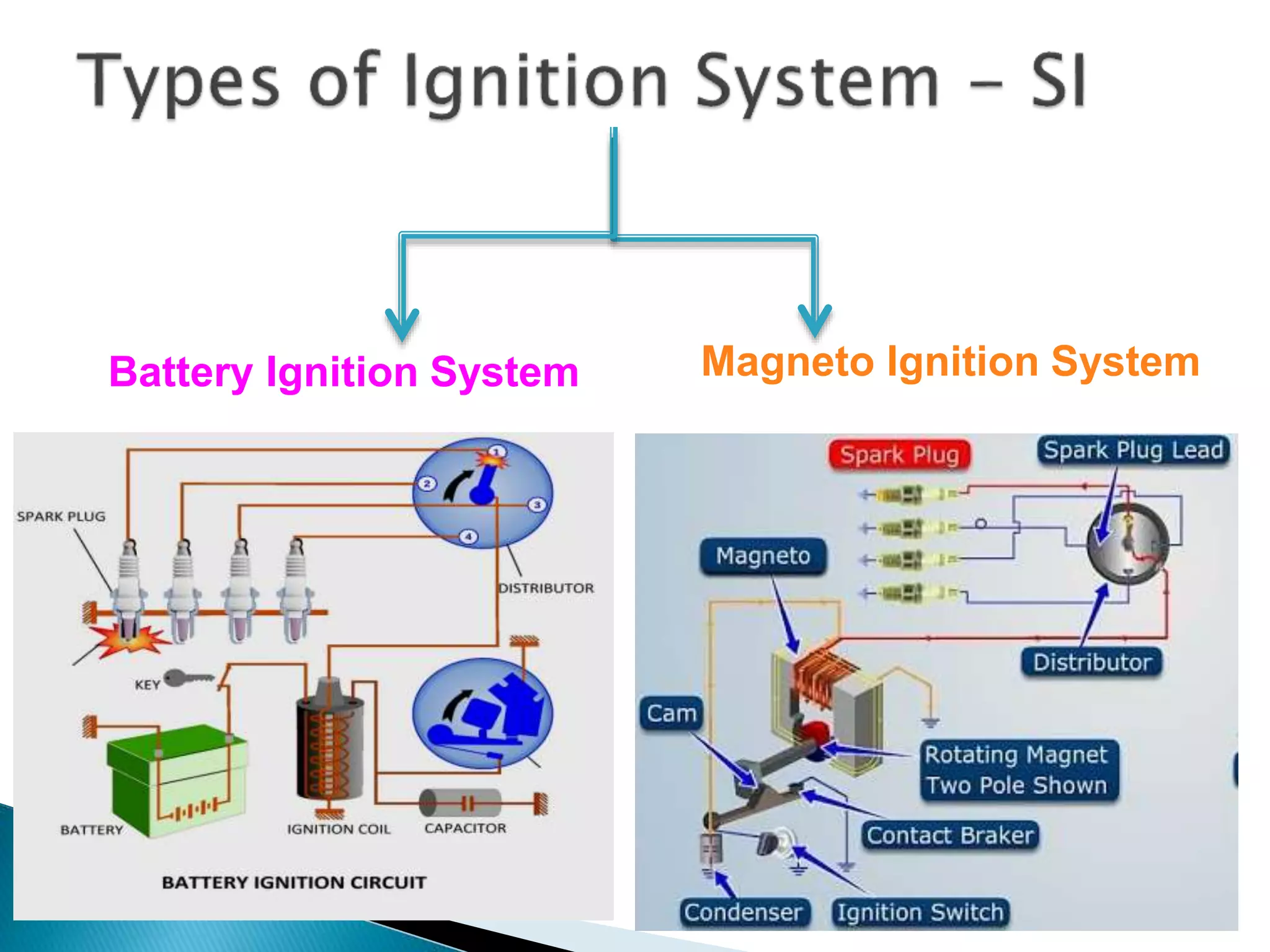

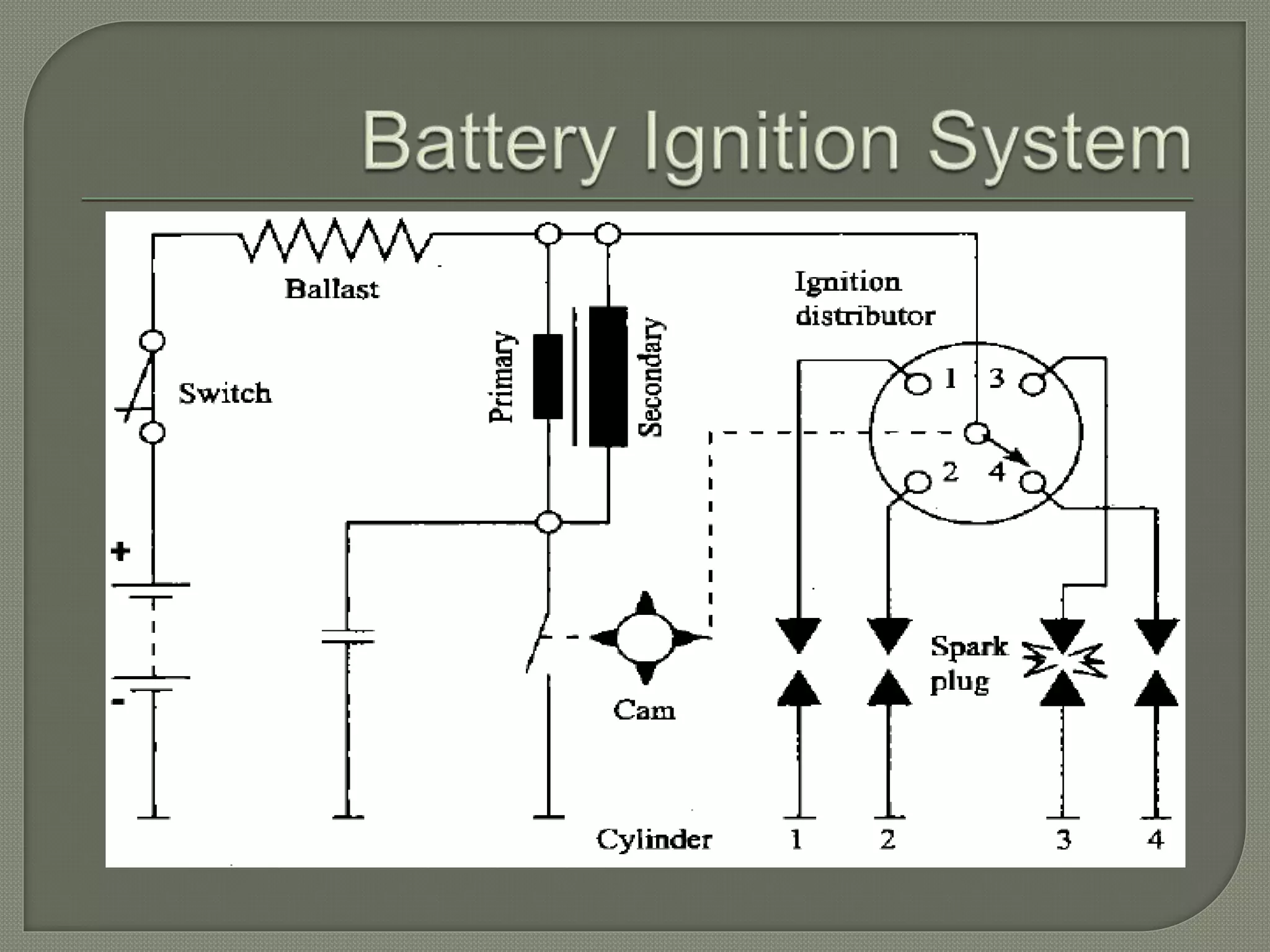

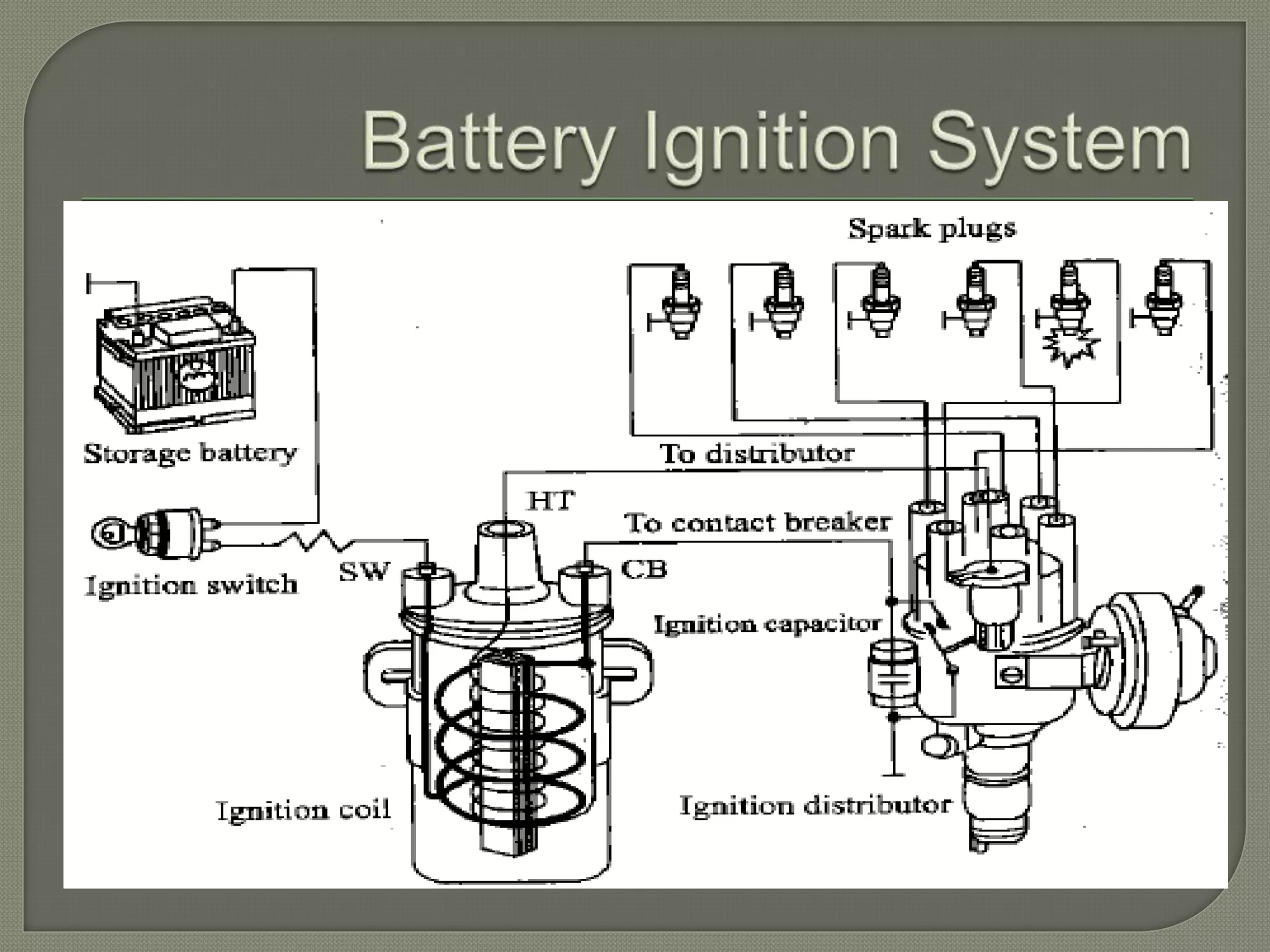

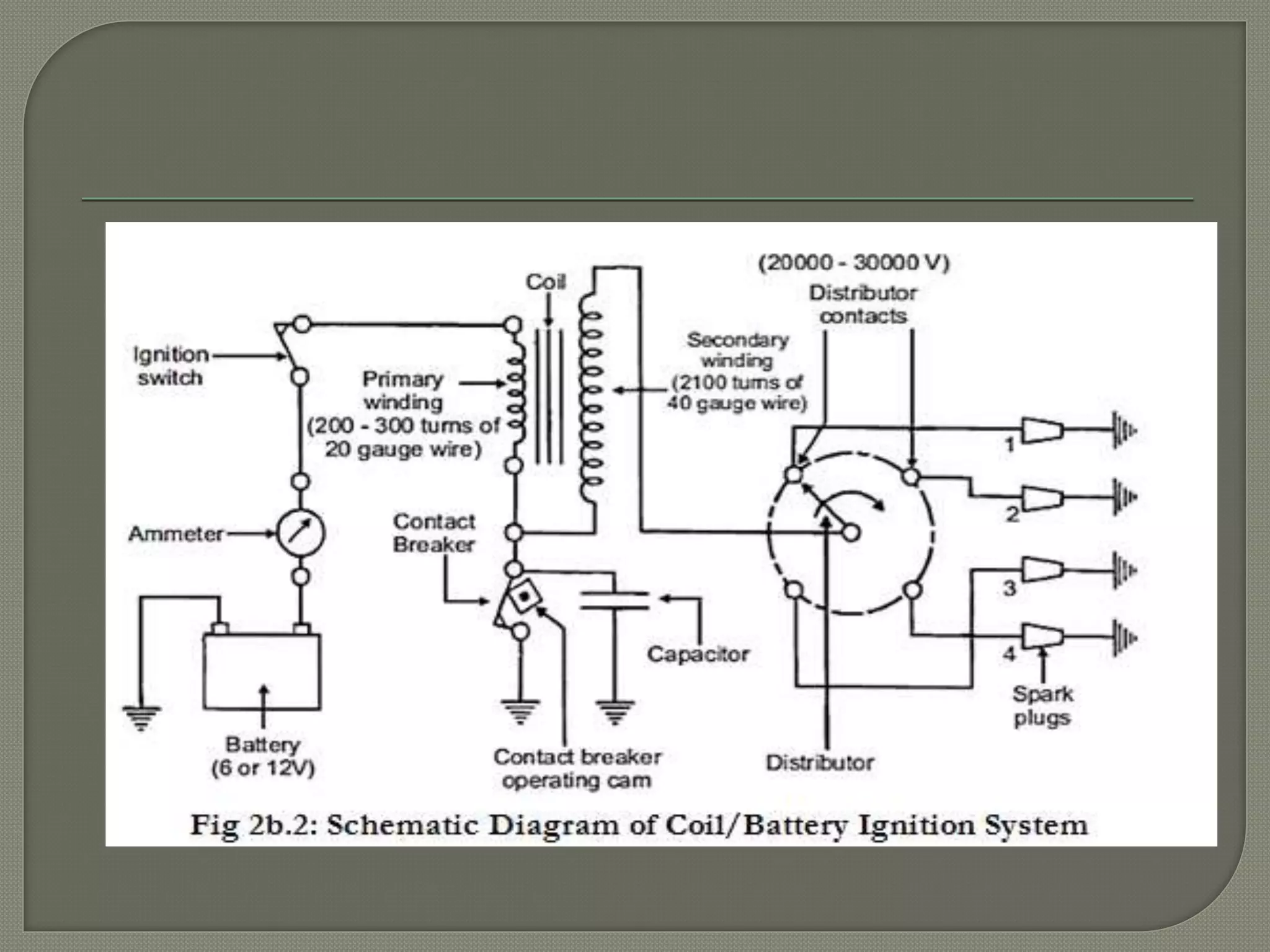

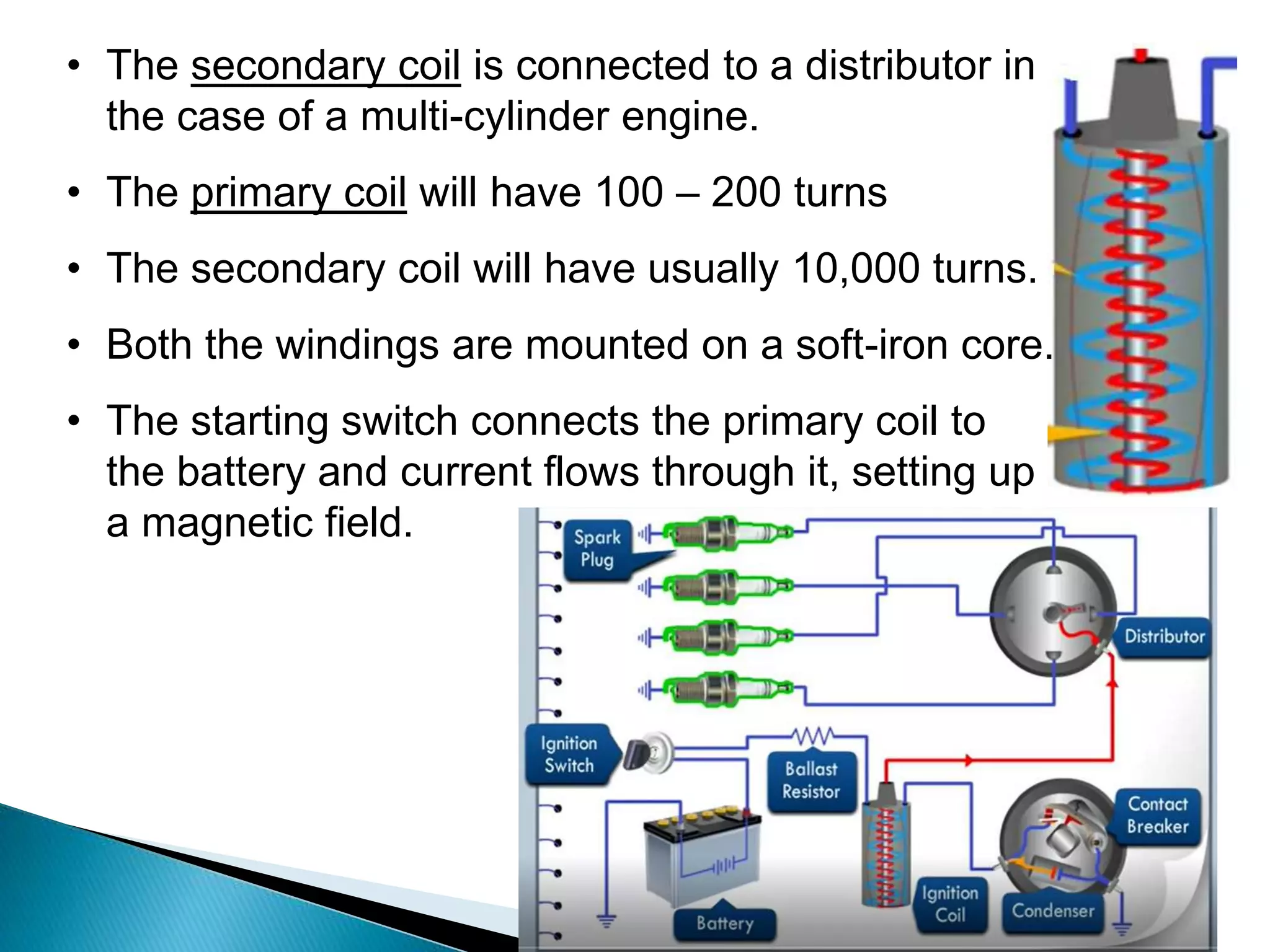

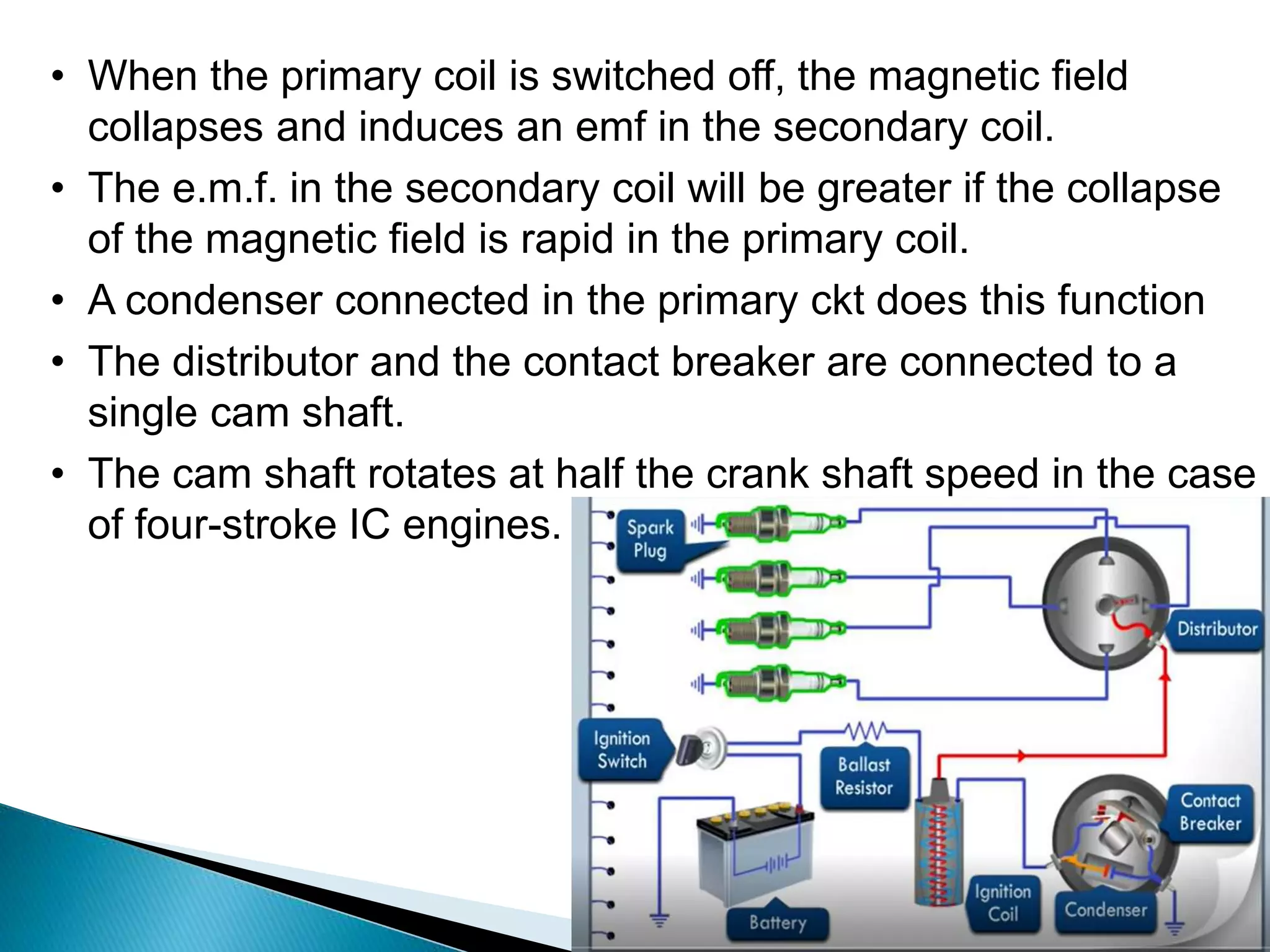

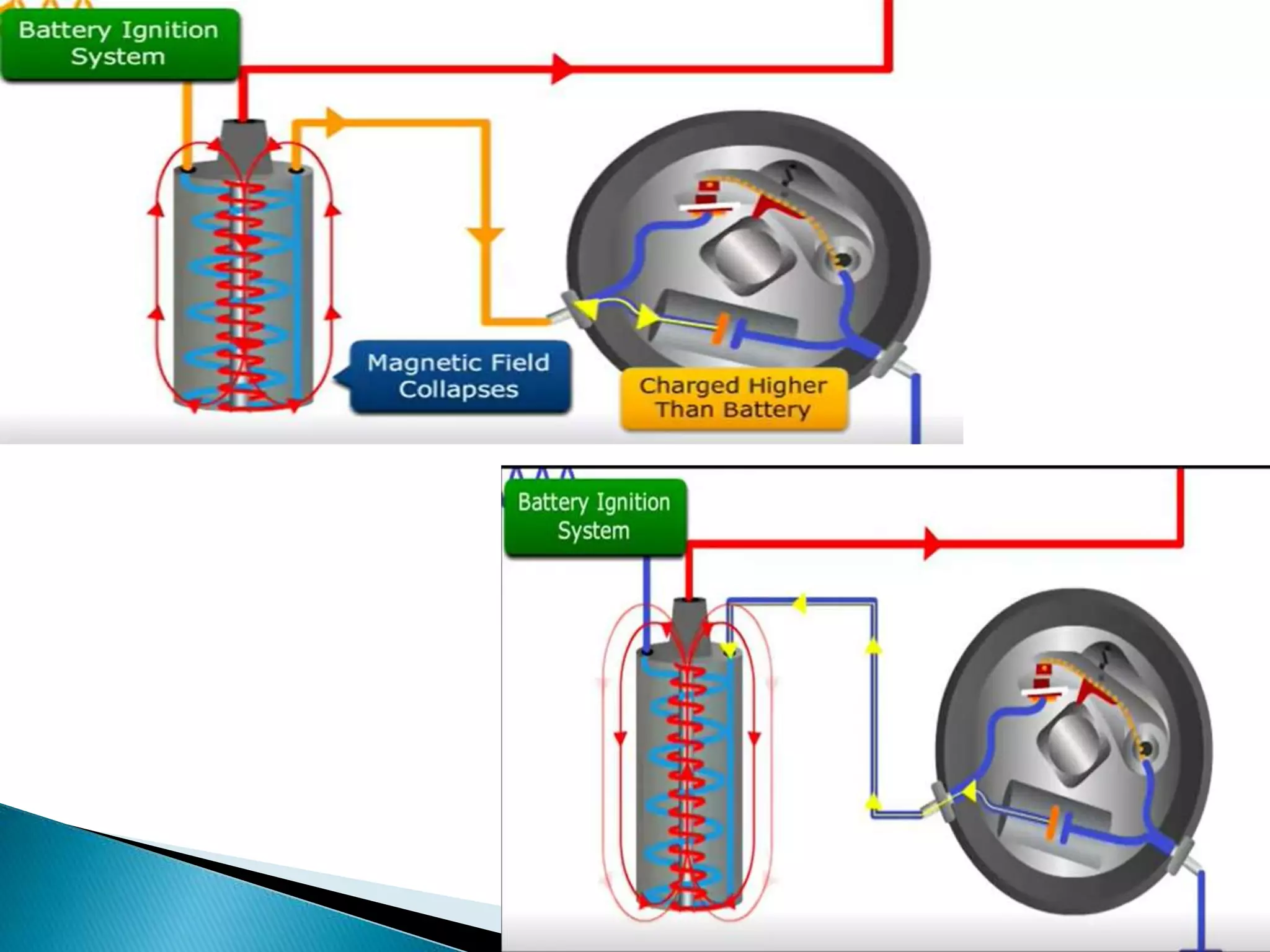

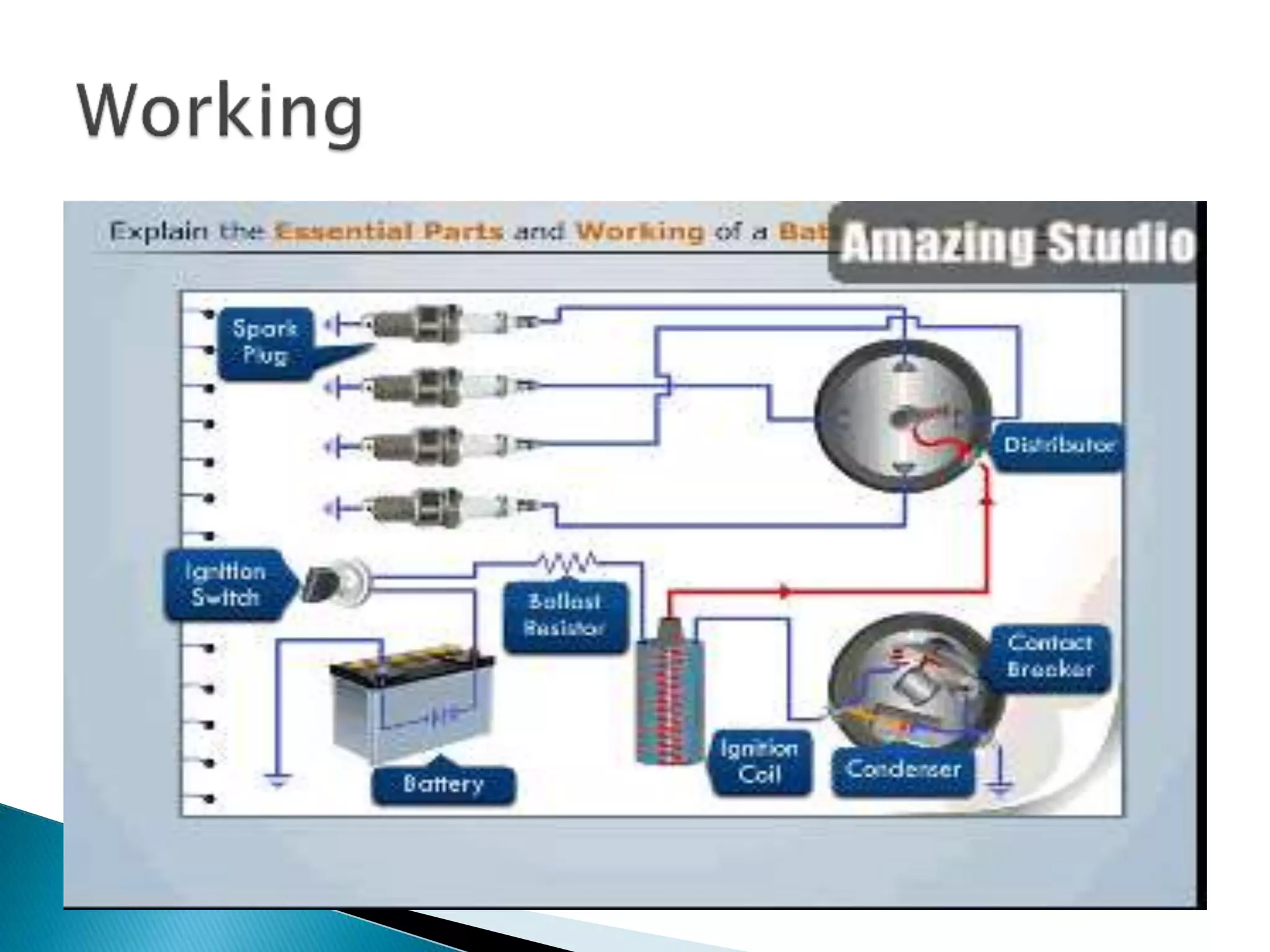

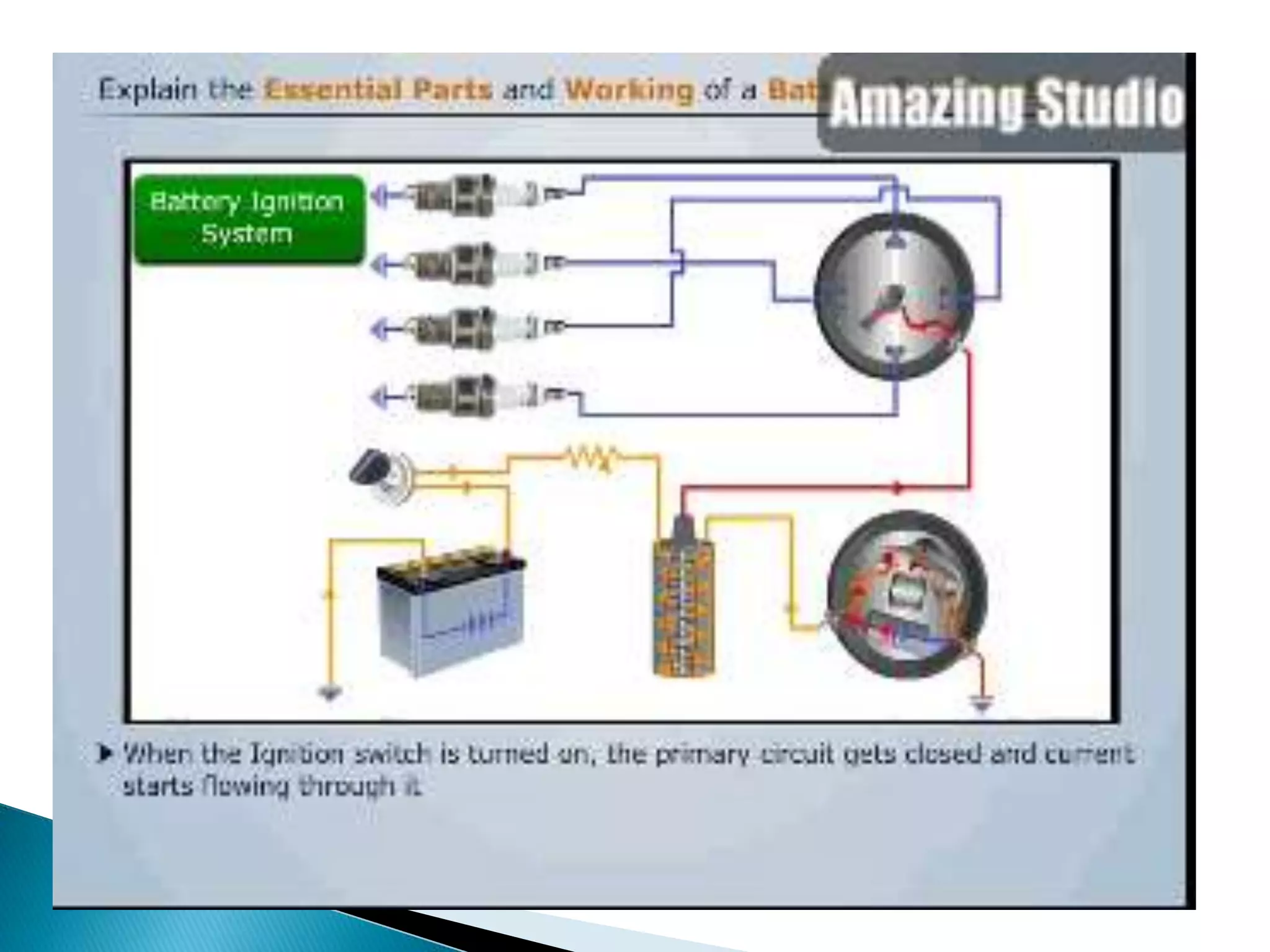

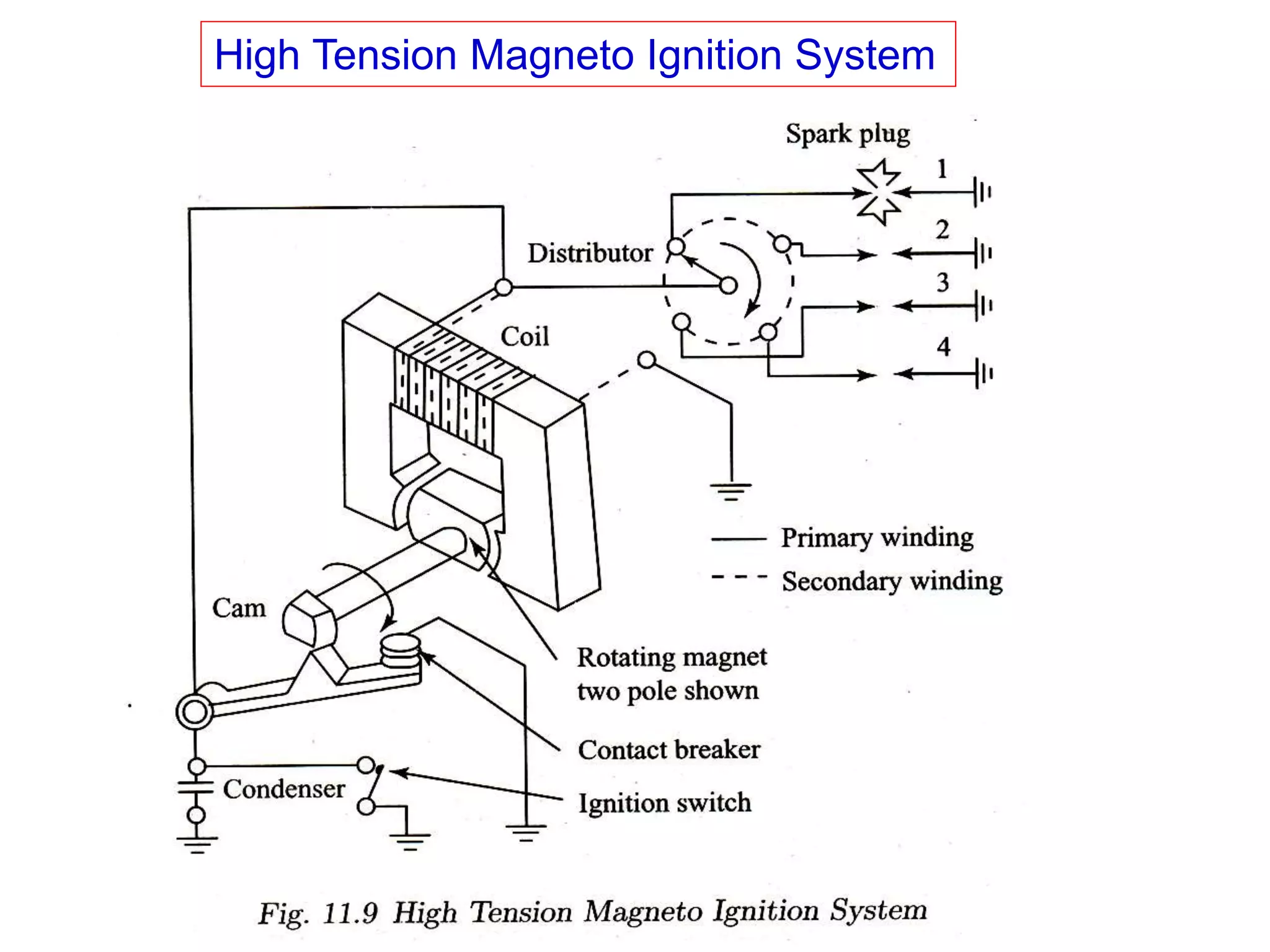

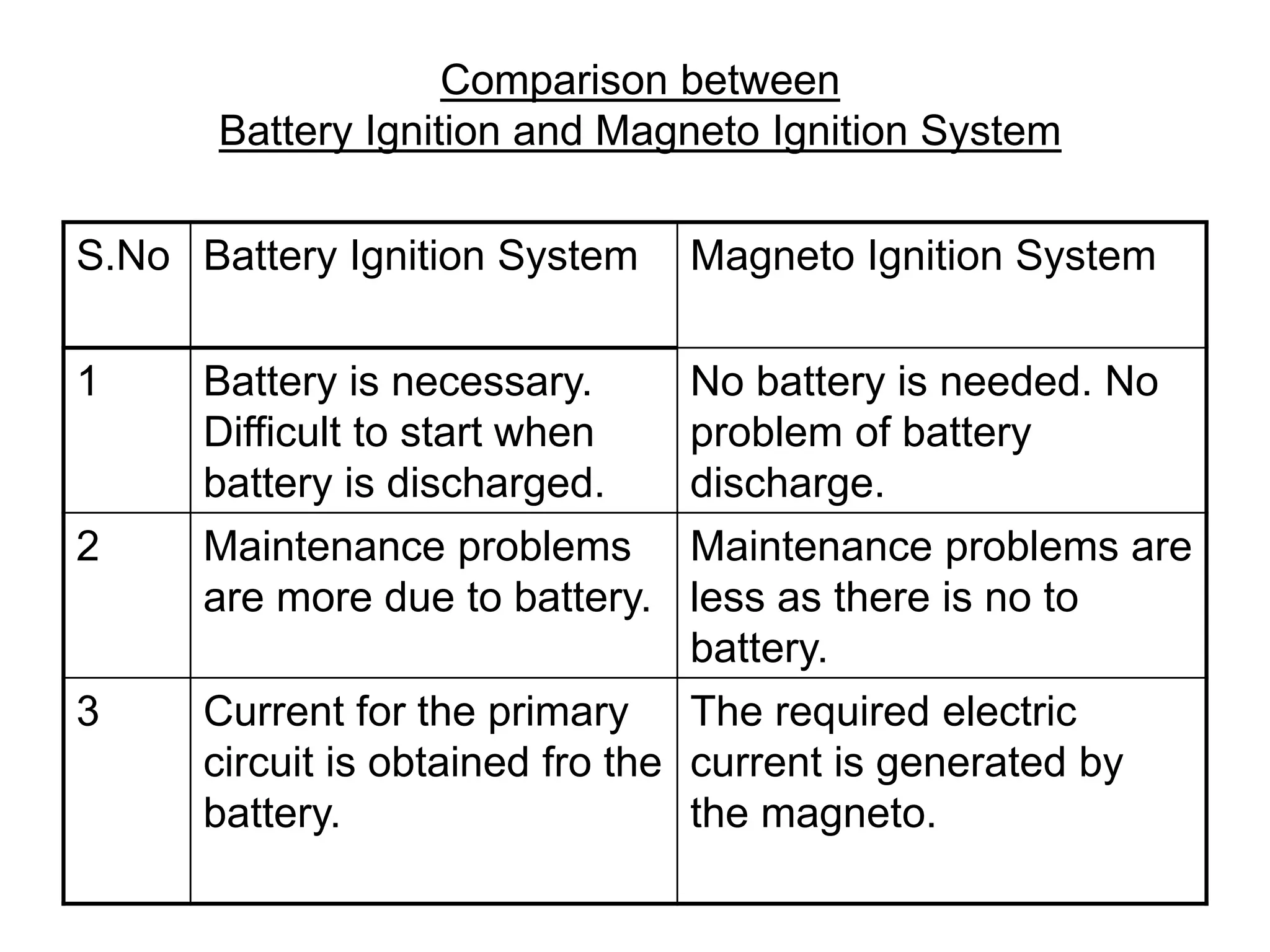

1. Battery ignition systems and magneto ignition systems are the two main types of ignition systems used in spark ignition engines. Battery ignition systems use a battery to provide electrical power to the primary coil, while magneto ignition systems generate their own electrical current using a magneto.

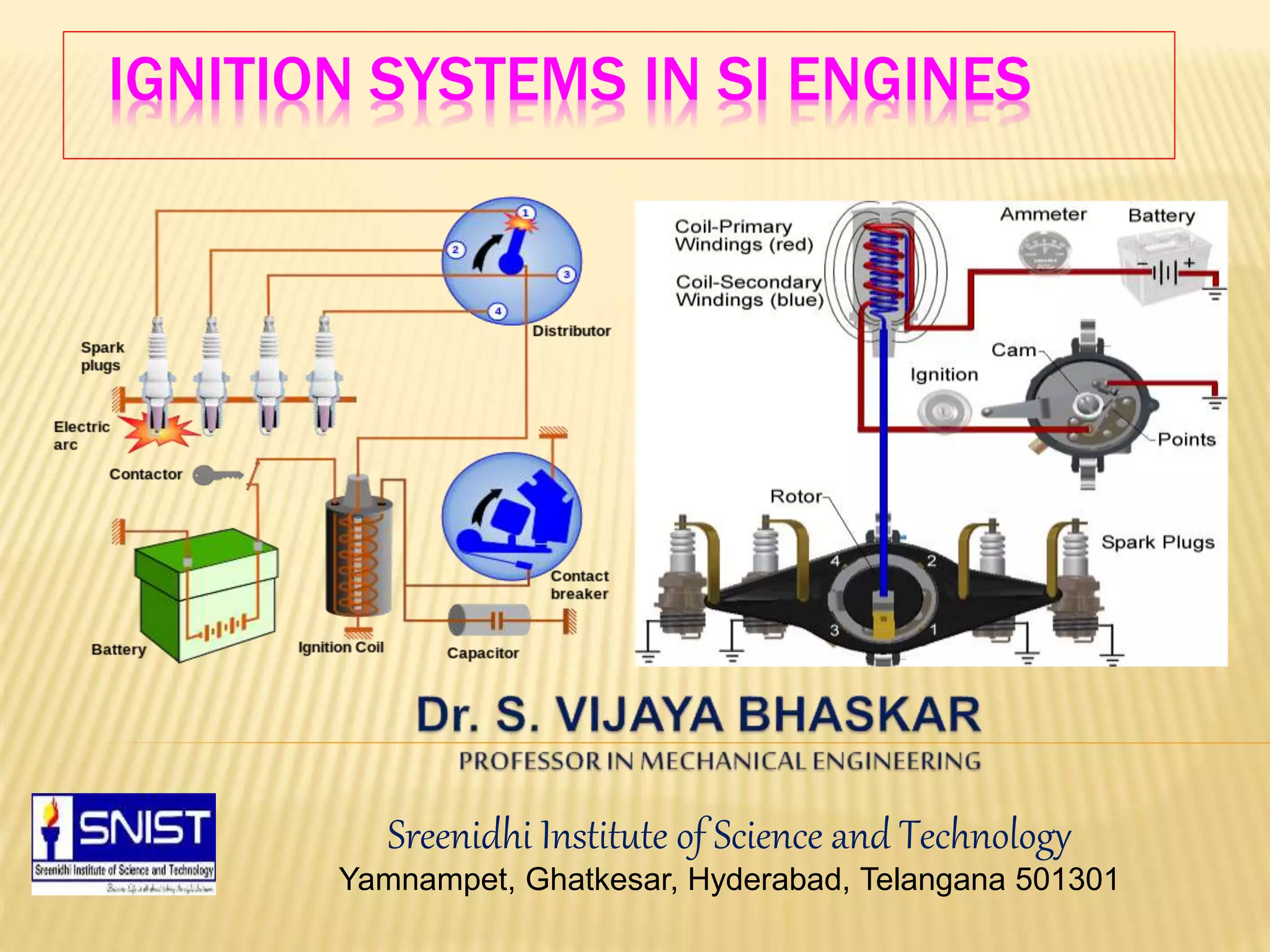

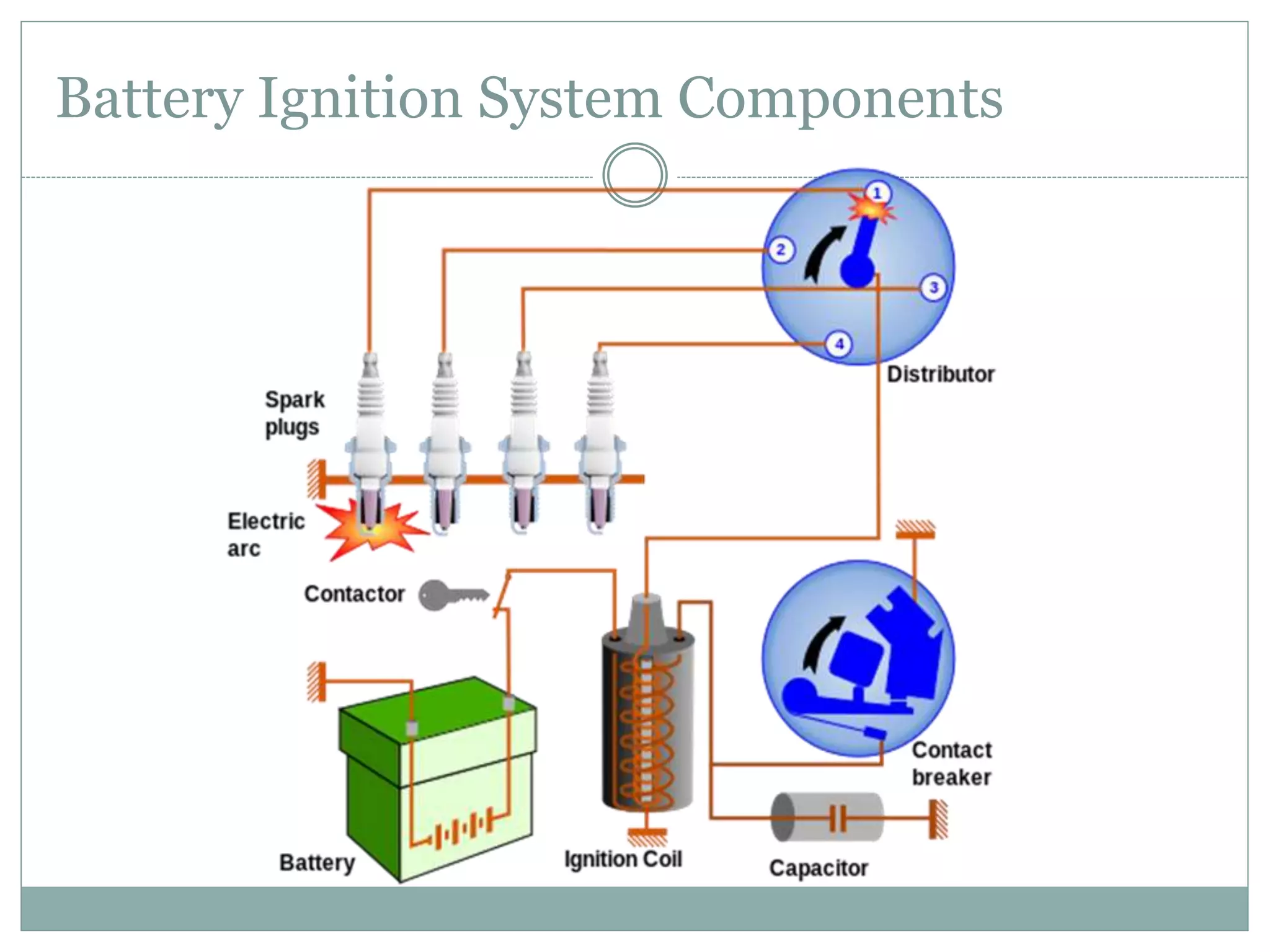

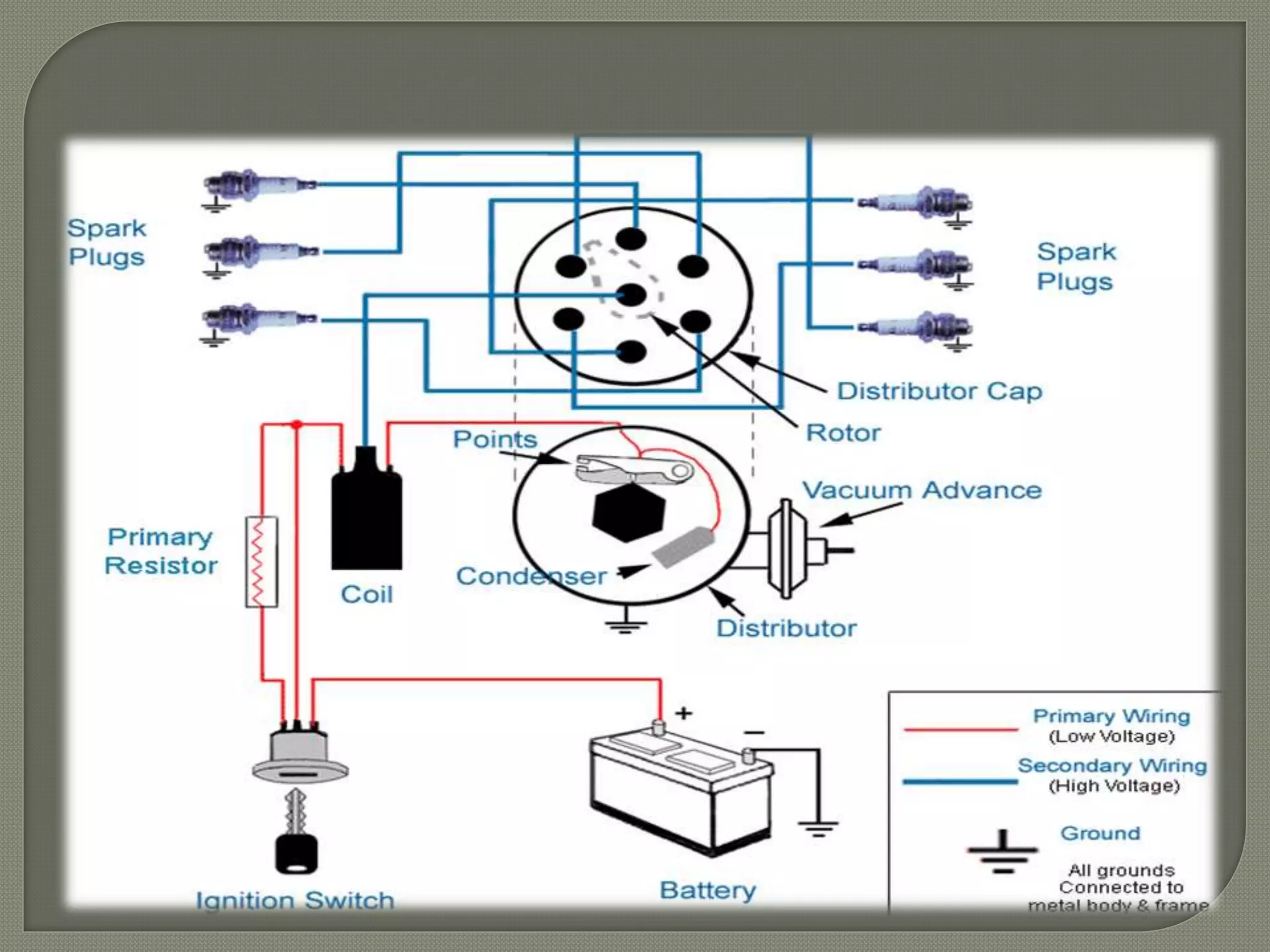

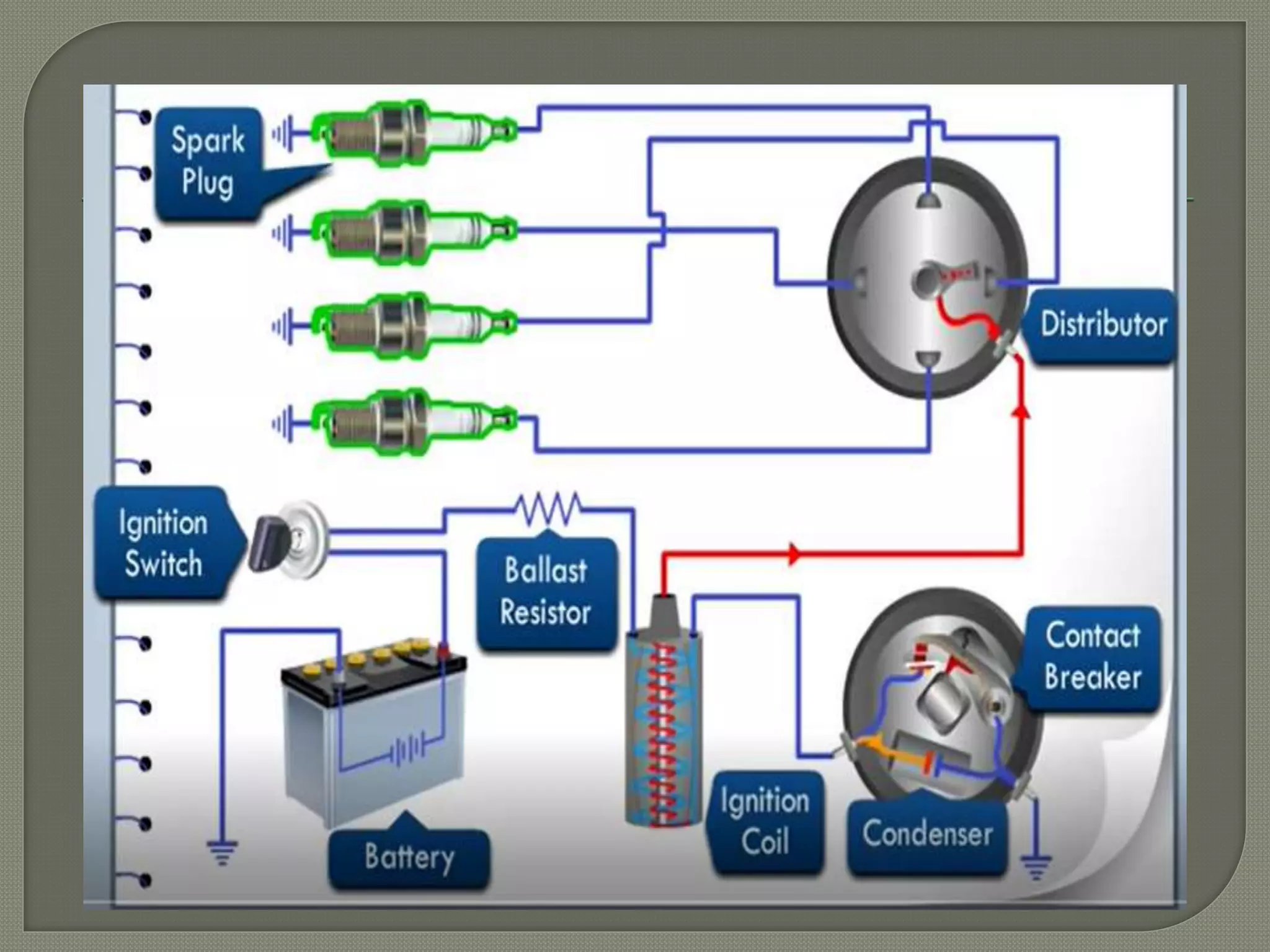

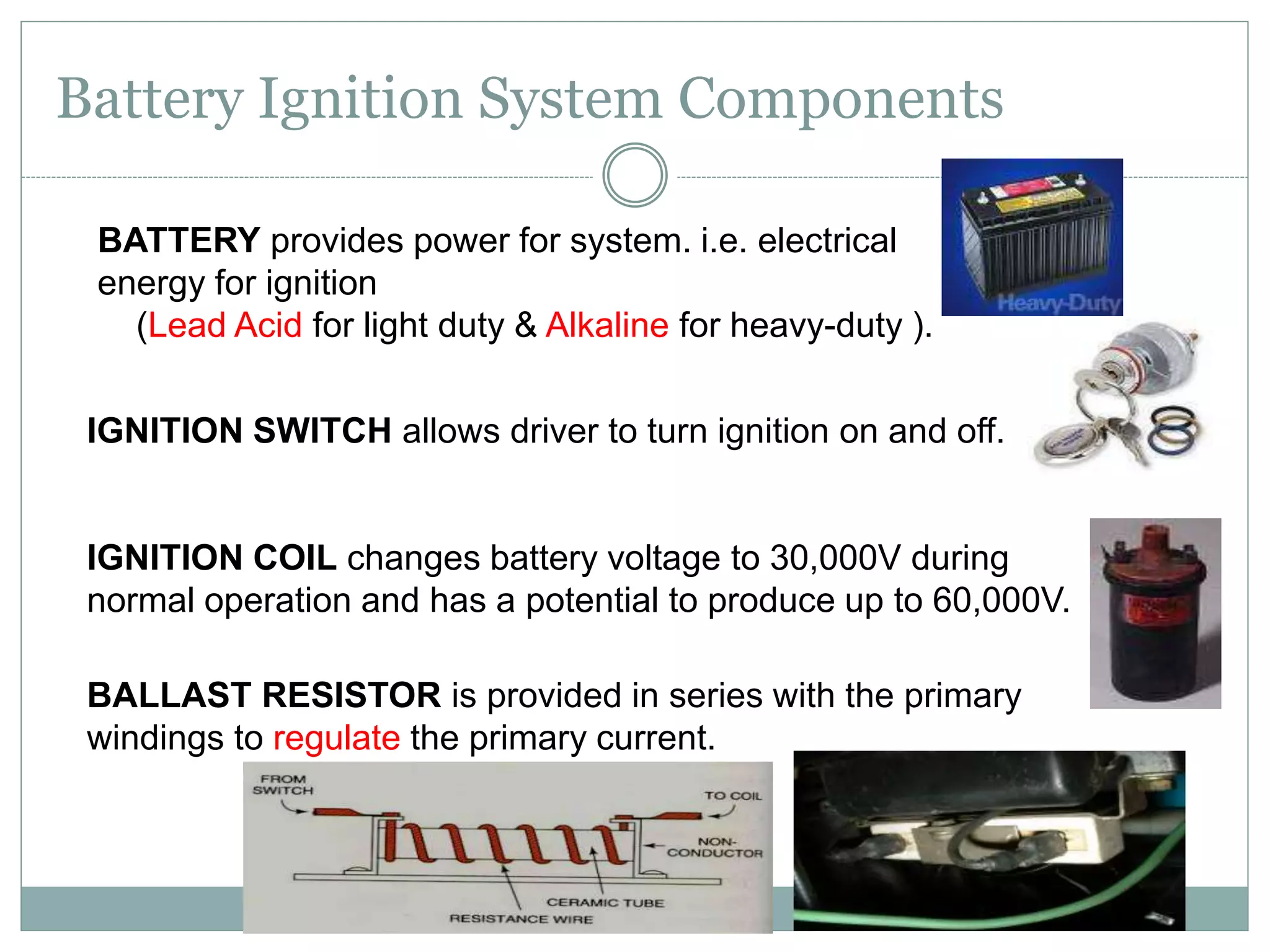

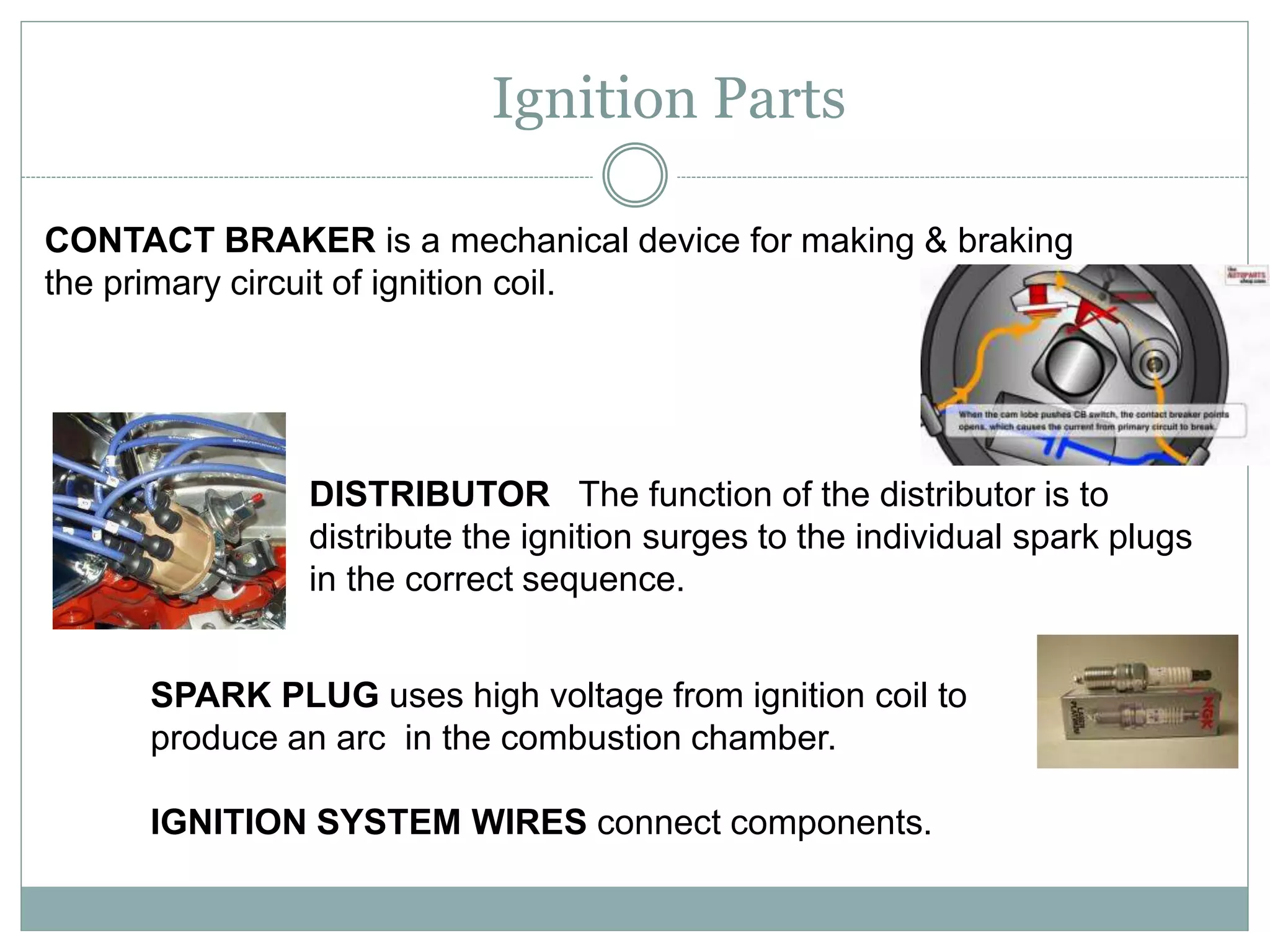

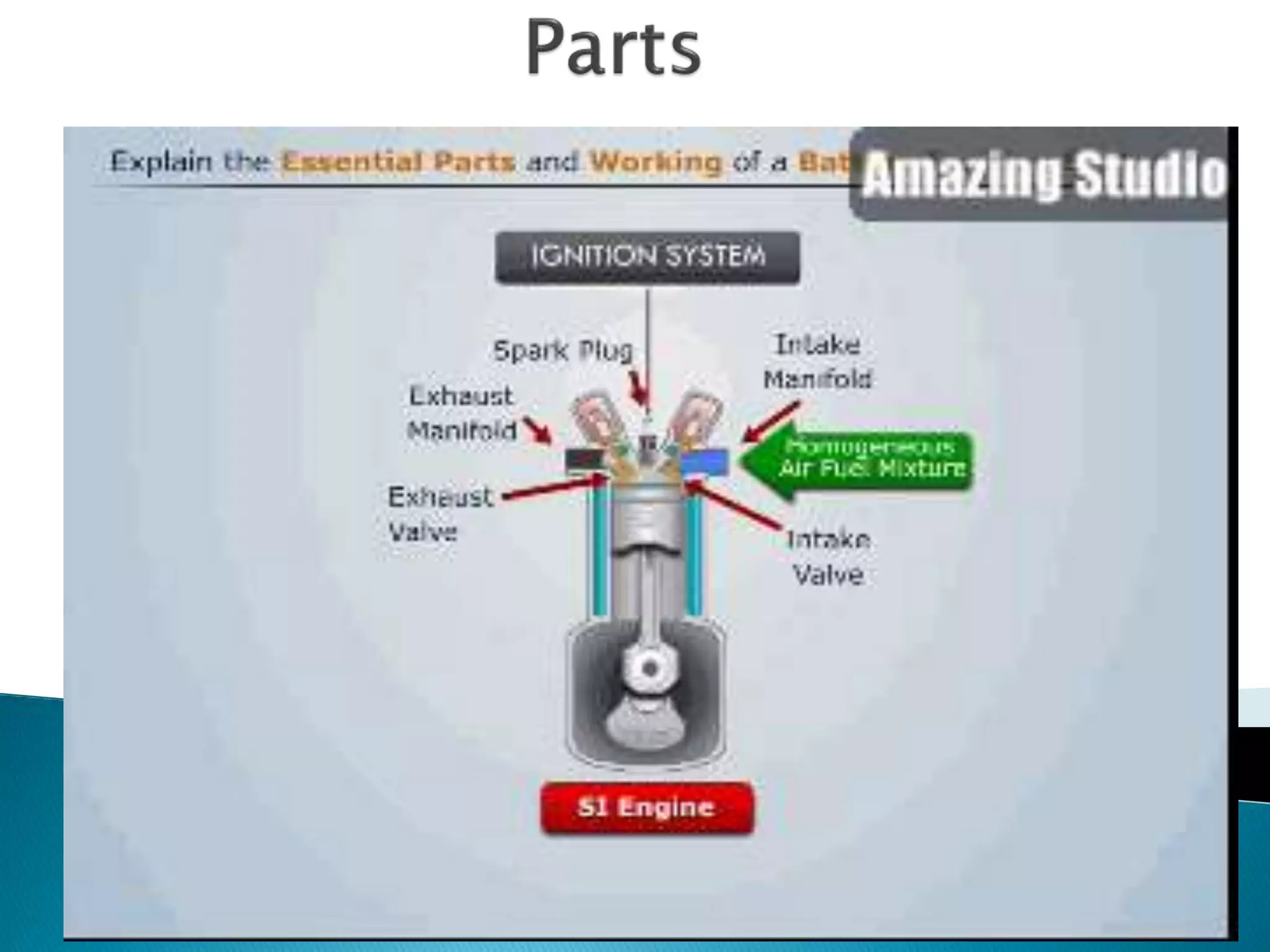

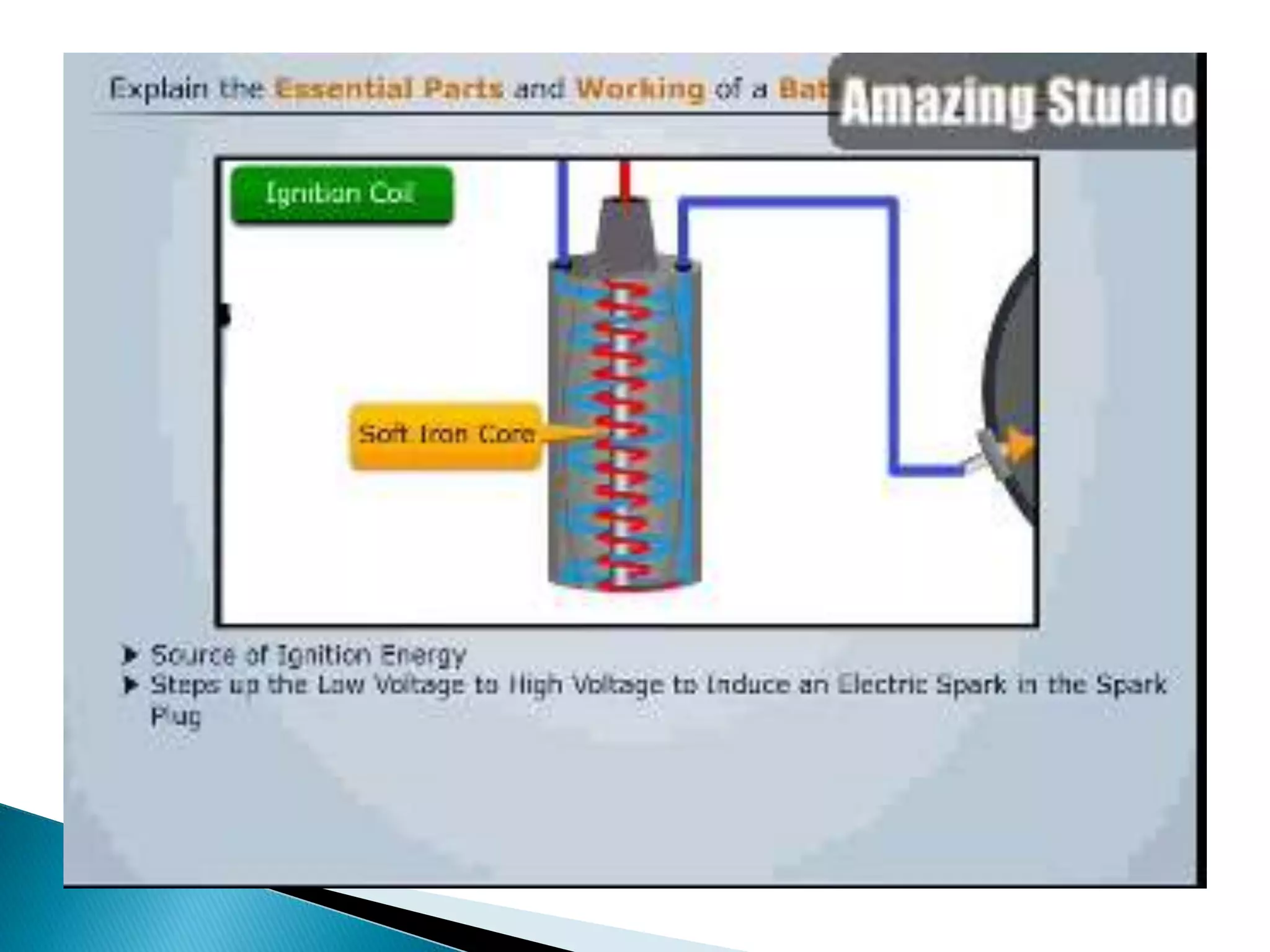

2. Key components of both systems include an ignition coil, distributor, contact breaker, and spark plugs. The ignition coil increases the voltage sent to the spark plugs, while the distributor and contact breaker control spark timing.

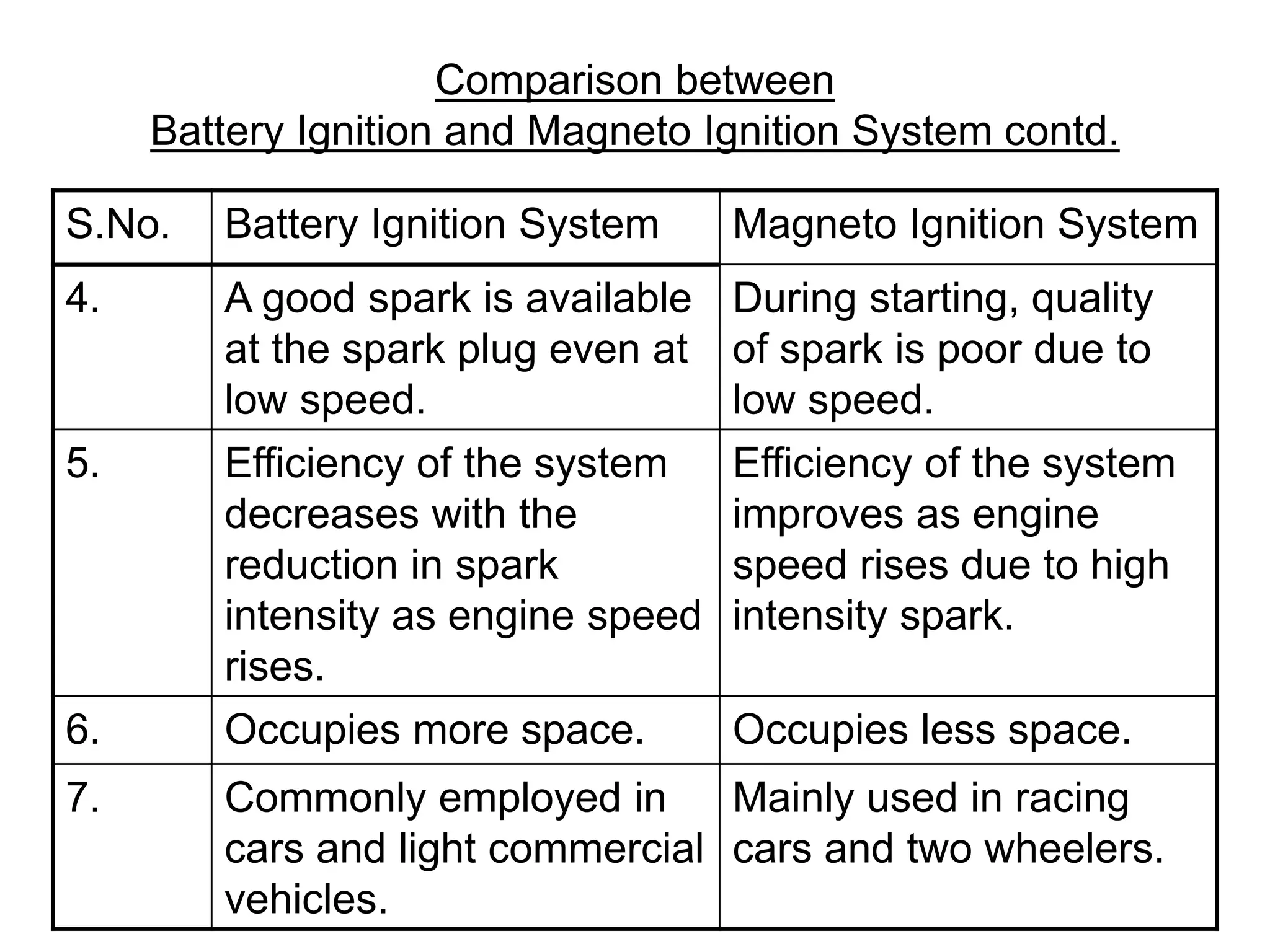

3. Battery ignition systems are more commonly used in cars and light commercial vehicles due to their ability to produce spark at low engine speeds, while magneto ignition systems are better suited for applications where high