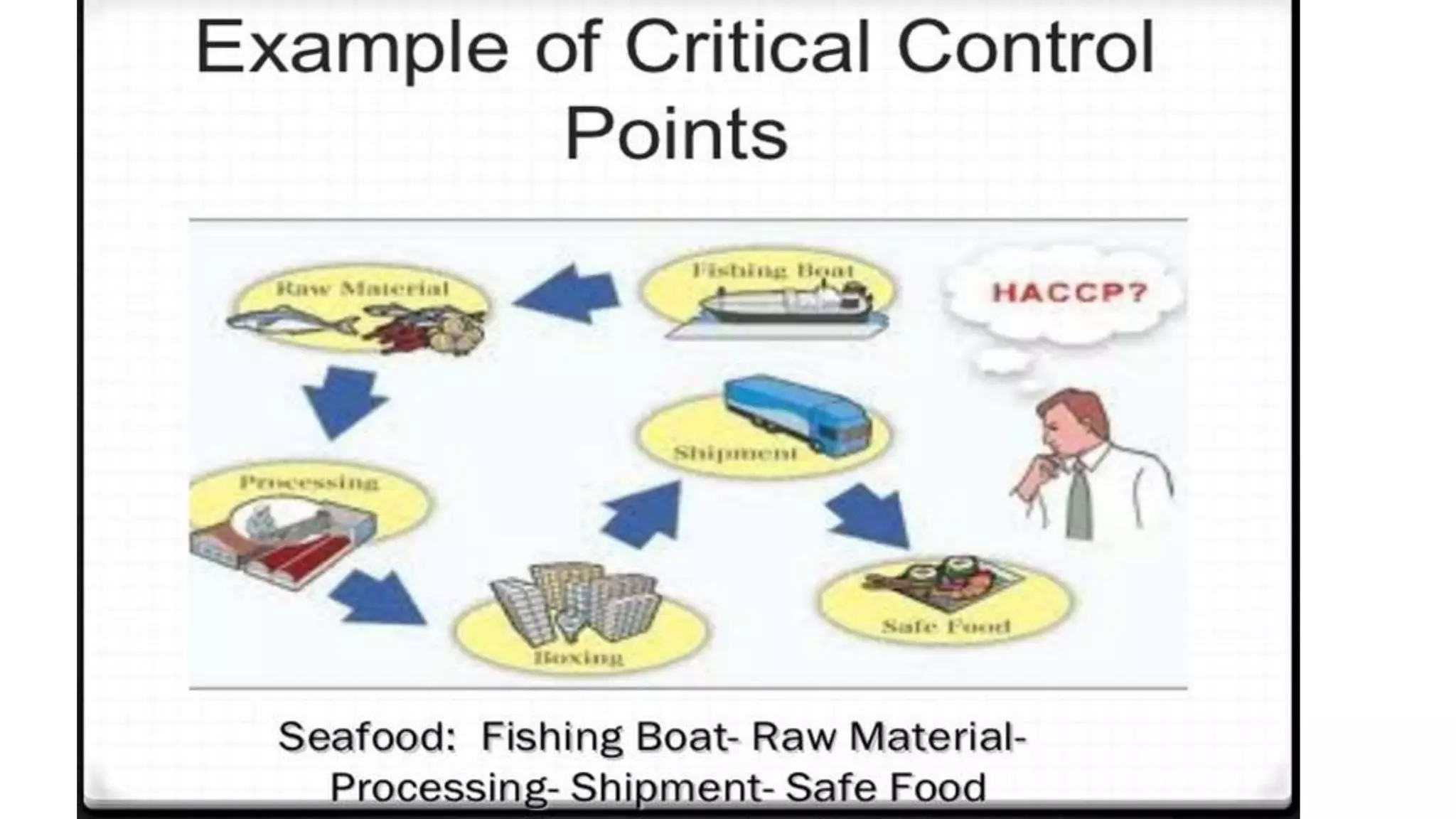

This document discusses quality control in the food industry. It outlines several key aspects of a quality control program, including ingredient specifications, approved supplier lists, product formulations, manufacturing procedures, in-process records, packaging and labeling standards, and adherence to good manufacturing practices and sanitation. Maintaining quality is important to ensure safe, consistent food products and protect public health.