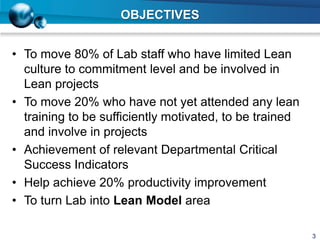

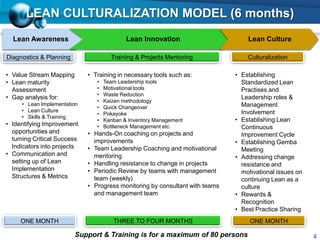

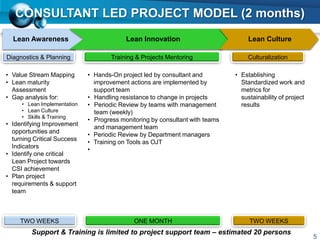

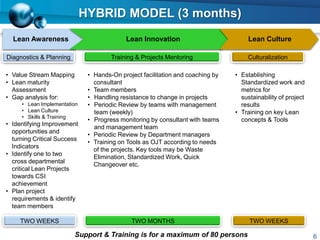

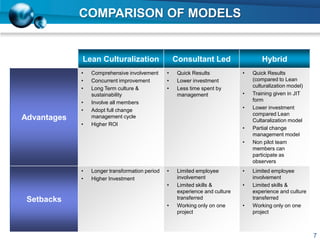

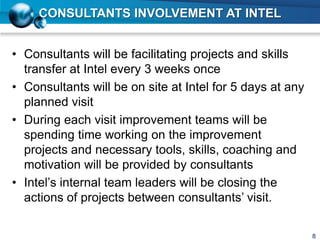

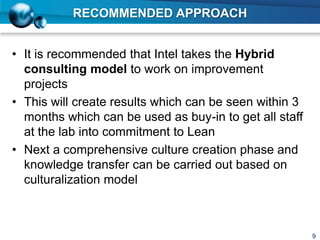

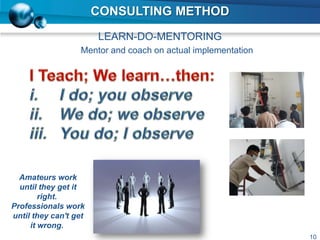

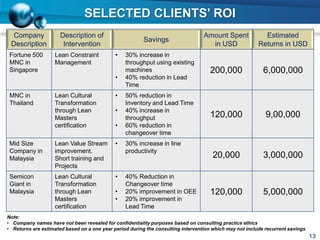

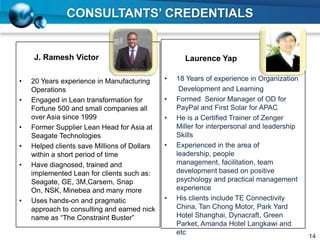

The document proposes implementing a Lean approach at a lab to improve productivity, reduce waste, and establish a Lean culture. It recommends a hybrid consulting model involving diagnostic assessments, training staff on Lean tools and methods, conducting improvement projects under consultant guidance, and cultural changes to sustain results. This approach aims to quickly generate results to gain buy-in for a longer-term Lean transformation applying the culturalization model to all staff. The proposal compares models and outlines the consultants' roles, credentials, and examples of significant ROI other clients have achieved through Lean interventions.