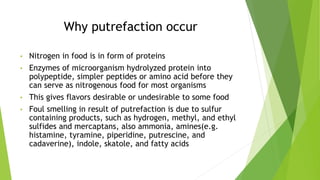

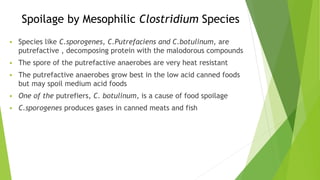

Putrefaction is the anaerobic breakdown of proteins by microorganisms, producing foul-smelling compounds such as hydrogen sulfide and amines. It occurs when protein foods are broken down by proteolytic microorganisms into amino acids, ammonia, and hydrogen sulfide. Factors that affect putrefaction include the chemical composition and structure of food, temperature, pH, and the types of microorganisms present. Putrefaction can change the nutritional value, organoleptic properties, and safety of foods. Various foods are susceptible to putrefaction by different microorganisms if temperature abuse or lack of preservation methods allows the microbes to grow.