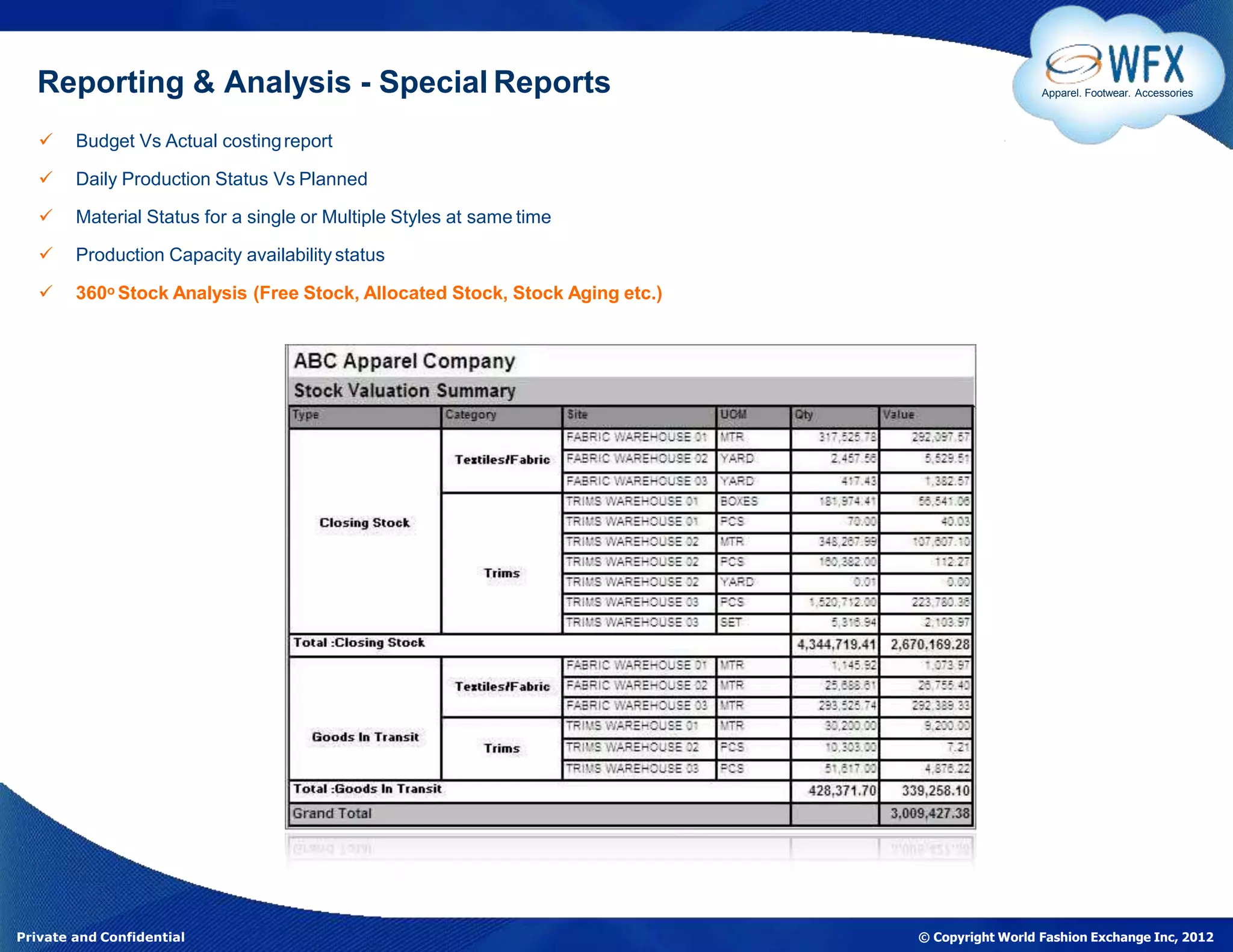

World Fashion Exchange (WFX) is a leading provider of cloud-based ERP and PLM solutions for the fashion industry. WFX's solutions are delivered via the cloud, providing advantages like lower costs, easy implementation, and accessibility from anywhere via the internet. The document describes WFX's cloud computing platform and the various feature-rich applications it provides, including product lifecycle management, costing and budgeting, inventory management, production planning, and reporting.