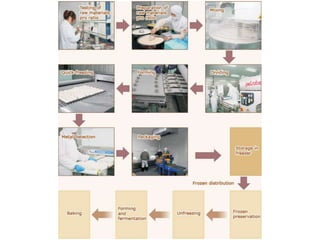

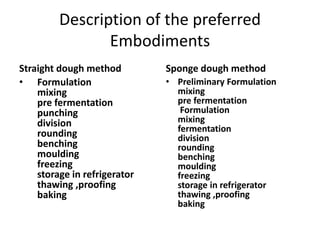

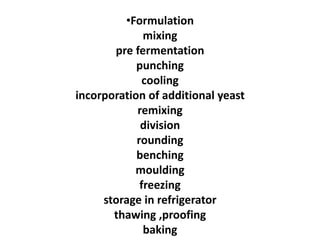

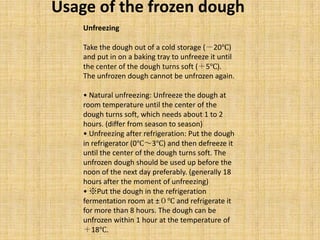

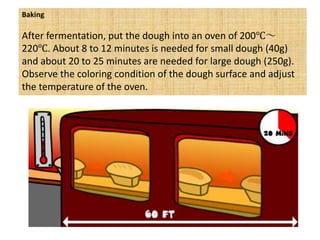

Frozen dough refers to semi-finished dough products that have been kneaded, processed by machine, and frozen for later use. There are two types - broad frozen dough includes all flour-based semi-finished products, while narrow frozen dough specifically refers to pre-made dough used in baking that contains yeast, freezing agents, and is frozen below -7°C. Frozen dough must be stored at -18°C and used within 3 months to maintain quality. It cannot be refrozen after thawing. The document describes methods for making straight dough and sponge dough, freezing, storing, thawing, proofing, and baking the frozen dough into final products.