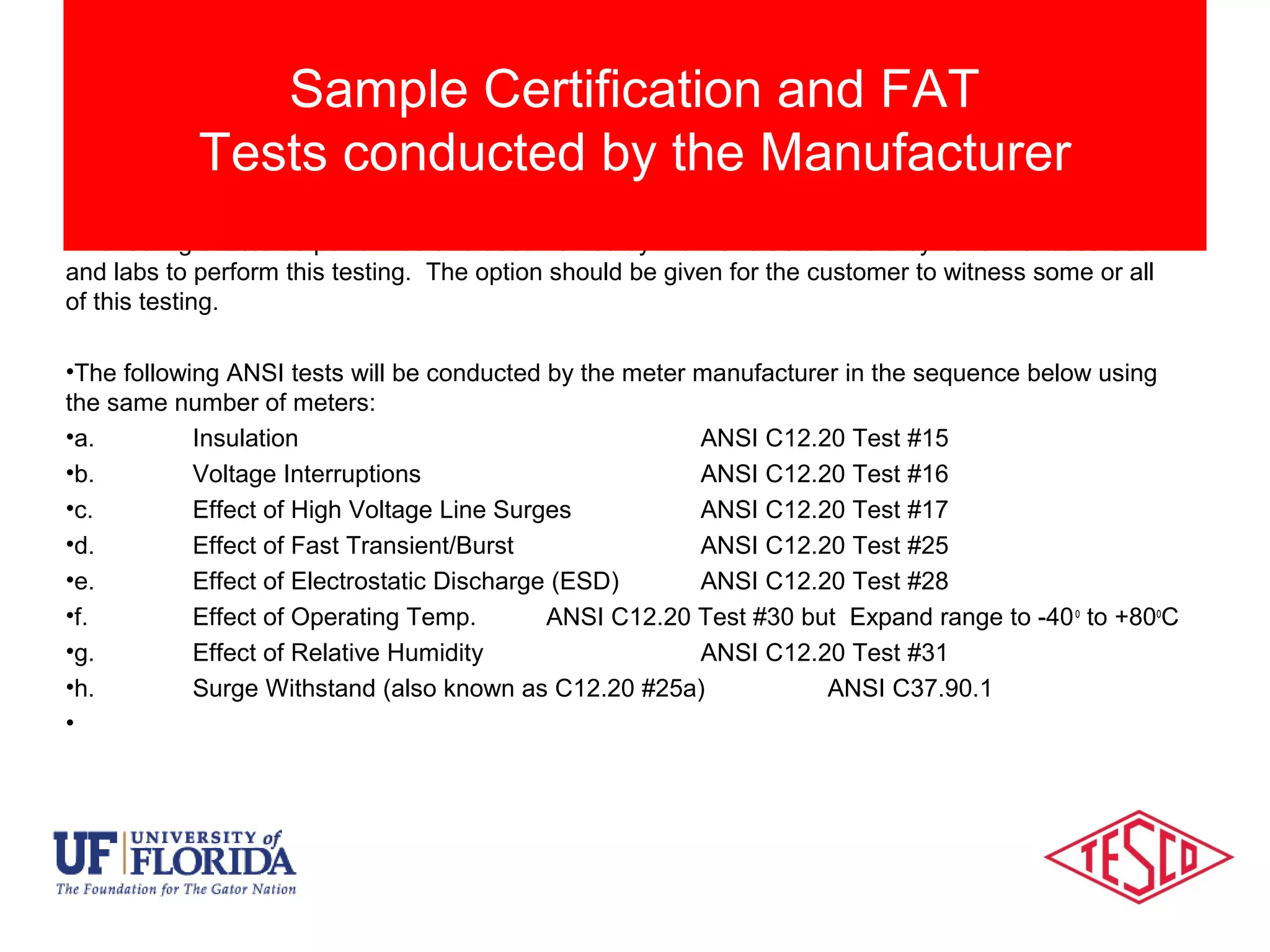

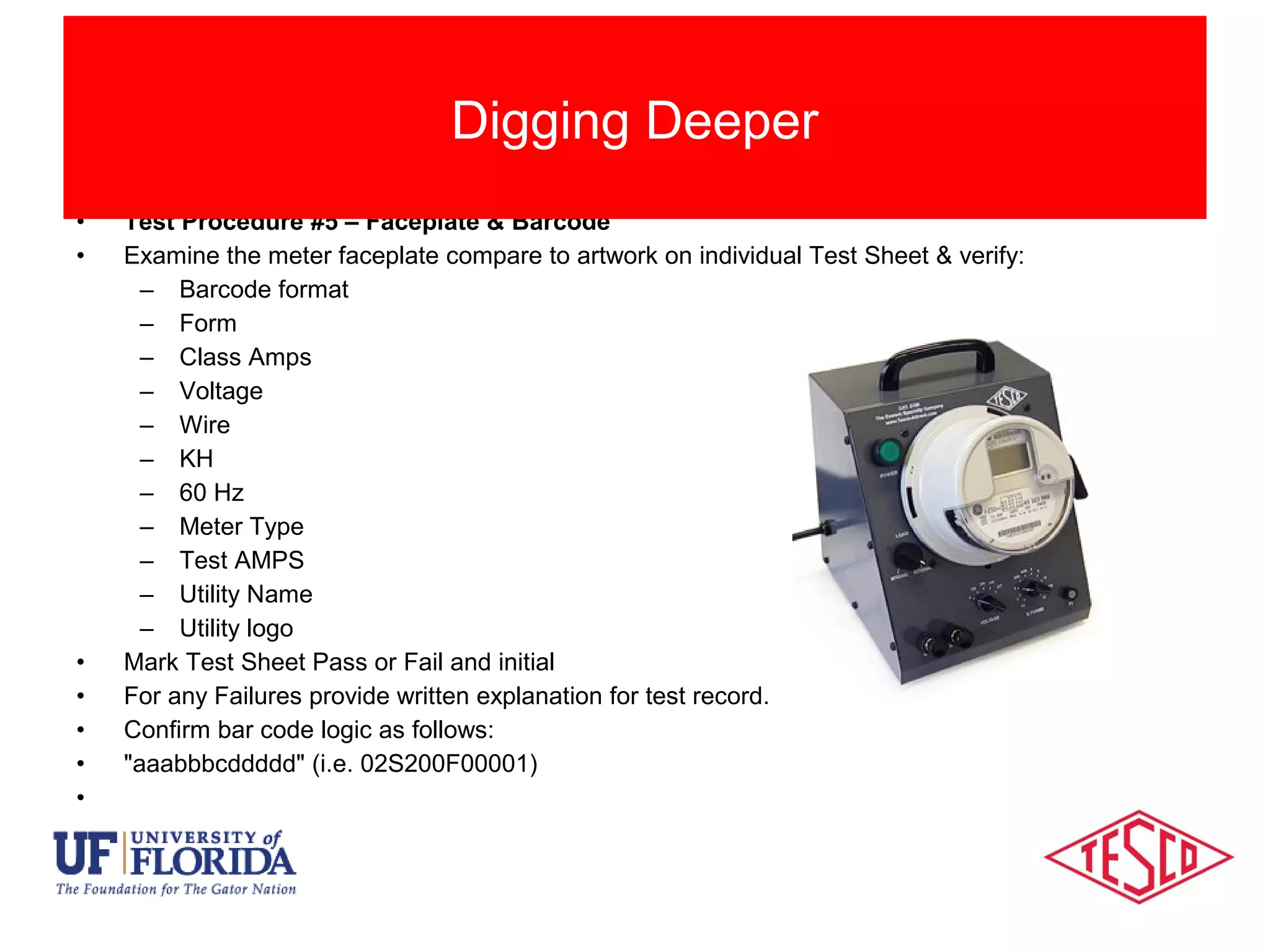

This document outlines protocols for testing smart meters before, during, and after deployment to certify their functionality and ensure quality. It discusses initial certification testing performed by manufacturers on new meters according to ANSI standards. First article testing is then used to validate the first delivered meters meet requirements. Regular certification testing is recommended whenever meters or their firmware/software change, as well as yearly on a sample, to manage risks from changes. The document provides examples of certification and first article tests performed by manufacturers and utilities, covering the meter, network functionality, and configurations. Digging deeper, it explains how to validate meter faceplates and barcodes according to utility specifications.