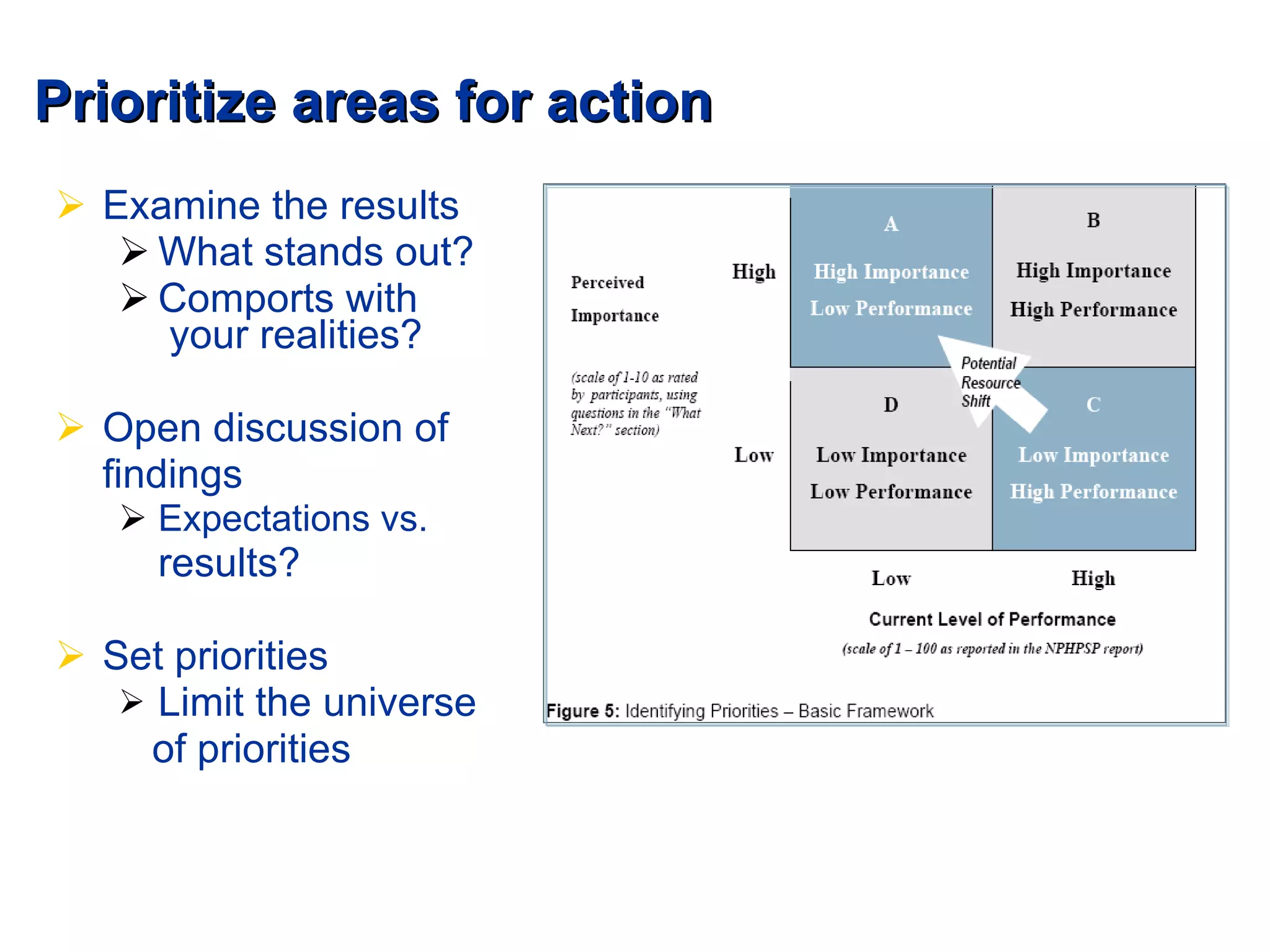

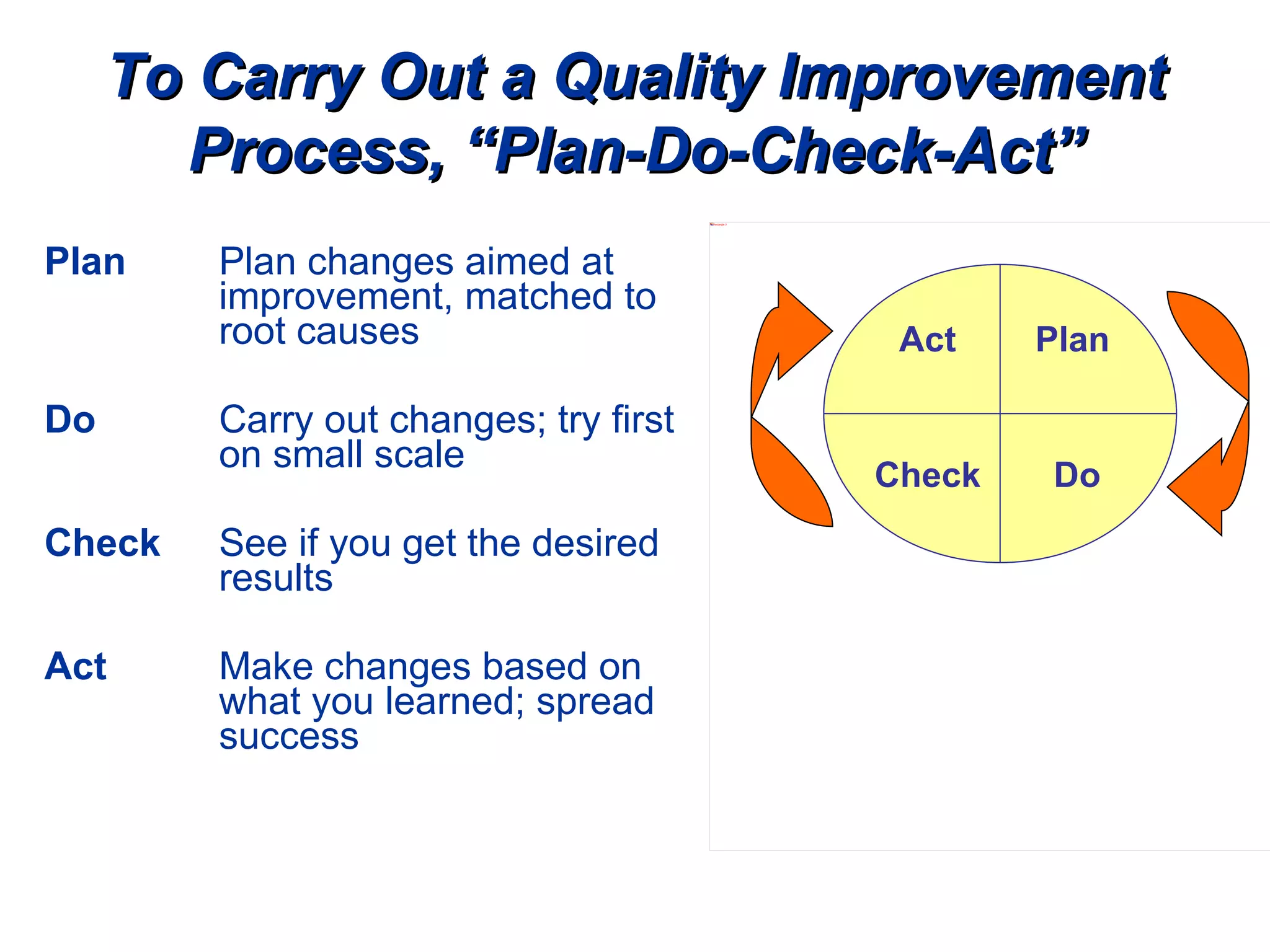

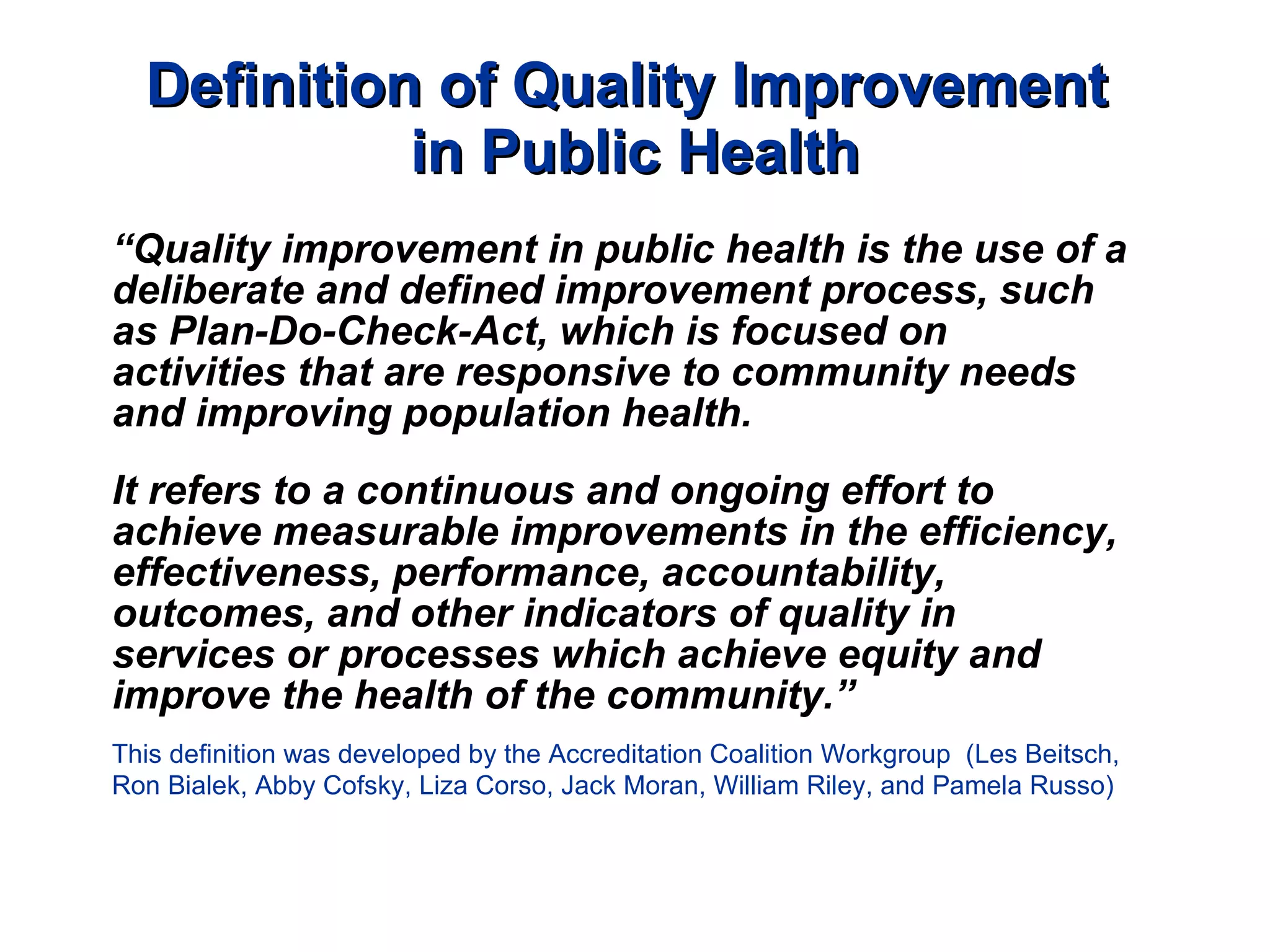

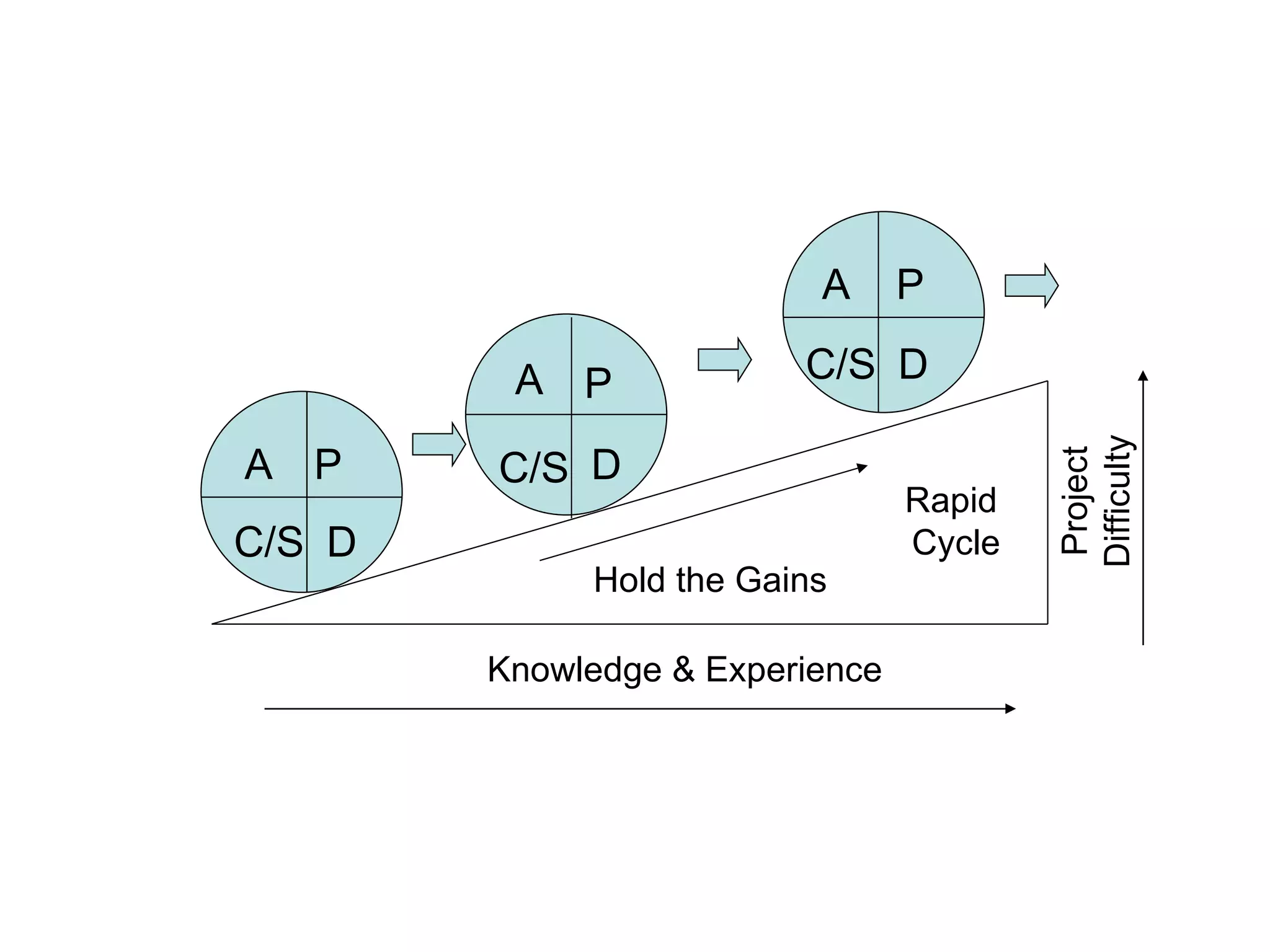

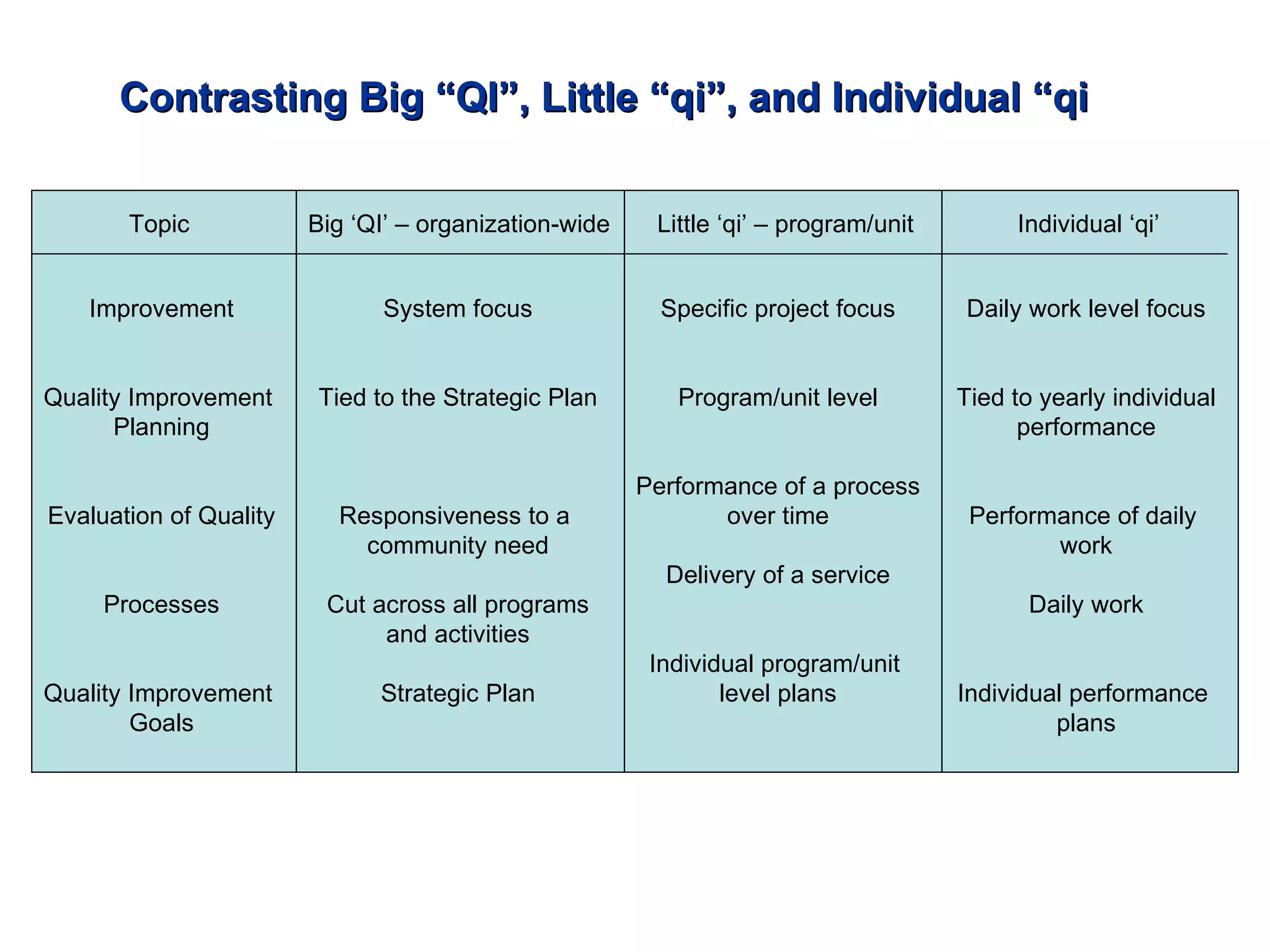

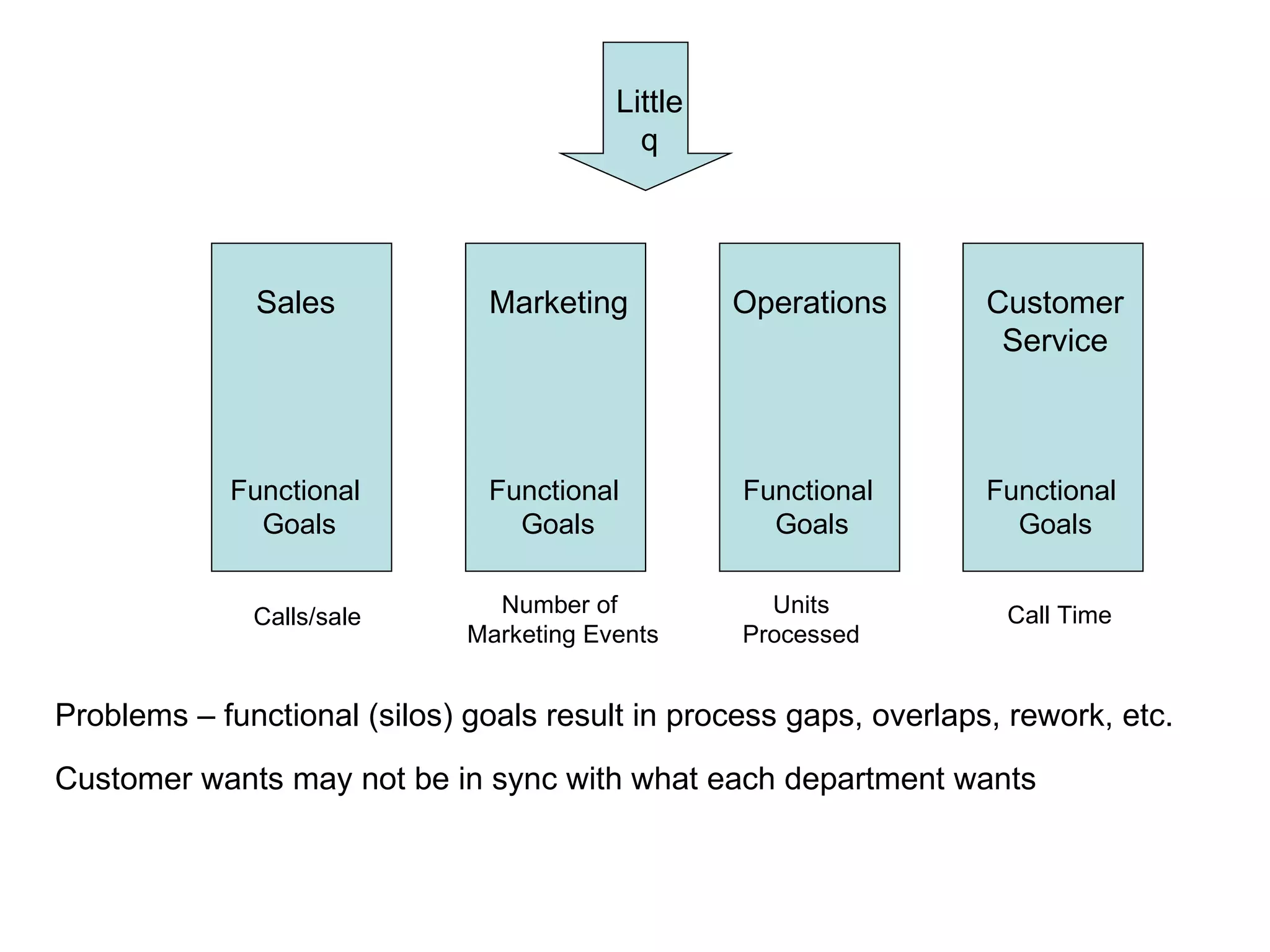

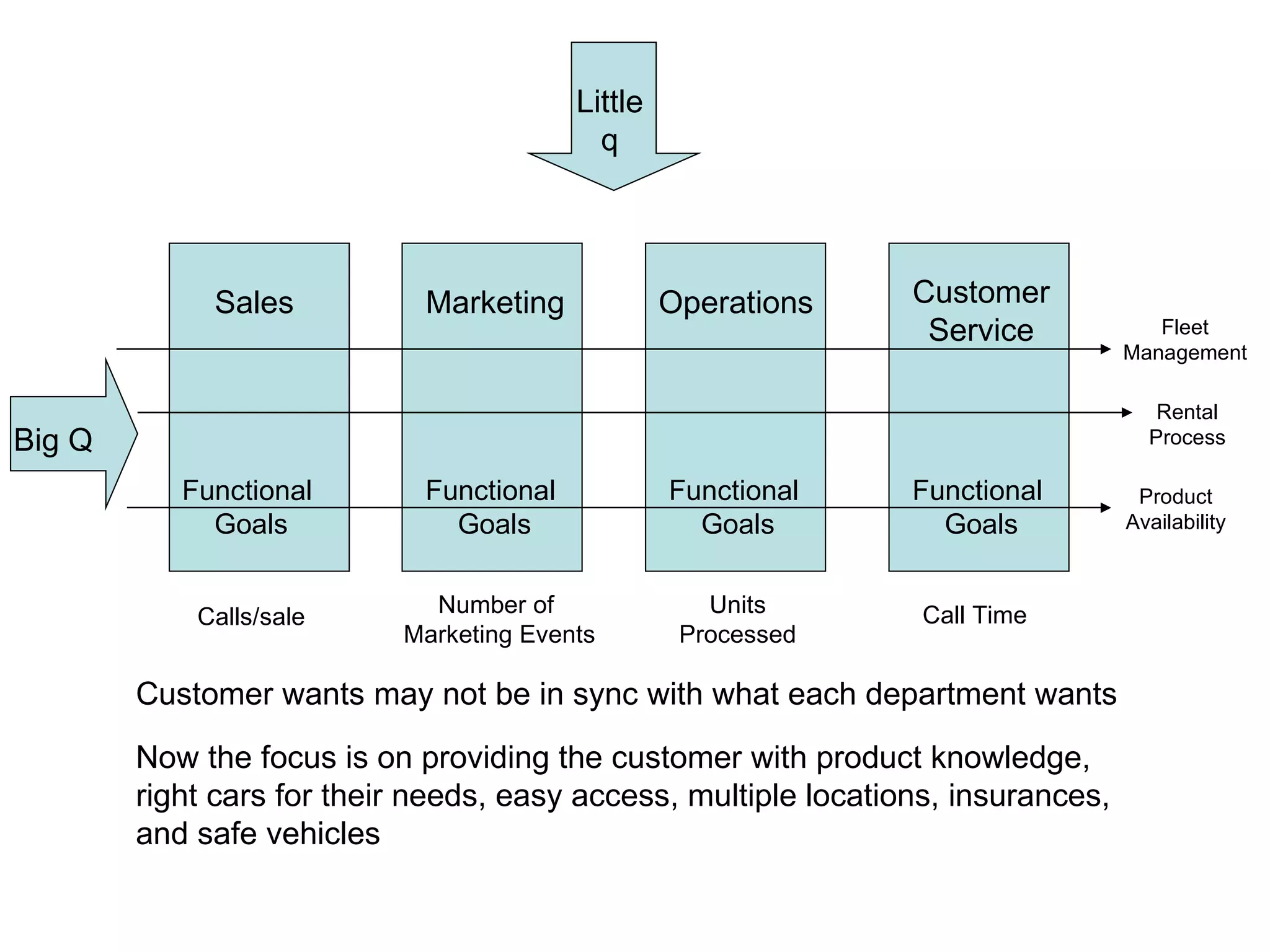

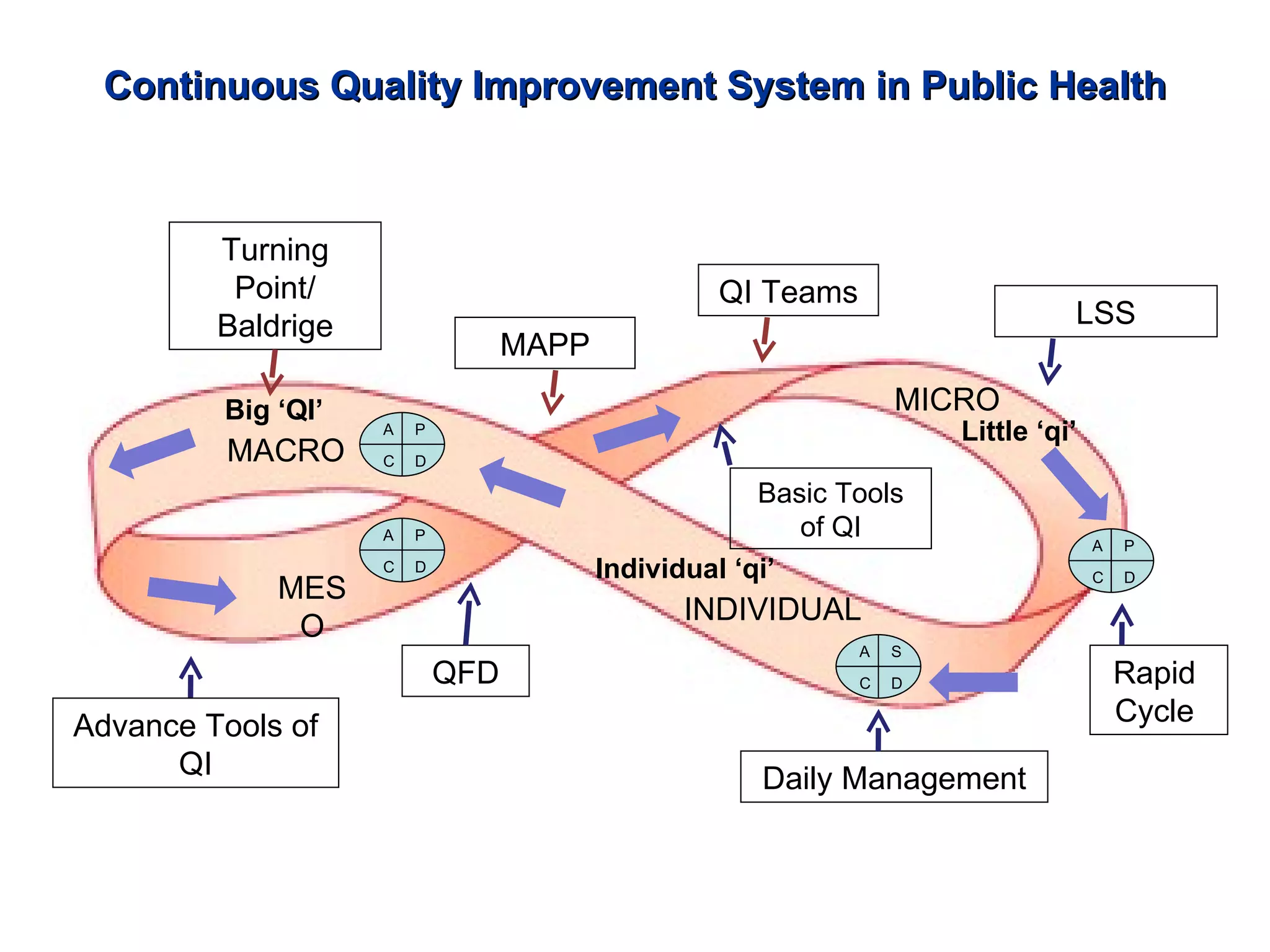

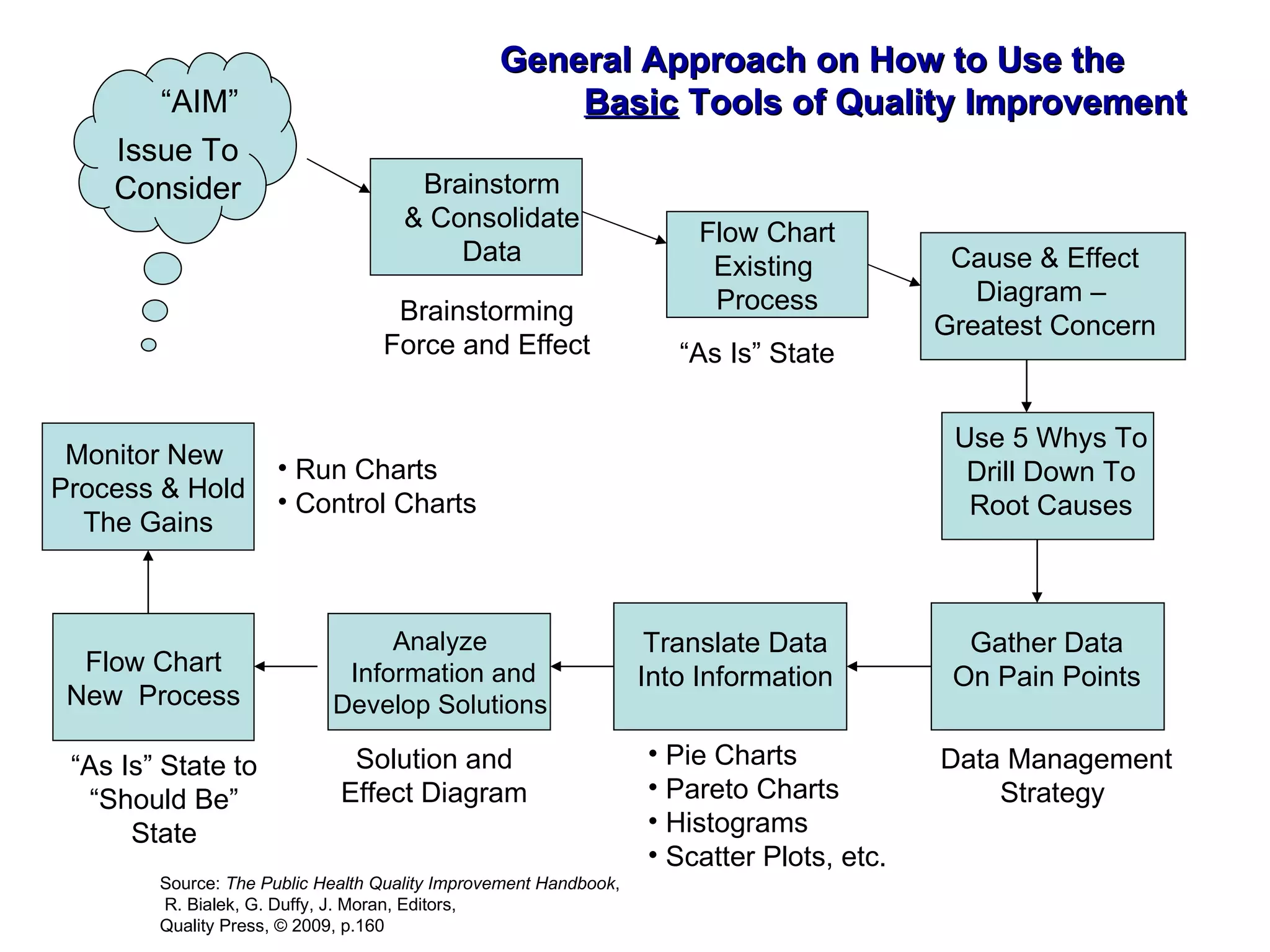

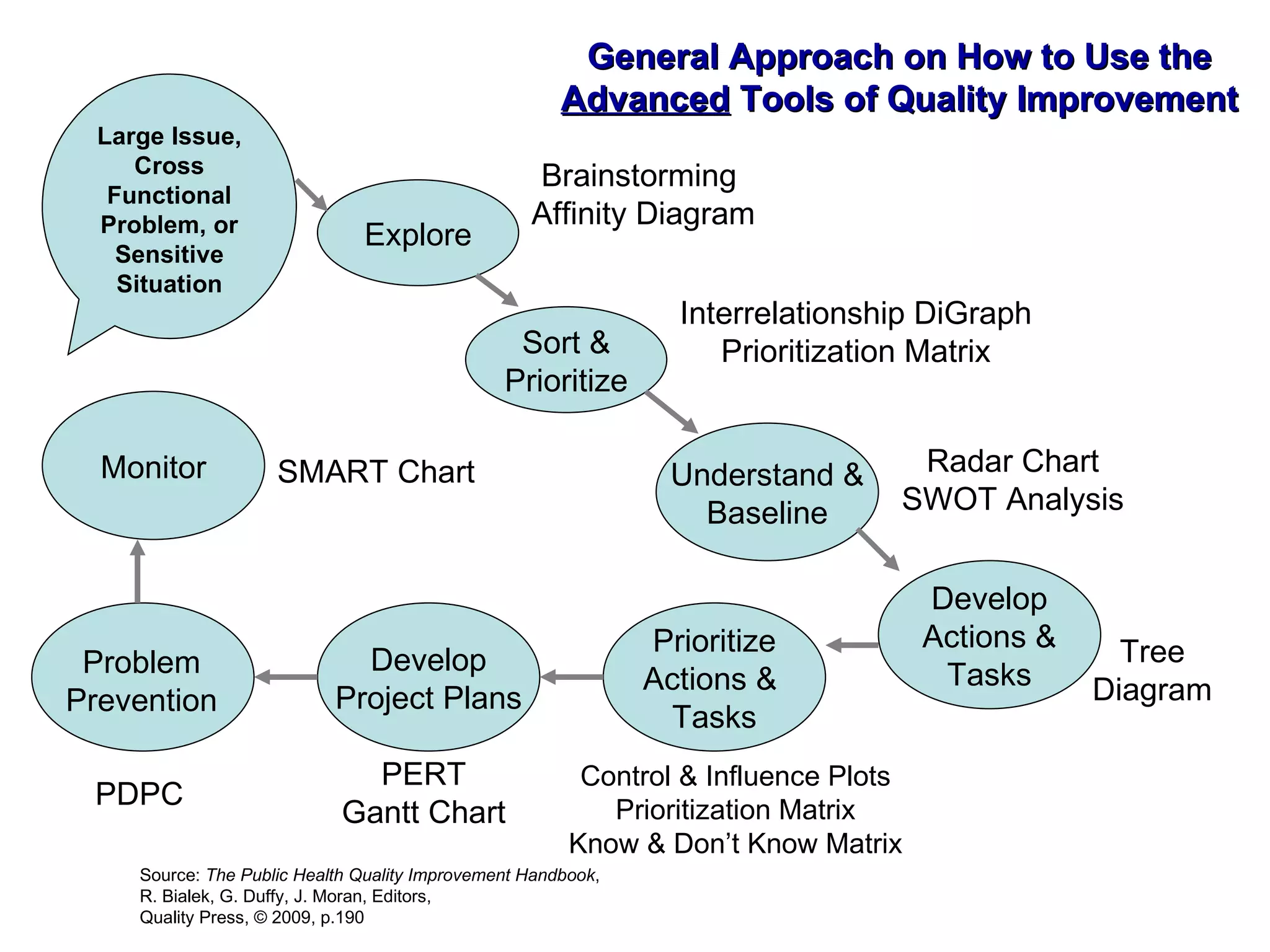

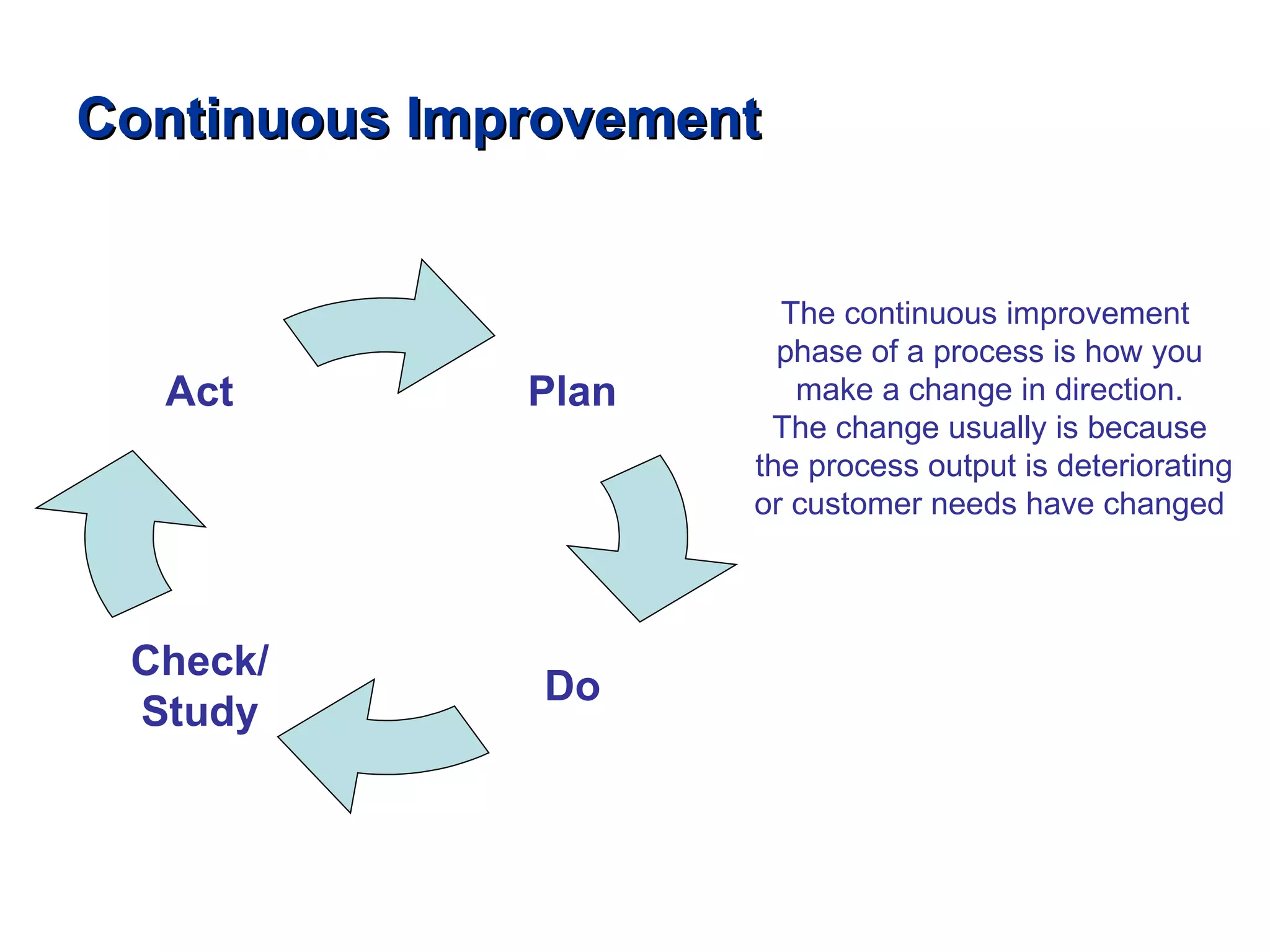

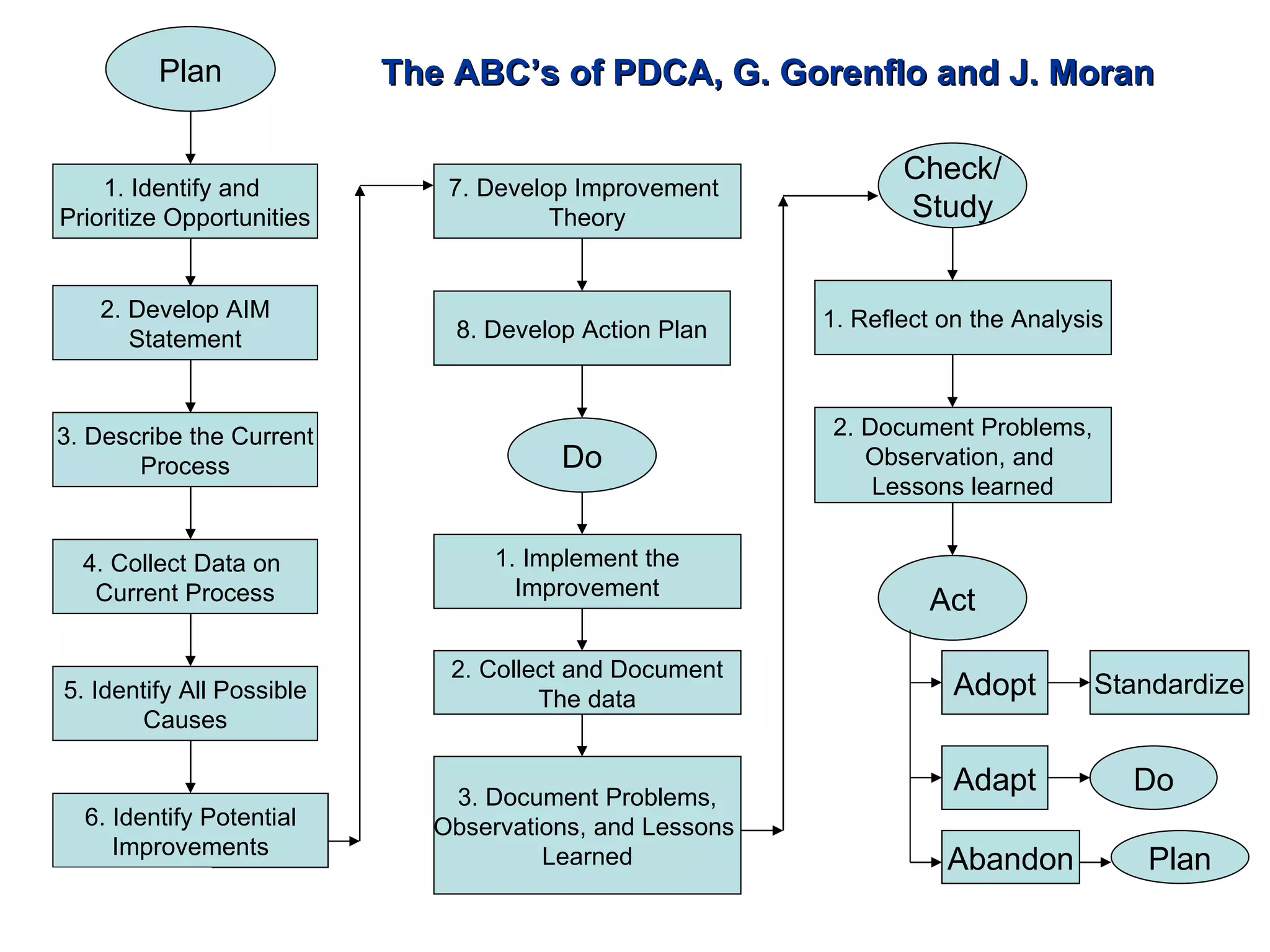

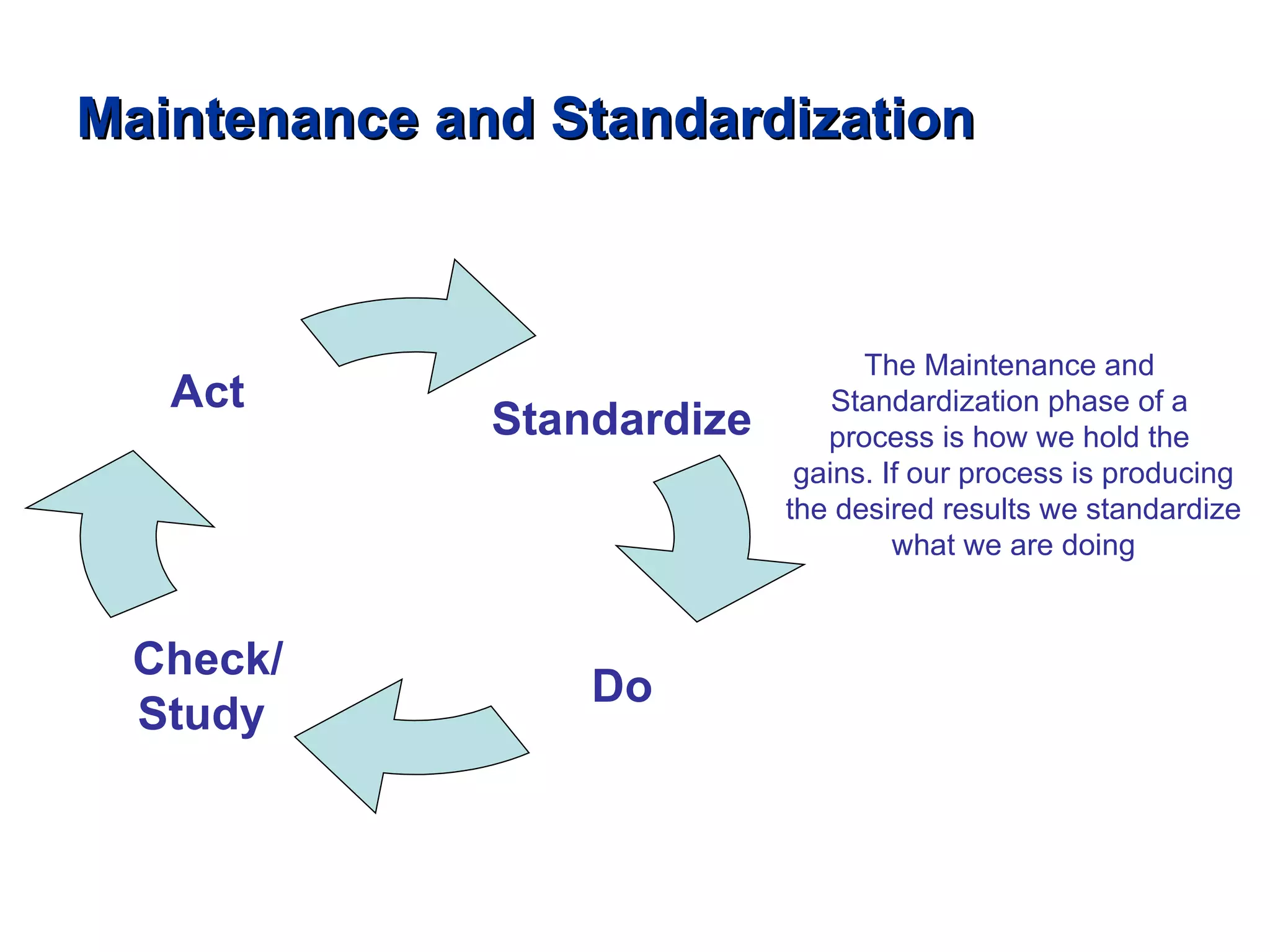

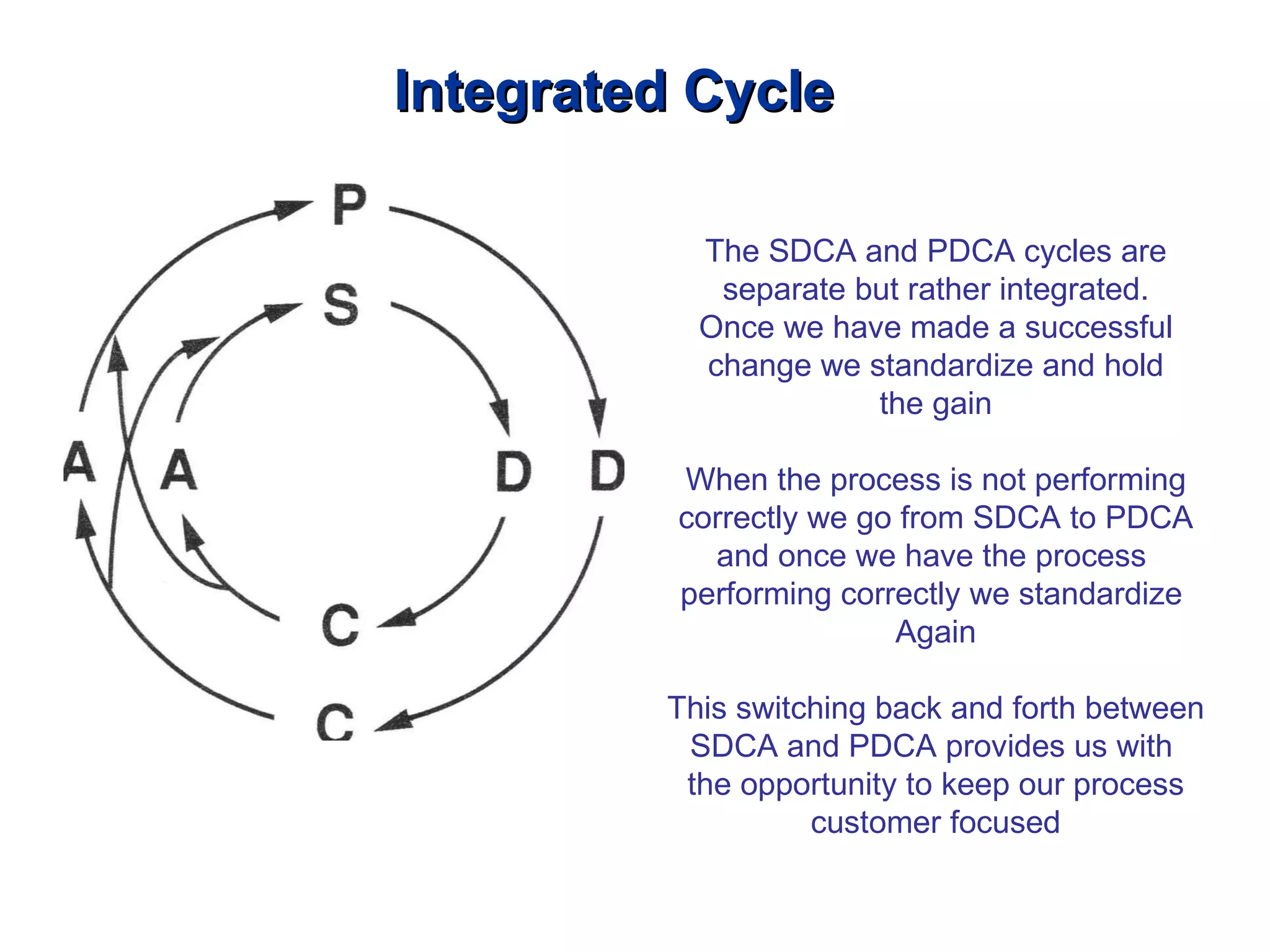

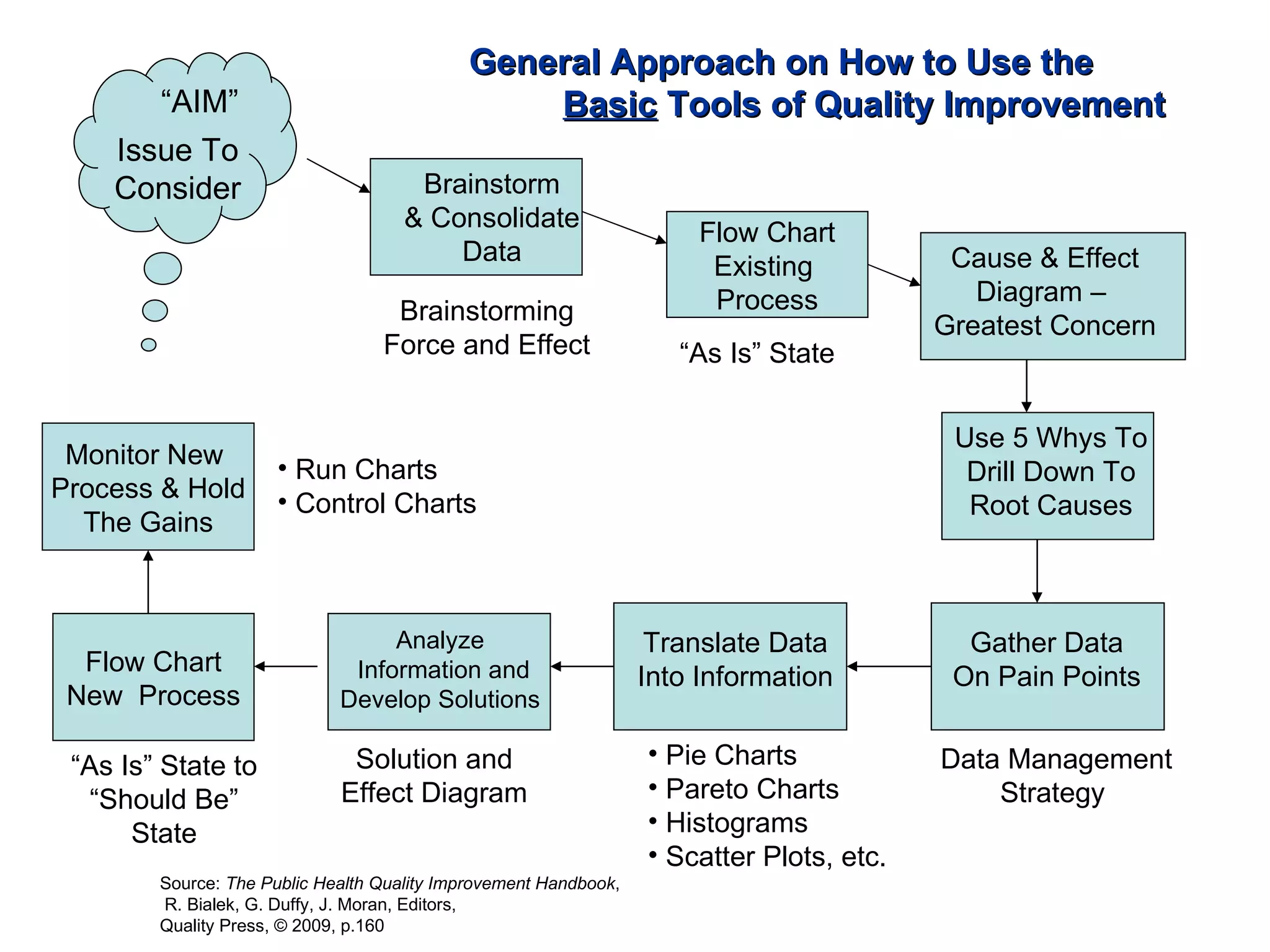

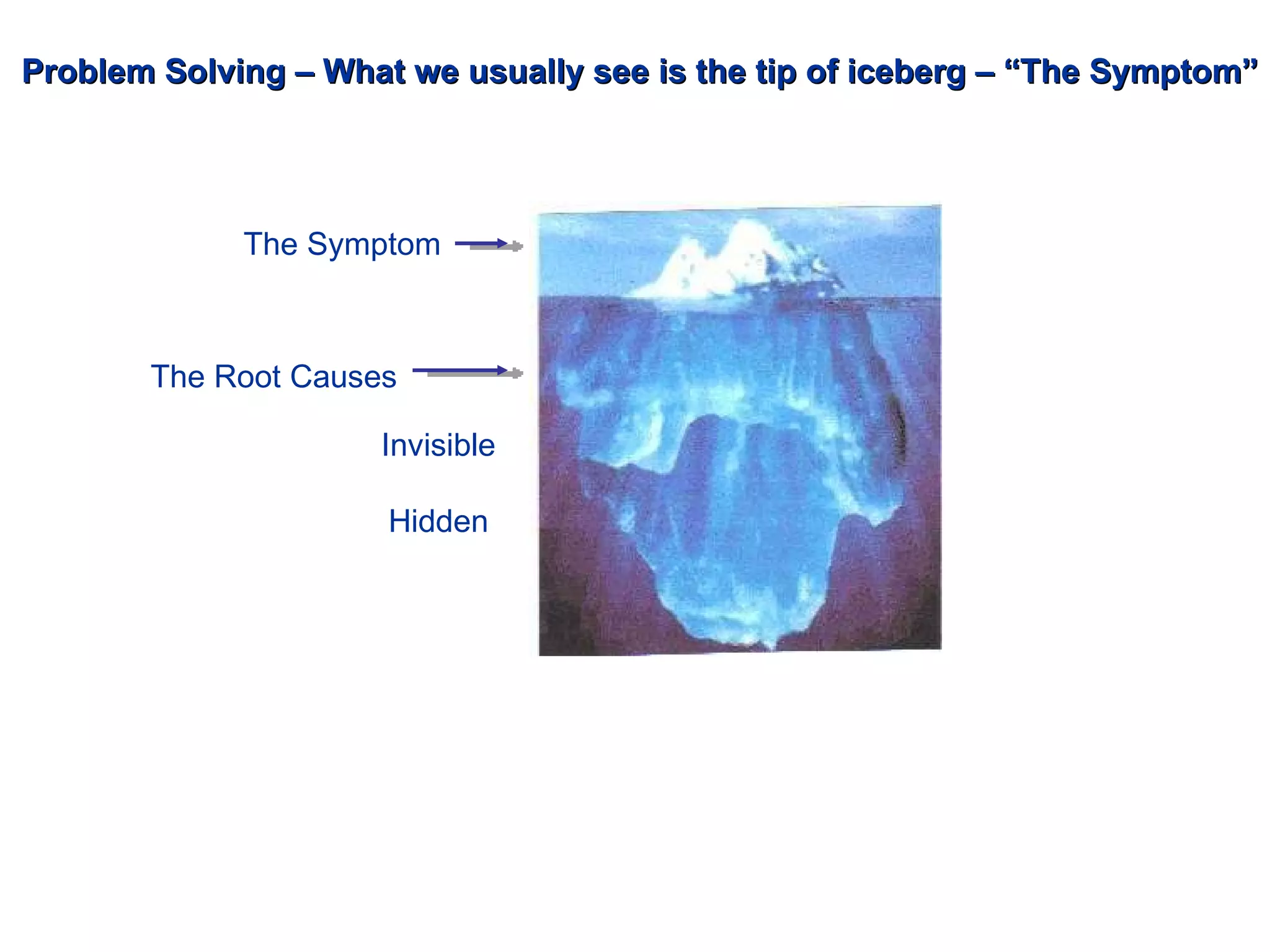

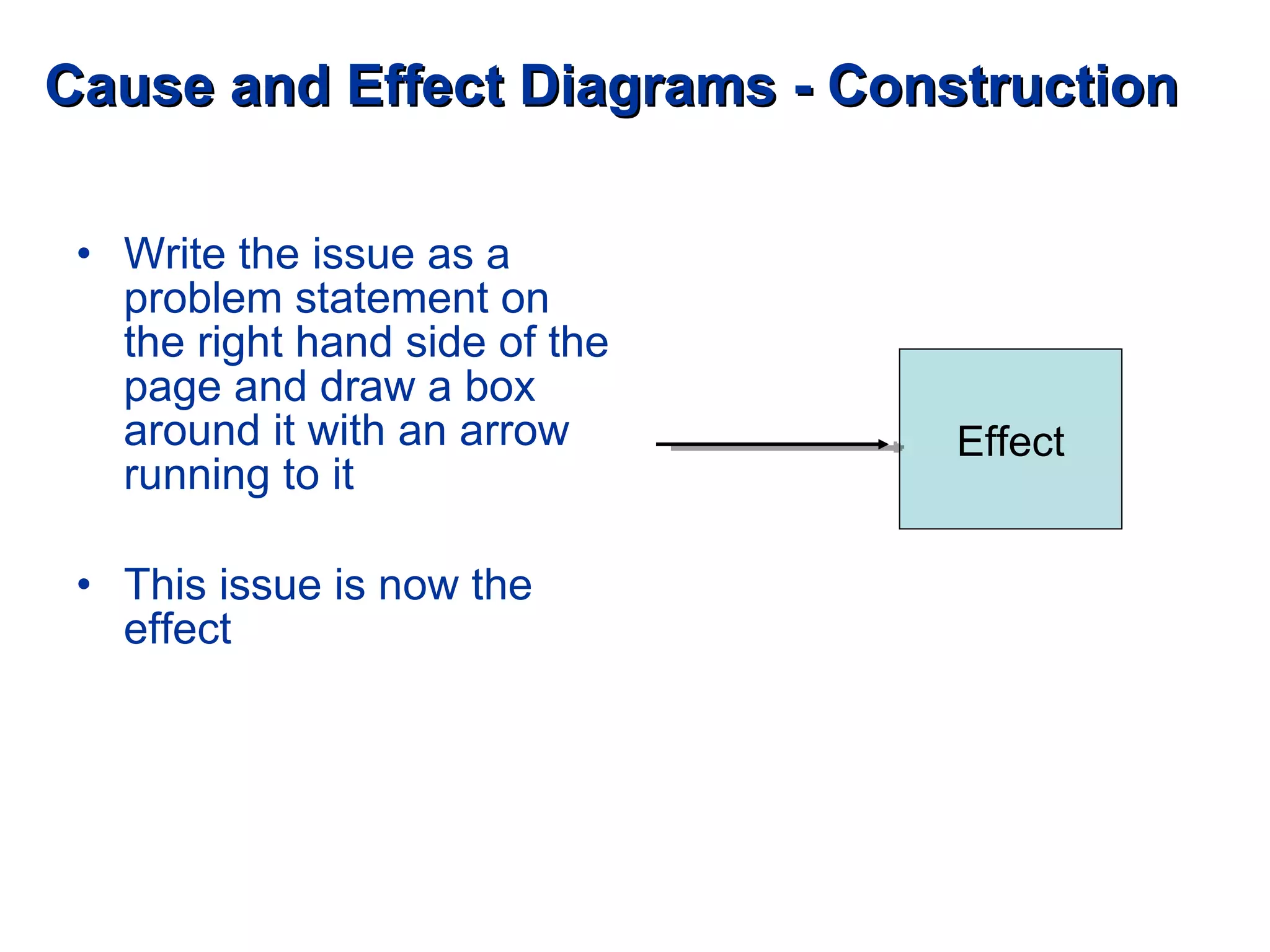

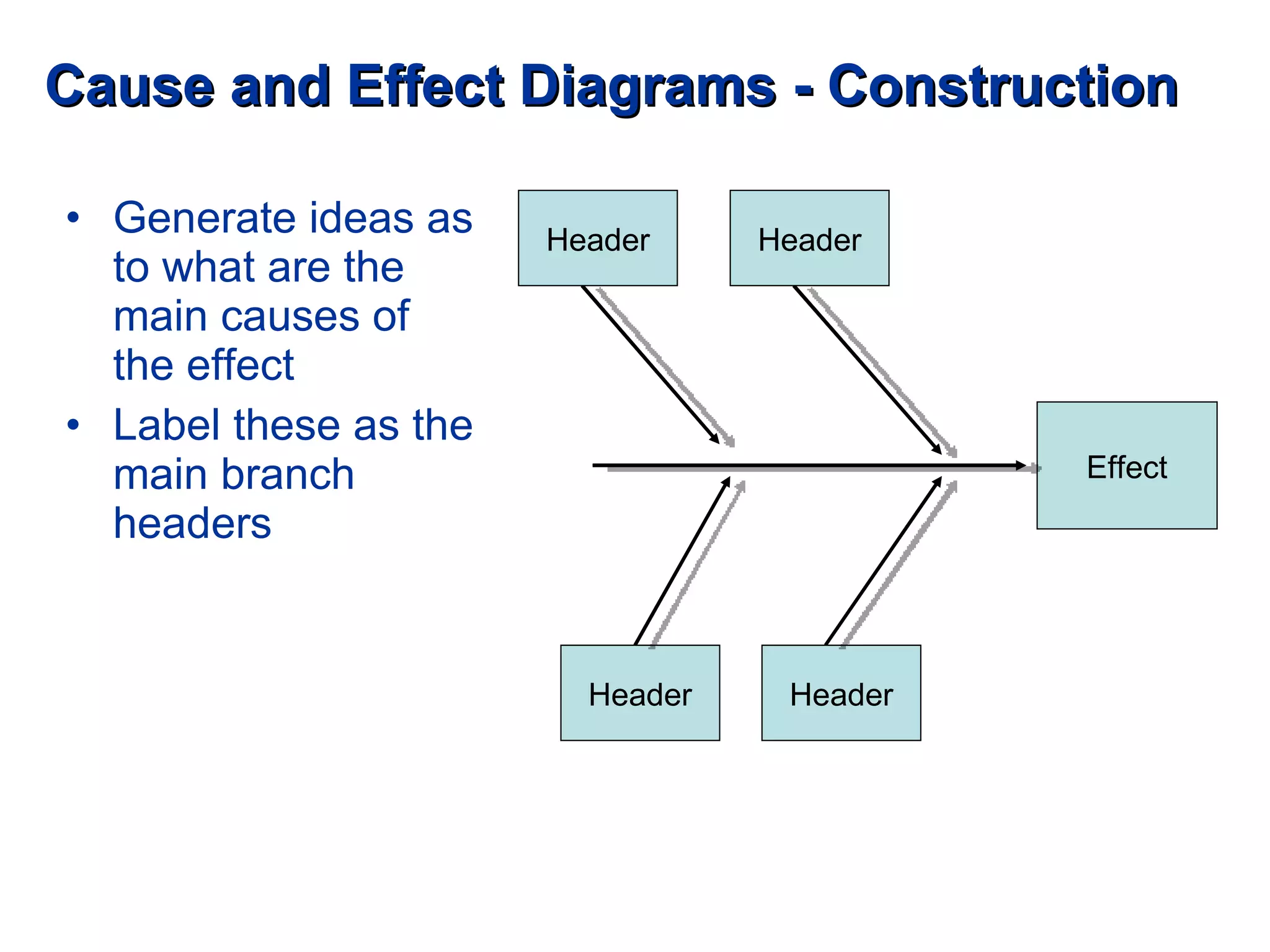

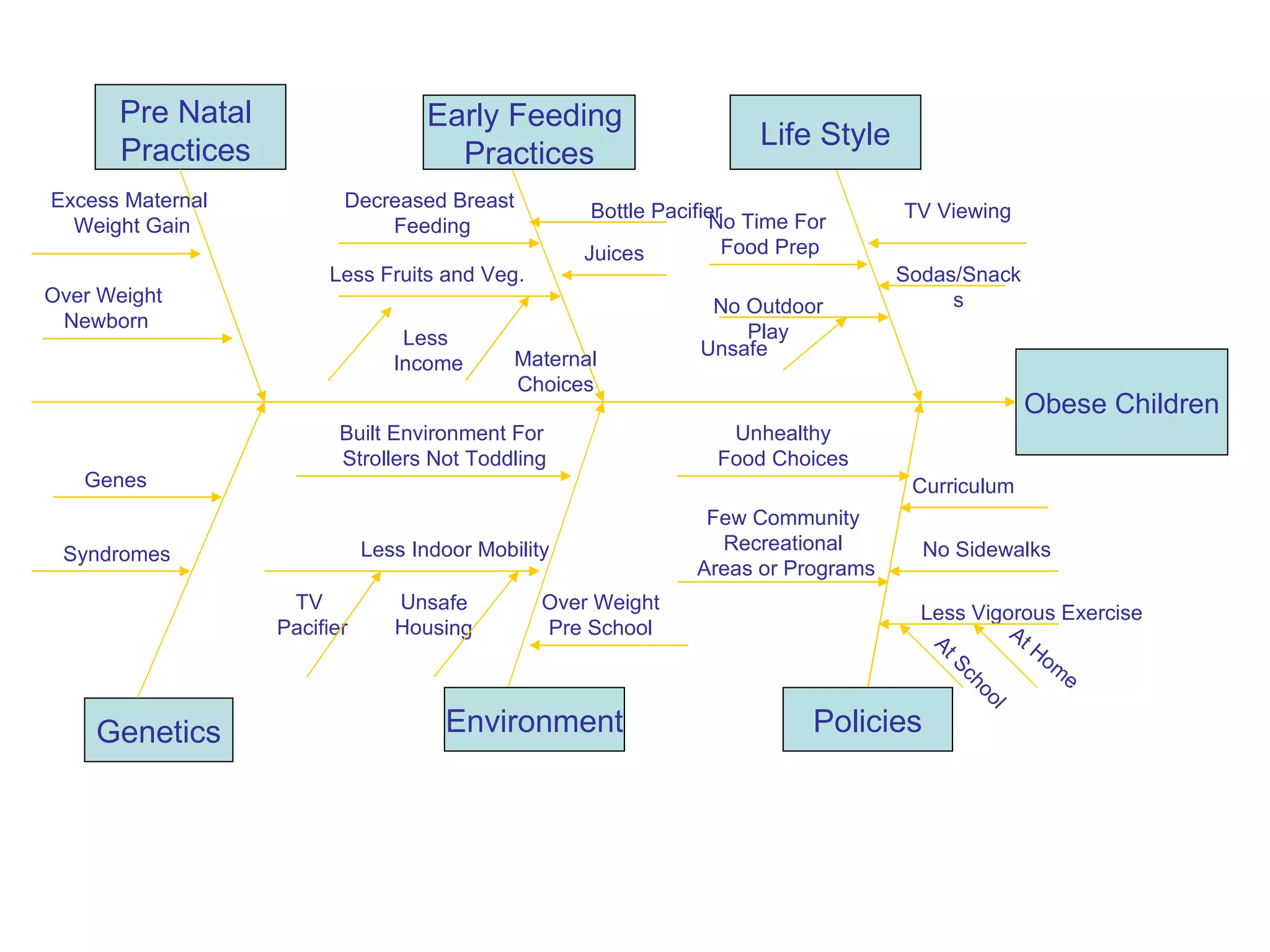

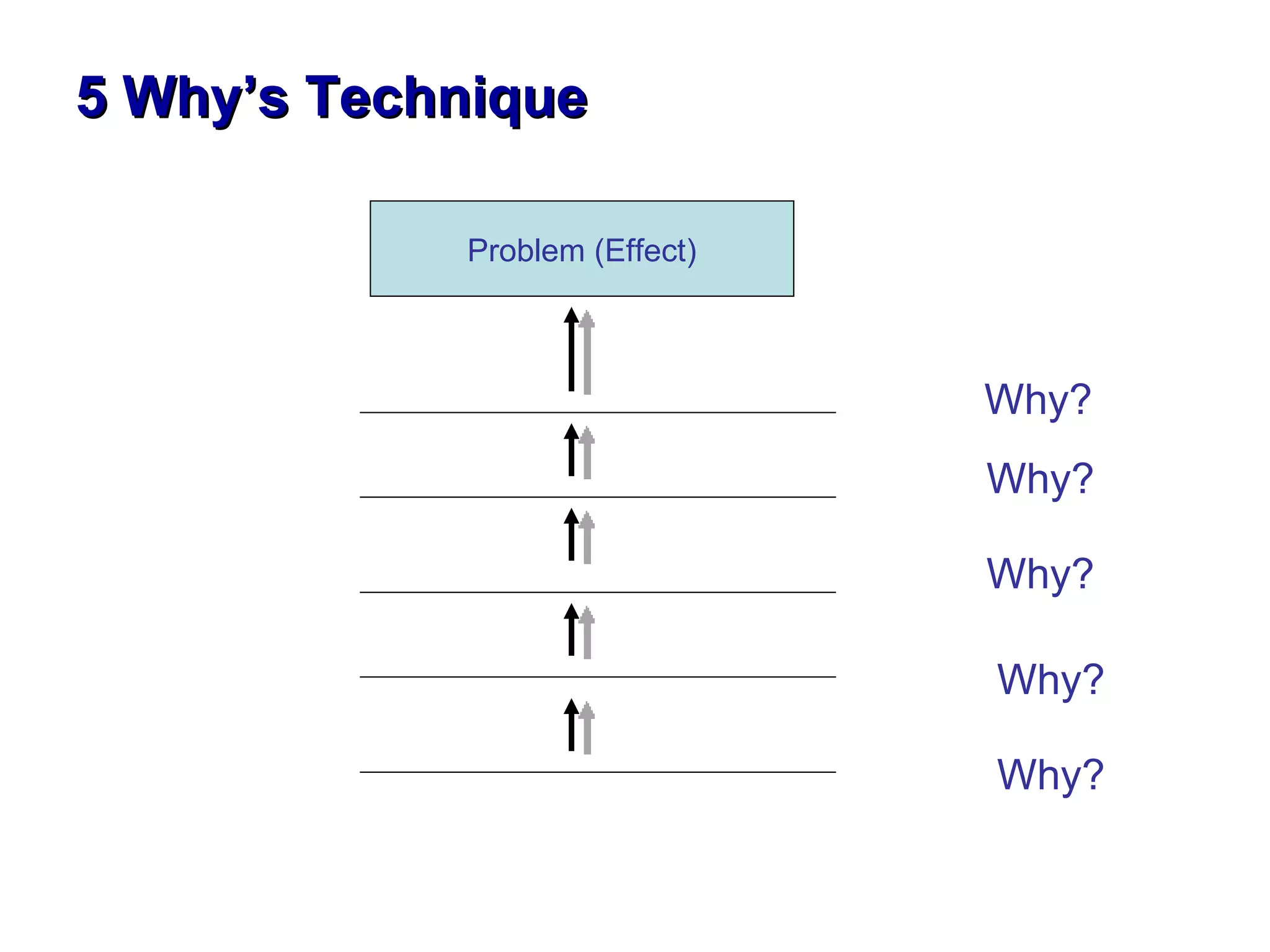

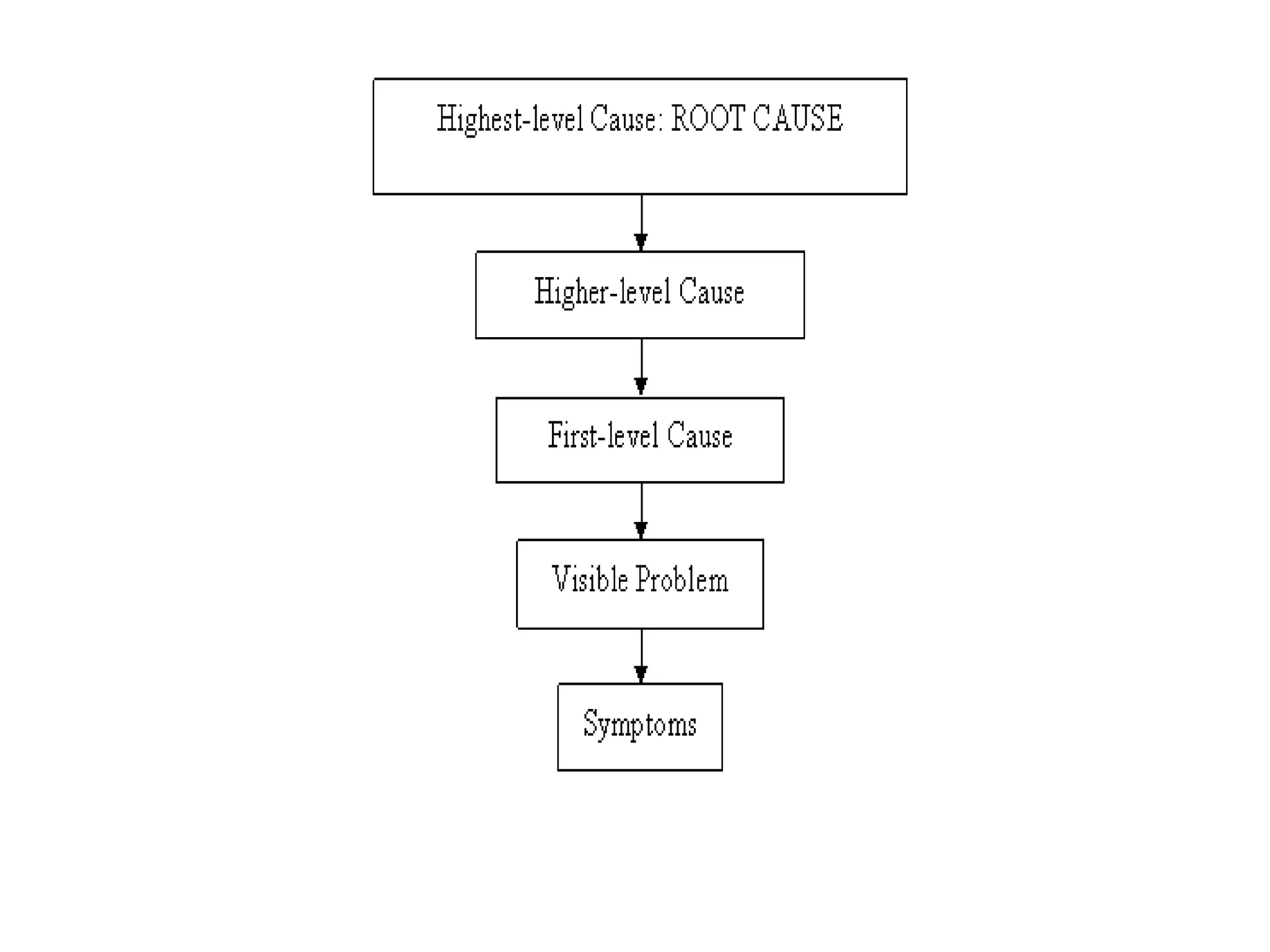

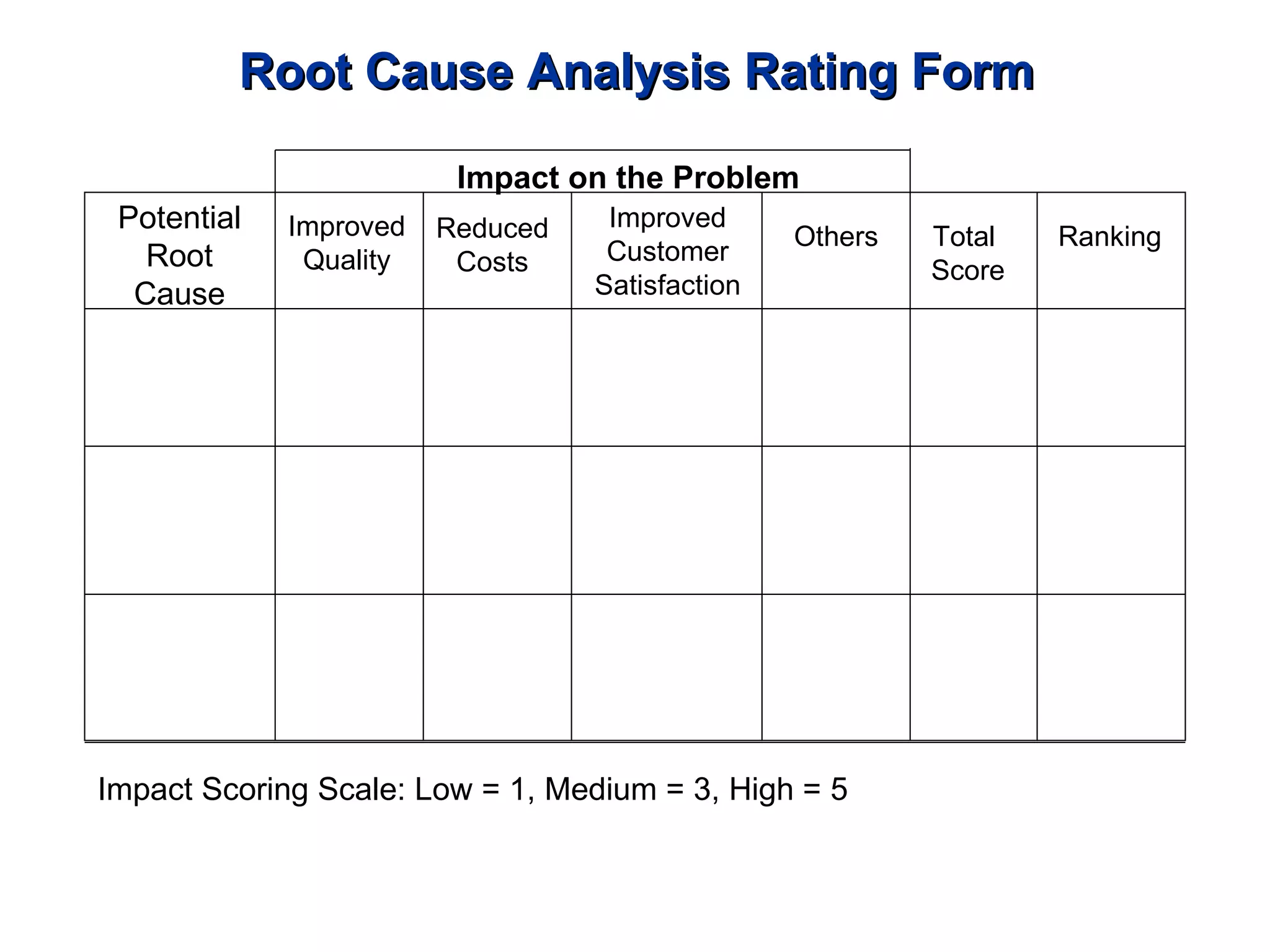

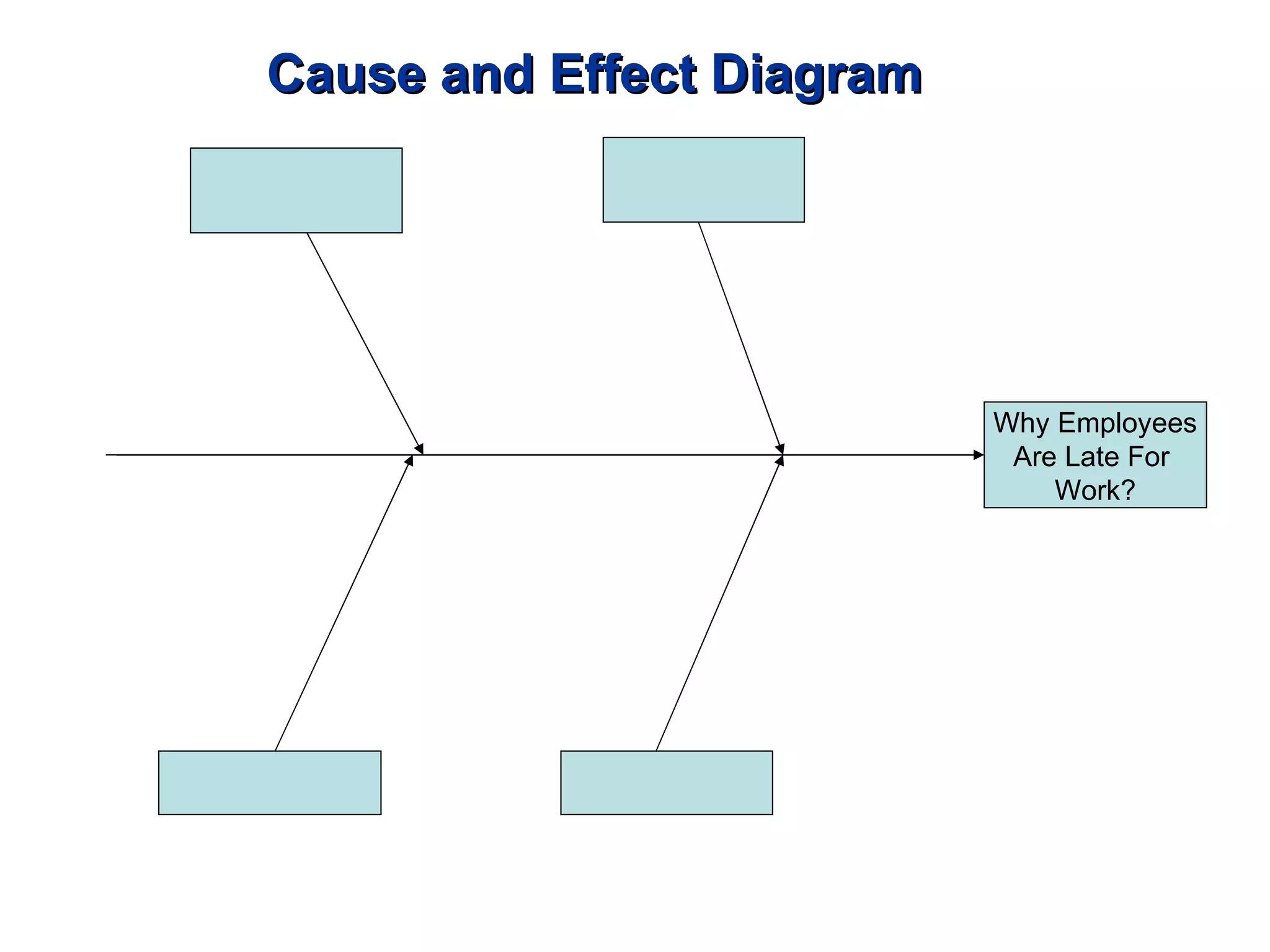

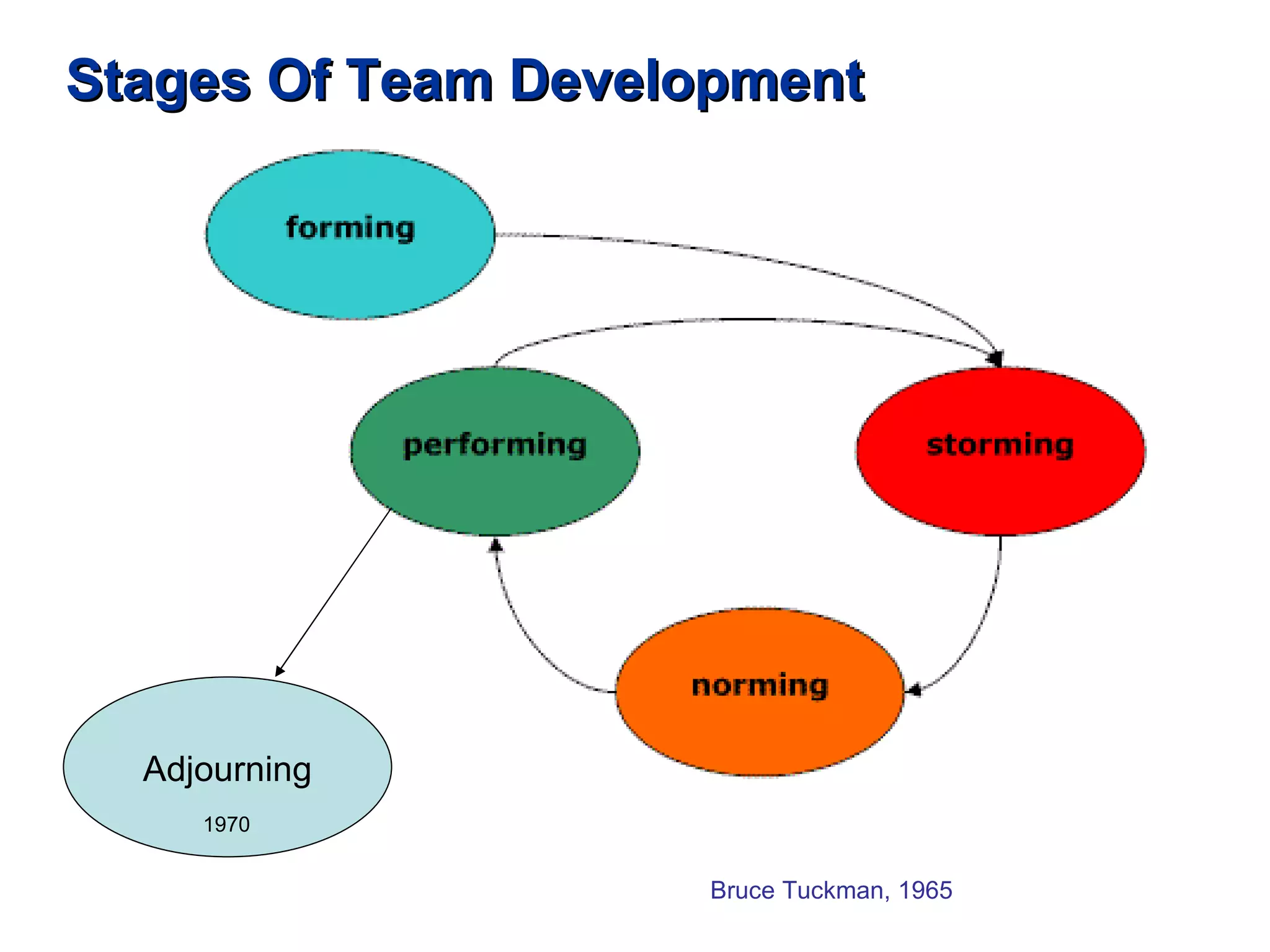

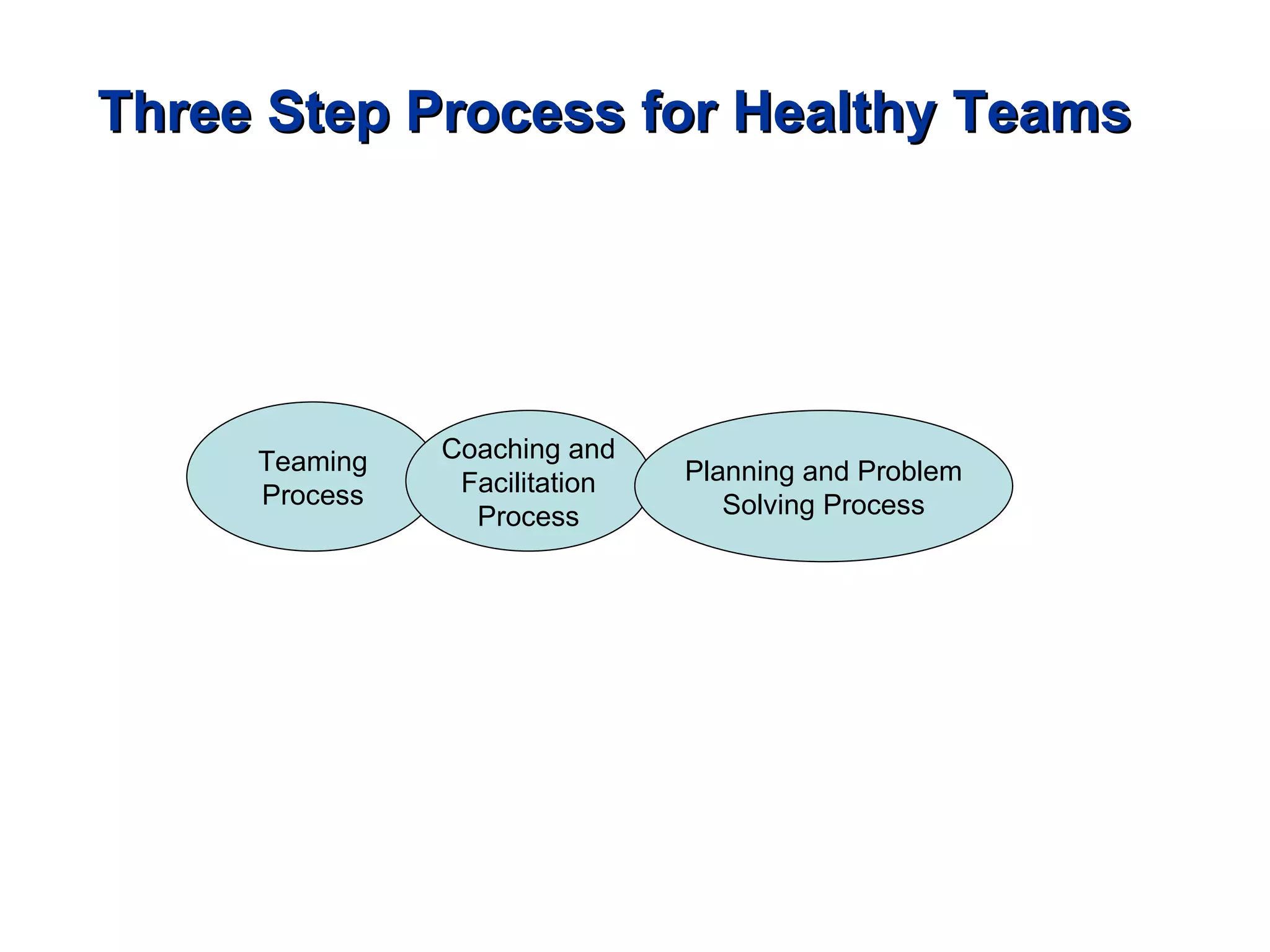

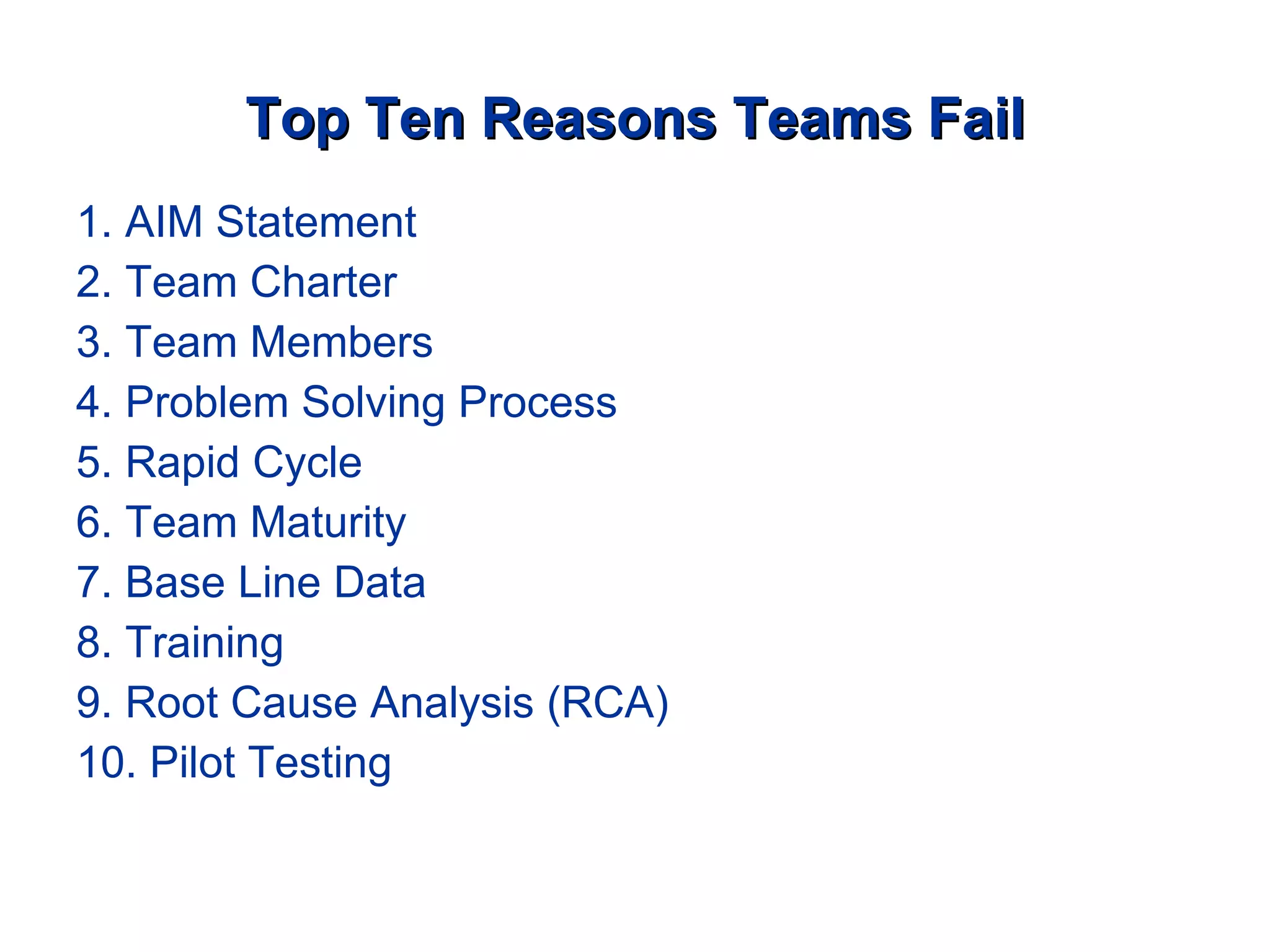

The document outlines quality improvement techniques in public health, emphasizing a structured approach to identify problems, explore root causes, and implement effective solutions. It introduces the 'plan-do-check-act' (PDCA) cycle as a framework for continuous improvement, encouraging regular monitoring and adaptation based on outcomes. The text also emphasizes the importance of customer perspective and collaboration across teams to enhance service quality and community health outcomes.