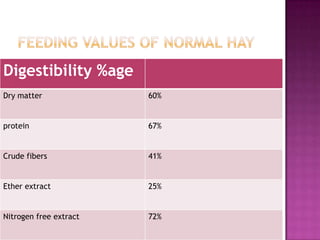

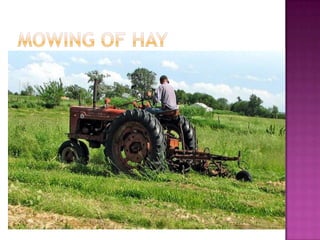

This document discusses hay making as a method for conserving green forages when fodder availability is low. It describes the steps involved, including mowing, tedding, raking and baling grasses and legumes once they have reached optimal maturity and dried sufficiently under sunlight. Losses of 10-15% of nutrients can occur during the hay making process. Proper drying and storage is important to prevent mold growth and reduce spoilage. Hay making provides a means to store forages while maintaining nutrients and quality over months until needed.