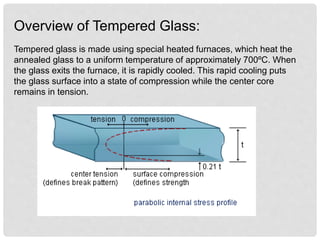

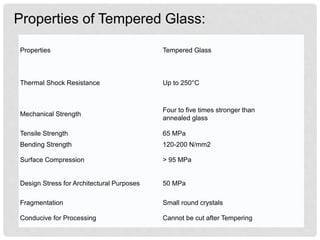

Tempered glass is made by heating glass to 700°C and then rapidly cooling it, putting the outer surfaces into compression and inner surfaces into tension. This makes the glass 4-5 times stronger than regular glass and able to break into small, relatively harmless pieces to prevent injury. The manufacturing process involves cutting the glass, inspecting for imperfections, smoothing edges, washing, heating in an oven up to 600°C, and then quenching the heated glass with high-pressure air blasts to rapidly cool it. Tempered glass has high thermal shock resistance up to 250°C, is difficult to break, and fragments into small globules, making it suitable for use in doors, shower stalls, and other applications