1. This document provides an overview of different types of glass used in structural applications and important considerations for structural engineers when designing with glass.

2. It discusses the main types of glass including annealed, heat-strengthened, toughened, heat soaked toughened, and chemically strengthened glass. Laminated glass and insulating glass units are also covered.

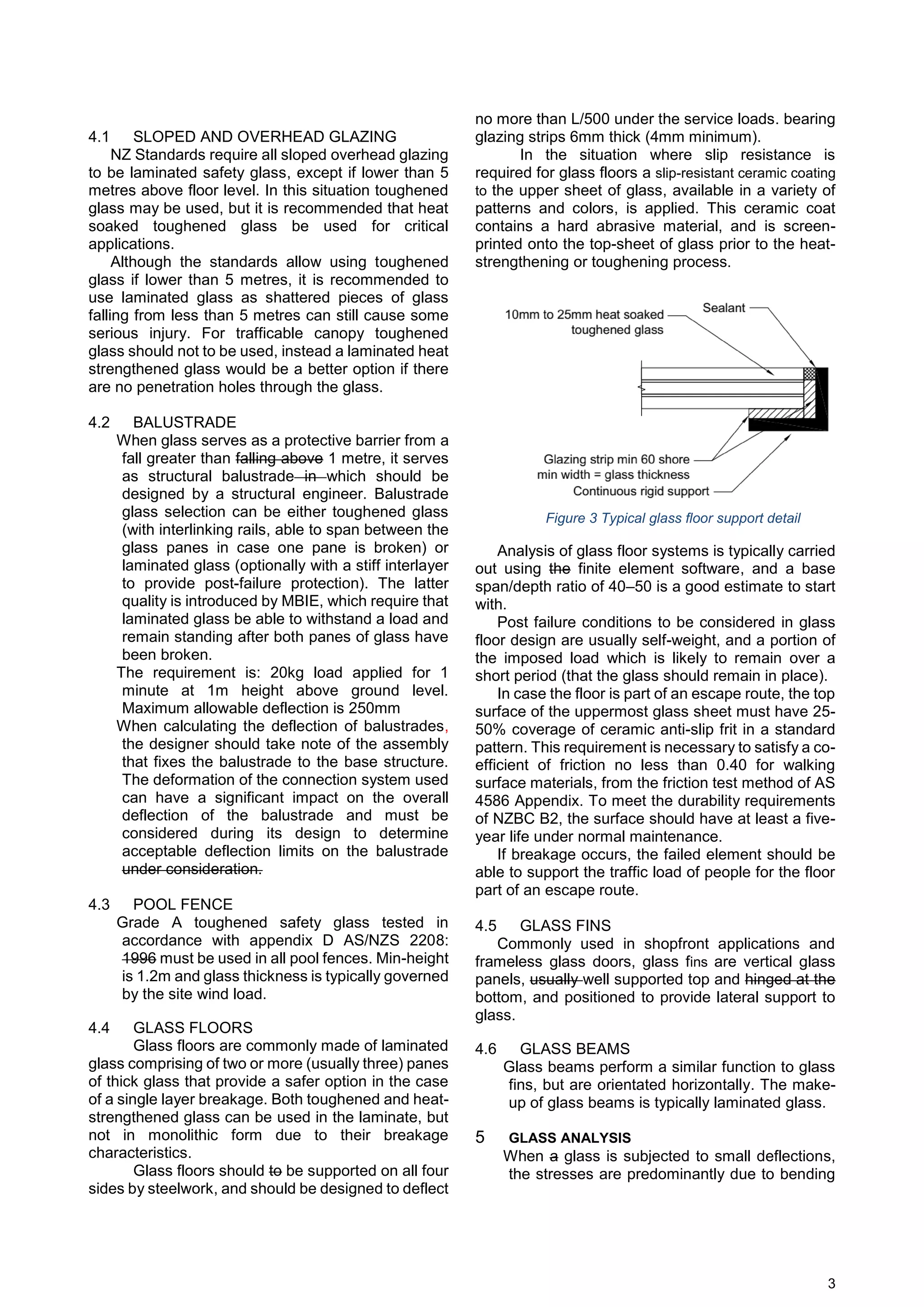

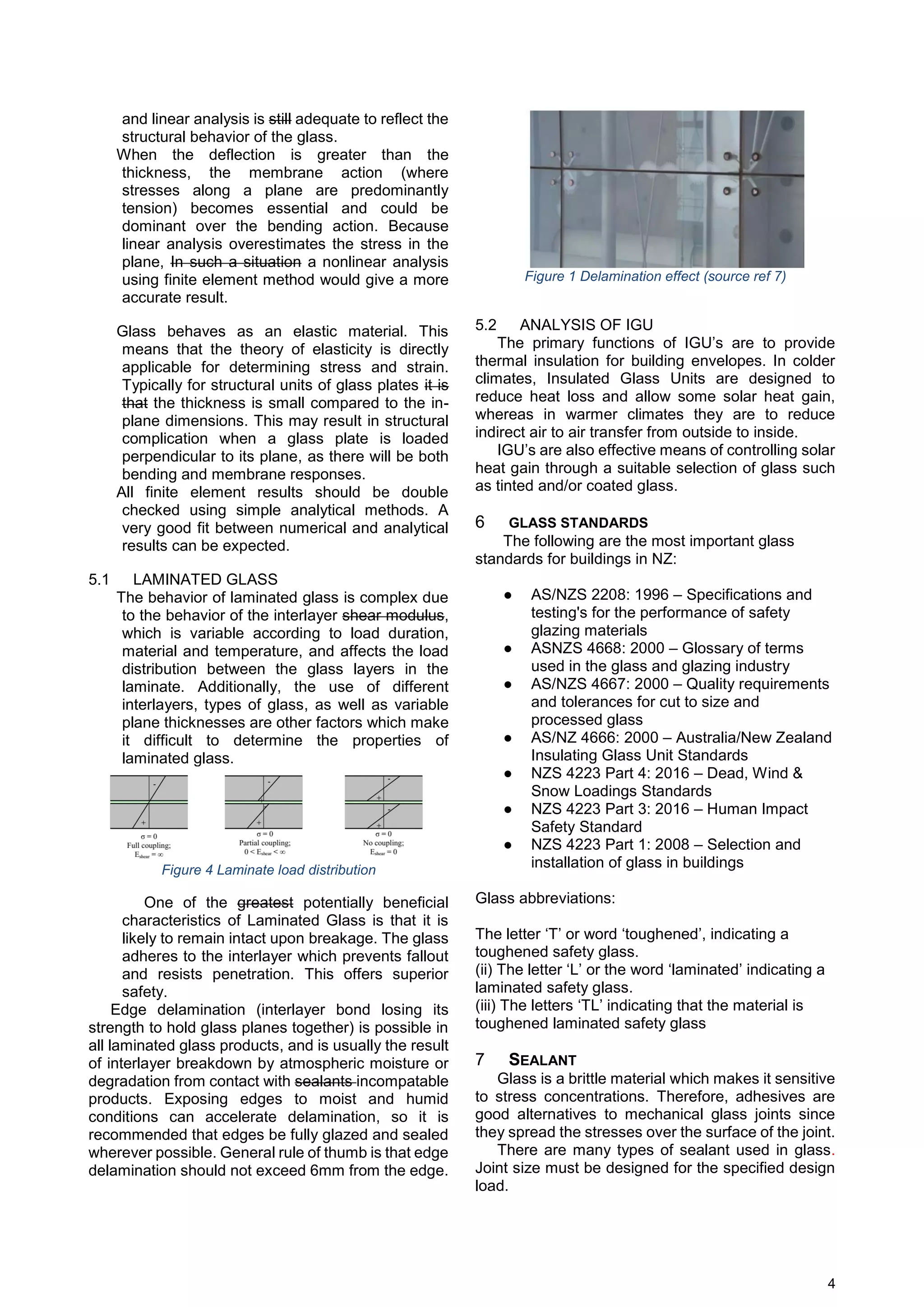

3. Key properties of glass are summarized, such as its brittle nature, linear elastic behavior, and time-dependent strength. Guidelines for selecting different glass types for structural applications like sloped glazing, balustrades, pool fences, and glass floors are provided.