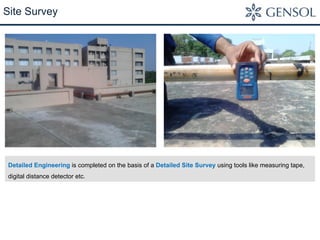

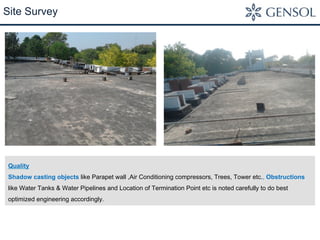

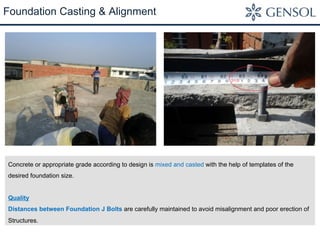

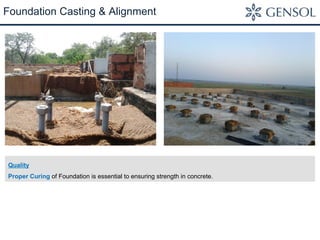

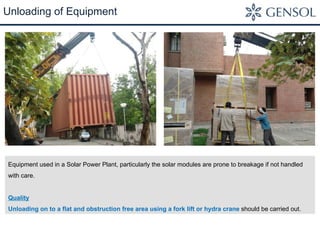

The document outlines the steps and quality assurance measures in executing solar rooftop projects, including site surveys, foundation casting, module installation, and electrical cabling. It emphasizes the importance of precise measurements and quality checks at each stage to prevent issues like misalignment or breakage. Gensol, as a leading consultant and system integrator in India, has successfully managed numerous solar projects and provides advisory and EPC services, ensuring compliance with regulatory requirements and industry standards.