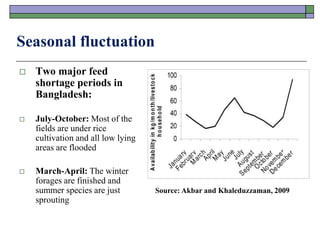

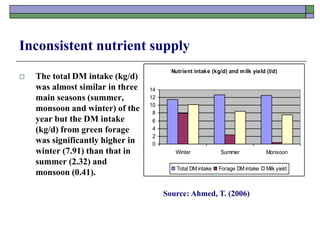

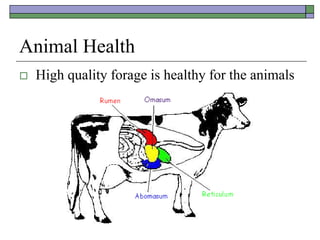

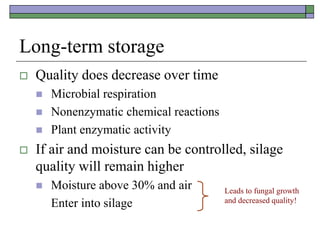

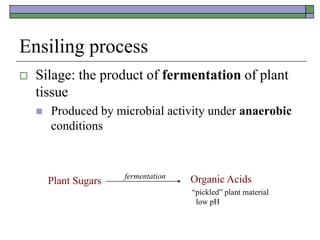

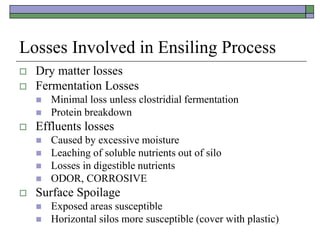

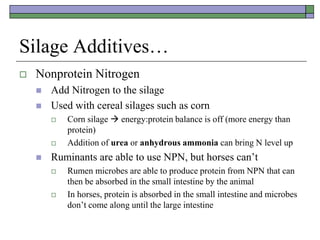

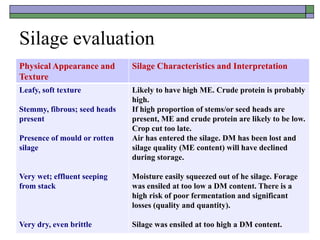

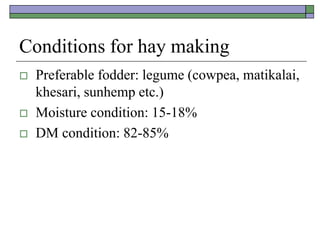

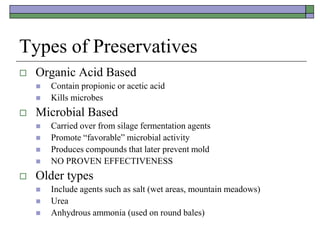

This document discusses methods for preserving forage through silage and hay making. It explains that forage preservation is important to address seasonal fluctuations in forage availability and quality. The main methods covered are silage, which involves fermenting green forage in an airtight environment, and hay, which involves drying forage to a low moisture level. Both methods aim to store forage for long periods while maintaining nutritional quality. Key factors that influence success include moisture level at preservation and exclusion of air during storage.