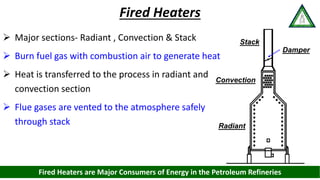

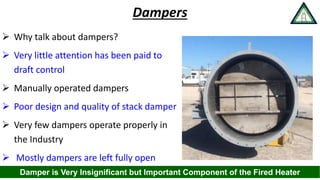

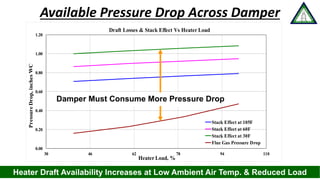

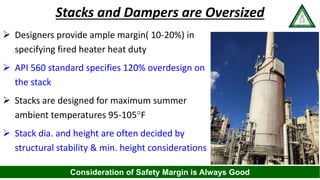

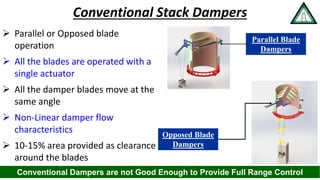

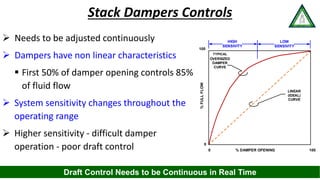

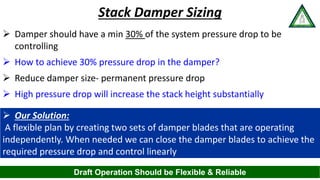

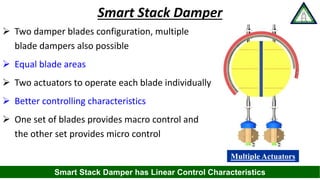

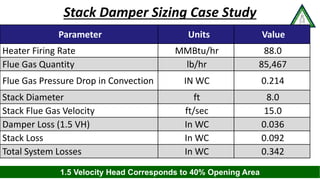

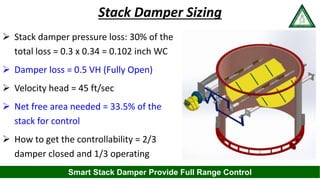

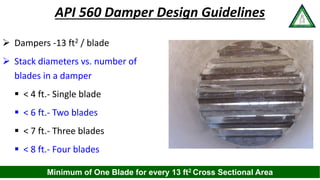

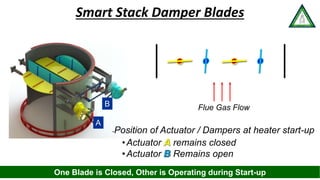

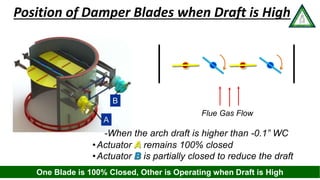

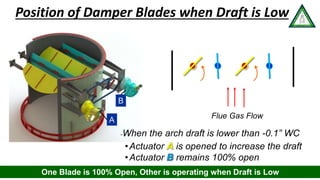

The document discusses the limitations of conventional stack dampers in fired heaters, particularly in controlling draft and ensuring efficient combustion. It introduces the 'smart stack damper' technology that features two independently operating blades, allowing for improved draft control under varying conditions. The smart stack damper aims to enhance the efficiency of fired heaters in petroleum refineries, with a quick return on investment for its implementation.