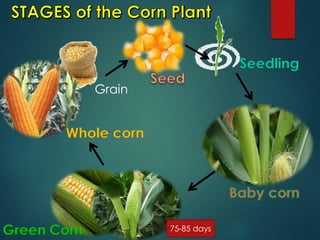

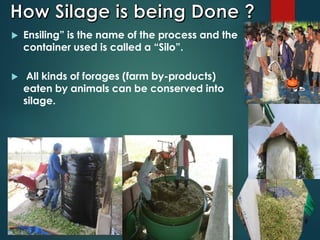

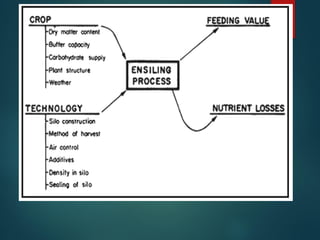

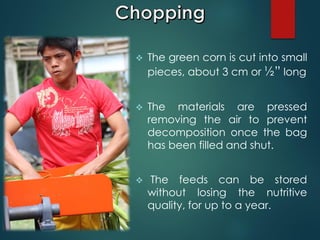

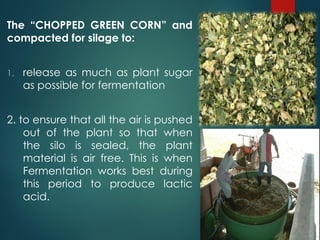

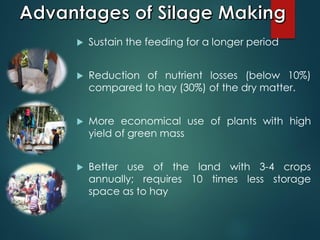

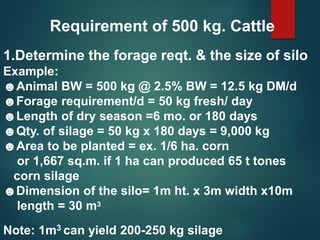

1) Silage making involves chopping green forage crops like corn and compacting them in an air-tight container to ferment. This preserves nutrients and allows feeding throughout the year.

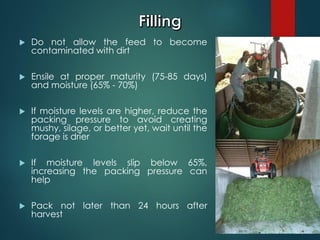

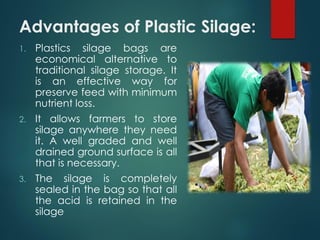

2) Plastic bag silage production has advantages over traditional methods, including lower costs, ease of use, and ability to store silage anywhere. Proper techniques like adding the right moisture content and quickly sealing bags are needed to produce high quality silage.

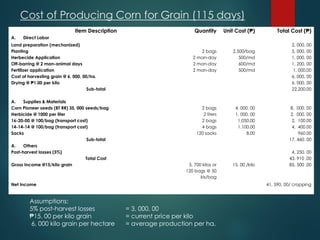

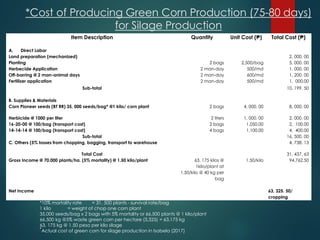

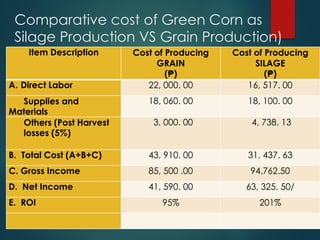

3) Producing green corn for silage rather than grain provides higher returns per hectare due to lower production costs and higher market price for silage compared to grain. Silage production yields over 50% more net income than grain production per cropping.