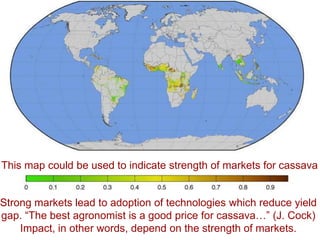

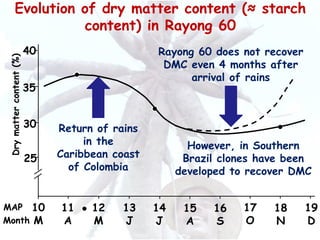

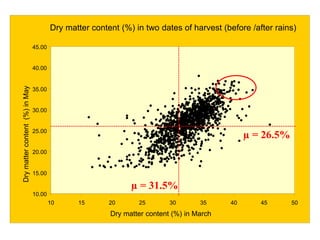

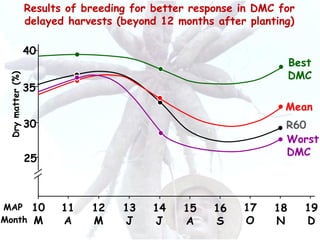

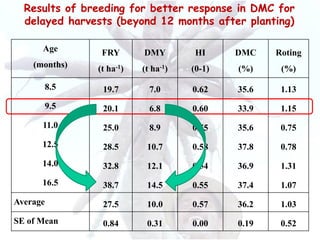

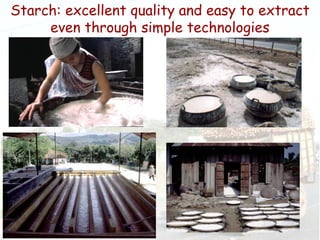

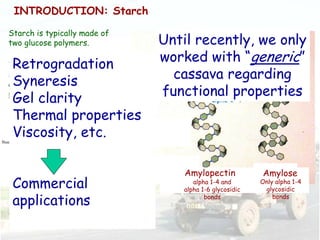

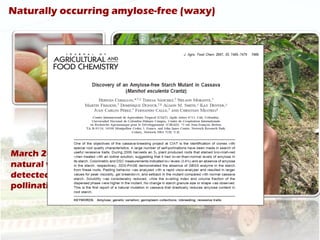

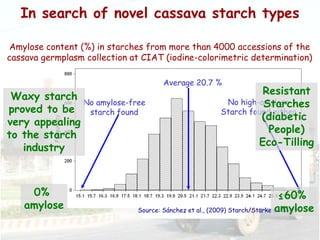

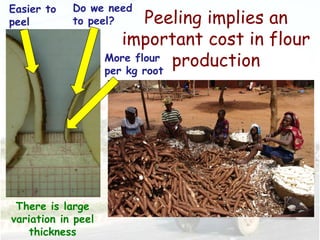

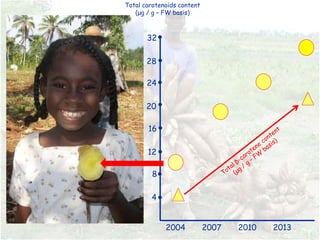

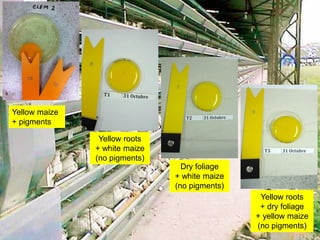

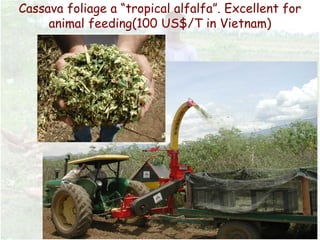

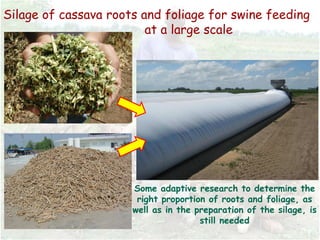

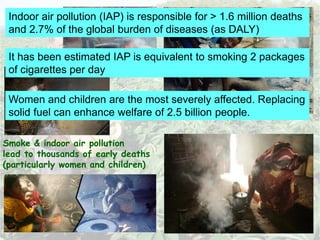

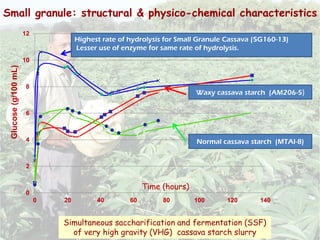

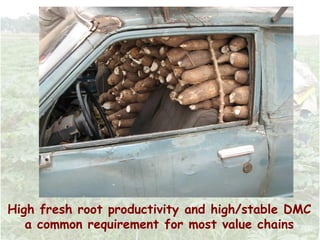

The document summarizes a workshop on cassava value chains, emphasizing the crop's importance in various sectors like nutrition, industrial applications, and biofuel production. It discusses the significance of high dry matter content for cassava's industrial uses and highlights advancements in breeding and technology for improved yields and quality. Additionally, it addresses the socio-economic impacts of cassava production, including its role in clean cooking fuel and the potential to enhance welfare in developing communities.