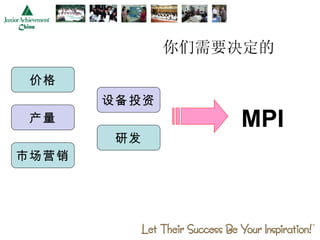

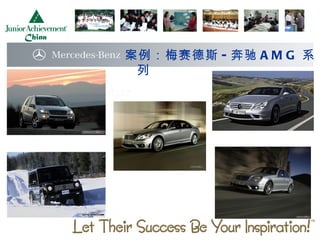

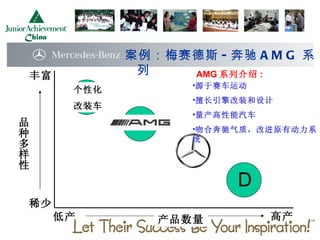

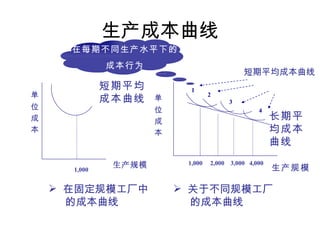

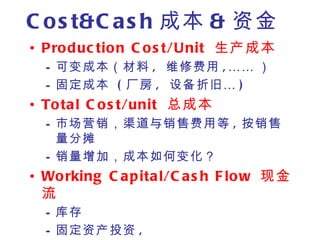

This document discusses production decisions for a Chinese company. It covers pricing strategies, equipment investment, production volume, research and development, and marketing. It provides examples on production strategy and product variety, as well as an example of Mercedes-Benz's AMG series. Key factors to consider include price, demand, supply, production efficiency, market share, and growth potential. The document also outlines MESE's six steps for pricing decisions.