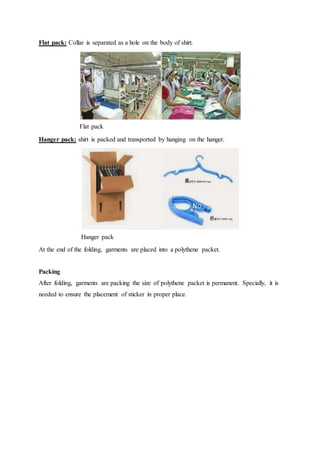

This document discusses various processes involved in garment finishing. It begins by explaining how garment finishing adds beauty and improves the look, feel, and texture of fabrics. It then discusses specific finishing processes like spotting, folding, pressing, packing, and packaging. It provides details on different types of machinery used for processes like fusing, ironing, folding, and finishing different garment types. It concludes by summarizing key steps in the garment finishing process such as inspection, spot removing, and final quality checks.