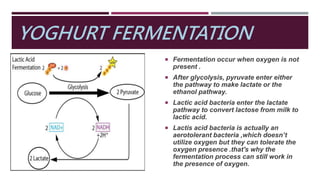

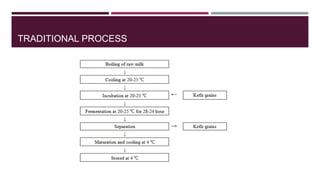

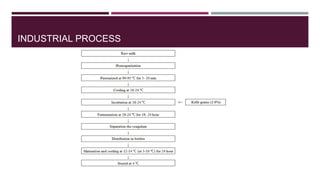

The document summarizes the production processes of yoghurt and kefir. Yoghurt is made by fermenting milk with bacteria that convert lactose into lactic acid. The milk is standardized, pasteurized, homogenized, cooled, inoculated with cultures, fermented, cooled, flavored, and packaged. Kefir is made by inoculating milk with kefir grains containing bacteria and yeast. The microbes produce a polysaccharide that causes the milk to thicken during fermentation. Kefir grains are separated and reused in the process.