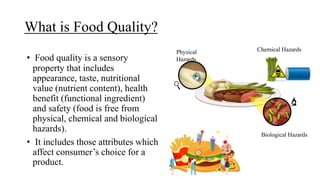

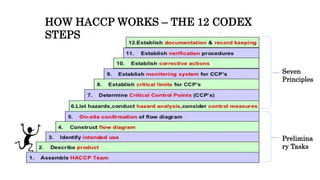

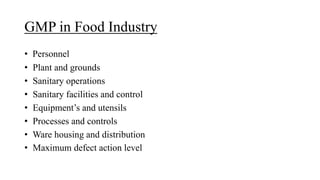

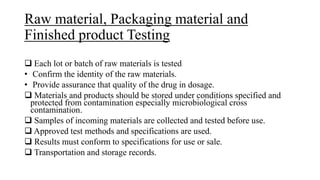

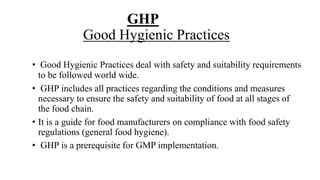

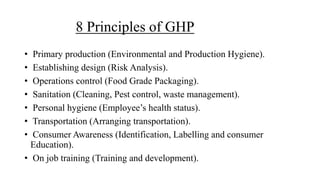

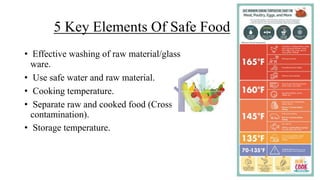

This document discusses food quality management systems. It begins by defining food quality and the need for quality control in the food industry to meet consumer requirements. It then explains several common food quality management systems used in the industry: ISO, HACCP, TACCP, VACCP, GMP, and GHP. ISO and HACCP are described in more detail. The key elements of producing safe food are effective washing, using safe materials and water, proper cooking temperatures, preventing cross-contamination, and correct storage temperatures.