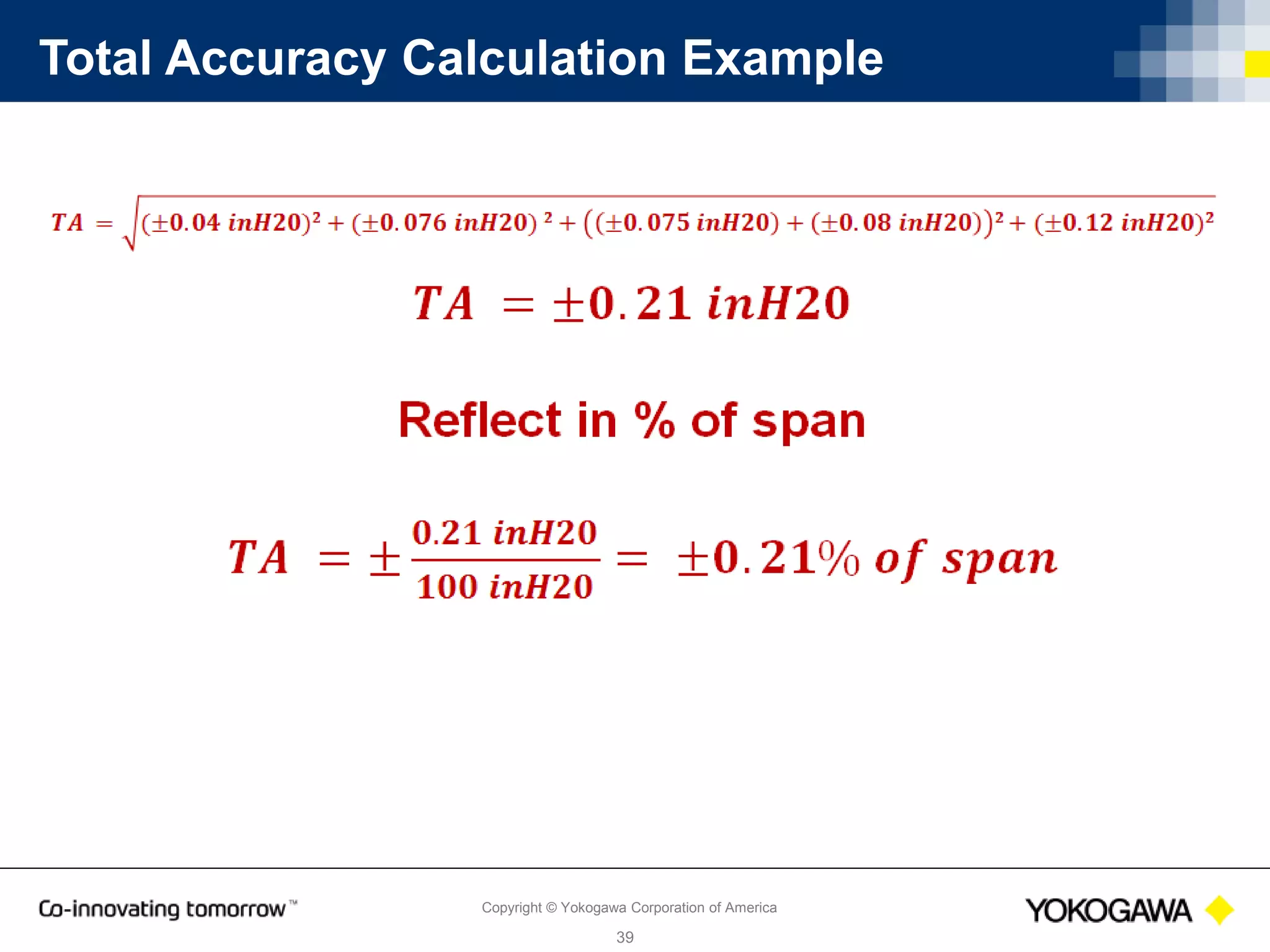

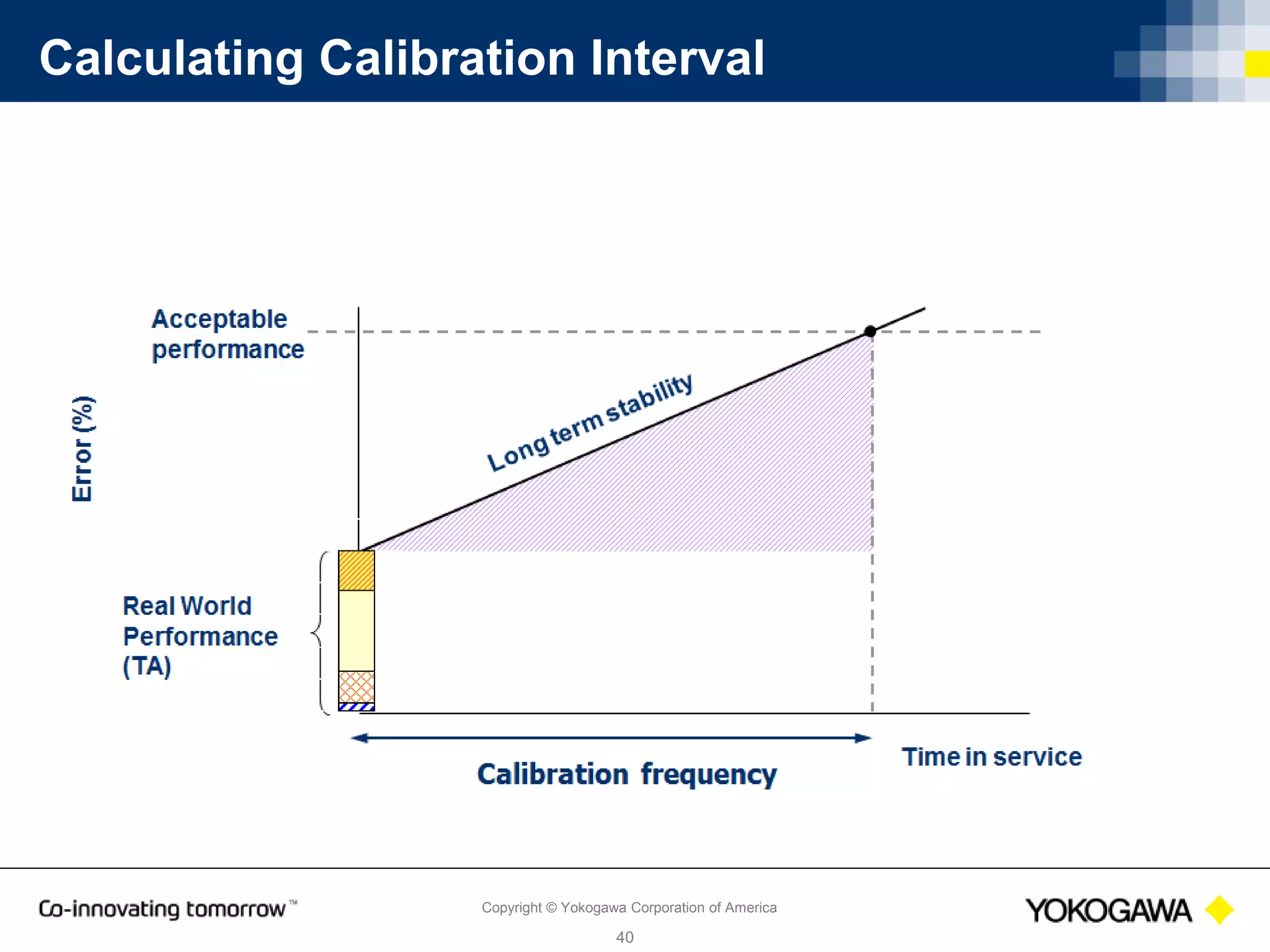

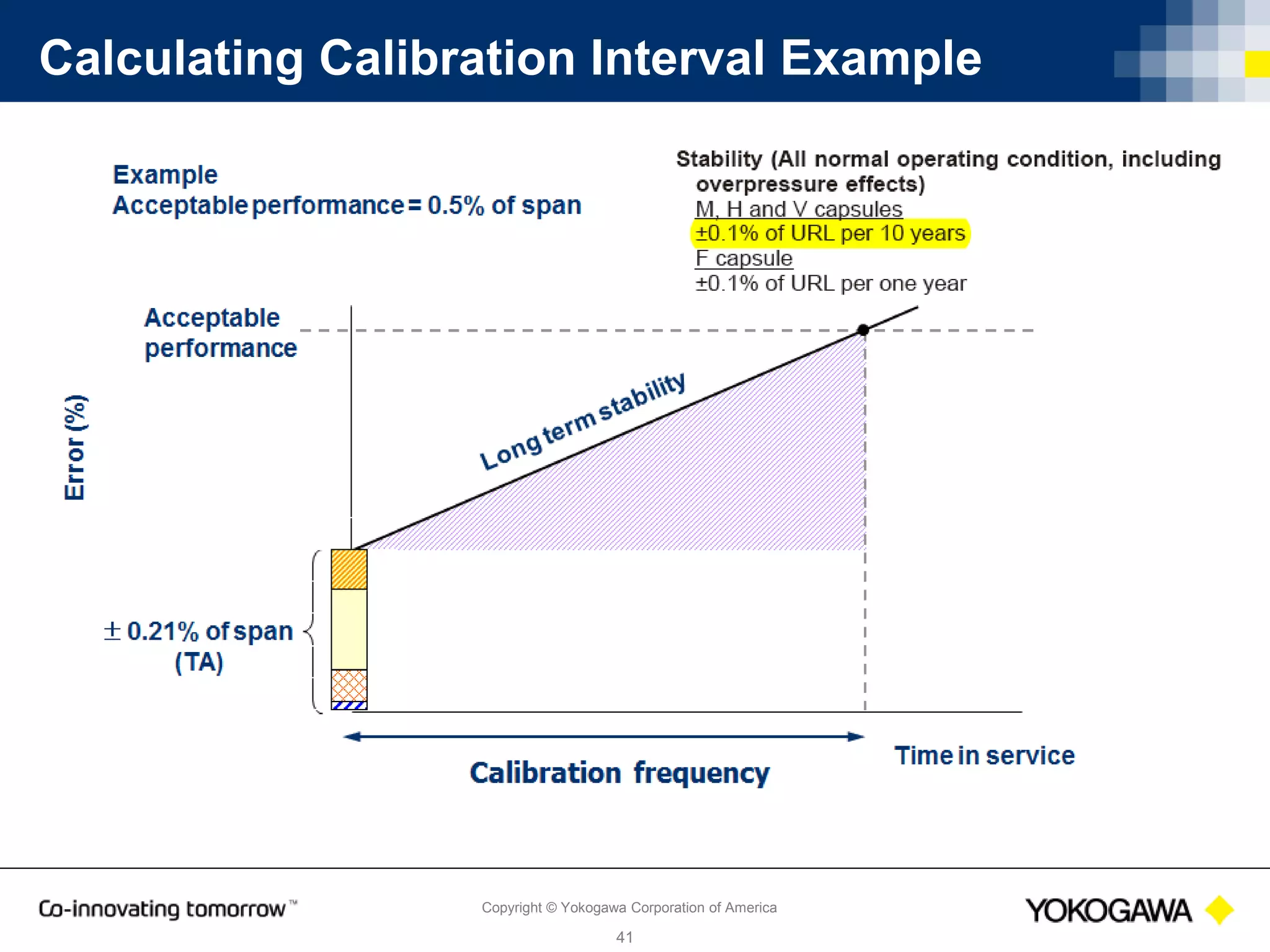

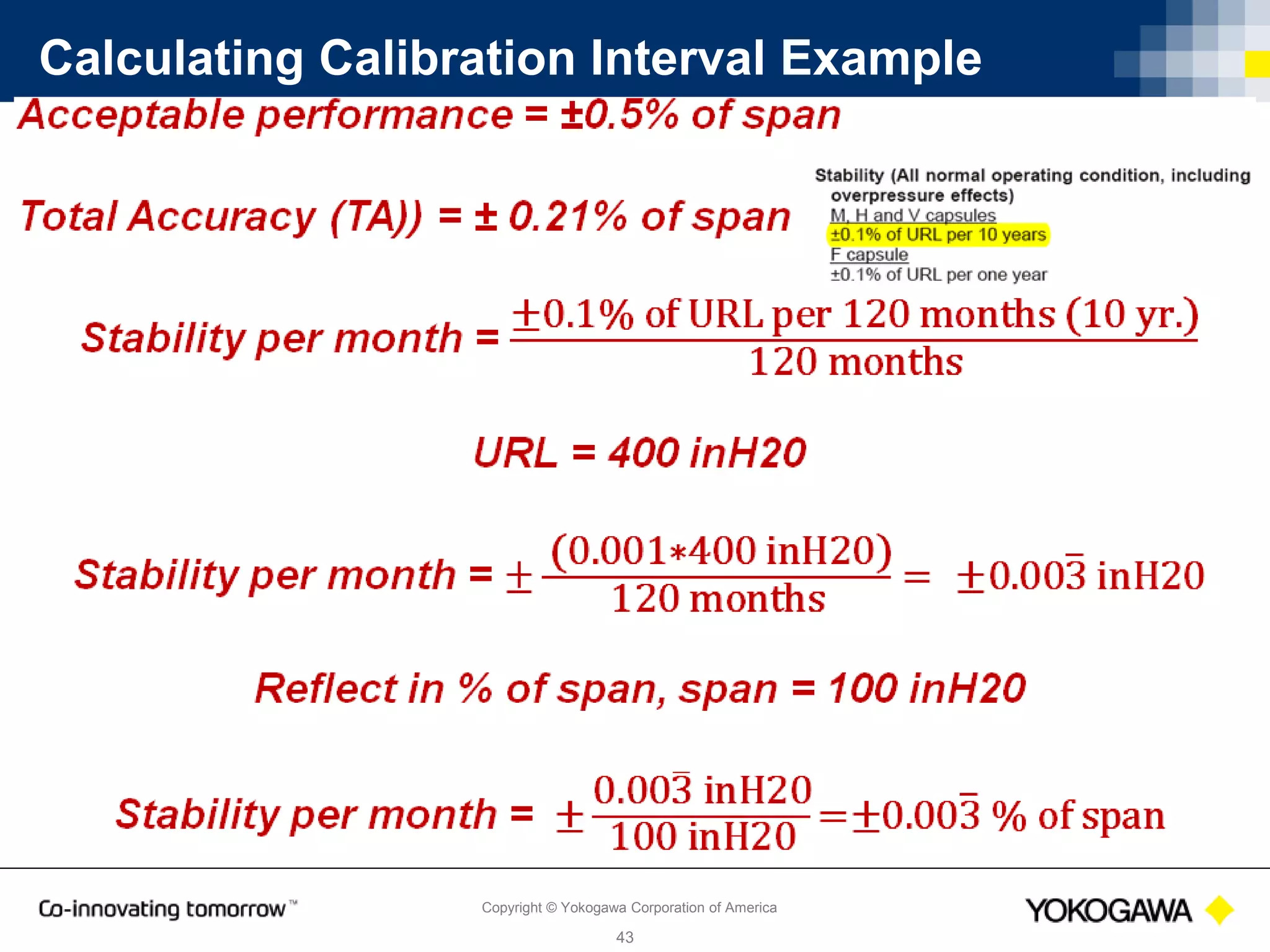

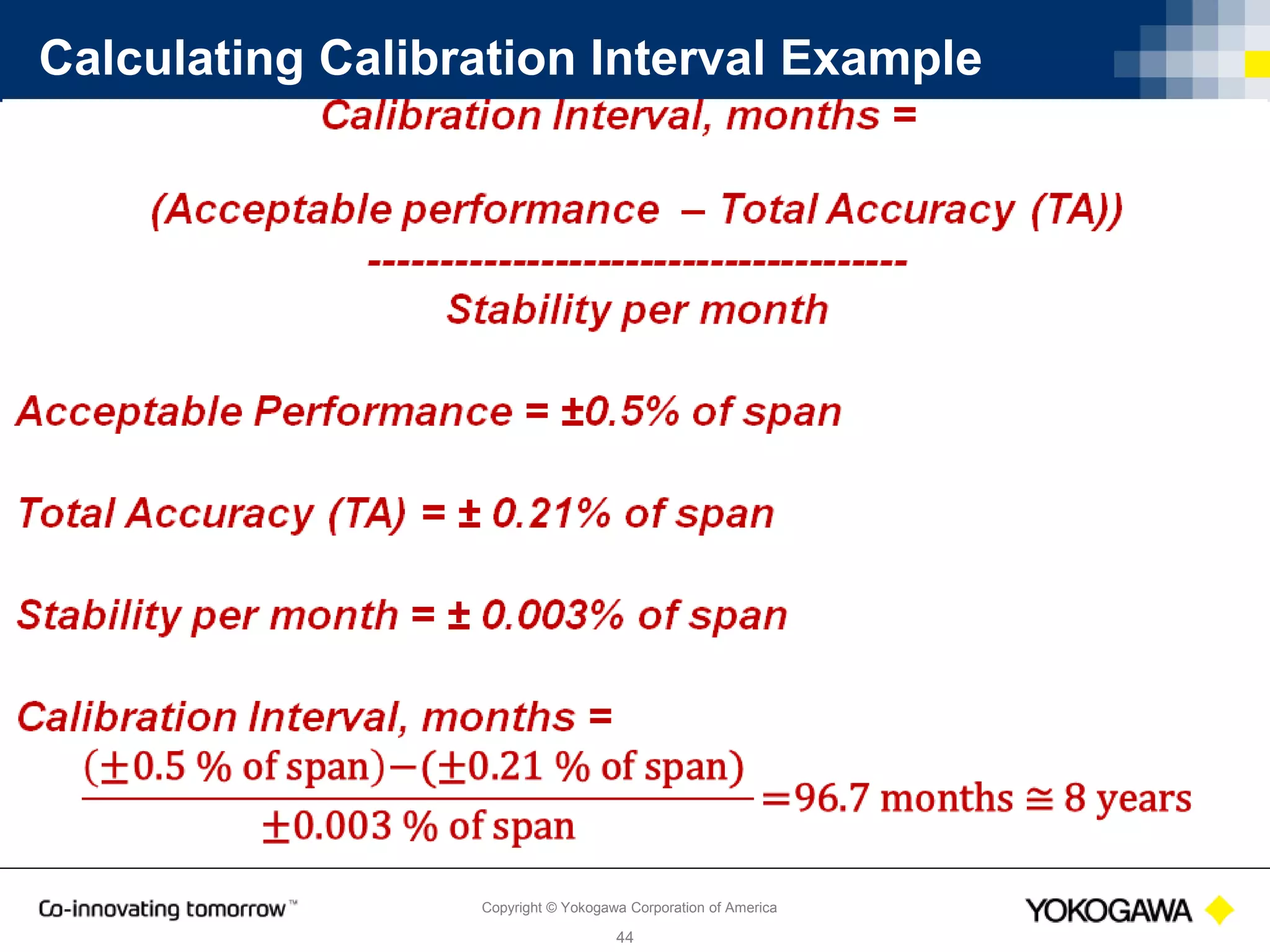

The document discusses best practices for maintaining pressure transmitters with a focus on calibration intervals. It covers various aspects such as pressure basics, errors, real-world performance, and total accuracy calculations. Additionally, it provides examples and a calibration interval calculator to assist with practical applications.