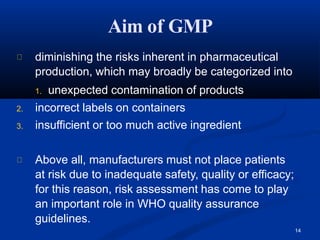

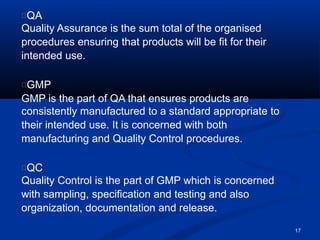

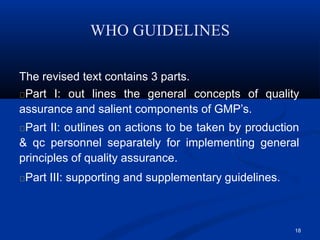

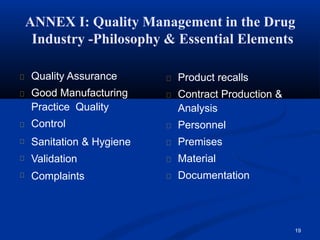

1. GMP aims to ensure quality, safety and efficacy of pharmaceutical products through proper manufacturing and quality control.

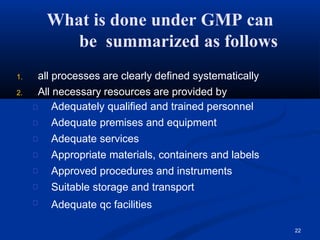

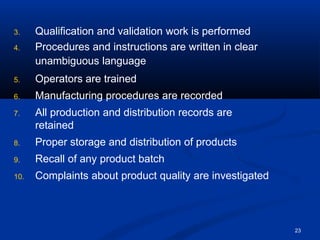

2. Key aspects of GMP include facilities and equipment design, sanitation, personnel training, validation processes, documentation systems, and quality control testing.

3. Adhering to GMP guidelines helps manufacturers consistently produce pharmaceuticals that meet specifications and protects patients from defective products.