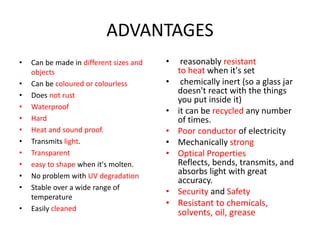

The document discusses different types of glass, their properties, manufacturing process, history, uses, advantages and disadvantages. It describes how glass is made by melting sand, soda ash and limestone in a furnace. The main types discussed are float glass, tinted glass, toughened glass, laminated glass, shatterproof glass and double glazed units. The document also outlines the various applications of glass in architecture, interior design and its benefits like transparency, strength and energy efficiency.