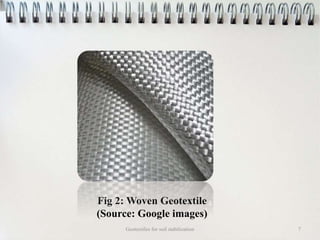

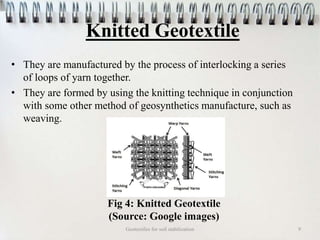

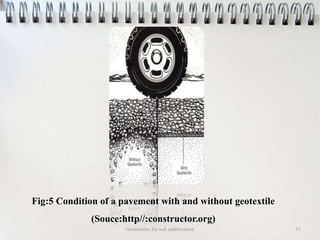

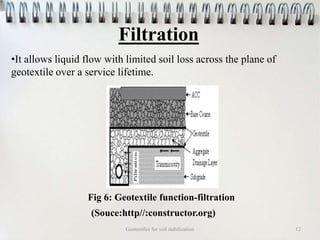

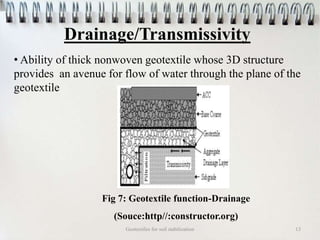

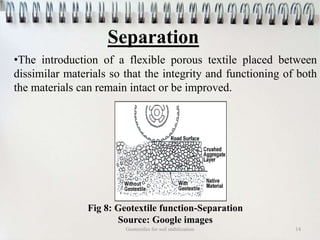

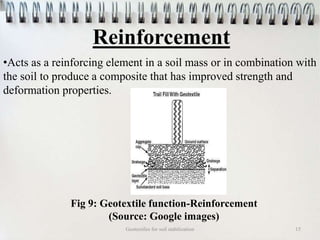

Geotextiles, made from polypropylene or polyester, are permeable fabrics used in soil stabilization since the 1970s, aiding in tasks like separation, filtration, reinforcement, and drainage. They come in woven, non-woven, and knitted forms, each serving distinct functions such as erosion control and improving bearing capacity in pavements. The document discusses various tests and applications to enhance soil strength and integrity using geotextiles.

![Table 2: Summary of the CBR values (Unsoaked condition)

Source:[1]

Geotextiles for soil stabilization 20](https://image.slidesharecdn.com/geotextilefosoilstabilization-190803034634/85/Geotextile-fo-soil-stabilization-20-320.jpg)

![Fig 11: CBR values for reinforced and unreinforced soil sample

Source:[1]

Geotextiles for soil stabilization 21](https://image.slidesharecdn.com/geotextilefosoilstabilization-190803034634/85/Geotextile-fo-soil-stabilization-21-320.jpg)