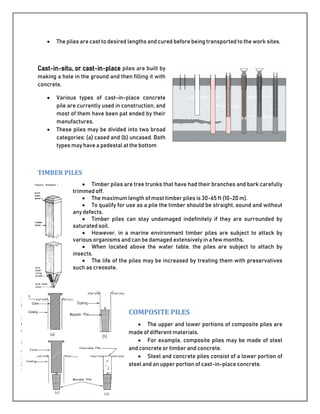

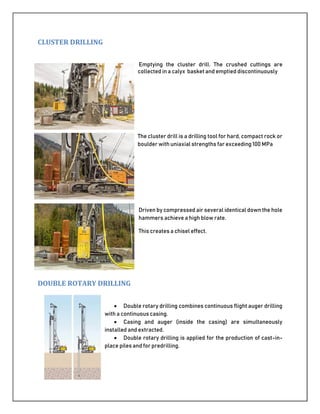

Pile foundations transfer structural loads through weak soil layers to stronger layers below. They consist of piles and a pile cap. Piles can be classified by load transfer method (end bearing or friction), installation method (displacement or replacement), or material (steel, concrete, timber, composite). Common pile installation methods include driven piles, bored piles, continuous flight auger drilling, and kelly drilling. Piles are used when soil cannot support a structure without excessive settlement.